Professional Documents

Culture Documents

Design of Internal Model Controller For A Heat Exchanger System

Uploaded by

Anonymous mIRrZKXOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Internal Model Controller For A Heat Exchanger System

Uploaded by

Anonymous mIRrZKXCopyright:

Available Formats

DESIGN OF INTERNAL MODEL CONTROLLER FOR A HEAT EXCHANGER SYSTEM

K.Rajalakshmi$1, Ms.V.Mangaiyarkarasi#2

$

PG student, Department of C&I, Valliammai Engineering College, Kancheepuram District, Tamilnadu, India

3

ralaks123@gmail.com

#

Department of C&I, Valliammai Engineering College, Kancheepuram District, Tamilnadu, India

Abstract- Heat exchanger is a device that exchange the controller exhibits high overshoots which is undesirable. To

heat between two fluids of different temperatures that minimize the overshoot Fuzzy logic controller and internal

are separated by a solid wall. The temperature gradient model based controller is implemented. Fuzzy logic

or the differences in temperature facilitate this transfer controller reduces the overshoot but it leads to the steady

of heat. In General, temperature control system has the state error in the process. The internal model based

characteristics of non-linearity, large inertia and time controller design has gained widespread acceptance

variability. It is difficult to overcome the effects of these because it has only a single tuning parameter namely the

factors and get the satisfactory results by using the closed loop time constant λ. The internal model controller

normal PID controller. Therefore, a controllers are reduces the overshoot and settling time. In this paper three

implemented in this paper based on comparative types of controllers are designed to achieve the control

analysis to control the output temperature of the heat objective and a comparative study between the controllers

exchanger system. The PID, FUZZY and IMC are the are evaluated.

controllers used for the comparison and based on their

overshoot and settling time the conclusions are given II. SHELL AND TUBE HEAT EXCHANGER SYSTEM

using simulation results. In addition to that FOPID

controller will be implemented in this paper later for A typical interacting chemical process for heating

better effective temperature control over other consists of a chemical reactor and a shell and tube

controllers. heat exchanger system. The super-heated steam comes from

Keywords-Internal model based controller, PID controller, the boiler and flows through the tubes. Whereas, the process

Fuzzy controller and Shell and tube heat exchanger fluid flows through the shells of the shell and tube heat

system. exchanger system. Different assumptions have been

considered in this paper. The first assumption is that the

I. INTRODUCTION inflow and the outflow rate of fluid are same. The second

assumption is the heat storage capacity of the

In practice, all chemical processes involve insulating wall is negligible. A thermocouple is used as

production or absorption of energy in the form of heat. the sensing element which is implemented in the

Heat exchanger is commonly used in chemical processes feedback path of the control architecture. The temperature

to transfer heat from a hot fluid through a solid wall of the outgoing fluid is measured by the thermocouple

to a cooler fluid. There are different types of heat and the output of the thermocouple is sent to the

exchanger used in the industry but most of the industry transmitter unit, which eventually converts the

use shell and tube type heat exchanger system. thermocouple output to a standardized signal in the

range of 4-20 mA. This output of the transmitter unit

Shell and tube heat exchangers are probably the is given to the controller unit. The controller

most common type of heat exchangers applicable for a implements the control algorithm, compares the output

wide range of operating temperatures and pressures. They with the set point and then gives necessary command to

have larger ratios of heat transfer surface to volume than the final control element via the actuator unit. The

double pipe heat exchangers and they are easy to actuator unit is a current to pressure converter and the final

manufacture in a large variety of sizes and configurations. A control unit is an air to open valve. The actuator unit takes

shell and tube heat exchanger is an extension of the double- the controller output in the range of 4-20 mA and

pipe configuration. In shell and tube heat exchanger one converts it in to a standardized pressure signal in the

fluid flows through the tubes and a second fluid flows range of 3-15 psig. The valve actuates according to the

within the space between the tubes and the shell [8]. controller decisions.

