Professional Documents

Culture Documents

Single Piece (Screw End) : Suitable For: - Water, Oil and Gas

Uploaded by

Bharat PrajapatiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Single Piece (Screw End) : Suitable For: - Water, Oil and Gas

Uploaded by

Bharat PrajapatiCopyright:

Available Formats

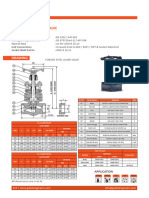

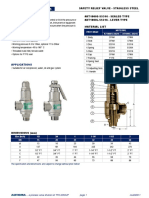

UNIMAC BALL VALVES Technical Data

Design & : BS 5351, API 602,

Single Piece (Screw End) Manufacturing IS:9890

STD

Testing & : API 598/ BS : 5146

Inspection STD

Face to Face : as per ANSI B

16.10

End : 16 Bar max (228

connections PSI)

Temp. Rating : Screwed : (BSP,

BSPT, NPT)

No. Description Material Qty.

01 Body C.I. / C.

S. / S.S.

304/ S.S.

316

02 Body C.I. / C.

connector S. / S.S.

304/ S.S.

316

03 Ball AISI 304 / 1

AISI 316

Suitable for : - Water, Oil and Gas 04 Stem AISI 304 / 1

AISI 316r

05 Gland nut AISI 304 / 1

Size A øC L THDS AISI 316

BSP/ BSPT/ NPT

06 Gland bush AISI 304 / 1

15 73 13 126 1/2" AISI 316

20 76 19 126 3/4" 07 Lock Nut AISI 304 /

AISI 316

25 88 26 126 1"

08 Seat Ring PTFE

32 100 33 176 1.1/4"

09 Stem Seal PTFE

40 118 39 176 1.1/2"

10 Body Sealent PTFE

50 126 51 176 2"

ring

65 152 62 253 2.1/2"

11 Wrench M.S. / S.S.

50 170 76 253 3"

Primary service reating & test

pressure

all dimesion are in mm

Class Working HYD. Test pressure

press.

Body Seat Temp.

150 150 PSIG 500 250 200 °

PSIG PSIG F

Air Test - Seat 80 PSIG ± 10 PSIG

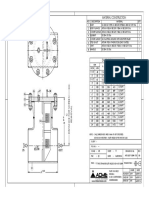

Three Piece (Screw End) No. Description Material Qty.

Technical Data 01 Body C.I./ C.S./ S.S. 1

Design & : BS 5351, API 602 304/316 /A 105

Manufacturing 02 Body connector C.I./C.S./ S.S. 1

STD 304/316/A 105

Testing & : API 598/ BS : 5146 03 Ball AISI 304 / AISI 1

Inspection STD 316

End Connections : BSP, BSPT, NPT, 04 Stem AISI 304 / AISI 1

SOCKET WELD 316

Socket Weld & : ANSI B 16.11 / ANSI B 05 Gland nut AISI 304 / AISI 1

Threaded to 1.20.1 316

06 Gland bush AISI 304 / AISI 1

316

07 Lock Nut AISI 304 / AISI 1

316

08 Seat Ring PTFE 2

09 Stem Seal PTFE 2

10 Body Sealent PTFE 2

ring

11 Wrench M.S. / S.S. 1

12 Stop M.S. 1

13 Stud & Nut C.S./ S.S. 4

Class 150

Size A øC L THDS. F G H

BSP/

BSPT/

NPT

15 91 13 155 1/2" 21.8 29 12.7

20 96 19 160 3/4" 27.3 35 19.0

25 101 25 160 1" 34.1 43 22.0

32 109 32 160 1.1/4" 43.0 54 22.0

40 121 38 178 1.1/2" 49.0 58 22.0

all dimesion are in mm 50 131 50 178 2" 61.3 71 23.0

Class 800

Suitable for : - Water, Oil and Gas

Size A øC L THDS. F G H

BSP/

Primary service reating & test pressure BSPT/

NPT

Class Working press. HYD. Test pressure

Body Seat Temp. 15 69 13 115 1/2" 21.8 29 12.7

150 150 PSIG 425 PSIG 300 PSIG 200 °F 20 80 15 122 3/4" 27.3 35 19.0

300 300 PSIG 1100 PSIG 800 PSIG 200 °F 25 96 19 153 1" 34.1 43 22.0

800 800 PSIG 3000 PSIG 2000 PSIG 200 °F 32 106 23 178 1.1/4" 43.0 54 22.0

Air Test - Seat 80 PSIG ± 10 PSIG 40 116 33 178 1.1/2 49.0 58 22.0

Note : Due to constant up gradation, dimensions 50 129 36 178 2" 61.3 71 23.0

are subject to change by the manufacturer.

