Professional Documents

Culture Documents

S4L1D-D41 Wdg.311 - Technical Data Sheet - Stamford

Uploaded by

scribbles_buddyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S4L1D-D41 Wdg.311 - Technical Data Sheet - Stamford

Uploaded by

scribbles_buddyCopyright:

Available Formats

S4L1D-D41 Wdg.

311 - Technical Data Sheet

Standards

Stamford industrial alternators meet the requirements of the relevant parts of the BS EN 60034 and the relevant

section of other international standards such as BS5000, VDE 0530, NEMA MG1-32, IEC34, CSA C22.2-100

and As1359. Other standards and certifications can be considered on request.

Quality Assurance

Alternators are manufactured using production procedures having a quality assurance level to BS EN ISO 9001.

Excitation and Voltage Regulators

Excitation System

AVR Type AS440 MX341 MX321

Voltage Regulation ± 1% ± 1% ± 0.5% with 4% Engine Governing

Excitation Type Self-Excited PMG PMG

No Load Excitation Voltage (V) 12 - 9

No Load Excitation Current (A) 0.7 - 0.5

Full Load Excitation Voltage (V) 41 - 39

Full Load Excitation Current (A) 2.3 - 2.2

Exciter Time Constant (seconds) 0.105

Page 1 S4L1D-D41_A056E878 Rev.B_ECO-168219_21.02.2017

S4L1D-D41 Wdg.311

Electrical Data

Insulation System Class H

Stator Winding Double Layer Lap

Winding Pitch Two Thirds

Winding Leads 12

Winding Number 311

Number of Poles 4

IP Rating IP23

RFI Suppression

BS EN 61000-6-2 & BS EN 61000-6-4,VDE 0875G, VDE 0875N.

Refer to factory for others

Waveform Distortion NO LOAD < 1.5% NON-DISTORTING BALANCED LINEAR LOAD < 5.0%

Short Circuit Ratio 1/Xd

Steady State X/R Ratio 12.29

50 Hz 60 Hz

Telephone Interference THF<2% TIF<50

Cooling Air 0.83 m³/sec 0.99 m³/sec

Voltage Star 380 400 415 440 416 440 460 480

kVA Base Rating (Class H) for

Reactance Values 300 310 310 290 344 370 375 390

Saturated Values in Per Unit at Base Ratings and Voltages

Xd Dir. Axis Synchronous 3.15 2.94 2.73 2.27 3.60 3.46 3.21 3.07

X'd Dir. Axis Transient 0.20 0.19 0.17 0.14 0.22 0.21 0.20 0.19

X''d Dir. Axis Subtransient 0.14 0.13 0.12 0.10 0.15 0.14 0.13 0.12

Xq Quad. Axis Reactance 2.66 2.48 2.30 1.92 3.09 2.97 2.75 2.63

X''q Quad. Axis Subtransient 0.40 0.37 0.34 0.29 0.40 0.39 0.36 0.34

XL Stator Leakage Reactance 0.07 0.06 0.06 0.05 0.09 0.08 0.08 0.07

X2 Negative Sequence Reactance 0.27 0.25 0.23 0.19 0.28 0.27 0.25 0.24

X0 Zero Sequence Reactance 0.10 0.09 0.09 0.07 0.10 0.09 0.09 0.08

Unsaturated Values in Per Unit at Base Ratings and Voltages

Xd Dir. Axis Synchronous 3.78 3.53 3.28 2.73 4.32 4.16 3.85 3.68

X'd Dir. Axis Transient 0.23 0.21 0.20 0.17 0.25 0.24 0.23 0.22

X''d Dir. Axis Subtransient 0.17 0.16 0.15 0.12 0.17 0.16 0.15 0.15

Xq Quad. Axis Reactance 2.74 2.55 2.37 1.97 3.18 3.06 2.84 2.71

X''q Quad. Axis Subtransient 0.48 0.45 0.41 0.34 0.48 0.46 0.43 0.41

XL Stator Leakage Reactance 0.08 0.07 0.07 0.05 0.10 0.09 0.09 0.08

Xlr Rotor Leakage Reactance 0.12 0.11 0.10 0.09 0.14 0.13 0.12 0.12

X2 Negative Sequence Reactance 0.32 0.30 0.28 0.23 0.34 0.32 0.30 0.29

X0 Zero Sequence Reactance 0.12 0.11 0.10 0.08 0.11 0.11 0.10 0.10

Page 2 S4L1D-D41_A056E878 Rev.B_ECO-168219_21.02.2017

S4L1D-D41 Wdg.311

Time Constants (Seconds)

