Professional Documents

Culture Documents

Lampiran: Contoh MSDS Gas Asetilen (C H)

Uploaded by

Abdi Wahyu KresnaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lampiran: Contoh MSDS Gas Asetilen (C H)

Uploaded by

Abdi Wahyu KresnaCopyright:

Available Formats

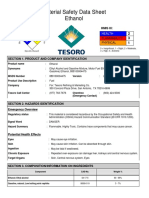

LAMPIRAN

Contoh MSDS Gas Asetilen ( C2H2 ) :

Product

Acetylene, dissolved

Name:

Chemical

Acetylene

Name:

Formula: C2H2 4

Chemical

Alkyne 0 3

Family:

Use: Welding, instrument fuel

Synonyms: Ethyne, Welding Gas

NFPA

4 HMIS Fire: 4 Acute: No

Fire:

NFPA

0 HMIS Health: 1 Chronic: No

Health:

NFPA HMIS

3 3 Fire: Yes

Reactivity: Reactivity:

NFPA Special Hazard: Mixture: No Reactive: Yes

Sudden Release

Yes

Pressure:

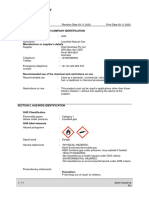

02. INGREDIENTS - COMPOSITION & INFORMATION

PERCENT EXPOSURE GUIDELINES

COMPONENT CAS No. (BY WT.) OSHA - TWA ACGIH - STEL

Acetylene 74-86-2 99.0% 100.0% Simple Asphyxiant

LD50: None. LC50: None.

03. HAZARDS IDENTIFICATION

EMERGENCY OVERVIEW:

Danger: Flammable gas under pressure.

Can form explosive mixtures with air.

Cylinders contain fusible metal pressure relief devices in the top,

bottom, or valve

which melt at 208-220°F (98-104°C).

Do not discharge cylinders at pressures above 15 psig (103 kPa).

Garlic-like odor.

Potential Health Effects Information:

Inhalation: Simple asphyxiant.

It should be noted that before suffocation could occur, the lower

flammability limit of

acetylene in air would be exceeded; possibly causing both an

explosive and an

oxygen deficient atmosphere. Exposure in moderate

concentrations may cause

dizziness, headache, and unconsciousness. Lack of sufficient

oxygen may cause

serious injury or death.

Eye: None.

Skin: None.

UNIBA D4 – K3 ∣ Keselamatan Lepas Pantai Page v

Ingestion: None.

Acetylene is a non-toxic gas that has no harmful effects even

Chronic Effects:

in high

concentrations. Acetylene has been used as an anesthetic.

Medical Conditions

None.

Aggravated By

Overexposure:

Carcinogenicity: Not listed in NTP, OSHA or IARC

04. FIRST AID MEASURES

Remove to fresh air. If not breathing, give artificial

Inhalation:

respiration. If breathing is

difficult, give oxygen. Get immediate medical attention.

Eye: None.

Skin: None.

Ingestion: None.

Notes To Physician: None.

05. FIRE FIGHTING MEASURES

Flash Point: Not applicable; Gas.

Auto ignition: 581°F (305°C) @ 1 atm

Flammable Limits - Lower: 2.5%

Flammable Limits - Upper: 80%

Extinguishing Media: Carbon Dioxide, Dry Chemical, Water.

DO NOT extinguish a gas fire unless effective immediate

Fire Fighting Instructions:

shut-off of gas flow is

possible. Explosive vapor could form. Keep adjacent cylinders

cool by spraying

large amounts of water until the fire burns itself out and the

cylinders are cool. If a

flame is extinguished and acetylene continues to escape, an

explosive re-ignition

could occur.

Fire And Explosion Excessive heat or fire will cause fusible metal pressure relief

Hazards: device to melt allowing

acetylene to escape. Cylinders may rupture violently if sidewalls

are exposed to

direct flame impingement. Cylinders exposed to fire should not

be moved until they

have reached ambient temperature in the event internal

decomposition is taking

place.

Hazardous Combustion

Carbon Monoxide, Carbon dioxide.

Products:

Sensitivity To Static

Ignitable by static electricity.