You might also like

- Steel and Its Heat Treatment: Bofors HandbookFrom EverandSteel and Its Heat Treatment: Bofors HandbookRating: 2.5 out of 5 stars2.5/5 (3)

- Forged Steel Globe ValveDocument1 pageForged Steel Globe ValveShakir AnsariNo ratings yet

- Gauge GlassDocument1 pageGauge GlassShakir AnsariNo ratings yet

- WTC ValveDocument16 pagesWTC ValveASA PolyPlastNo ratings yet

- VB 635 Ag N: BS 5351 Trim MaterialsDocument1 pageVB 635 Ag N: BS 5351 Trim Materialskais rguiguiNo ratings yet

- Bellow Seal Valves: AN ISO 9001:2000 COMPANYDocument20 pagesBellow Seal Valves: AN ISO 9001:2000 COMPANYDeepak HishikarNo ratings yet

- Check Ranurado RH84X MechDocument1 pageCheck Ranurado RH84X MechFLOW INDUSTRIAL SACNo ratings yet

- Plummech Check ValvesDocument1 pagePlummech Check ValvesNguyễn Đăng PhúcNo ratings yet

- LintasGroup AQ BV 01 SE AICQStainlessSteelBallValveEconomicalDesignDocument1 pageLintasGroup AQ BV 01 SE AICQStainlessSteelBallValveEconomicalDesignSKN8700No ratings yet

- 3-Piece Firesafe Ball Valve Figure Numbering System: E Seswbw A 305 A CDocument5 pages3-Piece Firesafe Ball Valve Figure Numbering System: E Seswbw A 305 A CAbigail Lupe Aguilar YapuraNo ratings yet

- Ball Three Pieces Steel A105 / A216 WCB 1000 PSIG: Pressure Temperature RatingsDocument2 pagesBall Three Pieces Steel A105 / A216 WCB 1000 PSIG: Pressure Temperature RatingsAlicia MartinezNo ratings yet

- LintasGroup LI BV 01 SE StainlessSteelTwoPieceDesignBallValveHeavyDutyDocument1 pageLintasGroup LI BV 01 SE StainlessSteelTwoPieceDesignBallValveHeavyDutySKN8700No ratings yet

- Pressure Gauges With Syphon PDFDocument2 pagesPressure Gauges With Syphon PDFhussamengNo ratings yet

- DS-786 FIG.Z 16 TTTGV CL150 Valve SpecsDocument1 pageDS-786 FIG.Z 16 TTTGV CL150 Valve SpecsYerson JuarezNo ratings yet

- Arita SS Full Port 2 PC Body Ball Valve SE 1Document1 pageArita SS Full Port 2 PC Body Ball Valve SE 1muzakkir muzNo ratings yet

- Ft-Valvula Compuerta Roscada Imox 316Document1 pageFt-Valvula Compuerta Roscada Imox 316Galindo FivigaorNo ratings yet

- IC Y Type StrainerDocument1 pageIC Y Type StrainerShakir AnsariNo ratings yet

- Flowjet Valves Product BrochureDocument18 pagesFlowjet Valves Product BrochureUday GokhaleNo ratings yet

- Valvulas Compuerta VGADocument1 pageValvulas Compuerta VGAOscar David Benavides CastilloNo ratings yet

- GLT Small ValvesDocument5 pagesGLT Small ValvesAristo MNo ratings yet

- Bronze Globe ValveDocument1 pageBronze Globe ValveCarlos BritoNo ratings yet

- Válvula Esfera SBV210 - DatasheetDocument4 pagesVálvula Esfera SBV210 - DatasheetFabio GiehlNo ratings yet

- High Pressure Bar Stock Needle Valves: SHBNV SeriesDocument2 pagesHigh Pressure Bar Stock Needle Valves: SHBNV SeriesToty DzNo ratings yet