This paper reports a work that considers a shell and

tube heat exchanger. The outlet temperature of the shell and

tube heat exchanger system has to be kept at a desired set

point according to the process requirement. Firstly a

classical PI controller is implemented in a feedback

control loop so as to achieve the control objectives. PI

Gain of current to pressure converter = 0.75

Transfer function of disturbance variables

Flow =1/30s+1

Temperature =3/30s+1

Transfer function of thermocouple = 0.16/10s+1

To control the exit temperature of the heat

exchanger system a classical feedback controller is used.

The PI control algorithm remains the most popular

approach for industrial process control despite continual

advances in control theory. This is not only due to the

Fig.1 Shell and tube heat exchanger system control scheme simple structure which is conceptually easy to

There can be two types of disturbances in this understand and, which makes manual tuning possible.

process, one is the flow variation of input fluid and the

second is the temperature variation of input fluid. But in

practice the flow variation of input fluid is a more

prominent disturbance than the temperature variation in

input fluid.

III. MATHEMETICAL MODELING

In this section the heat exchanger system, actuator,

valve, sensor are mathematically modelled using the

available experimental data. The experimental process

data’s are summarized below [3].

Exchanger response to the steam flow gain

50°C/ (kg/sec)

Time constants =30 sec

Fig.2 Feedback control of shell and tube heat exchanger

Exchanger response to variation of process fluid flow gain system

=1 °C/ (kg/sec)

Exchanger response to variation of process temperature gain

= 3°C/°C The PI tuning rule used here is Zeigler – Nicholas

tuning rule because it provides simple tuning formulae to

Control valve capacity for steam = 1.6 kg/sec determine the P, PI and PID controller parameters [4].

According to Z - N tuning criteria the obtained Ku & Pu are

Time constant of control valve = 3 sec 16.57 and 32.5 respectively. For the PI controller in the

heat exchanger, the values of tuning parameters obtained

The range of temperature sensor = 50°C to 150°C

are Kp = 7.53, Ti = 27.08. Usually, initial design values of

Time constant of temperature sensor = 10 sec PI controller obtained by all means needs to be

adjusted repeatedly through computer simulations until

the closed loop system performs or compromises as

desired.

From the experimental data, transfer functions and

the gains are obtained as below.

IV. FUZZY LOGIC CONTROLLER

-s

Transfer function of process = 50e /30s+1 The design of fuzzy logic controller consists of

several steps. First, the variables for the fuzzy control

Gain of valve = 0.13

system are determined. The universe of Discourse for

Transfer function of valve = 0.13/3s+1 all the variables involved are then set. Here, the

fuzzy controller is designed with two input variables

and one output variable. The input variables are error

and change in error that is difference between the set

point temperature and the actual temperature (error-'e')

and the rate of change of error (de) and output is

controller output (co).

Fig. 5 Membership function for change in error input

Fig.3 structure of fuzzy logic controller

The above figure shows the fuzzy logic

controller to control the temperature in the outlet of the

shell and tube heat exchanger system with error and

change in error as input [2]. once a step change of flow

is given at shell side it directly affects the heat transfer Fig. 6 Membership function for output signal

rate between the two fluids in shell and tube side ,

lesser the flow greater is the heat transfer between

fluids . Both the input variables and the output variable

The rule base developed for this system is

is designed using five membership functions shown in

based on MAXMIN inference[9]. That is MIN is used

fig 4, 5 and 6 for the given process. The linguistic terms

for the AND conjunction and MAX is used for the OR

associated with variables are very low (VL), low (L),

conjunction. For this system MIN conjunction is used.

medium (M), high (H), very high (VH).

TABLE I

Rule base Matrix

Fig .4 Membership function for error input

V. INTERNAL MODEL CONTROLLER

Internal model controller provides a transparent

framework for control system design and tuning. The

main feature of internal model controller is that the

process model is in parallel with the actual process.

The transfer function of the process is shown below The simulations for the different control mechanism

discussed above were carried out in Simulink and the

simulation results have been obtained.

Fig .7: Internal model controller Fig. 8: Simulink model of feedback PI controller

The process model Gp (s) is factored in to two

parts, that is invertible part Gp-(s) and non-invertible

part Gp+(s), The non-invertible part consists of RHP

zeros and time delays. This factorization is performed so

as to make the resulting internal model controller stable.