T’d TRANSIENT TIME CONST. 0.08

T’’d SUB-TRANSTIME CONST. 0.019

T’do O.C. FIELD TIME CONST. 1.7

Ta ARMATURE TIME CONST. 0.018

T’’q SUB-TRANSTIME CONST. 0.0077

Resistances in Ohms (Ω) at 220C

Stator Winding Resistance (Ra), per

0.0124

phase for series connected

Rotor Winding Resistance (Rf) 1.05

Exciter Stator Winding Resistance 18

Exciter Rotor Winding Resistance per

0.068

phase

PMG Phase Resistance (Rpmg) per

1.9

phase

Positive Sequence Resistance (R1) 0.0155

Negative Sequence Resistance (R2) 0.017856

Zero Sequence Resistance (R0) 0.0155

Saturation Factors 400V 480V

SG1.0 0.31 0.31

SG1.2 1.25 1.25

Mechanical Data

Shaft and Keys All alternator rotors are dynamically balanced to better than BS6861: Part 1 Grade 2.5 for

minimum vibration in operation. Two bearing generators are balanced with a half key.

1 Bearing 2 Bearings

SAE Adaptor SAE 0.5, 1 N/A

Moment of Inertia 4.0771 kgm2 N/A

Weight Wound Stator 415 kg N/A

Weight Wound Rotor 361 kg N/A

Weight Complete Alternator 940 kg N/A

Shipping weight in a Crate 1010 kg N/A

Packing Crate Size 155 x 87 x 107(cm) N/A

Maximum Over Speed 2250 RPM for two minutes

Bearing Drive End N/A N/A

Bearing Non-Drive End Ball 6314 N/A

Page 3 S4L1D-D41_A056E878 Rev.B_ECO-168219_21.02.2017

S4L1D-D41 Wdg.311

THREE PHASE EFFICIENCY CURVES

50Hz 60Hz

insert curves of 50Hz insert curves of 60Hz

Page 4 S4L1D-D41_A056E878 Rev.B_ECO-168219_21.02.2017

S4L1D-D41 Wdg.311

Locked Rotor Motor Starting Curves - Separately Excited

50Hz

380V 400V 415V 440V

insert

35 curve

30

25

PER CENT TRANSIENT VOLTAGE DIP

20

15

10

0

0 200 400 600 800 1000 1200 1400

LOCKED ROTOR kVA

60Hz

416V 440V 460V480V

insert

35 curve

30

25

PER CENT TRANSIENT VOLTAGE DIP

20

15

10

0

0 200 400 600 800 1000 1200 1400

LOCKED ROTOR kVA

Transient Voltage Dip Scaling Factor Transient Voltage Rise Scaling Factor

PF Factor

< 0.5 1 For voltage rise multiply voltage dip by 1.25

0.5 0.97

0.6 0.93

0.7 0.9

0.8 0.85

0.9 0.83

Page 5 S4L1D-D41_A056E878 Rev.B_ECO-168219_21.02.2017

S4L1D-D41 Wdg.311

Locked Rotor Motor Starting Curves - Self Excited

50Hz

380V 400V 415V 440V

insert

35 curve

30

25

PER CENT TRANSIENT VOLTAGE DIP

20

15

10

0

0 100 200 300 400 500 600 700 800 900 1000

LOCKED ROTOR kVA

60Hz

416V 440V 460V 480V

insert

35 curve

30

25

PER CENT TRANSIENT VOLTAGE DIP

20

15

10

0

0 200 400 600 800 1000 1200

LOCKED ROTOR kVA

Transient Voltage Dip Scaling Factor Transient Voltage Rise Scaling Factor

PF Factor

< 0.5 1 For voltage rise multiply voltage dip by 1.25

0.5 0.97

0.6 0.93

0.7 0.9

0.8 0.85

0.9 0.83

Page 6 S4L1D-D41_A056E878 Rev.B_ECO-168219_21.02.2017

S4L1D-D41 Wdg.311

Three-phase Short Circuit Decrement Curve

50Hz

10000

insert curve

SYMM. ASYMMETRICAL

CURRENT (Amps)

1000

100

0.001 0.01 0.1 1 10

TIME (secs)

Sustained Short Circuit = 1200 Amps

60Hz

insert curve 10000

SYMM. ASYMMETRICAL

CURRENT (Amps)

1000

100

0.001 0.01 0.1 1 10

TIME (secs)