Discharge:

Sensitivity To Mechanical

Decomposition may occur.

Impact:

06. ACCIDENTAL RELEASE MEASURES

If this material is released into a work area, evacuate the area

Evacuate:

immediately. Isolate

hazard area. Eliminate any possible sources of ignition, provide

maximum explosion

proof ventilation. Shut off source of acetylene, if possible.

Isolate any leaking

UNIBA D4 – K3 ∣ Keselamatan Lepas Pantai Page vi

cylinder. If leaking from cylinder, valve or fusible metal

pressure relief device,

contact your supplier. Never enter a confined space or other area

where the

concentration is greater that 10% of the lower flammable limit

which is 0.25%.

07. HANDLING AND STORAGE

Store and use only in a well-ventilated area. Cylinders should

Storage:

be separated from

oxygen and other oxidizers by a minimum of 20 ft. or by a

barrier of

non-combustible material at least 5 ft. high having a fire

resistance rating of at least

1/2 hour. Storage in excess of 2,500 cu. Ft. is prohibited in

buildings with other

occupancies. Cylinders should be stored upright with a valve

protection cap in place

and firmly secured to prevent falling or being knocked over.

Protect cylinders from

physical damage; do not drag, roll, slide or drop. Use a suitable

hand truck for

cylinder movement. Post "No Smoking or Open Flames" signs in

the storage or use

areas. There should be no sources of ignition. All electrical

equipment should be

explosion-proof in the storage and use areas. Storage areas must

meet national

electrical codes for class 1 hazardous areas.

Do not allow storage temperature to exceed 125°F (52°C). Full

and empty

cylinders should be segregated. Use a first-in, first-out inventory

system to prevent

full containers from being stored for long periods of time.

All acetylene piped systems and associated equipment must be

Handling:

grounded.

Non-sparking tools should be used. Never use copper piping for

acetylene service,

only steel or wrought iron pipe should be used. An acetylene

cylinder valve should

be opened the minimum amount required to deliver acceptable

flow so that it can be

closed as quickly as possible in an emergency situation. Do not

open acetylene

valves more than one and one-half turns. Never use acetylene in

excess of 15 psig

pressure. Acetylene cylinders are heavier than other cylinders

because they are

packed with a porous filler material and acetone. Leak check

with soapy water;

never use a flame. Never insert an object (e.g., wrench,

screwdriver, pry bar, etc.)

into valve openings. Doing so may damage valve, causing a leak

to occur. Do not

strike cap with a hammer. Use an adjustable strap wrench to

remove over-tight or

UNIBA D4 – K3 ∣ Keselamatan Lepas Pantai Page vii

rusted caps. Never strike an arc on a compressed gas cylinder or

make a cylinder a

part of an electrical circuit. For additional precautions in using

acetylene see

Section 16 - Other Information.

When Used In Welding Or Read and understand the manufacturer's instructions and the

Cutting: precautionary label on

the products. See American National Standard Institute (ANSI)

Z49.1 Safety in

Welding and Cutting published by the American Welding

Society, P.O. Box 351040,

Miami, Florida 33135 and National Fire protection Association

(NFPA) 51 Oxygen

Fuel Gas Welding and Cutting.

08. EXPOSURE CONTROLS - PERSONAL PROTECTION

Engineering Controls:

Provide adequate natural or explosion-proof mechanical

Ventilation:

ventilation to ensure

acetylene does not accumulate and reach its lower explosive

limit of 2.5%

Personal Protective Equipment (PPE):

Skin Protection:

Cotton clothing is recommended for use to prevent static

Clothing:

buildup.

Glasses: Safety glasses are recommended when handling cylinders.

Shoes: Safety shoes are recommended when handling cylinders.

Gloves: Work gloves are recommended when handling cylinders.

Before entering area you must check for flammable and

Respiratory Protection:

oxygen deficient

atmospheres.

Respirator: None required in general use.

Wear a NIOSH/MSHA-approved (or equivalent) full-face piece

airline respirator in

the positive pressure mode in oxygen deficient atmospheres (air

purifying respirators

will not function).

09. PHYSICAL AND CHEMICAL PROPERTIES

Physical State: Gas

Color: Colorless gas.