Several methods of tuning of internal model controller and

efficient calculation of filter parameter have been proposed

in literature [1, 5, 6, and 7].

Fig.9 Response of PI controller

In practice λ is taken higher than the time constant

value. So, the values of λ is obtained as 11.4. Substituting

the value as 11.4 in the above equation we get the transfer

function of internal model controller denoted by Q(s).

Fig .10: Simulink model of fuzzy logic controller

VI. SIMULATION AND TESTING

VII. RESULTS AND DISCUSSION

To evaluate the performance of the different

controllers this paper has considered two vital

parameters of the step response of the system. The first

parameter is the maximum overshoot and the second

parameter is the settling time. Compared to PI and Fuzzy

logic controller internal model based controller performs

well and give the effective control.

VIII. CONCLUSION

This paper takes a case study of shell and tube

heat exchanger system and evaluates different methods

to control the outlet fluid temperature. Three different

Fig.11 Response of fuzzy controller kind of controllers are designed to control the outlet

temperature of fluid and the performances of these

controllers are evaluated by one of the methods for

performance evaluation is the time domain analysis of

overshoot and settling time. This paper takes the process

model to be the same as the process, which is

practically impossible to achieve. So as a further work we

can implement FOPID controller for effective temperature

control of the heat exchanger system.

REFERENCES

[1] Ian G Hom et.al, "Improved Filter Design in Internal Model

Control," Ind. Eng. Chem. Res., vol. 35, no.10, pp. 3437-3441, Oct 1996.

[2] Mridul Pandey, K. Ramkumar & V. Alagesan “Design of Fuzzy Logic

Controller for a Cross Flow Shell and Tube Heat-Exchanger,” IEEE, Mar

Fig .12: Simulink model of internal model controller 2012.

[3] Subhransu Padhee, Yuvraj Bhushan Khare, Yaduvir Singh “Internal

Model Based PID Control of Shell and Tube Heat Exchanger

System,”IEEE, JAN 2011.

[4] Kiam Heong Ang, Gregory Chong and Yun Li, "PID Control

System Analysis, Design, and Technology," IEEE Trans., Control Syst.

Technol., vol. 13, no. 4, pp. 559-576, Ju12005.

[5]Ahmad Ali and Somnath Majhi, "PI / PID Controller Design based on

IMC and Percentage Overshoot Specification to Controller design Set point

Change," ISA Trans, 48, pp. 10-15, Jan 2009.

[6] Gang Fu et.al, "An IMC-PID Controller Tuning Strategy Based on the

DE and NLJ Hybrid Algorithm," in Proc. Int. Colloq Com put,

Commun, Control, Manage., pp. 307-310, Aug 2009.

[7] T. Liu and F. GAO, "New Insight in to Internal Model Control Filter

Fig.13 Response of IMC controller Design for Load Disturbance Rejection,” lET Control the. Appl., vol. 4,

issue 3, pp. 448-460, Mar 2010.

[8] Anton Sodja et.al, "Some Aspects of Modeling of Tube-and-Shell Heat-

Figure 13 shows the unit step response of the shell Exchangers," in Proc of 7th Modelica Corif-, Italy, pp. 716-721, Sep 2009.

and tube heat exchanger system when an internal model

[9] J.A. Bernard, “Use of Rule-Based System for Process Control", IEEE

controller is implemented in the series of the real cont.sys.Mag. Pp3-l3, Octoberl988.

process and an approximate model of the process is

placed in parallel of the real process. The step response

shows less overshoot and steady state error from feedback

PI controller and fuzzy logic controller.

You might also like

- Temperature Control Lab Report MuzDocument18 pagesTemperature Control Lab Report MuzAhmad Muzammil75% (8)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- HON-FIN4000xxK-10K - User Guide V1.3 (EN)Document63 pagesHON-FIN4000xxK-10K - User Guide V1.3 (EN)RantiNo ratings yet

- Heat Exchanger ExampleDocument7 pagesHeat Exchanger ExampleBrian MasonNo ratings yet

- Design of Fuzzy Logic Controller For A Cross Flow Shell and Tube Heat-ExchangerDocument3 pagesDesign of Fuzzy Logic Controller For A Cross Flow Shell and Tube Heat-ExchangerSmilyAkankshaNo ratings yet