Sustained Short Circuit = 1300 Amps

Note 1 Note 2

The following multiplication factors should be used to The following multiplication factor should be used to convert

adjust the values from curve between time 0.001 the values calculated in accordance with NOTE 1 to those

seconds and the minimum current point in respect of applicable to the various types of short circuit :

nominal operating voltage :

50Hz 60Hz 3-phase 2-phase L-L 1-phase L-N

Voltage Factor Voltage Factor Instantaneous x 1.00 x 0.87 x 1.30

380V X 1.00 416V X 1.00 Minimum x 1.00 x 1.80 x 3.20

400V X 1.05 440V X 1.06 Sustained x 1.00 x 1.50 x 2.50

415V X 1.09 460V X 1.10 Max. sustained duration 10 sec. 5 sec. 2 sec.

440V X 1.16 480V X 1.15 All other times are unchanged

The sustained current value is constant irrespective of voltage

Note 3

level

Curves are drawn for Star connected machines under no-load

excitation at rated speeds. For other connection the following

multipliers should be applied to current values as shown :

Parallel Star = Curve current value X 2

Series Delta = Curve current value X 1.732

Page 7 S4L1D-D41_A056E878 Rev.B_ECO-168219_21.02.2017

S4L1D-D41 Wdg.311

Typical Alternator Operating Charts

400V/50Hz

Inser chart

480V/60Hz

Inser chart

Page 8 S4L1D-D41_A056E878 Rev.B_ECO-168219_21.02.2017

S4L1D-D41 Wdg.311

RATINGS AT 0.8 POWER FACTOR

Class - Temp Rise Standby - 163/27°C Standby - 150/40°C Cont. H - 125/40°C Cont. F - 105/40°C

Series Star (V) 380 400 415 440 380 400 415 440 380 400 415 440 380 400 415 440

50 kVA 330 340 340 320 320 330 330 310 300 310 310 290 280 285 285 270

Hz

kW 264 272 272 256 256 264 264 248 240 248 248 232 224 228 228 216

Efficiency (%) 92.1 92.3 92.6 93.2 92.3 92.5 92.7 93.3 92.7 92.9 93.1 93.6 93.1 93.3 93.4 93.8

kW Input 287 295 294 275 277 285 285 266 259 267 266 248 241 244 244 230

Series Star (V) 416 440 460 480 416 440 460 480 416 440 460 480 416 440 460 480

60 kVA 375 410 415 430 365 400 400 415 344 370 375 390 315 340 345 355

Hz

kW 300 328 332 344 292 320 320 332 275 296 300 312 252 272 276 284

Efficiency (%) 92.4 92.2 92.5 92.6 92.5 92.4 92.7 92.8 92.8 92.9 93.1 93.1 93.2 93.2 93.4 93.5

kW Input 325 356 359 372 316 346 345 358 296 319 322 335 270 292 295 304

De-Rates

All values tabulated above are subject to the following reductions:

- 5% when air inlet filters are fitted

- 3% for every 500 meters by which the operating altitude exceeds 1000 meters above mean sea level

- 3% for every 5°C by which the operational ambient temperature exceeds 40°C

- For any other operating conditions impacting the cooling circuit please refer to applications

Note: Requirement for operating in an ambient exceeding 60°C and altitude exceeding 4000 meters must be

referred to applications.

Dimensional and Torsional Drawing

For dimensional and torsional information please refer to the alternator General Arrangement and rotor drawings

available on our website (http://stamford-avk.com/)

Note: Continuous development of our products means that the information contained in our data sheets can change

without notice, and specifications should always be confirmed with Cummins Generator Technologies prior to

purchase.

Page 9 S4L1D-D41_A056E878 Rev.B_ECO-168219_21.02.2017

Follow us @stamfordavk

Cummins Generator Technologies

View our videos at youtube.com/stamfordavk

news.stamford-avk.com

For Applications Support:

applications@cummins.com

For Customer Service:

service-engineers@stamford-avk.com

For General Enquiries:

info@cumminsgeneratortechnologies.com

Copyright 2016. Cummins Generator Technologies Ltd. All rights reserved.

Cummins and the Cummins logo are registered trade marks of Cummins Inc.

STAMFORD is a registered trade mark of Cummins Generator Technologies Ltd.

