Professional Documents

Culture Documents

Subject Production Techology Syllabus

Uploaded by

bmdbmdbmdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Subject Production Techology Syllabus

Uploaded by

bmdbmdbmdCopyright:

Available Formats

Subject: Production Technology (DE-III)

Program: B.Tech. Automobile Engineering Subject Code: AU0714 Semester: VII

Teaching Scheme Examination Evaluation Scheme

University University Continuous Continuous Total

Theory Practical Internal Internal

Lecture Tutorial Practical Credits Examination Examination Evaluation Evaluation

(CIE)- (CIE)-

Theory Practical

3 0 0 3 24/60 0 16/40 0 100

Course Objectives

1. Students will be able to apply basics of metal machining processes very well. They can

have enough knowledge of different forces acting while cutting with tool life and wear.

They can interpret and utilize the economics of machining.

2. Learning of the technology of Gear and threads manufacturing which is grassroots

knowledge of any manufacturing industries. They are able understand the usefulness of Jig

& Fixtures, Presses & Press work, Types of Dies and various forces acting during cutting.

They also understand non conventional machining processes its importance, application

advantages and economy aspect in production technology.

CONTENTS

UNIT 1

[12 hours]

THEORY OF METAL CUTTING

Principles of metal machining, cutting tools and

tool materials, tool signature, mechanics of chip removal, cutting forces and parameters effecting

it, cutting fluids, tool wear, tool life, economics of machining. Multi point cutting tools,

temperature measurement at tool-work interface and its effects

UNIT 2

[12 hours]

GEAR AND THREADS MANUFACTURING

Different types of Threads manufacturing methods, and tools involved, Different gear forming and

generating methods with their special features, Gears finishing processes.

JIGS & FIXTURES

Definition, its usefulness in mass production, design principles,

locating systems and types of locators & clamps, jig bushes, design of jigs and fixtures for various

machining operations.

UNIT 3

[12 hours]

PRESSES AND PRESS WORK

Classification Of Presses, Classification Of Dies,Cutting Actions In Dies, Clearance, Cutting

Forces, Center Of Pressure Design Of PressTools, Methods Of Mounting Of Punches, Scrap

Reduction, Strip Layout.

CONTROLS IN MACHINE TOOLS

Machine tool drives, Machine tool structures, Machinetool spindles, Special purpose machines ,

Capstan and turret lathes, single spindle andmulti spindle automats, bar type and chucking type

machines, Design of cam forsingle spindle automat Transfer Machines.

UNIT 4

[12 hours]

NON-CONVENTIONAL MACHINING

EDM, IBM, ECM, ECG, CM, AJM, wire cut EDM, ,USM, LBM process principle, process

parameters and their applications

Course Outcomes

1. Students will be able to apply basics of metal machining processes very well with the

detailed signature of tools.

2. Students able to understand different forces acting while metal cutting and can draw

merchant circle diagram and also able to apply knowledge to economic metal cutting.

3. Students can able to grasp distinctive knowledge of gear forming and its generating

methods.

4. Students are able to clutch its usefulness and design of such locating and fixing devises.

5. Learn in depth about press and press work

6. Gained elementary knowledge in Non-conventional machining and its application in

industries.

Text Books

1. Fundamentals of machining and machine tools, by Boothroyd -CRC publication

2. Metal Cutting principles, by M C Shaw, Oxford University press

Reference Books

1. Tool Design by Donaldson, Tata McGraw Hill Pub.

2. Metal cutting Principles by Trent McGraw Hill Pub.

3. Workshop Technology Vol.II by Raghuvanshi , Dhanpat rai Pub.

4. Production Technology by R.K.Jain, Khanna Pub.

Web Resources

1. http://nptel.ac.in/downloads/112105127/ - Metal Cutting

2. http://nptel.ac.in/courses/112105126/33 - Gear and Threads Manufacturing

3. http://nptel.ac.in/courses/112105126/34 - Jigs & Fixtures

4. http://nptel.ac.in/courses/112107144/8 - Presses And Press Work

5. http://nptel.ac.in/courses/112104028/ - Non-Conventional Machining

You might also like

- Gujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2161909Document3 pagesGujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2161909ShahinNo ratings yet

- Manufacturing Processes II Year B.E. (Mechanical EnggDocument2 pagesManufacturing Processes II Year B.E. (Mechanical EnggRohan NewaskarNo ratings yet