Acetylene of 100% purity is odorless but commercial purity has

Odor:

a distinctive

garlic-like odor.

Molecular Weight: 26.04

Boiling Point: -103.4°F ( -75°C) @10 psig

Specific Gravity: 0.906 At 70°F (21.1°C) @ 1 atm, Air = 1

Freezing/Melting Point: -116°F (-82.2°C), at 10 psig

Vapor Pressure: 635 psig, At 70°F (21.1°C)

Vapor Density: 0.07314 lb./cu ft (1.176 kg/CuM), At 32°F (0°C) @ 1 atm

Water Solubility: 1.7 Vol./Vol. At 32° F (0°C) at 1 atm

Expansion Ratio: Not Applicable - Gas

pH: Not Applicable - Gas

Odor Threshold: 565 ppm

UNIBA D4 – K3 ∣ Keselamatan Lepas Pantai Page viii

Evaporation Rate: Not Applicable - Gas

Coefficient Of Water/Oil

Information not available

Distribution:

10. STABILITY AND REACTIVITY

Unstable. Stable as Shipped. Do not use at pressure above 15

Chemical Stability:

psig (103 kPa).

Conditions To Avoid: Avoid mechanical shock.

Avoid high temperatures

Incompatibility With Other Under certain conditions, acetylene can react with copper,

Materials: silver, and mercury to

form acetylides, compounds which can act as ignition sources.

Brasses containing

less than 65% copper in the alloy and certain nickel alloys are

suitable for acetylene

service under normal conditions. Acetylene can react explosively

when combined

with oxygen and other oxidizers including all halogens and

halogen compounds. The

presence of moisture, certain acids, or alkaline materials tends to

enhance the

formation of copper acetylides.

Hazardous Decomposition

Hydrogen, Carbon

Products:

Hazardous Polymerization: Will not occur

11. TOXICOLOGICAL INFORMATION

LCLo: 50% inhalation-man/5min

TCLo: (Anesthesia) 33% inhalation-man/7 min

Irritancy Of Material: None.

Sensitization To Material: None.

Reproductive Effects: None.

Teratogenicity: None.

Mutagenicity: None.

Synergistic Materials: None.

12. ECOLOGICAL INFORMATION

No adverse ecological effects are expected. Acetylene does

Ecotoxicity:

not contain any Class

I or Class II Ozone depleting chemicals (40 CFR Part 82).

Acetylene is not listed

as a marine pollutant by DOT (49 CFR Part 171).

13. DISPOSAL CONSIDERATIONS

Do not attempt to dispose of residual or unused quantities.

Waste Disposal Method:

Return cylinder to

supplier.

Unserviceable cylinders should be returned to the supplier for

safe and proper

disposal.

14. TRANSPORT INFORMATION

DOT/IMO Shipping Name: Acetylene, dissolved

Hazard Class: 2.1 (Flammable gas.)

Identification Number: UN 1001

PIN: 1001

Product RQ: None.

UNIBA D4 – K3 ∣ Keselamatan Lepas Pantai Page ix

Shipping Label: Flammable Gas.

Special Shipping Cylinders should be transported in a secure position, in a well

Information: ventilated vehicle.

The transportation of compressed gas cylinders in automobiles or

in closed-body

vehicles can present serious hazards and should be discouraged.

Placard (When Required): Flammable gas.

UNIBA D4 – K3 ∣ Keselamatan Lepas Pantai Page x

You might also like

- Material Safety Data Sheet: Acetylene DissolvedDocument3 pagesMaterial Safety Data Sheet: Acetylene Dissolvedandi permana100% (1)

- Safety Data Sheet (MSDS) Acetylene: Please Ensure That This MSDS Is Received by The Appropriate Person)Document3 pagesSafety Data Sheet (MSDS) Acetylene: Please Ensure That This MSDS Is Received by The Appropriate Person)Pasko DaboNo ratings yet

- Material Safety Data Sheet: Chemical Name Class: AcetyleneDocument9 pagesMaterial Safety Data Sheet: Chemical Name Class: AcetyleneArian JackNo ratings yet

- 2018 Safety Data Sheet SDS Final English Web FileDocument2 pages2018 Safety Data Sheet SDS Final English Web FileAnonymous y3tPCbVrNo ratings yet

