Professional Documents

Culture Documents

Wb4606e E312-17

Uploaded by

cwiksjOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wb4606e E312-17

Uploaded by

cwiksjCopyright:

Available Formats

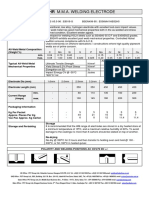

WB4606E M.M.A.

WELDING ELECTRODE

Classifications ~AWS A5.4-92 : E312-17 BSEN 1600-97 : E29 9 R 1 2

Product Description All positional, rutile coated, stainless steel electrode for welding problem and

dissimilar steels. Having excellent deslag and bead profile.

Used mainly for welding and repairing steels of unknown specifications and for

Applications dissimilar welds between Ferritic and Austenitic steels. Also used for welding difficult

to weld medium and high carbon steels, can also tolerate high rates of dilution.

Typical grades include: - 709M40 (En19), 070M55, BS970 Part 1, 080M40 (En8),

070M55 (En9).

Not recommended where PWHT is required or where materials will be subject to low

temperature service.

All-Weld Metal Composition

(Weight %) C Mn Si S P Mo Cr Ni Cu V

min. 0.05 0.5 0.60 - - 0.20 27.0 8.0 - -

max. 0.12 2.5 1.20 0.020 0.025 0.40 31.0 12.0 0.20 0.15

Typical All-Weld Metal Ultimate Tensile Strength N/mm² 812

Mechanical Properties Yield Stress/0.2% Proof Stress N/mm² 653

Elongation on 5D % 19

Impact Energy CV @ +20C Joules 20

as-welded

Electrode Dia (mm) 1.6mm 2.0mm 2.5mm 3.2mm 4.0mm 5.0mm 6.0mm

Electrode Length (mm) - - 350 350 350 350 -

min. - - 60 80 100 130 -

Current Range

(Amps) max. - - 90 120 150 210 -

Packaging Information

Kg Per Packet - - 5 5 5 5 -

Approx. Pieces Per Kg - - 50 30 19 12 -

Storage

Storage and Re-baking It is recommended that the WB range of electrodes are stored in a dry heated store at

a minimum temperature of 18C, and a maximum relative humidity of 60%. To avoid

damage to the coatings no more than 6 cartons should be staked on top of another.

Re-drying

Re-dry @ 350C for 2 hours and then transfer to holding oven and hold @ 100 -

200C, or 50-100C in heated quiver.

Current Conditions AC OCV70 DC +/- and Welding Positions

You might also like

- Wb35S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb35S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Wb2318e E9018-MDocument1 pageWb2318e E9018-McwiksjNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- WB4303EDocument1 pageWB4303EcwiksjNo ratings yet

- Wb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageM.M.A. Welding Electrode: Classifications & ApprovalscwiksjNo ratings yet

- WB56S E7016-1Document1 pageWB56S E7016-1cwiksjNo ratings yet

- WB5525E ENiCrMo-5Document1 pageWB5525E ENiCrMo-5cwiksjNo ratings yet

- Wb56S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb56S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Wb2000e E6013Document1 pageWb2000e E6013cwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Wb76S M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageWb76S M.M.A. Welding Electrode: Classifications & Approvalslathasri78No ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- Wb9009E M.M.A. Welding Electrode: Bs en 14700-2005: Efe2Document1 pageWb9009E M.M.A. Welding Electrode: Bs en 14700-2005: Efe2lathasri78No ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- C 70 SuperthermDocument2 pagesC 70 SuperthermMandeep SinghNo ratings yet

- Railrod: Data SheetDocument1 pageRailrod: Data Sheetmohamed AdelNo ratings yet

- LFBCW510L TN enDocument4 pagesLFBCW510L TN endrgilleNo ratings yet

- CZLLCW511L TN enDocument4 pagesCZLLCW511L TN endrgilleNo ratings yet

- Metrode ER110S-G FillerDocument6 pagesMetrode ER110S-G FillerBernie SimcsNo ratings yet

- Creep-Resistant Steels - TWIDocument6 pagesCreep-Resistant Steels - TWIJlkKumarNo ratings yet

- Creep-Resistant Steels - TWI PDFDocument6 pagesCreep-Resistant Steels - TWI PDFFarid Ahmed KhwajaNo ratings yet

- SMAW Bohler Fox S EV 50 1 E7018 1H4RDocument1 pageSMAW Bohler Fox S EV 50 1 E7018 1H4RYoga ArdiansyahNo ratings yet

- Tenalloy 125: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 125: LOW ALLOY STEEL (High Strength)satnamNo ratings yet

- Chromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelDocument2 pagesChromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelVVan TanNo ratings yet