- 3 Way Valve - BallDocument2 pages3 Way Valve - BallchintanNo ratings yet

- P 110825 01887Document9 pagesP 110825 01887jajakaNo ratings yet

- JC-TDS-515 - 530 Rev.0 - Baj1Document4 pagesJC-TDS-515 - 530 Rev.0 - Baj1Nourdine EL-HASANYNo ratings yet

- Vs 235 Ag E: Api STD 602 Trim MaterialsDocument1 pageVs 235 Ag E: Api STD 602 Trim Materialskais rguiguiNo ratings yet

- T Type Strainer Butt Weld 1 PDFDocument1 pageT Type Strainer Butt Weld 1 PDFprashant mishraNo ratings yet

- Swing Check Valve - Flanged: Technical FeaturesDocument1 pageSwing Check Valve - Flanged: Technical FeaturesAhmed El MorsyNo ratings yet

- Acople Inteva TGWDocument12 pagesAcople Inteva TGWIMPO FREICONo ratings yet

- 01SD1B01Document5 pages01SD1B01Jhonny RinconesNo ratings yet

- Ball Valves Jis10k Flanged End 0Document5 pagesBall Valves Jis10k Flanged End 0Royal BoardNo ratings yet

- FlowBiz High Pressure Universal Design Non Return ValveDocument1 pageFlowBiz High Pressure Universal Design Non Return ValveFlowBiz Exports Pvt. Ltd.No ratings yet

- 140 Sheree Blvd. PO Box 566, Exton, PA 19341-0566 US - Web SiteDocument3 pages140 Sheree Blvd. PO Box 566, Exton, PA 19341-0566 US - Web SitegeorgyNo ratings yet

- Bola 3 ViasDocument1 pageBola 3 ViasOperaciones Aqua CareNo ratings yet

- 01SD0J02Document5 pages01SD0J02Jhonny RinconesNo ratings yet

- Butterfly Valve Wafer TypeDocument2 pagesButterfly Valve Wafer TypeHardik ShahNo ratings yet

- Swing Check Valve Technical SpecificationDocument2 pagesSwing Check Valve Technical SpecificationSuthan M RNo ratings yet

- FlowBiz Needle ValveDocument2 pagesFlowBiz Needle ValveShakir AnsariNo ratings yet

- 03SD1B01Document5 pages03SD1B01Jhonny RinconesNo ratings yet

- MECH - Valvula de Compuerta OSY XZ41XDocument1 pageMECH - Valvula de Compuerta OSY XZ41XAlfredo BravoNo ratings yet

- Plummech OS&Y Gate ValvesDocument1 pagePlummech OS&Y Gate ValvesNguyễn Đăng PhúcNo ratings yet

- FlowBiz-FORGED-STEEL-CHECK-VALVE 800 ClassDocument2 pagesFlowBiz-FORGED-STEEL-CHECK-VALVE 800 ClassShakir AnsariNo ratings yet

- Cast Iron Gate Valves: OS& Y, Bolted Bonnet, JIS 10KDocument9 pagesCast Iron Gate Valves: OS& Y, Bolted Bonnet, JIS 10KSamuel GermatusNo ratings yet

- Pressure Relief Valves Without ContactsDocument8 pagesPressure Relief Valves Without ContactsANGEL STRAGLIATINo ratings yet

- Forged High Pressure Ball Valves: SBVF360 SeriesDocument4 pagesForged High Pressure Ball Valves: SBVF360 SeriesToty DzNo ratings yet

- Wilo 497649Document24 pagesWilo 497649Gustavo AmezquitaNo ratings yet

- Ficha Tecnica Valvula Check 10 MilDocument1 pageFicha Tecnica Valvula Check 10 MilTrujillo TrujilloNo ratings yet

- Data Sheet Purgador PT65-40Document2 pagesData Sheet Purgador PT65-40Douglas Tondello100% (1)

- Outside Screw and Yoke (OS&Y) Gate Valve: Technical FeaturesDocument2 pagesOutside Screw and Yoke (OS&Y) Gate Valve: Technical FeaturesMuhammad ElbarbaryNo ratings yet