You might also like

- Diesel generator specificationsDocument10 pagesDiesel generator specificationsJohn GarnetNo ratings yet

- Shindaiwa DGW400DM-ANZ-Owners-Manual-1Document40 pagesShindaiwa DGW400DM-ANZ-Owners-Manual-1Guruh SuprayitnoNo ratings yet

- DYNA CONTROLLERSDocument4 pagesDYNA CONTROLLERSOmarColonNo ratings yet

- AUTO MAINS FAILURE MODULEDocument2 pagesAUTO MAINS FAILURE MODULESOSNo ratings yet

- Principles of Power QualityDocument4 pagesPrinciples of Power Qualitykartheek427No ratings yet

- Generator Checklist TemplateDocument1 pageGenerator Checklist Templatesmart channelNo ratings yet

- Moorish Science Numerical Explanation of RealityDocument18 pagesMoorish Science Numerical Explanation of Realitygheorghe100% (1)

- Engine GENERATOR SDG series AIRMANDocument12 pagesEngine GENERATOR SDG series AIRMANDave Wallace100% (1)

- Cable HandbookDocument548 pagesCable Handbookphuonganh8681100% (7)

- Technical Information: For V1505Document27 pagesTechnical Information: For V1505hendra100% (1)

- Perkins M215C and M185C 1006 SeriesDocument2 pagesPerkins M215C and M185C 1006 SeriesDamian Cid Morales100% (1)

- ATS - Design Manual CaterpillarDocument84 pagesATS - Design Manual CaterpillarSharik Khan100% (1)

- Alternator Data Sheet Allied Generator.Document14 pagesAlternator Data Sheet Allied Generator.muhammad nomanNo ratings yet

- Heavy Duty StarterDocument11 pagesHeavy Duty StarterMahmudur Rahman MithunNo ratings yet

- Owners Manual Kubota Silent-Comap Amf20Document27 pagesOwners Manual Kubota Silent-Comap Amf20CarlosNo ratings yet

- Baudouin 12M33 SpecSheetDocument2 pagesBaudouin 12M33 SpecSheetMartin KratkyNo ratings yet

- Application Notes: Application Notes P64X/En Ap/A11 Micom P642, P643, P645Document92 pagesApplication Notes: Application Notes P64X/En Ap/A11 Micom P642, P643, P645sogetsu kazamaNo ratings yet

- 16.D50S-5 Hyd SB4278E01Document4 pages16.D50S-5 Hyd SB4278E01Francisco Javier Reyes AguirreNo ratings yet

- Dca PDFDocument12 pagesDca PDFvcharles100% (1)

- (Customer) G2 Stage V and LPG Engine Service Training - ElectricDocument28 pages(Customer) G2 Stage V and LPG Engine Service Training - ElectricXuân Quang PhạmNo ratings yet

- General PresentationDocument81 pagesGeneral PresentationĐại DươngNo ratings yet

- Mil M 8090FDocument83 pagesMil M 8090Feuroporsche914No ratings yet

- Trion Wiring PDFDocument2 pagesTrion Wiring PDFAung Htut100% (1)

- Low Voltage Alternators - 4 Pole: TAL-A46 - TAL-A47 - TAL-A49Document5 pagesLow Voltage Alternators - 4 Pole: TAL-A46 - TAL-A47 - TAL-A49Duc Thao VuNo ratings yet

- Catalog Tong May Phat Dien CumminsDocument114 pagesCatalog Tong May Phat Dien CumminsTrần Việt HoàngNo ratings yet

- Schneider CatalogDocument56 pagesSchneider CatalogSani Poulou100% (1)

- Kirloskar: Diesel Generating SetsDocument4 pagesKirloskar: Diesel Generating Setsnam phạm100% (1)

- Aspire Catalogue PDFDocument13 pagesAspire Catalogue PDFJose BaptistaNo ratings yet

- P22-1 (50HZ)Document2 pagesP22-1 (50HZ)Daniel StanNo ratings yet

- Motor Cummins X2,5-G2: Kit Mantenimiento y RepuestosDocument1 pageMotor Cummins X2,5-G2: Kit Mantenimiento y RepuestosJulio Felipe Miranda MarzanNo ratings yet

- EMS98R3 User GuideDocument22 pagesEMS98R3 User GuideAnas BasarahNo ratings yet

- 2206a-E13tag2 Electropak Pn1880Document2 pages2206a-E13tag2 Electropak Pn1880ibrahemNo ratings yet

- Cummins QSL9-G5 engine data sheetDocument4 pagesCummins QSL9-G5 engine data sheetHéctor VilaNo ratings yet

- p1500-4012-46TAG2A - TDS (1500) - Gross Engine Power, Fan PowerDocument6 pagesp1500-4012-46TAG2A - TDS (1500) - Gross Engine Power, Fan PowerKarlaNo ratings yet