- Material Safety Data Sheet Ethanol: Nfpa: Hmis IiiDocument11 pagesMaterial Safety Data Sheet Ethanol: Nfpa: Hmis IiiNanaris variiNo ratings yet

- Oxygen Gas MsdsDocument2 pagesOxygen Gas MsdsROSSI100% (4)

- H2 Gas Samator Msds Produknya PDFDocument3 pagesH2 Gas Samator Msds Produknya PDFFlorentina Endah Welling100% (1)

- Oxygen MSDS-Bristol GasesDocument5 pagesOxygen MSDS-Bristol GasesAhmad TalaatNo ratings yet

- Acetyline Cylinder PDFDocument2 pagesAcetyline Cylinder PDFniazNo ratings yet

- MSDSLPGDocument9 pagesMSDSLPGmoroe.No ratings yet

- MSDS - SGT - 2Document7 pagesMSDS - SGT - 2SajidNo ratings yet

- Stabilis SDS LNG Rev 4Document6 pagesStabilis SDS LNG Rev 4Thaufik MucsinNo ratings yet

- MSDS - LPGDocument9 pagesMSDS - LPGPrathamesh ShevaleNo ratings yet

- Health Health Hazards Hazards: Chemical Hazard Bulletin No. 49Document1 pageHealth Health Hazards Hazards: Chemical Hazard Bulletin No. 49shinto LawrenceNo ratings yet

- Material Safety Data Sheet: AcetyleneDocument1 pageMaterial Safety Data Sheet: AcetyleneNuri Estiana AnggrainiNo ratings yet

- C2H2 MSDS ApDocument13 pagesC2H2 MSDS ApMaterial Coordinator - WLNo ratings yet

- Acetylene Material Safety Data Sheet (MSDS) : Stoody Industrial and Welding Supply, IncDocument4 pagesAcetylene Material Safety Data Sheet (MSDS) : Stoody Industrial and Welding Supply, Incsami1243No ratings yet

- Dokumen - Tips - h2 Gas Samator Msds ProduknyaDocument4 pagesDokumen - Tips - h2 Gas Samator Msds ProduknyachindyNo ratings yet

- Material Safety Data Sheet: U066 1. Identification of The Substance/Preparation and of The Company/UndertakingDocument5 pagesMaterial Safety Data Sheet: U066 1. Identification of The Substance/Preparation and of The Company/UndertakingPranav DubeyNo ratings yet

- Cui Aw Hydraulic OilsDocument4 pagesCui Aw Hydraulic OilsDIEGO CAMPOS JIMENEZNo ratings yet

- Medigas (PVT) Ltd. Argon - Compressed: 5 Fire Fighting Measures 1 ProductDocument2 pagesMedigas (PVT) Ltd. Argon - Compressed: 5 Fire Fighting Measures 1 Productazam RazzaqNo ratings yet

- A-Typical Composition B-Physiological Effects and Health InformationDocument2 pagesA-Typical Composition B-Physiological Effects and Health Informationslamet4riadiNo ratings yet

- MSDS Ethyl MercaptanDocument5 pagesMSDS Ethyl MercaptanAjinkya PatilNo ratings yet

- 8-International Interthane 990 - Base MediumDocument1 page8-International Interthane 990 - Base MediumWinda Febriana [MMS]No ratings yet

- 1359 Eng PDFDocument1 page1359 Eng PDFHaleem Ur Rashid BangashNo ratings yet

- 1359 Eng PDFDocument1 page1359 Eng PDFHaleem Ur Rashid BangashNo ratings yet

- Chemical Hazard Bulletin: OPT D 1127Document1 pageChemical Hazard Bulletin: OPT D 1127HaleemUrRashidBangashNo ratings yet

- Health Hazards: Chemical Hazard Bulletin No. 49Document1 pageHealth Hazards: Chemical Hazard Bulletin No. 49shinto LawrenceNo ratings yet

- Technical Specification LPGDocument7 pagesTechnical Specification LPGLAL SANKARNo ratings yet

- Acetylene Msds AirtecDocument9 pagesAcetylene Msds AirtecManzur AhmadNo ratings yet

