Professional Documents

Culture Documents

FHWA NHI 02 039 Micropile Foundations

Uploaded by

Emmanuel Lizama0 ratings0% found this document useful (0 votes)

20 views85 pagesFHWA NHI 02 039 Micropile Foundations

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFHWA NHI 02 039 Micropile Foundations

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views85 pagesFHWA NHI 02 039 Micropile Foundations

Uploaded by

Emmanuel LizamaFHWA NHI 02 039 Micropile Foundations

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 85

CHAPTER 5

DESIGN OF MICROPILES FOR STRUCTURE FOUNDATIONS

5.1 INTRODUCTION

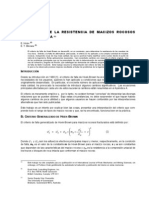

A typical micropile cross section used for structural foundation support is shown on Figure 5-

1. This micropile consists of an upper length reinforced with a permanent steel casing with a

center steel reinforcing bar and a lower grouted bond length reinforced with the center

reinforcing bar.

The geotechnical load capacity of a micropile is sensitive to the process used during

micropile construction, especially the techniques used for drilling the micropile shaft,

flushing the drill cuttings, and grouting the micropile, Therefore, verification of the shaft

resistance developed at the grout — ground interface assumed in design via micropile load

testing is essential to confirm structure safety; load testing should therefore be considered a

part of the design.

The basic philosophy of micropile design differs little from that for a drilled shaft. The

system must be capable of sustaining the anticipated loading conditions with the micropile

components operating at safe stress levels, and with resulting displacements being within

tolerable (or allowable) limits. For conventional drilled shafts, where the large cross

sectional area results in high structural capacity and stiffness, the design is normally

governed by the geotechnical load capacity, iie., side and base resistance. Because

micropiles have a relatively small cross sectional area, the design is usually controlled by

structural considerations. Moreover, the high grout to ground capacities that can be

developed using pressure grouting techniques will typically result in high geotechnical load

capacities.

The purpose of this chapter is to present a step-b;

step generalized method for the design of

micropiles used for structural foundations. The major steps and substeps in this design

method are outlined in Table 5-1. Detailed information for each of these steps is presented in

this chapter and a complete design is shown in Sample Problem No. 1

FHWA NHL-05.039 (Chapter 5 ~ Design for Structure Foundations

Micropile Design & Construction SI December 2005

Table 5-1. Design Steps for Micropiles used for Structural Foundations.

1 Identify project requirements and evaluate micropile feasibility

2, Review available information and perform subsurface exploration and laboratory testing

program

3. Develop all loading combinations

4, Preliminary design of micropiles

+ spacing

+ Iength

# cross section

5. Evaluate allowable structural capacity of cased length

6, Evaluate allowable structural capacity of uncased length

7. Compare design loads to structural capacity from Steps 5 and 6 and modify structural

section, if necessary

8. Evaluate geotechnical capacity of micropile

* evaluate suitable ground stratum for bond zone

+ select bond stress and calculate bond length required to resist design load

+ evaluate micropile group capacity for compression and tension (i.c., uplift)

9. Estimate micropile group settlement

10, Design micropile to footing connection at pile cap

11, Develop load testing program

12, Prepare Drawings and Specifications

Other Design Considerations

1. Corrosion Protection**

2. Plunge Length

3. End Bearing Micropiles

4. Downdrag

5. Lateral Loads on Single Vertical Micropiles

6. Lateral Loads on Micropile Groups

7. Buckling

8. Seismic

Corrosion protection is a critical component of all micropile designs,

FHWA NHL05-039 Chapter 5 — Design for Structure Foundations

Micropile Design & Construction 52 December 2005

MICROPILE

€ REINFORCING BAR

TOP OF FOOTING —— N\ ’

L

I

PILE CAP ANCHORAGE —

BOTTOM OF —

TOP OF DENSE

SOIL/ROCK

CASED UPPER

MICROPILE

LENGTH

‘CASING PLUNGE

LENGTH

a PRESSURE,

GROUTED

MICROPILE

BOND LENGTH

STEEL CASING

TOTAL MICROPILE LENGTH

CENTRALIZER

J GROUTED BOND ZONE

DIAMETER (DIA sona)

Figure 5-1, Detail of a Composite Reinforced Micropile.