- Data Sheet: Diesel Generator 880Kw 50HZ/1500RPM Cummins Model: Kta38-G5Document7 pagesData Sheet: Diesel Generator 880Kw 50HZ/1500RPM Cummins Model: Kta38-G5MrShaz ZainalNo ratings yet

- 280kw Cummins GeneratorDocument3 pages280kw Cummins GeneratorChen CarolineNo ratings yet

- 4008TAG2 Electro Unit PN2199Document2 pages4008TAG2 Electro Unit PN2199RioNo ratings yet

- Leroy Somer LSA 50.2 From Macfarlane Generators PDFDocument12 pagesLeroy Somer LSA 50.2 From Macfarlane Generators PDFAnonymous 3RS6JNcNo ratings yet

- 4000 Series: 4008TAG2ADocument5 pages4000 Series: 4008TAG2ALopo LesmanaNo ratings yet

- PERKÿNS SABRE 6TG2AM AYRDIMCI MOTORDocument2 pagesPERKÿNS SABRE 6TG2AM AYRDIMCI MOTORRiki Akbar100% (1)

- Hoja de Datos QSK60G5 - fr6321Document3 pagesHoja de Datos QSK60G5 - fr6321acere18100% (1)

- 6SL8800TA-Engine 250kVA 50Hz Rev00-1Document3 pages6SL8800TA-Engine 250kVA 50Hz Rev00-1hunais ali aliNo ratings yet

- Fan-cooled drive cooling requirementsDocument8 pagesFan-cooled drive cooling requirementsBeto LexNo ratings yet

- Phase Sequence Relay PFN Mecotron: OperationDocument1 pagePhase Sequence Relay PFN Mecotron: Operationhonafa- R.O.N.ONo ratings yet

- Dca 60eseiDocument10 pagesDca 60eseinelsonyNo ratings yet

- Analysis of Copper Vs Aluminum Winding MotorsDocument6 pagesAnalysis of Copper Vs Aluminum Winding MotorsSwapnil DesaiNo ratings yet

- P800p1-P900e1 (4PP) GB (0313) PDFDocument4 pagesP800p1-P900e1 (4PP) GB (0313) PDFNom YusNo ratings yet

- Fujian Aspire Electron Co.,Ltd: Model: MX341 Model: R220Document13 pagesFujian Aspire Electron Co.,Ltd: Model: MX341 Model: R220Jose BaptistaNo ratings yet

- QSK 60G & 60HE Gas Engines Data & SpecificationsDocument21 pagesQSK 60G & 60HE Gas Engines Data & Specificationsagvass100% (1)

- Catalog Baudouin Generatory ENG Oman & MuscatDocument12 pagesCatalog Baudouin Generatory ENG Oman & MuscatmustafaNo ratings yet

- Series: 973 - 1327 KWM (Gross) at 1500 RPMDocument18 pagesSeries: 973 - 1327 KWM (Gross) at 1500 RPMlahcen boudaoudNo ratings yet

- Manual DDFPDocument92 pagesManual DDFPCarlos VegaNo ratings yet

- TP 6434Document38 pagesTP 6434Roberto Sanchez Zapata100% (1)

- 02-CUMARK Inverter Application On Air CompressorDocument17 pages02-CUMARK Inverter Application On Air Compressorvictor riveroNo ratings yet

- Air Compressor PDS175 BrochureDocument1 pageAir Compressor PDS175 BrochureTom Karewur100% (1)

- QSK60G4Document4 pagesQSK60G4Mohamed Hamdallah100% (1)

- Industrial Open Power Unit: SeriesDocument9 pagesIndustrial Open Power Unit: Serieseli abdul rohimNo ratings yet

- Fire Pump Diesel Engine CatalogueDocument3 pagesFire Pump Diesel Engine CatalogueAnoir AkkariNo ratings yet

- DG8500SE - T: Diesel Generator Portable Soundproof TypeDocument1 pageDG8500SE - T: Diesel Generator Portable Soundproof TypeWilfried VISSIENNONNo ratings yet

- S4L1D-G41 Wdg.311 - Technical Data SheetDocument10 pagesS4L1D-G41 Wdg.311 - Technical Data SheetsarahlawaNo ratings yet

- Ficha Tecnica GeneradorDocument10 pagesFicha Tecnica GeneradorEnrique Esquivel PalaciosNo ratings yet