- 10 11648 J Acis 20140201 11 PDFDocument5 pages10 11648 J Acis 20140201 11 PDFwsa wsaNo ratings yet

- PID Control of Heat Exchanger SystemDocument6 pagesPID Control of Heat Exchanger SystemTuấn Anh Nguyễn100% (1)

- PHE Control Mechanism PDFDocument6 pagesPHE Control Mechanism PDFNaren VmdNo ratings yet

- Pid Feedforward ControllerDocument6 pagesPid Feedforward ControllermitudevilNo ratings yet

- Dynamic Simulation of Double Pipe Heat Exchanger Using MATLAB SimulinkDocument8 pagesDynamic Simulation of Double Pipe Heat Exchanger Using MATLAB SimulinkacepwcxNo ratings yet

- PID Control of Heat Exchanger SystemDocument7 pagesPID Control of Heat Exchanger SystemHaris IhsannurNo ratings yet

- Process Control Exp 5Document4 pagesProcess Control Exp 5RickLeeNo ratings yet

- 10 11648 J Acis 20140201 11 PDFDocument5 pages10 11648 J Acis 20140201 11 PDFEric DiazNo ratings yet

- A125703 288 PDFDocument7 pagesA125703 288 PDFTimothy FieldsNo ratings yet

- PID Control of Heat Exchanger System: Yuvraj Bhushan Khare Yaduvir SinghDocument6 pagesPID Control of Heat Exchanger System: Yuvraj Bhushan Khare Yaduvir SinghJudy Ann BoseNo ratings yet

- Simulation of Intelligent Controller For Temperature of Heat Exchanger System Using MatlabDocument14 pagesSimulation of Intelligent Controller For Temperature of Heat Exchanger System Using MatlabAnonymous Gke2wm7No ratings yet

- PFC Heat Exchanger 1 2001Document9 pagesPFC Heat Exchanger 1 2001KAMELNo ratings yet

- Temprature Control of Heat Exchanger.Document20 pagesTemprature Control of Heat Exchanger.Akash verma0% (1)

- Swarm Optimization Based Controller For Temperature Control of A Heat ExchangerDocument6 pagesSwarm Optimization Based Controller For Temperature Control of A Heat ExchangerBaa BakNo ratings yet

- Design and Implementation of A Fuzzy Logic Based Controller For Refrigerating SystemsDocument5 pagesDesign and Implementation of A Fuzzy Logic Based Controller For Refrigerating SystemsAnupriya GhoshNo ratings yet

- Heatexchanger PDDocument29 pagesHeatexchanger PDbhavinaNo ratings yet

- Controller Design For Temperature Control of Heat Exchanger System: Simulation StudiesDocument7 pagesController Design For Temperature Control of Heat Exchanger System: Simulation StudiesAnonymous G04WC68JXfNo ratings yet

- A125703 288 PDFDocument7 pagesA125703 288 PDFAnonymous G04WC68JXfNo ratings yet

- PID Based Temperature Control of A Plant Heat Exchanger System-239Document5 pagesPID Based Temperature Control of A Plant Heat Exchanger System-239Mark Anthony CaroNo ratings yet

- Introduction To Control: The ProcessDocument7 pagesIntroduction To Control: The ProcessshajiNo ratings yet

- Eteiac1411 (Heat Exchanger)Document6 pagesEteiac1411 (Heat Exchanger)Evans IraborNo ratings yet

- Heat Exchanger & Furnace Operations and ControlsDocument6 pagesHeat Exchanger & Furnace Operations and Controlsnilesh_092No ratings yet

- Biochemical Engineering B.SC, University of DebrecenDocument6 pagesBiochemical Engineering B.SC, University of DebrecenArifuzzamanNo ratings yet

- CS LabReport 8Document10 pagesCS LabReport 8Muhammad AfzaalNo ratings yet

- Refrigerant Unit Lab ReportDocument19 pagesRefrigerant Unit Lab Reportakmal100% (2)

- A Didactic Test Rig To Analyze The Shell and Tube Heat Exchange and Stability of Control SystemDocument10 pagesA Didactic Test Rig To Analyze The Shell and Tube Heat Exchange and Stability of Control Systemnicacio_89507470No ratings yet

