Professional Documents

Culture Documents

RC SLAB DESIGN (BS8110:PART1:1997) : Project Job No

Uploaded by

engrrozayOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RC SLAB DESIGN (BS8110:PART1:1997) : Project Job No

Uploaded by

engrrozayCopyright:

Available Formats

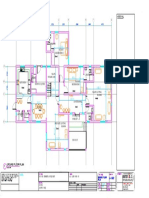

Project Job no.

MRS GLORY VICTOR EDDIE - MAIN BUILDING 0036

Calcs for Start page no./Revision

TYPICAL 1ST FLOOR SLAB PANEL 1

SIROC Engineeers Calcs by Calcs date Checked by Checked date Approved by Approved date

77 Ntiedo Udosen Street, Uyo, AKS NJE 5/31/2017 NJE 5/31/2017 EEM 5/31/2017

RC SLAB DESIGN (BS8110:PART1:1997)

T EDDS calculation version 1.0.04

TWO WAY SPANNING SLAB DEFINITION - RESTRAINED

; Overall depth of slab; h = 150 m m

Outer sagging steel

; Cover to outer tension reinforcem ent resisting sagging; c sag = 25 m m

; Trial bar diam eter; D tryx = 12 m m

Depth to outer tension steel (resisting sagging)

d x = h - c sag - D tryx/2 = 119 m m

Inner sagging steel

; Trial bar diam eter; D tryy = 12 m m

Depth to inner tension steel (resisting sagging)

d y = h - c sag - D tryx - D tryy/2 = 107 m m

Outer hogging steel

; Cover to outer tension reinforcem ent resisting hogging; c hog = 25 m m

; Trial bar diam eter; D tryxhog = 12 m m

Depth to outer tension steel (resisting hogging)

d xhog = h - c hog - D tryxhog /2 = 119 m m

Inner hogging steel

; Trial bar diam eter; D tryyhog = 12 m m

Depth to inner tension steel (resisting hogging)

d yhog = h - c hog - D tryxhog - D tryyhog /2 = 107 m m

Materials

; Characteristic strength of reinforcem ent; f y = 410 N/m m 2

; Characteristic strength of concrete; f cu = 25 N/m m 2

Project Job no.

MRS GLORY VICTOR EDDIE - MAIN BUILDING 0036

Calcs for Start page no./Revision

TYPICAL 1ST FLOOR SLAB PANEL 2

SIROC Engineeers Calcs by Calcs date Checked by Checked date Approved by Approved date

77 Ntiedo Udosen Street, Uyo, AKS NJE 5/31/2017 NJE 5/31/2017 EEM 5/31/2017

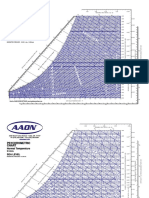

Asyhog Nom inal 1 m w idth Asxhog

h dx

h dxhog

Asy Nom inal 1 m w idth Asx

Shorter Span

Asyhog Asxhog

h dy

h dyhog

Asy (sagging m om ents) Asx (hogging m om ents)

Longer Span

Two-way spanning slab

(restrained)

RESTRAINED – 2 WAY SPANNING (CL 3.5.3)

M AXIM UM DESIGN M OM ENTS

; Length of shorter side of slab; l x = 3.825 m

; Length of longer side of slab; l y = 5.350 m

; Design ultim ate load per unit area; n s = 10.0 kN/m 2

; Edge condition shorter side (1); Edge1 = "C"

; Edge condition other shorter side (2); Edge2 = "D"

; Edge condition longer side (3); Edge3 = "C"

; Edge condition other longer side (4); Edge4 = "D"

Num ber of discontinuous edges

Nd = 2

Mom ent coefficients

sy = (24 + 2N d + 1.5N d 2) / 1000 =0.034

1 = if(Edge1 == "C", 4/3 sy,0) = 0.045

2 = if(Edge2 == "C", 4/3 sy,0) = 0.000

= 2/9 [3 - (18) l x/l y (( sy + 1) + ( sy + 2))] = 0.353

3x = if(Edge3 == "C", 4/3,0) = 1.333

4x = if(Edge4 == "C", 4/3,0) = 0.000

sx = / [(1+ 3x) 0.5 + (1+ 4x) 0.5] 2 = 0.055

Project Job no.