- Basic Coated Electrode For Creep Resisting Steels: 1501 GR 622 To 1504 GR 622, BS 359 GR 622/640 1503 GR 660, 1504Gr 660Document1 pageBasic Coated Electrode For Creep Resisting Steels: 1501 GR 622 To 1504 GR 622, BS 359 GR 622/640 1503 GR 660, 1504Gr 660mohamed AdelNo ratings yet

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- 1564 Fox Ev 85 ElettrodoDocument1 page1564 Fox Ev 85 ElettrodoAminNo ratings yet

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocument7 pages22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeOnM deptNo ratings yet

- Aluminium 6082 Spec SheetDocument3 pagesAluminium 6082 Spec SheetDeepak KumarNo ratings yet

- 2205 Technical Data Sheet: Chemistry Mechanical PropertiesDocument6 pages2205 Technical Data Sheet: Chemistry Mechanical PropertiesJandri JacobNo ratings yet

- Esab 309lmo Ok 67.68Document1 pageEsab 309lmo Ok 67.68Sadashiva sahooNo ratings yet

- Supabase-X-Plus AdorDocument1 pageSupabase-X-Plus AdorJagan TnNo ratings yet

- Bohler Fox N CM 2 KBDocument1 pageBohler Fox N CM 2 KBkamals55No ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- 02112015000000B - Boehler FOX EASN 25 M - CeDocument1 page02112015000000B - Boehler FOX EASN 25 M - CeABNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetJAYA BHARATHA REDDYNo ratings yet

- X Bond: Welding Electrode For Structural Welding ApplicationDocument1 pageX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNo ratings yet

- OK 67.60 Esab 309LcDocument1 pageOK 67.60 Esab 309LcSadashiva sahooNo ratings yet

- Case Hardening Alloy Steel Bar 6587 Atlas 6587: Colour Code: Signal Red (Band) - BlackDocument3 pagesCase Hardening Alloy Steel Bar 6587 Atlas 6587: Colour Code: Signal Red (Band) - BlackCelsoNo ratings yet

- 70cuni TigDocument3 pages70cuni TigGiannhs SeitaridhsNo ratings yet

- Datasheet Sandvik 2212htDocument2 pagesDatasheet Sandvik 2212htDarryl007No ratings yet

- Electrode Booklet F Web 93Document1 pageElectrode Booklet F Web 93satnamNo ratings yet

- Interlloy Grade 8620 Case Hardening SteelDocument3 pagesInterlloy Grade 8620 Case Hardening Steelajitchavan2150No ratings yet

- Sandvik 25.22.2.Lmn: (Welding Wire)Document3 pagesSandvik 25.22.2.Lmn: (Welding Wire)Anonymous w6TIxI0G8lNo ratings yet

- Alloy 6082 - Rev2012Document2 pagesAlloy 6082 - Rev2012Ysraels Santisteban DurandNo ratings yet

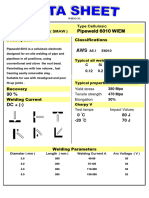

- Pipeweld 6010 WIEM E 6010: Type Cellulosic Shield Metal Arc Weld (SMAW) Classifications DescriptionDocument1 pagePipeweld 6010 WIEM E 6010: Type Cellulosic Shield Metal Arc Weld (SMAW) Classifications DescriptionagrinjoshNo ratings yet

- 253 MA-NF AC/DC: Covered ElectrodesDocument1 page253 MA-NF AC/DC: Covered ElectrodesElMacheteDelHuesoNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- L1 34264 en T Thermanit MTS 3 Se en v2Document1 pageL1 34264 en T Thermanit MTS 3 Se en v2Enrique MurgiaNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- Stainless Steel PlateDocument19 pagesStainless Steel PlateHarsh AdvaniNo ratings yet

- Westermann Table 8Document1 pageWestermann Table 8muhd.qasimNo ratings yet

- Boehler CM2-UPDocument1 pageBoehler CM2-UPdiahNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- K034 - Daikoflux 940Document1 pageK034 - Daikoflux 940cwiksjNo ratings yet

- Hardfacing Wood Chipper KnivesDocument1 pageHardfacing Wood Chipper KnivescwiksjNo ratings yet

- N004 - Daiko Strip 625Document1 pageN004 - Daiko Strip 625cwiksjNo ratings yet

- Robo TiPTiG Data Sheet FinalDocument2 pagesRobo TiPTiG Data Sheet FinalcwiksjNo ratings yet

- Carboklad Cr36 Data SheetDocument1 pageCarboklad Cr36 Data SheetcwiksjNo ratings yet

- Specifications: Product TypeDocument1 pageSpecifications: Product TypecwiksjNo ratings yet

- Specifications: Product TypeDocument1 pageSpecifications: Product TypecwiksjNo ratings yet

- A Max WearplateDocument1 pageA Max WearplatecwiksjNo ratings yet

- Red To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorsDocument3 pagesRed To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorscwiksjNo ratings yet