- Boiling and CondensingDocument2 pagesBoiling and CondensingZia Ul NoorNo ratings yet

- Lab Sheet Air CondDocument8 pagesLab Sheet Air CondAhmad AbaNo ratings yet

- Heat Exchanger2Document5 pagesHeat Exchanger2Motaz Ahmad AmeenNo ratings yet

- Cooper Union Engineering Faculty: Controls Heating System Cooling SystemDocument6 pagesCooper Union Engineering Faculty: Controls Heating System Cooling SystemErmiasNo ratings yet

- FinalllllllDocument47 pagesFinalllllllSoresa JemalNo ratings yet

- Process Control LabDocument25 pagesProcess Control LabShubhashish Bhakta100% (1)

- Armfield Ht31 Tubular Heat Exchanger in The Education KeywordsDocument3 pagesArmfield Ht31 Tubular Heat Exchanger in The Education KeywordsCHERUYIOT IAN100% (1)

- Optimal Design and Control of CPU Heat Sink Processes Chyi-Tsong Chen, Ching-Kuo Wu and Chyi HwangDocument6 pagesOptimal Design and Control of CPU Heat Sink Processes Chyi-Tsong Chen, Ching-Kuo Wu and Chyi HwangFegiri JefferyNo ratings yet

- Experiment #10 Part A Parallel and Counter Flow Heat ExchangersDocument7 pagesExperiment #10 Part A Parallel and Counter Flow Heat Exchangersibrahim sundayNo ratings yet

- The Analyses of Variable Refrigerant: Flow and Exergy in An Air Conditioning UnitDocument31 pagesThe Analyses of Variable Refrigerant: Flow and Exergy in An Air Conditioning UnitHackersReunionNo ratings yet

- Homework 1-Heat ExchangerDocument2 pagesHomework 1-Heat ExchangerPe1L1ngNo ratings yet

- Chapter 8 FTDocument40 pagesChapter 8 FTUthaiyavani RajendranNo ratings yet

- Lab Report Heat ExchangerDocument17 pagesLab Report Heat ExchangerFirdaus Zainal AbidinNo ratings yet

- ObjectivesDocument7 pagesObjectivesPeeka booNo ratings yet

- M.Givelberg, SH - Gurevich, R&D Israel IsraelDocument4 pagesM.Givelberg, SH - Gurevich, R&D Israel IsraelEdna LópezNo ratings yet

- Controller Design For Temperature Control of Heat Exchanger System: Simulation StudiesDocument8 pagesController Design For Temperature Control of Heat Exchanger System: Simulation StudiesJhoanaNo ratings yet

- Chapter 1 - IntroductionDocument49 pagesChapter 1 - IntroductionFakhrulShahrilEzanieNo ratings yet

- Hvac BMS: HVAC Systems Eng. Ahmed MoustafaDocument126 pagesHvac BMS: HVAC Systems Eng. Ahmed MoustafaBahaa bunniNo ratings yet

- Process Control Lab ManualDocument19 pagesProcess Control Lab ManualAnkit Singh100% (1)

- Temperature ControlDocument9 pagesTemperature ControlMauricio López NúñezNo ratings yet

- Dynamics and ControlDocument5 pagesDynamics and Controlbhagwat26No ratings yet

- Simulation of Self-Tuning Pid-Type Fuzzy Adaptive Control of A Hvac SystemDocument7 pagesSimulation of Self-Tuning Pid-Type Fuzzy Adaptive Control of A Hvac SystemwendyNo ratings yet

- PDC - Advance Control Strategy MethodDocument7 pagesPDC - Advance Control Strategy MethodFaiz IdzwanNo ratings yet

- HumidificationDocument22 pagesHumidificationmohammed hussienNo ratings yet

- Fuzzy Control of A Heat ExchangerDocument6 pagesFuzzy Control of A Heat ExchangerAdnan NimachwalaNo ratings yet