MRS GLORY VICTOR EDDIE - MAIN BUILDING 0036

Calcs for Start page no./Revision

TYPICAL 1ST FLOOR SLAB PANEL 3

SIROC Engineeers Calcs by Calcs date Checked by Checked date Approved by Approved date

77 Ntiedo Udosen Street, Uyo, AKS NJE 5/31/2017 NJE 5/31/2017 EEM 5/31/2017

3 = 3x sx = 0.074

4 = 4x sx = 0.000

Maxim um span m om ents per unit width - restrained slabs

m sx = sx n s l x2 = 8.1 kNm /m

m sy = sy n s l x2 =5.0 kNm /m

Maxim um support m om ents per unit width - restrained slabs

m sxhog = m ax( 3 , 4 ) n s l x2 = 10.8 kNm /m

m syhog = m ax( 1 , 2 ) n s l x2 =6.6 kNm /m

CONCRETE SLAB DESIGN – SAGGING – OUTER LAYER OF STEEL (CL 3.5.4)

; Design sagging m om ent (per m width of slab); m sx = 8.1 kNm /m

; Mom ent Redistribution Factor; bx = 1.0

Area of reinforcem ent required

;; K x = abs(m sx) / ( d x2 f cu ) = 0.023

K'x = m in (0.156 , (0.402 ( bx - 0.4)) - (0.18 ( bx - 0.4) 2 )) = 0.156

Outer compression steel not required to resist sagging

Slab requiring outer tension steel only - bars (sagging)

;; zx = m in (( 0.95 d x),(d x(0.5+0.25-K x/0.9)))) = 113 m m

Neutral axis depth; xx = (d x - zx) / 0.45 = 13 m m

Area of tension steel required

;;; A sx_req = abs(m sx) / (1/ ms f y zx) = 200 m m 2/m

Tension steel

;;Provide 12 dia bars @ 250 centres; outer tension steel resisting sagging

A sx_prov = A sx = 452 m m 2/m

Area of outer tension steel provided sufficient to resist sagging

Concrete Slab Design - Sagging - Inner layer of steel (cl. 3.5.4)

; Design sagging m om ent (per m width of slab); m sy = 5.0 kNm /m

; Mom ent Redistribution Factor; by = 1.0

Area of reinforcem ent required

;; K y = abs(m sy ) / ( d y2 f cu ) = 0.017

K'y = m in (0.156 , (0.402 ( by - 0.4)) - (0.18 ( by - 0.4) 2 )) = 0.156

Project Job no.

MRS GLORY VICTOR EDDIE - MAIN BUILDING 0036

Calcs for Start page no./Revision

TYPICAL 1ST FLOOR SLAB PANEL 4

SIROC Engineeers Calcs by Calcs date Checked by Checked date Approved by Approved date

77 Ntiedo Udosen Street, Uyo, AKS NJE 5/31/2017 NJE 5/31/2017 EEM 5/31/2017

Inner compression steel

not required to resist

sagging

Slab requiring inner tension steel only - bars (sagging)

;; zy = m in (( 0.95 d y),(d y(0.5+0.25-K y/0.9)))) = 102 m m

Neutral axis depth; xy = (d y - zy) / 0.45 = 12 m m

Area of tension steel required

;;; A sy_req = abs(m sy) / (1/ ms f y zy ) = 137 m m 2/m

Tension steel

;;Provide 12 dia bars @ 250 centres; inner tension steel resisting sagging

A sy_prov = A sy = 452 m m 2/m

Area of inner tension steel provided sufficient to resist sagging

CONCRETE SLAB DESIGN – HOGGING – OUTER LAYER OF STEEL (CL 3.5.4)

; Design hogging m om ent (per m width of slab); m sxhog = 10.8 kNm /m

; Mom ent Redistribution Factor; bx = 1.0

Area of reinforcem ent required

;; K xhog = abs(m sxhog ) / ( d xhog 2 f cu ) = 0.030

K'x = m in (0.156 , (0.402 ( bx - 0.4)) - (0.18 ( bx - 0.4) 2 )) = 0.156

Outer compression steel not required to resist hogging

Slab requiring outer tension steel only - bars (hogging)