- r05010302 Engineering MechanicsDocument39 pagesr05010302 Engineering Mechanicsdassault megecNo ratings yet

- Solapur University Tool Engineering Course OverviewDocument3 pagesSolapur University Tool Engineering Course OverviewAmirDeshmukhNo ratings yet

- Machining Science: Jigs & FixturesDocument29 pagesMachining Science: Jigs & FixturesChidu KNo ratings yet

- Production Processes and MetrologyDocument3 pagesProduction Processes and MetrologymaheshNo ratings yet

- Ptam CP 25.7.22Document8 pagesPtam CP 25.7.22SAMUEL SANJAY RAJA R MECHNo ratings yet

- Manufacturing Processes UTA026Document9 pagesManufacturing Processes UTA026Tania CENo ratings yet

- Gujarat Technological University Automobile Engineering (02) /mechanical EngineeringDocument3 pagesGujarat Technological University Automobile Engineering (02) /mechanical EngineeringRavi SidhpuriaNo ratings yet

- PMC ModuleDocument91 pagesPMC ModuleAbdi ZerihunNo ratings yet

- MCMT SyllabusDocument3 pagesMCMT SyllabusshahazadNo ratings yet

- PDFDocument11 pagesPDFjaniirNo ratings yet

- Fdocuments - in Swami Ramanand Teerth Marathwada Ramanand Teerth Marathwada University DesignDocument52 pagesFdocuments - in Swami Ramanand Teerth Marathwada Ramanand Teerth Marathwada University DesignPankaj AghavNo ratings yet

- Ii Year B.Tech. (Mechanical Engineering) Ii Semester Prepared by K.VIJAY, Asst. ProfessorDocument17 pagesIi Year B.Tech. (Mechanical Engineering) Ii Semester Prepared by K.VIJAY, Asst. ProfessorsanthoshNo ratings yet

- PEC-IVDocument6 pagesPEC-IV3111hruthvikNo ratings yet

- GTU Bachelor of Engineering Manufacturing Processes SyllabusDocument3 pagesGTU Bachelor of Engineering Manufacturing Processes Syllabuskk bhattNo ratings yet

- 19eme331 - Manufacturing TechnologyDocument3 pages19eme331 - Manufacturing TechnologySridhar AtlaNo ratings yet

- B Tech Mechanical Engineering 6thDocument17 pagesB Tech Mechanical Engineering 6thprakashkumarsenNo ratings yet

- Manufacturing Process 4 PDFDocument2 pagesManufacturing Process 4 PDFVijayalaxmi MudhigondaNo ratings yet

- MT Manufacturing TechnologyDocument135 pagesMT Manufacturing TechnologyIts meNo ratings yet

- Course Outine (Production Engineering I)Document2 pagesCourse Outine (Production Engineering I)GetahunNo ratings yet

- Production Technology PDFDocument2 pagesProduction Technology PDFRamana Kumar NarsipuramNo ratings yet

- Course File EditED 1.1.1...Document54 pagesCourse File EditED 1.1.1...jyothi bogaNo ratings yet

- MachinistDocument28 pagesMachinistabyzenNo ratings yet

- JNTUK METAL CUTTING & MACHINE TOOLSDocument2 pagesJNTUK METAL CUTTING & MACHINE TOOLSsanyasirao1No ratings yet

- Machining Science: Jigs & FixturesDocument26 pagesMachining Science: Jigs & FixturesChidu KNo ratings yet

- Production Management Op KannaDocument18 pagesProduction Management Op Kannasam_swamynathanNo ratings yet

- VIIIth Semester Scheme and SyllabusDocument21 pagesVIIIth Semester Scheme and SyllabusJitesh DewanganNo ratings yet

- Syllabus-Manufacturing Technology - IIDocument1 pageSyllabus-Manufacturing Technology - IIMoney vasagamNo ratings yet

- 5 MPDocument3 pages5 MPASIST MechNo ratings yet

- Manufacturing Tech SyllDocument4 pagesManufacturing Tech SyllJagjit SinghNo ratings yet

- V Semster Mechanical Engineering RTMNU NagpurDocument15 pagesV Semster Mechanical Engineering RTMNU NagpurAnand NilewarNo ratings yet

- Machining Science: Jigs & FixturesDocument29 pagesMachining Science: Jigs & FixturesChidu KNo ratings yet

- 2.me 8462-Mt-II Lab ManualDocument48 pages2.me 8462-Mt-II Lab ManualMURALI KRISHNAN RNo ratings yet