- 856060 FILTRODocument1 page856060 FILTRORoLopNo ratings yet

- ADCA TSS22 Thermostatic Steam TrapDocument1 pageADCA TSS22 Thermostatic Steam TrapedlistiantoNo ratings yet

- Tosaca-Valvula AlivioDocument2 pagesTosaca-Valvula AlivioAntony BonillaNo ratings yet

- 360 6S3R, C00 8 (-NRD3-VY1,) - ModelDocument1 page360 6S3R, C00 8 (-NRD3-VY1,) - ModelRajNo ratings yet

- AWWA C515 Flanged Resilient NRS Gate Valve (Z45X) NSF ApprovedDocument1 pageAWWA C515 Flanged Resilient NRS Gate Valve (Z45X) NSF Approvedlenin jarquinNo ratings yet

- ZolotoIndustries BSENISO17292Document6 pagesZolotoIndustries BSENISO17292QC apollohxNo ratings yet

- Butterfly ValvesDocument27 pagesButterfly ValvesИгорьNo ratings yet

- PN01SA0B03Document5 pagesPN01SA0B03Julian GaleanoNo ratings yet

- REL OSY 399F - FM UL OS&Y Multi LingualDocument2 pagesREL OSY 399F - FM UL OS&Y Multi LingualAhmed Salah Abd EL-WahedNo ratings yet

- AUTOMA AT1000-SS316 - Rev202011Document1 pageAUTOMA AT1000-SS316 - Rev202011Jefril SiruNo ratings yet

- Faint Print Fix Cheat SheetDocument1 pageFaint Print Fix Cheat SheetBharat PrajapatiNo ratings yet

- Ansi B 16.34Document22 pagesAnsi B 16.34Vinoth Rajendra100% (2)

- MM ThreadDocument1 pageMM ThreadBharat PrajapatiNo ratings yet

- Process Flow For Alert Subscription / Non - Subscription: Registration of Mobile NumberDocument1 pageProcess Flow For Alert Subscription / Non - Subscription: Registration of Mobile NumberBharat PrajapatiNo ratings yet

- Back to Ferrule Dimensions and PricingDocument2 pagesBack to Ferrule Dimensions and PricingBharat PrajapatiNo ratings yet

- Thread TablesDocument22 pagesThread TablesMuthukumar VeerappanNo ratings yet

- " " 1" 1 " 1 " 2" 2 " 3" 4" 5" 6" 8" 10" 12" 14" Data Chart SpecificationDocument1 page" " 1" 1 " 1 " 2" 2 " 3" 4" 5" 6" 8" 10" 12" 14" Data Chart SpecificationBharat PrajapatiNo ratings yet

- Allen Cap DimentiomDocument1 pageAllen Cap DimentiomBharat PrajapatiNo ratings yet

- Thread Methos PDFDocument5 pagesThread Methos PDFBharat PrajapatiNo ratings yet

- Asme B 1.20.1Document1 pageAsme B 1.20.1Bharat PrajapatiNo ratings yet

- Teflone (PTFE) Seat SuggetionDocument1 pageTeflone (PTFE) Seat SuggetionBharat PrajapatiNo ratings yet

- Teflone (PTFE) Seat SuggetionDocument1 pageTeflone (PTFE) Seat SuggetionBharat PrajapatiNo ratings yet

- British Standard Pipe ThreadDocument3 pagesBritish Standard Pipe ThreadBharat PrajapatiNo ratings yet

- British Standard Pipe ThreadDocument3 pagesBritish Standard Pipe ThreadBharat PrajapatiNo ratings yet

- British Standard Pipe ThreadDocument3 pagesBritish Standard Pipe ThreadBharat PrajapatiNo ratings yet

- BSPT Thread Sizes & TypesDocument3 pagesBSPT Thread Sizes & TypesuttampokharkarNo ratings yet

- Computer Safety and Maintenance TipsDocument17 pagesComputer Safety and Maintenance TipsVAITO UGANDA LTDNo ratings yet

- $$ List of Material:: Just For Showing PurposeDocument2 pages$$ List of Material:: Just For Showing Purposenitin_jagtap9495No ratings yet

- In-Line Multi Fit: IrripodDocument2 pagesIn-Line Multi Fit: Irripodrightnow1000No ratings yet