;; zxhog = m in (( 0.95 d xhog ),(d xhog (0.5+0.25-K xhog /0.9)))) = 113 m m

Neutral axis depth; xxhog = (d xhog - zxhog ) / 0.45 = 13 m m

Area of tension steel required

;;; A sxhog_req = abs(m sxhog ) / (1/ ms f y zxhog ) = 267 m m 2/m

Tension steel

;;Provide 12 dia bars @ 250 centres; outer tension steel resisting hogging

A sxhog_prov = A sxhog = 452 m m 2/m

Area of outer tension steel provided sufficient to resist hogging

Concrete Slab Design - hogging - Inner layer of steel (cl. 3.5.4)

; Design hogging m om ent (per m width of slab); m syhog = 6.6 kNm /m

; Mom ent Redistribution Factor; by = 1.0

Area of reinforcem ent required

;; K yhog = abs(m syhog ) / ( d yhog 2 f cu ) = 0.023

K'y = m in (0.156 , (0.402 ( by - 0.4)) - (0.18 ( by - 0.4) 2 )) = 0.156

Project Job no.

MRS GLORY VICTOR EDDIE - MAIN BUILDING 0036

Calcs for Start page no./Revision

TYPICAL 1ST FLOOR SLAB PANEL 5

SIROC Engineeers Calcs by Calcs date Checked by Checked date Approved by Approved date

77 Ntiedo Udosen Street, Uyo, AKS NJE 5/31/2017 NJE 5/31/2017 EEM 5/31/2017

Inner compression steel

not required to resist

hogging

Slab requiring inner tension steel only - bars (hogging)

;; zyhog = m in (( 0.95 d yhog ),(d yhog (0.5+0.25-K yhog /0.9)))) = 102 m m

Neutral axis depth; xyhog = (d yhog - zyhog ) / 0.45 = 12 m m

Area of tension steel required

;;; A syhog_req = abs(m syhog ) / (1/ ms f y zyhog ) = 183 m m 2/m

Tension steel

;;Provide 6 dia bars @ 250 centres; inner tension steel resisting hogging

A syhog_prov = A syhog = 113 m m 2/m

Insufficient area of inner tension steel provided to resist hogging

Check min and max areas of steel resisting sagging

;Total area of concrete; A c = h = 150000 m m 2/m

; Minim um % reinforcem ent; k = 0.13 %

A st_min = k A c = 195 m m 2/m

A st_max = 4 % A c = 6000 m m 2/m

Steel defined:

; Outer steel resisting sagging; A sx_prov = 452 m m 2/m

Area of outer steel provided (sagging) OK

; Inner steel resisting sagging; A sy_prov = 452 m m /m 2

Area of inner steel provided (sagging) OK

Check min and max areas of steel resisting hogging

;Total area of concrete; A c = h = 150000 m m 2/m

; Minim um % reinforcem ent; k = 0.13 %

A st_min = k A c = 195 m m 2/m

A st_max = 4 % A c = 6000 m m 2/m

Steel defined:

; Outer steel resisting hogging; A sxhog_prov = 452 m m 2/m

Area of outer steel provided (hogging) OK

; Inner steel resisting hogging ; A syhog_prov = 113 m m 2/m

Less than min area of inner steel (hogging) FAIL

CONCRETE SLAB DEFLECTION CHECK (CL 3.5.7)

; Slab span length; l x = 3.825 m

Project Job no.

MRS GLORY VICTOR EDDIE - MAIN BUILDING 0036

Calcs for Start page no./Revision

TYPICAL 1ST FLOOR SLAB PANEL 6

SIROC Engineeers Calcs by Calcs date Checked by Checked date Approved by Approved date

77 Ntiedo Udosen Street, Uyo, AKS NJE 5/31/2017 NJE 5/31/2017 EEM 5/31/2017

; Design ultim ate m om ent in shorter span per m width; m sx = 8 kNm /m

; Depth to outer tension steel; d x = 119 m m

Tension steel

; Area of outer tension reinforcem ent provided; A sx_prov = 452 m m 2/m

; Area of tension reinforcem ent required; A sx_req = 200 m m 2/m

; Mom ent Redistribution Factor; bx = 1.00

M odification Factors

;Basic span / effective depth ratio (Table 3.9); ratio span_depth = 23

The m odification factor for spans in excess of 10m (ref. cl 3.4.6.4) has not been included.