- Lab Heat PumpDocument9 pagesLab Heat PumpShahran IezzatNo ratings yet

- Automatic Controls for Heating and Air Conditioning: Principles and ApplicationsFrom EverandAutomatic Controls for Heating and Air Conditioning: Principles and ApplicationsRating: 4 out of 5 stars4/5 (2)

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemFrom EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNo ratings yet

- I 4Document19 pagesI 4B B Sylvester Easun - MRNo ratings yet

- Nexans 500 KV CableDocument22 pagesNexans 500 KV CableFiras Atwan100% (1)

- Coordinating Parallel Hierarchical Storage ManagemDocument16 pagesCoordinating Parallel Hierarchical Storage ManagemAdane AbateNo ratings yet

- Instalación Opera en Win7Document12 pagesInstalación Opera en Win7pedro_orozco_80No ratings yet

- IAS Chapter 1 EditedDocument36 pagesIAS Chapter 1 Editedteshu wodesaNo ratings yet

- G7 Manual (Inverter)Document416 pagesG7 Manual (Inverter)PhamDinhNo ratings yet

- Aristotelis OperaDocument921 pagesAristotelis OperaAllison HobbsNo ratings yet

- Mogo Marketing StrategyDocument10 pagesMogo Marketing StrategyBeth MugoNo ratings yet

- Virtual Reality: Sitaram ThripuralaDocument32 pagesVirtual Reality: Sitaram ThripuralaThripurala sitaramNo ratings yet

- 4 ElogisticsDocument360 pages4 Elogisticsmino_mino86No ratings yet

- The 10 Principles at Nike.Document1 pageThe 10 Principles at Nike.Olaoluwa SamagbeyiNo ratings yet

- Trango DatasheetDocument2 pagesTrango Datasheetkhurana1982No ratings yet

- H BurndyDocument1 pageH BurndyJuan Carlos ParedesNo ratings yet

- Reading Comprehension Stat3 Exercise2Document8 pagesReading Comprehension Stat3 Exercise2Amandine GbayeNo ratings yet

- ACOS730 Flyer 201707 ENDocument5 pagesACOS730 Flyer 201707 ENSentaNo ratings yet

- Fast Fourier Transform of Frequency Hopping Spread Spectrum in Noisy EnvironmentDocument5 pagesFast Fourier Transform of Frequency Hopping Spread Spectrum in Noisy EnvironmentNaveed RamzanNo ratings yet

- Introduction To Digital TransformationDocument8 pagesIntroduction To Digital TransformationvrjgopiNo ratings yet

- BITZER 4P.2Y - Part ListDocument6 pagesBITZER 4P.2Y - Part Listаа аааNo ratings yet

- UMS9117 SR3595D - RF - NV - 配置指导 - V1.0Document91 pagesUMS9117 SR3595D - RF - NV - 配置指导 - V1.0Andrew Yefremov100% (1)

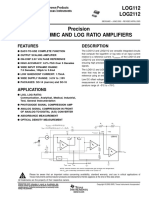

- LOG112Document21 pagesLOG112Otto Lambertus0% (1)

- Data Connections and NetworkingDocument2 pagesData Connections and NetworkingNaiyara NeehaNo ratings yet

- A2 005 Slickline Alu UnitDocument2 pagesA2 005 Slickline Alu Unitabdullah boulifaNo ratings yet

- HW2 - TCMT - Nhóm ADocument4 pagesHW2 - TCMT - Nhóm ALớp 18DT3 DUT - Bách Khoa Đà NẵngNo ratings yet

- ED-EDM-P1-F1 Service Information Sheet PDFDocument4 pagesED-EDM-P1-F1 Service Information Sheet PDFMohammed sabatinNo ratings yet

- Machine Learning Applications Used in Accounting and AuditsDocument6 pagesMachine Learning Applications Used in Accounting and AuditsVIVA-TECH IJRI100% (1)

- Module 7Document2 pagesModule 7prof_ktNo ratings yet

- Installer DebugDocument14 pagesInstaller DebugHohoweoNo ratings yet

- Gary White Network EngineerDocument14 pagesGary White Network EngineerUgochukwu FidelisNo ratings yet

- CV - en - Rui GonçalvesDocument3 pagesCV - en - Rui GonçalvesRui GonçalvesNo ratings yet