- RTM Nagpur University Syllabus (Theory)Document5 pagesRTM Nagpur University Syllabus (Theory)Milind KshirsagarNo ratings yet

- RTM Nagpur University Mechanical Engineering Machining Processes Syllabus (Theory) Course code-BEME401TDocument27 pagesRTM Nagpur University Mechanical Engineering Machining Processes Syllabus (Theory) Course code-BEME401TxaloliNo ratings yet

- Manufacturing Processes GuideDocument22 pagesManufacturing Processes GuideMeer UmarNo ratings yet

- PDFDocument13 pagesPDFShlok PatelNo ratings yet

- BGS Institute of Technology B.G.Nagar-571448: Course Objectives & OutcomesDocument23 pagesBGS Institute of Technology B.G.Nagar-571448: Course Objectives & OutcomeshemarajuNo ratings yet

- MP405 Tool EngineeringDocument2 pagesMP405 Tool EngineeringAbhay SajeevNo ratings yet

- Course OverviewDocument14 pagesCourse OverviewVinayaka G PNo ratings yet

- 4th Sem Milling MachineDocument32 pages4th Sem Milling MachineKaran KantiNo ratings yet

- B.Tech 1st Year Mechanical Engineering SyllabusDocument12 pagesB.Tech 1st Year Mechanical Engineering SyllabusRaunak GuptaNo ratings yet

- Me Vtu DFM Syllabus CBCS SchemeDocument2 pagesMe Vtu DFM Syllabus CBCS SchemeNitheeshNo ratings yet

- PP Syllabus (R2019)Document3 pagesPP Syllabus (R2019)shaikh javedNo ratings yet

- Milling Section Workshop ManualDocument41 pagesMilling Section Workshop ManualIshan VermaNo ratings yet

- MC401 Machine Elements Course at National University of EngineeringDocument3 pagesMC401 Machine Elements Course at National University of EngineeringEduardo RNo ratings yet

- Machine Design NotesDocument349 pagesMachine Design NotesAkshay More100% (1)

- Tool Die MakerDocument32 pagesTool Die MakerUmesh KsNo ratings yet

- Dme Question Bank by Syam Prasad AmmineniDocument22 pagesDme Question Bank by Syam Prasad AmmineniDharmendra SharmaNo ratings yet

- L0 MEC205 Zero Lecture UpdatedDocument42 pagesL0 MEC205 Zero Lecture UpdatedJames PrakashNo ratings yet

- Mfg Tech 2 Course OverviewDocument2 pagesMfg Tech 2 Course Overviewraghav dhamaniNo ratings yet

- Manufaturing ProcessDocument2 pagesManufaturing ProcessSakshi VermaNo ratings yet

- JigsDocument5 pagesJigsTamilSelvanSoundararajNo ratings yet

- 6th Sem SyllabusDocument16 pages6th Sem SyllabusSOUMIK DASNo ratings yet

- Renewable Energy TechnologiesDocument8 pagesRenewable Energy Technologiesd.sarukNo ratings yet

- Manufacturing Technology-IIDocument70 pagesManufacturing Technology-IISaideep GhimireNo ratings yet

- Design For Manufacturing and Assembly Web ReferencesDocument3 pagesDesign For Manufacturing and Assembly Web ReferencesGopinath GangadhariNo ratings yet

- MEng3181-Manufacturing Engineering I-Course Outline - 103309Document2 pagesMEng3181-Manufacturing Engineering I-Course Outline - 103309Yonael MezmureNo ratings yet

- Student Mentoring FormDocument3 pagesStudent Mentoring FormbmdbmdbmdNo ratings yet

- REP - REM - Exam-CIE - Syllabus 2020-JULY - MATHEMATICS DEPT.-25-06-20Document3 pagesREP - REM - Exam-CIE - Syllabus 2020-JULY - MATHEMATICS DEPT.-25-06-20bmdbmdbmdNo ratings yet

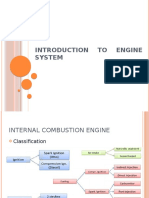

- Brief About Engine SystemDocument13 pagesBrief About Engine SystembmdbmdbmdNo ratings yet

- APDocument26 pagesAPbmdbmdbmdNo ratings yet

- Mentor File: Department of Automobile Engieering Indus Institute of Technology & Research Indus UniversityDocument9 pagesMentor File: Department of Automobile Engieering Indus Institute of Technology & Research Indus UniversitybmdbmdbmdNo ratings yet