;f s = 2 f y A sx_req / (3 A sx_prov bx ) = 121.1 N/m m 2

factor tens = m in ( 2 , 0.55 + ( 477 N/m m 2 - f s ) / ( 120 ( 0.9 N/m m 2 + m sx / d x2))) = 2.000

Calculate M axim um Span

This is a sim plified approach and further attention should be given where special circum stances exist. Refer to clauses

3.4.6.4 and 3.4.6.7.

Maxim um span; l max = ratio span_depth factor tens d x = 5.47 m

Check the actual beam span

Actual span/depth ratio; l x / d x = 32.14

Span depth lim it; ratio span_depth factor tens = 46.00

Span/Depth ratio check satisfied

;

You might also like

- Suspended basement slab design RC slab calculationDocument8 pagesSuspended basement slab design RC slab calculationShabana ferozNo ratings yet

- Other 1314382 PDFDocument8 pagesOther 1314382 PDFanon_702462456No ratings yet

- RC SLAB DESIGN (BS8110:PART1:1997) : Project Job RefDocument8 pagesRC SLAB DESIGN (BS8110:PART1:1997) : Project Job RefOscarKonzultNo ratings yet

- ADMIN Building Calculation SheetDocument95 pagesADMIN Building Calculation Sheetorode franklynNo ratings yet

- REINFORCED CONCRETE SLABDocument6 pagesREINFORCED CONCRETE SLABAmadi HenryNo ratings yet

- RC SLAB DESIGN (BS8110:PART1:1997) : Project Job RefDocument9 pagesRC SLAB DESIGN (BS8110:PART1:1997) : Project Job RefAkela RichardNo ratings yet

- 15 SlabDocument3 pages15 SlabNiranjan ShresthaNo ratings yet

- RC SLAB DESIGN (BS8110:PART1:1997) : Project Job NoDocument6 pagesRC SLAB DESIGN (BS8110:PART1:1997) : Project Job NoextoutsNo ratings yet

- Braced RC Circular Column Design - Sample Calculation (As 3600)Document5 pagesBraced RC Circular Column Design - Sample Calculation (As 3600)Tiam MarapeNo ratings yet

- Example Beam Column Design IS800 PDFDocument3 pagesExample Beam Column Design IS800 PDFvrajan1988No ratings yet

- One Way Spanning Slab Design CalculationDocument4 pagesOne Way Spanning Slab Design Calculationikanyu79No ratings yet

- Punching Shear Example2Document2 pagesPunching Shear Example2Adrian NatoNo ratings yet

- RF SlabDocument8 pagesRF Slabcheligp1981No ratings yet

- 1 Way Continous SlabDocument5 pages1 Way Continous SlabZayyan RomjonNo ratings yet

- GF SlabDocument8 pagesGF Slabcheligp1981No ratings yet

- Project Job No.: CHS 139.7x4.0 (Tata Steel Celsius)Document4 pagesProject Job No.: CHS 139.7x4.0 (Tata Steel Celsius)Ruemu Godwin InikoriNo ratings yet

- RC Slab Design (BS8110)Document5 pagesRC Slab Design (BS8110)Mike0% (1)

- Punching Shear ExampleDocument3 pagesPunching Shear Exampleikanyu7950% (2)

- Stub ColumnDocument4 pagesStub ColumnCHRISTOPHER EKIRAPANo ratings yet

- PASS - Support Reinforcement Is OK: Project Job NoDocument1 pagePASS - Support Reinforcement Is OK: Project Job Nokevinyulive.com.sgNo ratings yet

- Unbraced RC Circular Column Design - Sample Calculation (AS3600)Document4 pagesUnbraced RC Circular Column Design - Sample Calculation (AS3600)Tiam MarapeNo ratings yet