- Msds-Thinnal 4280101Document2 pagesMsds-Thinnal 4280101محمد عزتNo ratings yet

- Material Safety Data Sheet: 1. Product Identification Chemical Name Class: H A /H /N A G MDocument9 pagesMaterial Safety Data Sheet: 1. Product Identification Chemical Name Class: H A /H /N A G MbismuthsunilNo ratings yet

- Material Safety Data Sheet: Product IdentificationDocument4 pagesMaterial Safety Data Sheet: Product Identificationمحمد عزتNo ratings yet

- MiniSDS Acetone 2022 December 23 USA ENDocument1 pageMiniSDS Acetone 2022 December 23 USA ENArisa SNo ratings yet

- Hydrogen Chloride 0163: April 2000Document2 pagesHydrogen Chloride 0163: April 2000vivekpattniNo ratings yet

- Safety Data Sheet Kerosene: NfpaDocument9 pagesSafety Data Sheet Kerosene: NfpaAliNo ratings yet

- Msds of ChlorineDocument3 pagesMsds of ChlorineRahul ParmarNo ratings yet

- Synthetic Natural Gas SNG SDS Rev.5 1Document11 pagesSynthetic Natural Gas SNG SDS Rev.5 1rizkboss8312No ratings yet

- Material Safety Data Sheet ON Acetone: Submitted By: Nacario, Stephanie IDocument5 pagesMaterial Safety Data Sheet ON Acetone: Submitted By: Nacario, Stephanie ILee GhaiaNo ratings yet

- Chemical Hazard Bulletin: Baker Hughes E-31Document1 pageChemical Hazard Bulletin: Baker Hughes E-31mohamed thabetNo ratings yet

- MSDS Syntal HG 4230102Document2 pagesMSDS Syntal HG 4230102محمد عزتNo ratings yet

- 01 Sep 2017 130337400Q17VEVQBMATERIALSAFETYDATASHEET-HSDDocument3 pages01 Sep 2017 130337400Q17VEVQBMATERIALSAFETYDATASHEET-HSDRiki FernandesNo ratings yet

- Acetylene PDFDocument4 pagesAcetylene PDFDaniel_Parker_k4B6oNo ratings yet

- W 221Document11 pagesW 221ShaikhRizwanNo ratings yet

- 00 Hydrogen - 2Document6 pages00 Hydrogen - 2sujit5584No ratings yet

- AcetyleneDocument11 pagesAcetyleneMuhammad Habibullah [MMS]No ratings yet

- Acetylene MSDS-Bristol GasesDocument6 pagesAcetylene MSDS-Bristol GasesAhmad TalaatNo ratings yet

- Lem AltecoDocument4 pagesLem AltecodewiyulianiNo ratings yet

- Ethanol (Anhydrous) 0044: October 2000Document2 pagesEthanol (Anhydrous) 0044: October 2000vivekpattniNo ratings yet

- Leah MaeDocument4 pagesLeah MaeLEAH MAE CANDADONo ratings yet

- Diesel Fuel No. 2 1561: October 2004Document2 pagesDiesel Fuel No. 2 1561: October 2004vivekpattniNo ratings yet

- LNG Sds Au enDocument17 pagesLNG Sds Au enThaufik MucsinNo ratings yet

- TRIETHYLENE GLYCOL - CAMEO Chemicals - NOAADocument4 pagesTRIETHYLENE GLYCOL - CAMEO Chemicals - NOAAhorstiillingNo ratings yet

- LPGMSDSDocument5 pagesLPGMSDSrinaNo ratings yet

- Msds LNG LeiplDocument5 pagesMsds LNG LeiplhariNo ratings yet

- DiaQueen SUPER LONG LIFE COOLANT PREMIUM PDFDocument5 pagesDiaQueen SUPER LONG LIFE COOLANT PREMIUM PDFJohannes VGNo ratings yet

- Material Safety Data Sheet Nafs Iii: Dangerous Goods. Non Hazardous SubstanceDocument2 pagesMaterial Safety Data Sheet Nafs Iii: Dangerous Goods. Non Hazardous SubstanceicsNo ratings yet