- S4L1D G4Document10 pagesS4L1D G4mohsen_cumminsNo ratings yet

- Data Subtransien Generator StamfordDocument10 pagesData Subtransien Generator StamfordMuhamad WahyudinNo ratings yet

- S7L1D-G4 Wdg.312 - Technical Data SheetDocument9 pagesS7L1D-G4 Wdg.312 - Technical Data Sheet3efoo100% (1)

- EN DS SG33CX SG40CX SG50CX Datasheet V153 20200723Document2 pagesEN DS SG33CX SG40CX SG50CX Datasheet V153 20200723Alcides Araujo SantosNo ratings yet

- IGCSE 24 ElectricalResistanceDocument21 pagesIGCSE 24 ElectricalResistanceHAMAD NoorNo ratings yet

- Eddy Current DrivesDocument36 pagesEddy Current DrivesBenedict EromoseleNo ratings yet

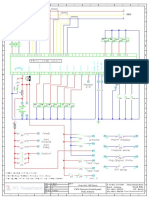

- Description of Schematic DiagramDocument18 pagesDescription of Schematic Diagramtest2k3No ratings yet

- Battery TenderDocument2 pagesBattery TenderEduardo VicoNo ratings yet

- Energy Efficient Electric Vehicle Using Regenerative Braking SystemDocument4 pagesEnergy Efficient Electric Vehicle Using Regenerative Braking SystemRrdbjdNo ratings yet

- Optimizing With eGaN FETsDocument6 pagesOptimizing With eGaN FETskhsniperNo ratings yet

- Midterm2 1BB3 w2014Document14 pagesMidterm2 1BB3 w2014luluNo ratings yet

- Mechanical Design of Overhead Transmission LinesDocument61 pagesMechanical Design of Overhead Transmission LinesGetahun shankoNo ratings yet

- Syncrosnap® Centrifugal Switches For Single-Phase Electric MotorsDocument4 pagesSyncrosnap® Centrifugal Switches For Single-Phase Electric MotorsMohit GargNo ratings yet

- 55-4-1 PhysicsDocument19 pages55-4-1 Physicsvikas aggarwalNo ratings yet

- A37 Four Point Probe Measurement of Semiconductor Sheet ResistanceDocument2 pagesA37 Four Point Probe Measurement of Semiconductor Sheet ResistanceRamu NelapatiNo ratings yet

- Old Enthuse Phase 1Document92 pagesOld Enthuse Phase 1bhooshan japeNo ratings yet

- SDQSFDocument103 pagesSDQSFHuy Khôi HàNo ratings yet

- A Textile Antenna For On Body Communication Using EBG SurfacesDocument11 pagesA Textile Antenna For On Body Communication Using EBG SurfacesMade SantanuNo ratings yet

- Load Break SwitchDocument16 pagesLoad Break SwitchAditya Pratama VTNo ratings yet

- Elcb & MCBDocument2 pagesElcb & MCBmuhammad zeeshan khanNo ratings yet

- Displacement-Velocity-Time Problems: IGCSE Coordinated Science 9.10 Quiz B NameDocument2 pagesDisplacement-Velocity-Time Problems: IGCSE Coordinated Science 9.10 Quiz B NamepixelhoboNo ratings yet

- VaristorsDocument2 pagesVaristorsskynet123No ratings yet

- June 2014 QP - Unit 4 Edexcel Physics A-LevelDocument24 pagesJune 2014 QP - Unit 4 Edexcel Physics A-Levelpaolo maldiniNo ratings yet

- CT Burden, Knee Point Voltage, Core Saturation - Details of Current Transformer CharacteristicsDocument6 pagesCT Burden, Knee Point Voltage, Core Saturation - Details of Current Transformer Characteristicsmarkigldmm918No ratings yet

- Chapter 9: Waves and Water DynamicsDocument32 pagesChapter 9: Waves and Water DynamicsMendozaNo ratings yet

- Transformer ProtectionDocument7 pagesTransformer ProtectionJeyson BarreraNo ratings yet

- Gen Physics 2 - Las 3 - Allas - Version 4Document4 pagesGen Physics 2 - Las 3 - Allas - Version 4J-heart Basabas MalpalNo ratings yet

- M50 Diode Series: High Surge Current Rectifier Circuits 5 Different Circuits To Choose FromDocument5 pagesM50 Diode Series: High Surge Current Rectifier Circuits 5 Different Circuits To Choose FromSiding BarroNo ratings yet

- Easy lift gas springsDocument26 pagesEasy lift gas springsRajeesh P RaviNo ratings yet