- Engineering Calculation Sheet Consulting EngineersDocument11 pagesEngineering Calculation Sheet Consulting EngineersJONAS NGNo ratings yet

- RC Wall DesignDocument7 pagesRC Wall DesignImaduddin KhajaNo ratings yet

- Unbraced WallDocument7 pagesUnbraced WallakanagesNo ratings yet

- Chequered Plate 1250mm-cDocument28 pagesChequered Plate 1250mm-casvenk309100% (3)

- RC Beam Design (BS8110)Document2 pagesRC Beam Design (BS8110)Parthiban ArivazhaganNo ratings yet

- Timber Fitch Beam PDFDocument4 pagesTimber Fitch Beam PDFYHK3001No ratings yet

- LANDINGDocument2 pagesLANDINGGaneshalingam Ramprasanna2No ratings yet

- Crack Width Check BS5400 4Document4 pagesCrack Width Check BS5400 4fontec.info2023No ratings yet

- Active Pressure Calculation For The Shoring Plate: New Bridge Centre, BLK 336, Smith Street #06-305, SINGAPORE 050336Document13 pagesActive Pressure Calculation For The Shoring Plate: New Bridge Centre, BLK 336, Smith Street #06-305, SINGAPORE 050336ThaungMyintNo ratings yet

- Design Basis: Mercedes Flagship Building Commercial Complex at Square 1Document2 pagesDesign Basis: Mercedes Flagship Building Commercial Complex at Square 1Zohaib Sattar NagraNo ratings yet

- Comments Marked in Grade Slab Design For 20T/m2 Also Applicable For This Document. UpdateDocument2 pagesComments Marked in Grade Slab Design For 20T/m2 Also Applicable For This Document. UpdateElancheliyan0% (2)

- New Plan House Epsom Project Job No. Calcs For Start Page No./revision Calcs by Calcs Date Checked by Checked Date Approved by Approved DateDocument4 pagesNew Plan House Epsom Project Job No. Calcs For Start Page No./revision Calcs by Calcs Date Checked by Checked Date Approved by Approved DateGirinathNo ratings yet

- Deck Plate Check at Upper Deck: Proj No Calc No X Deck Plating CheckDocument2 pagesDeck Plate Check at Upper Deck: Proj No Calc No X Deck Plating Checkhk089No ratings yet

- Calcs for steel beam designDocument3 pagesCalcs for steel beam designYHK3001No ratings yet

- Pile Cap 6P-PC5Document6 pagesPile Cap 6P-PC5balaji gmscNo ratings yet

- Design Concrete SheetDocument14 pagesDesign Concrete SheetIan Roderick JafferyNo ratings yet

- 07 Steel Lagging PDFDocument1 page07 Steel Lagging PDFThaungMyintNo ratings yet

- New Bridge Centre, BLK 336, Smith Street # 0 6 - 3 0 5, S I N G A P O R E 0 5 0 3 3 6Document1 pageNew Bridge Centre, BLK 336, Smith Street # 0 6 - 3 0 5, S I N G A P O R E 0 5 0 3 3 6ThaungMyintNo ratings yet

- Crack Width Calculation To Bs8110:Part 2:1985: Project Job RefDocument1 pageCrack Width Calculation To Bs8110:Part 2:1985: Project Job RefJonn MashNo ratings yet

- Calculation For The Base Plate at The PoleDocument3 pagesCalculation For The Base Plate at The PoleJanaka KarunarathnaNo ratings yet

- Steel Column Base PlateDocument17 pagesSteel Column Base PlateVAN HUNG TRANNo ratings yet

- Crack Width CalculationDocument3 pagesCrack Width Calculationasvenk309No ratings yet

- Calculation Sheet For Slug CatcherDocument12 pagesCalculation Sheet For Slug CatcherchumaNo ratings yet

- PT Design StatementDocument4 pagesPT Design StatementoscarNo ratings yet

- Rafters British Standards 06-02-2023 0931Document4 pagesRafters British Standards 06-02-2023 0931João SidônioNo ratings yet

- BASEPLATE DESIGNDocument38 pagesBASEPLATE DESIGNameyyammai100% (1)