- AesDocument29 pagesAesbmdbmdbmdNo ratings yet

- Common Questions of PTMDocument1 pageCommon Questions of PTMbmdbmdbmdNo ratings yet

- OLD - Exam Schedule - RemedialDocument2 pagesOLD - Exam Schedule - RemedialbmdbmdbmdNo ratings yet

- Course Plan Format For StudentsDocument7 pagesCourse Plan Format For StudentsbmdbmdbmdNo ratings yet

- Automobile Systems Design OptimizationDocument4 pagesAutomobile Systems Design OptimizationbmdbmdbmdNo ratings yet

- APDocument26 pagesAPbmdbmdbmdNo ratings yet

- Automobile Electrical Fundamentals: Prepared By: 110250102042Document42 pagesAutomobile Electrical Fundamentals: Prepared By: 110250102042bmdbmdbmdNo ratings yet

- Cim Test 1Document5 pagesCim Test 1bmdbmdbmdNo ratings yet

- Assignment 08-09-2019Document2 pagesAssignment 08-09-2019bmdbmdbmdNo ratings yet

- Subject Tribology SyllabusDocument3 pagesSubject Tribology SyllabusbmdbmdbmdNo ratings yet

- Automobile Electrical Fundamentals: Prepared By: 110250102042Document42 pagesAutomobile Electrical Fundamentals: Prepared By: 110250102042bmdbmdbmdNo ratings yet

- Subject Tribology SyllabusDocument3 pagesSubject Tribology SyllabusbmdbmdbmdNo ratings yet

- Automobile Electrical Systems CourseDocument9 pagesAutomobile Electrical Systems CoursebmdbmdbmdNo ratings yet

- Subject Production Techology SyllabusDocument3 pagesSubject Production Techology SyllabusbmdbmdbmdNo ratings yet

- BOS - New Exam SchmeDocument28 pagesBOS - New Exam SchmebmdbmdbmdNo ratings yet

- Indian Trade Union Act 1926Document4 pagesIndian Trade Union Act 1926bmdbmdbmdNo ratings yet

- SonuDocument10 pagesSonubmdbmdbmdNo ratings yet

- Fluid Power Learning ObjectivesDocument40 pagesFluid Power Learning Objectivesbmdbmdbmd100% (1)

- Intake and Exhaoust SystemDocument21 pagesIntake and Exhaoust SystembmdbmdbmdNo ratings yet

- Factors Affecting Plant Location & Layout, Production Planning, Quality ControlDocument7 pagesFactors Affecting Plant Location & Layout, Production Planning, Quality ControlbmdbmdbmdNo ratings yet

- SPV Question BankDocument2 pagesSPV Question BankbmdbmdbmdNo ratings yet

- VDDocument9 pagesVDbmdbmdbmdNo ratings yet

- Fluid Power Learning ObjectivesDocument40 pagesFluid Power Learning Objectivesbmdbmdbmd100% (1)

- Classification of Vehicles - LayoutDocument41 pagesClassification of Vehicles - LayoutbmdbmdbmdNo ratings yet

- 1D Advection-Diffusion MATLAB Code SolutionsDocument6 pages1D Advection-Diffusion MATLAB Code SolutionsAnonymous OrhjVLXO5sNo ratings yet

- Lyft Pec FootprintsDocument1 pageLyft Pec FootprintsZoran TripunovskiNo ratings yet

- Lucas TuningDocument12 pagesLucas TuningMichael RohrNo ratings yet

- PLC Simulation ReportDocument62 pagesPLC Simulation ReportAsraful Goni NirabNo ratings yet

- InterpolationDocument7 pagesInterpolationElianne GabbayNo ratings yet

- Liebherr Hs DimensionsDocument12 pagesLiebherr Hs DimensionsLiebherrNo ratings yet

- Performance Evaluation of Elevated Storage Reservoir With Hybrid StagingDocument11 pagesPerformance Evaluation of Elevated Storage Reservoir With Hybrid StagingVelumani sNo ratings yet

- Water Control Procedures and Chemical TreatmentsDocument16 pagesWater Control Procedures and Chemical TreatmentsDarko DuiloNo ratings yet

- Newton's Law of Cooling ExplainedDocument7 pagesNewton's Law of Cooling ExplainedReggie DuenasNo ratings yet