- Valeo Garage Equipment 2016-2017 955661 English CatalogueDocument72 pagesValeo Garage Equipment 2016-2017 955661 English Cataloguejose luis tocoNo ratings yet

- Items GameDocument1,917 pagesItems Gameclearmoon247No ratings yet

- SW EotE Gear CardsDocument4 pagesSW EotE Gear Cardsgr1bble100% (1)

- Heavy Duty Marine EquipmentDocument14 pagesHeavy Duty Marine EquipmentChieuNo ratings yet

- TLE Worksheets Carpentry 7 and 8 Q3Document2 pagesTLE Worksheets Carpentry 7 and 8 Q3Xyra Zheniel PerezNo ratings yet

- Dortronics W5286-P23DAXE1 Pneumatic Button DsDocument2 pagesDortronics W5286-P23DAXE1 Pneumatic Button Dsbloper2No ratings yet

- Technical Data Demag Hoist Units Volume 1: DH 600, DH 1000, DH 2000Document44 pagesTechnical Data Demag Hoist Units Volume 1: DH 600, DH 1000, DH 2000mohammad khoraminiaNo ratings yet

- Design Kegalle A & E 2023.05.23Document157 pagesDesign Kegalle A & E 2023.05.23Dilina De SilvaNo ratings yet

- RFN 7015 RFN 7015: Ringfeder RingfederDocument20 pagesRFN 7015 RFN 7015: Ringfeder RingfederTran DucNo ratings yet

- Fischer S - 102 - A053 130+ Datasheet PDFDocument1 pageFischer S - 102 - A053 130+ Datasheet PDFmyanshitaNo ratings yet

- Rota Disc OPERATORS MANUALDocument53 pagesRota Disc OPERATORS MANUALCoco BangoNo ratings yet

- 5 Spec For Fume CabinetDocument5 pages5 Spec For Fume CabinetLengNo ratings yet

- SOP 032 - QC Hoist Wire Rope Replacement - V 2.0Document6 pagesSOP 032 - QC Hoist Wire Rope Replacement - V 2.0ncthanhck0% (1)

- TM - 698 Tech Manual AusP PES - V2 - Compressed PDFDocument42 pagesTM - 698 Tech Manual AusP PES - V2 - Compressed PDFSaswita SaktiNo ratings yet

- Technical overview of BMK components for Liebherr LTM 1055-3.1 craneDocument36 pagesTechnical overview of BMK components for Liebherr LTM 1055-3.1 cranejosselin quatrainNo ratings yet

- Komponen Panel Listrik - HW ElektrindoDocument6 pagesKomponen Panel Listrik - HW ElektrindodhanysiregarNo ratings yet

- LPG Leakage Detector Using Arduino With SMS Alert and Sound AlarmDocument12 pagesLPG Leakage Detector Using Arduino With SMS Alert and Sound AlarmNkj242089No ratings yet

- Differential Pressure Control, Types MP 54, MP 55 and MP 55ADocument8 pagesDifferential Pressure Control, Types MP 54, MP 55 and MP 55AMilosgl100% (1)

- TL7 HVG InstallGuideDocument2 pagesTL7 HVG InstallGuideCarlos CastilloNo ratings yet

- Relief Valve (Swing) - Test and Adjust: SMCS - 5454-036Document4 pagesRelief Valve (Swing) - Test and Adjust: SMCS - 5454-036Steven Manuputty100% (1)

- Service Manual - Pala Eléctrica 7495 CATDocument1 pageService Manual - Pala Eléctrica 7495 CATRafael Ccalla0% (1)

- Fisher 1098 Egr Pilot OperatedDocument34 pagesFisher 1098 Egr Pilot OperatedDavid Jesus Mejias LlanosNo ratings yet

- Activity A.: Personalities and Their Contribution To The Development of FirearmDocument2 pagesActivity A.: Personalities and Their Contribution To The Development of FirearmJud AurintoNo ratings yet

- B. Fault-FindingDocument29 pagesB. Fault-FindingJesús David Diaz MontesNo ratings yet

- Canon SPEEDLITE 420EX Parts CatalogDocument13 pagesCanon SPEEDLITE 420EX Parts Catalogchrisground2010No ratings yet

- Spare Parts CatalogueDocument11 pagesSpare Parts CataloguedechetoNo ratings yet