- Crack Width Check BS5400 4Document6 pagesCrack Width Check BS5400 4amirNo ratings yet

- Crack Width Check BS5400 4 4Document6 pagesCrack Width Check BS5400 4 4Marvin MalicdemNo ratings yet

- Steel Column Slab Support MukonoDocument3 pagesSteel Column Slab Support Mukonosoly2k12No ratings yet

- Wall Chart For Hardness TestingDocument1 pageWall Chart For Hardness TestingWeld Bro SandeepNo ratings yet

- Loads:: Housing Layout-Sd-EastDocument2 pagesLoads:: Housing Layout-Sd-Eastpvrk_78No ratings yet

- Steel Member Design (AS4100) SHSDocument3 pagesSteel Member Design (AS4100) SHSpssr2008No ratings yet

- Newbridgecentre, Blk336, Smithstreet # 0 6 - 3 0 5, S I N G A P O R E 0 5 0 3 3 6Document1 pageNewbridgecentre, Blk336, Smithstreet # 0 6 - 3 0 5, S I N G A P O R E 0 5 0 3 3 6ThaungMyintNo ratings yet

- Chequered DesignDocument2 pagesChequered DesignSaravana N100% (1)

- CRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFDocument28 pagesCRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFHazim AffendiNo ratings yet

- Appendix 02 Elastomeric Bearing Calculation ReportDocument8 pagesAppendix 02 Elastomeric Bearing Calculation ReportYasela100% (1)

- RTWDocument1 pageRTWengrrozayNo ratings yet

- Fo MR Joseph Akpan (Recovery)Document8 pagesFo MR Joseph Akpan (Recovery)engrrozayNo ratings yet

- Nigeria bottling plant structural plansDocument21 pagesNigeria bottling plant structural plansengrrozayNo ratings yet

- RTWDocument1 pageRTWengrrozayNo ratings yet

- ©2008 Infinite Skills, Inc.: Terms & Conditions of UseDocument3 pages©2008 Infinite Skills, Inc.: Terms & Conditions of Usekaran976No ratings yet

- L03 Sect. 1: Drawing Title Job Title NotesDocument1 pageL03 Sect. 1: Drawing Title Job Title NotesengrrozayNo ratings yet

- Elevated Intz Tank 279Document23 pagesElevated Intz Tank 279Navasivayam Sankar100% (2)

- Rfem Enu PDFDocument586 pagesRfem Enu PDFengrrozayNo ratings yet

- Two Pile GroupDocument12 pagesTwo Pile GroupJammy KingNo ratings yet

- CPT PDFDocument3 pagesCPT PDFengrrozayNo ratings yet

- SP 152Document260 pagesSP 152deviationz100% (1)

- CADS RC3D - Release Notes PDFDocument6 pagesCADS RC3D - Release Notes PDFengrrozayNo ratings yet

- T. A. E. Engineering: Cone Penetrometer Test (10 Tons)Document3 pagesT. A. E. Engineering: Cone Penetrometer Test (10 Tons)engrrozayNo ratings yet

- T. A. E. Engineering: Soft Dark Peaty Organic Decomposed MaterialsDocument2 pagesT. A. E. Engineering: Soft Dark Peaty Organic Decomposed MaterialsengrrozayNo ratings yet

- Abatete ROBUSTB2Document1 pageAbatete ROBUSTB2engrrozayNo ratings yet

- SP 152Document260 pagesSP 152deviationz100% (1)

- Lateral Deflection of MultiDocument10 pagesLateral Deflection of MultiengrrozayNo ratings yet

- RTWDocument1 pageRTWengrrozayNo ratings yet

- RTWDocument1 pageRTWengrrozayNo ratings yet

- UPS BEAM DESIGN AT NBC IKEJA PLANTDocument8 pagesUPS BEAM DESIGN AT NBC IKEJA PLANTengrrozayNo ratings yet

- RTWDocument1 pageRTWengrrozayNo ratings yet

- RTWDocument1 pageRTWengrrozayNo ratings yet

- ASTM C1403 - pdqv6897Document3 pagesASTM C1403 - pdqv6897Nayth Andres GalazNo ratings yet