- Red To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorsDocument3 pagesRed To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorscwiksjNo ratings yet

- Meeting Minutes Roberts RulesDocument1 pageMeeting Minutes Roberts RulessaeedNo ratings yet

- Utp 068 HHDocument1 pageUtp 068 HHRoberto_PrrNo ratings yet

- IN150 ProHeat 35 WaterCooled Induction System EnglishDocument4 pagesIN150 ProHeat 35 WaterCooled Induction System EnglishCARLOSNo ratings yet

- Metrode WPS SuperduplexDocument4 pagesMetrode WPS SuperduplexClaudia Mms100% (3)

- WB5525E ENiCrMo-5Document1 pageWB5525E ENiCrMo-5cwiksjNo ratings yet

- WB4303EDocument1 pageWB4303EcwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Wb2000e E6013Document1 pageWb2000e E6013cwiksjNo ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- sl-dz1200 ServiceDocument256 pagessl-dz1200 ServiceAdrian DuMayNo ratings yet

- Popular Woodworking - Essential Guide To Routers PDFDocument95 pagesPopular Woodworking - Essential Guide To Routers PDFkeatz100% (5)

- Comparison of Switching Strategies For An Ultrasonic Cleaner PDFDocument5 pagesComparison of Switching Strategies For An Ultrasonic Cleaner PDFBogdan HaiducNo ratings yet

- Lintel Design ExampleDocument8 pagesLintel Design ExamplemmediboyinaNo ratings yet

- VOLVO PF4410 TRACKED PAVER Service Repair Manual PDFDocument15 pagesVOLVO PF4410 TRACKED PAVER Service Repair Manual PDFfjjsjekdmme0% (1)

- Ashtech QuotationDocument13 pagesAshtech Quotationmehul dholakiyaNo ratings yet

- CE470 Preface (06sept2012) - PDF PDFDocument6 pagesCE470 Preface (06sept2012) - PDF PDFNos GoteNo ratings yet

- Acti 9 iPF - iPRD - A9L20600 PDFDocument2 pagesActi 9 iPF - iPRD - A9L20600 PDFjoapmeNo ratings yet

- Birmingham Oakland HomesDocument32 pagesBirmingham Oakland HomesSCN Communications Group100% (1)

- TorsionDocument36 pagesTorsiondixn__No ratings yet

- MV Cable IEC STDDocument2 pagesMV Cable IEC STDrt1973No ratings yet

- V GuardDocument4 pagesV GuardJayashree MohantyNo ratings yet

- Trident CTD - 11 B LeafletDocument2 pagesTrident CTD - 11 B LeafletBOOBALANNo ratings yet

- Novec 1230 DesignDocument8 pagesNovec 1230 Designnandeesh100% (1)

- EN6115-P5 (Aerospace Series, Bolts) PDFDocument16 pagesEN6115-P5 (Aerospace Series, Bolts) PDFmtcengineeringNo ratings yet

- Tensile Testing of Polymer Matrix Composite Materials ASTM D3039, D3039MDocument2 pagesTensile Testing of Polymer Matrix Composite Materials ASTM D3039, D3039MchuranjitNo ratings yet

- Exhibition Space Guidelines PDFDocument36 pagesExhibition Space Guidelines PDFSophieNo ratings yet

- 2006 Radical Sr8 Owners ManualDocument11 pages2006 Radical Sr8 Owners ManualOscar PenteadoNo ratings yet

- Tutorial Answers Only 2002Document7 pagesTutorial Answers Only 2002Ahmed MoustafaNo ratings yet

- Introduction To Filament WindingDocument3 pagesIntroduction To Filament WindingAhmed Shady100% (1)

- Griffiths Diesel EngineDocument30 pagesGriffiths Diesel Enginesunahsuggs50% (2)

- WholesalerDocument116 pagesWholesalerFelix Gabriel VarelaNo ratings yet

- PW95 1Document440 pagesPW95 1marjan4386% (7)

- JBT Freezer PortfolioDocument36 pagesJBT Freezer Portfoliomohammed sallem100% (2)

- Tokisud Block-Report On Due Diligence StudyDocument22 pagesTokisud Block-Report On Due Diligence StudyChandan MukherjeeNo ratings yet

- Design of Railway Structures To The Structural Eurocodes - Part 1Document88 pagesDesign of Railway Structures To The Structural Eurocodes - Part 1Ion Pusculita100% (1)

- Clyde Lighthouse Trust 1755 - 1965Document8 pagesClyde Lighthouse Trust 1755 - 1965Clyde SteamersNo ratings yet

- Scissor Platforms For Goods & VehiclesDocument2 pagesScissor Platforms For Goods & VehiclesKleemmann Hellas SA0% (1)

- Fse100 FinalDocument37 pagesFse100 Finalapi-456985970100% (1)

- 9013Document4 pages9013jimmyboyjrNo ratings yet