- Carta Psicometrica - CarrierDocument1 pageCarta Psicometrica - CarrierJonathan Andres0% (1)

- FMDocument4 pagesFMvishalNo ratings yet

- Lesson Plan For Demo Class RumanaDocument2 pagesLesson Plan For Demo Class RumanaRumana PathanNo ratings yet

- PTC Slides 1Document36 pagesPTC Slides 1Argo LuusNo ratings yet

- General MT Procedure - Rekind OffshoreDocument5 pagesGeneral MT Procedure - Rekind OffshoreNicko Arya Dharma100% (1)

- Civco Solutionsguide For Web - 2016 PDFDocument94 pagesCivco Solutionsguide For Web - 2016 PDFAri Surya MiharjaNo ratings yet

- How Do We Classify An Antipumping Relay?: What Will Happen If Antipumping Relay Circuit Is Not Present?Document6 pagesHow Do We Classify An Antipumping Relay?: What Will Happen If Antipumping Relay Circuit Is Not Present?joseNo ratings yet

- Multi-Traffic Scene Perception Based On Supervised LearningDocument10 pagesMulti-Traffic Scene Perception Based On Supervised LearningChandhu DasariNo ratings yet

- Brief History of Remote SensingDocument16 pagesBrief History of Remote SensingFeyrisNo ratings yet

- Performance Evaluation For Inerter-Based Dynamic Vibration AbsorbersDocument28 pagesPerformance Evaluation For Inerter-Based Dynamic Vibration Absorbersgakada prbNo ratings yet

- George Van TasselDocument2 pagesGeorge Van TasselManea SilviuNo ratings yet

- A Detailed Lesson Plan in Grade IX ScienceDocument4 pagesA Detailed Lesson Plan in Grade IX ScienceAdrian TastarNo ratings yet

- 01 11 20-Cta5Document36 pages01 11 20-Cta5Goury ShankarNo ratings yet

- Contrasts Between Finite and Infinite Dimensional Spaces and Between Normed and Inner Product SpacesDocument5 pagesContrasts Between Finite and Infinite Dimensional Spaces and Between Normed and Inner Product SpacesQuinton WestrichNo ratings yet

- Astm 1500 2012Document5 pagesAstm 1500 2012Hugo MtzaNo ratings yet

- Structural Design For ArchitectureDocument274 pagesStructural Design For Architecturedamocca100% (13)

- MARK SCHEME For The June 2005 Question PaperDocument6 pagesMARK SCHEME For The June 2005 Question PaperUmer AbbasNo ratings yet

- Research Paper in MicrowavesDocument10 pagesResearch Paper in MicrowavesManoling PanopioNo ratings yet

- Extraction in Chemical Technology PrincipleDocument24 pagesExtraction in Chemical Technology PrincipleFatima ZaharaNo ratings yet

- Electrostatic ForceDocument3 pagesElectrostatic ForceAlyssa Cole100% (1)

- Paper ChromatographyDocument27 pagesPaper ChromatographyjayNo ratings yet

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (542)

- Off-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemFrom EverandOff-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemNo ratings yet

- Ramblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowFrom EverandRamblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowNo ratings yet

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsFrom EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsRating: 4 out of 5 stars4/5 (1)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4 out of 5 stars4/5 (331)

- 8051 Microcontroller: An Applications Based IntroductionFrom Everand8051 Microcontroller: An Applications Based IntroductionRating: 5 out of 5 stars5/5 (6)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- C++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingFrom EverandC++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingRating: 4 out of 5 stars4/5 (1)

- Lithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsFrom EverandLithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsRating: 5 out of 5 stars5/5 (2)

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026From EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Rating: 5 out of 5 stars5/5 (1)

- Current Interruption Transients CalculationFrom EverandCurrent Interruption Transients CalculationRating: 4 out of 5 stars4/5 (1)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesFrom EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesRating: 5 out of 5 stars5/5 (1)

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)From EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Rating: 5 out of 5 stars5/5 (2)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 5 out of 5 stars5/5 (8)

- Beginner's Guide to Reading Schematics, Fourth EditionFrom EverandBeginner's Guide to Reading Schematics, Fourth EditionRating: 3.5 out of 5 stars3.5/5 (10)

- The Graphene Revolution: The Weird Science of the Ultra-thinFrom EverandThe Graphene Revolution: The Weird Science of the Ultra-thinRating: 4.5 out of 5 stars4.5/5 (4)