- Tut 1Document5 pagesTut 1foranangelqwertyNo ratings yet

- Acson Hydrotech Chilled Water System Solution Application ManualDocument62 pagesAcson Hydrotech Chilled Water System Solution Application ManualDota NgNo ratings yet

- CMV Fracture Toughness ArticleDocument10 pagesCMV Fracture Toughness ArticleFlo RenceNo ratings yet

- 2 - Part RTVDocument2 pages2 - Part RTVCharles OlsenNo ratings yet

- Below Is A List of Power Stations in Iraq: RenewableDocument17 pagesBelow Is A List of Power Stations in Iraq: Renewableمصطفى العباديNo ratings yet

- Aaon ChartDocument2 pagesAaon ChartpabloNo ratings yet

- Dual StructureDocument21 pagesDual StructureSauhardra OjhaNo ratings yet

- Pro Rod BrochureDocument9 pagesPro Rod BrochureMIRCEA1305No ratings yet

- A New Standard For Repair and Maintenance of Installed Asbestos-Cement MaterialsDocument6 pagesA New Standard For Repair and Maintenance of Installed Asbestos-Cement MaterialsGustavoNo ratings yet

- Wear Resistance of Material Used in Slurry TransportDocument7 pagesWear Resistance of Material Used in Slurry TransportwoodoobooNo ratings yet

- DRAIN BBS (1mX1m)Document1 pageDRAIN BBS (1mX1m)vishal bhardwajNo ratings yet

- Boiler Water Chemistry: 1. Formation of Scales & Deposits On The Boiler TubesDocument4 pagesBoiler Water Chemistry: 1. Formation of Scales & Deposits On The Boiler TubesKumaraswamyNo ratings yet

- As 2601 en E Series Valves and ManifoldsDocument52 pagesAs 2601 en E Series Valves and ManifoldsdbmingoNo ratings yet

- ACSR/MZ 400/51 specificationDocument3 pagesACSR/MZ 400/51 specificationDuy TiếnNo ratings yet

- Ukanol Es 2018Document8 pagesUkanol Es 2018Muhammad Aasim HassanNo ratings yet

- Circuits Education Presentation in Blue Yellow Flat Cartoon StyleDocument14 pagesCircuits Education Presentation in Blue Yellow Flat Cartoon StyleMa Angelica BañariaNo ratings yet

- FXFA-A - 4PEN599624-1B - Installer and User Reference Guide - EnglishDocument84 pagesFXFA-A - 4PEN599624-1B - Installer and User Reference Guide - EnglishHewa AkreyNo ratings yet

- Hy200v3 Icc-Es Esr-4868Document46 pagesHy200v3 Icc-Es Esr-4868Nazmul HassanNo ratings yet

- Surflex: N - M F HDocument2 pagesSurflex: N - M F HJohn Shane100% (1)

- Leaflet Packo Open TanksDocument4 pagesLeaflet Packo Open TanksRicky Okwir Okello100% (1)

- Quality Assurence Büscher 2006Document71 pagesQuality Assurence Büscher 2006mustafNo ratings yet

- Interstitial Free Steels - IspatGuruDocument6 pagesInterstitial Free Steels - IspatGuruSilverio AcuñaNo ratings yet

- Kennametal Technical Data MetricDocument35 pagesKennametal Technical Data MetricVimaher Vila-realNo ratings yet

- Heat Effects on Dynamic Response of Steel ChimneyDocument8 pagesHeat Effects on Dynamic Response of Steel Chimneykhalid707No ratings yet

- Carbon BlackDocument7 pagesCarbon BlackJahidul OnirNo ratings yet

- Tec066 6700 PDFDocument2 pagesTec066 6700 PDFExclusivo VIPNo ratings yet

- DE GUZMAN Module 2 Activity No. 2Document5 pagesDE GUZMAN Module 2 Activity No. 2John Mark AlvesNo ratings yet

- Various Types of Shear Connectors in Composite StructuresDocument15 pagesVarious Types of Shear Connectors in Composite StructuresYasser OryassoNo ratings yet

- Deformation R01Document1 pageDeformation R01famfu94No ratings yet