- 8 MSDS Natural GasDocument8 pages8 MSDS Natural Gasankit kumar sinhaNo ratings yet

- ANSUL Inergen MSDS Sheet PDFDocument5 pagesANSUL Inergen MSDS Sheet PDFAlvaro Rojas AnzolaNo ratings yet

- Feedback Control Principle Instrumentation ToolsDocument10 pagesFeedback Control Principle Instrumentation ToolsLeDuNo ratings yet

- Sour Corrosion Control in Refinery 1597351611Document1 pageSour Corrosion Control in Refinery 1597351611Akshat AgrawalNo ratings yet

- Chapter 2 The Environmental Planning ProcessDocument55 pagesChapter 2 The Environmental Planning ProcessTole DelúxëNo ratings yet

- InterpretationDocument38 pagesInterpretationGM AbeNo ratings yet

- THE OF: Hydraulics Stepped Chutes and Spill W A YsDocument3 pagesTHE OF: Hydraulics Stepped Chutes and Spill W A YsChandeshwor ShahNo ratings yet

- Plumbing - External WaterDocument7 pagesPlumbing - External WaterKhin Thu Zar HtayNo ratings yet

- PET Bottle TroublesDocument6 pagesPET Bottle Troublesvnbhtpp100% (1)

- Foam FataleDocument12 pagesFoam FataleLilian AlvesNo ratings yet

- Tyranny of The DownbeatDocument576 pagesTyranny of The DownbeatKen White100% (1)

- MSDSS1Document4 pagesMSDSS1PeterWayNo ratings yet

- GMPDocument123 pagesGMPmoshejamNo ratings yet

- FINAL11Document2 pagesFINAL11JendaeNo ratings yet

- Industrial Water Recycle/reuse: Jir I Jaromı R KlemesDocument8 pagesIndustrial Water Recycle/reuse: Jir I Jaromı R KlemesHenrique Martins TavaresNo ratings yet

- Steam Jenny ManualDocument48 pagesSteam Jenny ManualPawan SehrawatNo ratings yet

- DeFlo - DesuperheatersDocument4 pagesDeFlo - DesuperheatersVarun PatelNo ratings yet

- Zoning Ordinance PDFDocument158 pagesZoning Ordinance PDFPaulineNo ratings yet

- Selection of Filter Bag HousingsDocument2 pagesSelection of Filter Bag Housingsanugrah_dimas5441No ratings yet

- Aquaculture: Business PlanDocument37 pagesAquaculture: Business PlanAbiodun AliNo ratings yet

- Thermal Physics NotesDocument17 pagesThermal Physics NotesNo PainNo ratings yet

- S.T.P DesignDocument70 pagesS.T.P DesignAmit Bhamre75% (12)

- Textile Dyeing Effluents and Environment Concerns - A Review M. R. Islam and M. G. MostafaDocument14 pagesTextile Dyeing Effluents and Environment Concerns - A Review M. R. Islam and M. G. MostafaZhulietaNo ratings yet

- Interbond 808Document4 pagesInterbond 808shameelNo ratings yet

- 9 Health Benefits of AlmondsDocument26 pages9 Health Benefits of Almondskahani20099731No ratings yet

- Heat Exchanger GuideDocument16 pagesHeat Exchanger GuideYoNo ratings yet

- SinkholesDocument3 pagesSinkholesAr Nhel DGNo ratings yet

- Technical Regulations On The Safety of Sea Transport Items - Part3Document15 pagesTechnical Regulations On The Safety of Sea Transport Items - Part3strijelavremenaNo ratings yet

- The Comfortable and Sustainable Home Giacomini 0340EN PDFDocument4 pagesThe Comfortable and Sustainable Home Giacomini 0340EN PDFAlex CoțNo ratings yet

- Paint Safety Checklist: BLR Audit ChecklistsDocument2 pagesPaint Safety Checklist: BLR Audit ChecklistssisayNo ratings yet

- Textile Industry in IndiaDocument97 pagesTextile Industry in IndiaDharmendra B MistryNo ratings yet

- GP - Migration Table - Holiday H.W.Document3 pagesGP - Migration Table - Holiday H.W.Mihika GuptaNo ratings yet