Professional Documents

Culture Documents

CL Stress Corrosion Cracking

Uploaded by

Mahmoud Alwasif0 ratings0% found this document useful (0 votes)

3 views1 pageCL Stress Corrosion Cracking

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCL Stress Corrosion Cracking

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 pageCL Stress Corrosion Cracking

Uploaded by

Mahmoud AlwasifCL Stress Corrosion Cracking

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

4.5.

4.5.

1 Chloride Stress Corrosion Cracking (CISCC)

4.1 Description of Damage

presence o'

Surface i \cks caused by environmental alloys

under the: The

45.

Affected Materials

a) All 300 Series SS are highly suscepti.

b)

c)

4.5.

a)

b)

°)

d)

e)

f)

9g)

h)

i

Duplex stainless steels are more resistant.

Nickel base alloys are highly resistant, but not immune.

1.3 Critical Factors

(iter, BA, tenner BRS, press GHGREH and aly conosttnyar crea

factors.

Increasing temperatures increase the susceptibility to cracking.

Increasing levels of chloride increase the likelihood of cracking.

No practical lower limit for chlorides exists because there is always a potential for chlorides to

concentrate.

Heat transfer conditions significantly increase cracking susceptibility because they allow chlorides to

concentrate. Alternate exposures to wet-dry conditions or steam and water are also conducive to

cracking,

DOORS UUMREREAIIN A over pH values, uniform corrosion generally

predominates. SCC tendency decreases toward the alkaline pH region.

Cracking usually occurs at metal teniperatures ebove about 440% (60°C), although exceptions can

be found at lower temperatures.

Stress may be applied or residual. Highly stressed or cold worked components, such as expansion

bollows, are highly susceptible to cracking.

((Gixyeen disseived in the water normally accelerates SCC but it is not clear whether there is an

‘oxygen concentration threshold below which chloride SCC is impossibl

Nickel ipiahsllane°Y, has a maior affect on resistance. The ai cel

content Alloys with nickel contents abovela5% are h bove

45% are nearly immune.

You might also like

- Engineering Encyclopedia: Metallic Communications CableDocument45 pagesEngineering Encyclopedia: Metallic Communications CableMahmoud AlwasifNo ratings yet

- Engineering Encyclopedia Materials & Corrosion Control Failure Analysis ReportDocument1 pageEngineering Encyclopedia Materials & Corrosion Control Failure Analysis ReportMahmoud AlwasifNo ratings yet

- Heat Treatment of Steel: Assessment Performance CriteriaDocument6 pagesHeat Treatment of Steel: Assessment Performance CriteriaMahmoud AlwasifNo ratings yet

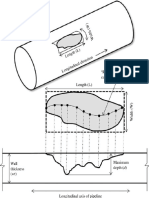

- Dimensions of A Typical Corrosion Defect On PipelineDocument1 pageDimensions of A Typical Corrosion Defect On PipelineMahmoud AlwasifNo ratings yet

- Objectives of A Consulting Services Failure Analysis ReportDocument1 pageObjectives of A Consulting Services Failure Analysis ReportMahmoud AlwasifNo ratings yet

- Engineering Encyclopedia: Failure Analysis ReportDocument1 pageEngineering Encyclopedia: Failure Analysis ReportMahmoud AlwasifNo ratings yet

- Pages: Engineering Encyclopedia Materials & Corrosion Control Failure Analysis ReportDocument1 pagePages: Engineering Encyclopedia Materials & Corrosion Control Failure Analysis ReportMahmoud AlwasifNo ratings yet

- Applying The Recommendations of A Failure Analysis Report To Prevent Future FailuresDocument1 pageApplying The Recommendations of A Failure Analysis Report To Prevent Future FailuresMahmoud AlwasifNo ratings yet

- Storage of Materials: Engineering Encyclopedia Project Management Managing Materials During ConstructionDocument4 pagesStorage of Materials: Engineering Encyclopedia Project Management Managing Materials During ConstructionMahmoud AlwasifNo ratings yet

- Basis For The Recommendations in A Consulting Services Failure Analysis ReportDocument1 pageBasis For The Recommendations in A Consulting Services Failure Analysis ReportMahmoud AlwasifNo ratings yet

- Procurement Responsibility: Consideration in Successful Materials ProcurementDocument3 pagesProcurement Responsibility: Consideration in Successful Materials ProcurementMahmoud Alwasif100% (1)

- MT-Procedure 7Document1 pageMT-Procedure 7Mahmoud AlwasifNo ratings yet

- Engineering Encyclopedia Project Management Managing Materials During ConstructionDocument4 pagesEngineering Encyclopedia Project Management Managing Materials During ConstructionMahmoud AlwasifNo ratings yet

- MT-Procedure 8Document1 pageMT-Procedure 8Mahmoud AlwasifNo ratings yet

- 12.1 Yoke: 12. Calibration RequirementsDocument1 page12.1 Yoke: 12. Calibration RequirementsMahmoud AlwasifNo ratings yet

- Engineering Encyclopedia: Managing Materials During ConstructionDocument4 pagesEngineering Encyclopedia: Managing Materials During ConstructionMahmoud AlwasifNo ratings yet

- Method of ExaminationDocument1 pageMethod of ExaminationMahmoud AlwasifNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)