5.2 STEP 1: EVALUATE PROJECT REQUIREMENTS AND MICROPILE

FEASIBILITY

It is essential to systematically consider various foundation types and to select the optimum

alternative based on the superstructure requirements, the subsurface conditions, and

foundation cost, Foundation types may include shallow foundations consisting of spread

FHWA NHL-05.039 (Chapter 5 ~ Design for Structure Foundations

Micropile Design & Construction 53 December 2005

You might also like

- 137 - Mesa Redonda de Ejecucion y Control PDFDocument8 pages137 - Mesa Redonda de Ejecucion y Control PDFEmmanuel LizamaNo ratings yet

- 123 Sistemas de Control Carlos Fernandez TadeoDocument14 pages123 Sistemas de Control Carlos Fernandez TadeoEmmanuel LizamaNo ratings yet

- Underwater Anchors for Budapest ProjectDocument33 pagesUnderwater Anchors for Budapest ProjectEmmanuel LizamaNo ratings yet

- Slope StabilityDocument8 pagesSlope Stabilitylxo08No ratings yet

- 25 Pilotes de Extraccion Carlos Oteo Mazo PDFDocument22 pages25 Pilotes de Extraccion Carlos Oteo Mazo PDFanon_321398445No ratings yet

- Decreto Estado de Catstrofe y Emergencia Santa BrbaraDocument2 pagesDecreto Estado de Catstrofe y Emergencia Santa BrbaraEmmanuel LizamaNo ratings yet

- 9 Pilotes Hincados Antonio SorianoDocument13 pages9 Pilotes Hincados Antonio SorianoEmmanuel LizamaNo ratings yet

- Control de calidad y mejoras del pilote STARSOL con barrena continuaDocument7 pagesControl de calidad y mejoras del pilote STARSOL con barrena continuaEmmanuel LizamaNo ratings yet

- 47 Mesa RedondaSobre DisenoDocument11 pages47 Mesa RedondaSobre DisenoEmmanuel LizamaNo ratings yet

- Detalle Cambio de Espesor-Model PDFDocument1 pageDetalle Cambio de Espesor-Model PDFEmmanuel LizamaNo ratings yet

- Errazuriz Ea PDFDocument145 pagesErrazuriz Ea PDFAlex E. MoralesNo ratings yet

- Ouvrages de Soutènement. Recommandations Pour L'inspection Détaillée, Le Suivi Et Le Diagnostic Des Parois ClouéesDocument69 pagesOuvrages de Soutènement. Recommandations Pour L'inspection Détaillée, Le Suivi Et Le Diagnostic Des Parois ClouéesessmustaphaNo ratings yet

- Gruas AC 350-6 Gruas Todo Terreno Terex PDFDocument70 pagesGruas AC 350-6 Gruas Todo Terreno Terex PDFconeclNo ratings yet

- Analysis of Blocky Rock Slopes With The Shear Strength Reduction MethodDocument6 pagesAnalysis of Blocky Rock Slopes With The Shear Strength Reduction MethodPawan KumarNo ratings yet

- 0549-G01-Vorspannung Durch DrehmomentDocument1 page0549-G01-Vorspannung Durch DrehmomentEmmanuel LizamaNo ratings yet

- 0549-G01-Vorspannung Durch DrehmomentDocument1 page0549-G01-Vorspannung Durch DrehmomentEmmanuel LizamaNo ratings yet

- AnálisisEstabilidadTaludesDocument46 pagesAnálisisEstabilidadTaludesFroilan BarrantesNo ratings yet

- 5 Mohr Coulomb - ModelDocument5 pages5 Mohr Coulomb - ModelEmmanuel LizamaNo ratings yet

- Estimacion D Ela Resistencia de Macizos Rocosos en La PracticaDocument28 pagesEstimacion D Ela Resistencia de Macizos Rocosos en La Practicacototo33100% (1)

- Tema MidasDocument29 pagesTema MidasEmmanuel LizamaNo ratings yet

- Efecto Circular SBDocument11 pagesEfecto Circular SBEmmanuel LizamaNo ratings yet

- Compactacion de SuelosDocument10 pagesCompactacion de SuelosAnonymous 4i3XpuNo ratings yet

- Clouterre 1991 - Additif 2002Document215 pagesClouterre 1991 - Additif 2002Emmanuel Lizama0% (1)

- DTU 13.2 MicropieuxDocument33 pagesDTU 13.2 MicropieuxEmmanuel LizamaNo ratings yet

- Coupe p27 1Document245 pagesCoupe p27 1Emmanuel LizamaNo ratings yet

- 18A12 AVB EXT 02 A2 Presentación2Document1 page18A12 AVB EXT 02 A2 Presentación2Emmanuel LizamaNo ratings yet

- Conjunto Habitacional Chinchorro OrienteDocument9 pagesConjunto Habitacional Chinchorro OrienteEmmanuel LizamaNo ratings yet

- Joint Label XYZ CoordinatesDocument47 pagesJoint Label XYZ CoordinatesEmmanuel LizamaNo ratings yet

- Indicaciones Generales de DibujoDocument2 pagesIndicaciones Generales de DibujoEmmanuel LizamaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)