Professional Documents

Culture Documents

Nice 3000控制系统常见问题解决指南.zh Cn.en

Uploaded by

Troubleshooting0 ratings0% found this document useful (0 votes)

129 views20 pagesUbbycvbnmoom

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUbbycvbnmoom

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

129 views20 pagesNice 3000控制系统常见问题解决指南.zh Cn.en

Uploaded by

TroubleshootingUbbycvbnmoom

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 20

NICE 3000Control system to solve common problems Gui

de

2011-08-09 20:43read:2,881

Service personnel summarizes some of the solutions to the problem site.

l FEGroup of elevators function setting parameter,

1. FE-00: Collective selective way. 0: Full selective 1: Down selective 2: Part

election

2. FE-01ToFE-31: Function code display setting content corresponding floor. The

value of4Bits, wherein the high floor ten two representatives display the code, the

lower two bits representative of the display codes. Floor display may be arbitrarily

combined. Specific settings See Commissioning Manual.

FE-31In addition to the first set31SUMMARY hall displaying an outer layer, also

represents a call through an outer door check function. whenFE-31Set value

equals10When expressed floors31Corresponding to the display contents. If the

floor is less than the maximum lift29Floor(F6-00 <29),whenFE-31Is smaller than

the set value10When it expresses1Dual layer double door hall display case, will set

the DIP switch address called door plate31The control system can identify through

the front and rear doors of the door, this timeFE-31 Setting parameter indicates

the content of the landing call board DIP31Corresponding floor.

For example: the highest floor is10, The lowest floor for the1;floor2It is a double

door and hall call buttons and the display panel. This time should beFE-31set

as2Such as DIP address31with2Two display panels can be used as2Hall call floor

display panel in this case, as DIP31The hall call on the display panel2Can be

realized using a double layer with an outer layer of a display panel function call.

3. FE-32: Factory function selection1.

The function code elevator factory setting function desired. Each function is

controlled by one binary number," 1"This feature allows representation,"0"It

indicates that the function is disabled. If a driver needs to lift function, the base

station functions return fire, Re-leveling, self-help advance door opening function

and the emergency function is active, the other function is invalid, the

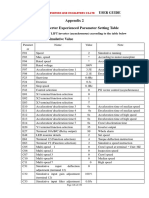

corresponding binary function provided in the following table:

Bit

Features

Binary settings

Bit

Features

Binary settings

Bit0

The driver features

1Bit8

Time-sharing service layer functions

0Bit1

Fire Homing function

1Bit9

Operate independently

0Bit2

Re-leveling

0Bit10

Maintenance automatic close

1Bit3

Advance door opening function

0Bit11

Summon move within accidentally deleted

1Bit4

Move outside to remove adhesions

0Bit12

Move outside call accidentally deleted

0Bit5

Night security layer functions

0Bit13

Emergency Survival function selection

0Bit6

Down selective peak service

0Bit14

Retention

0Bit7

Parallel peak service

0Bit15

Lock short detection function

0

Binary number on the table is expressed as:0000110000000011, Converted to

decimal number35843,thenFE-32Should be set3075.

If you need to open the other features in the appropriate"Place"Set1Effective, then

to decimal filledFE-32The function code, but the features used in conjunction with

other open settings. such asbit8Time-sharing services needsF6-18 ~ F6-25Time to

set up and used in conjunction with the service floor.

Please refer to the specific features described below.

4. FE-33: Factory function selection2. Function code setting and function selection

factory1The same method.

Bit

Features

Binary settings

Bit

Features

Binary settings

BIT0

Retention

1BIT8

Locking contactor normally closed output

0BIT1

In place to keep the door open

1BIT9

Anti-leveling immediately stop

0BIT2

Output operation is not closed

0BIT10

Weighing analogue input uses10PlaceADsampling

1BIT3

Maintenance detected closed place closed

0BIT11

Close instruction is not output lights of the car

1BIT4

Contact adhesion automatic reset

0BIT12

Non-service layer does not stop anti-leveling function selection

0BIT5

Blocking detection forced deceleration switch

0BIT13

High-speed elevators protection selection

0BIT6

Synchronous motor contactor shutdown output star

0BIT14

Under no circumstances call after parking, the elevator does not show direction

0BIT7

Retention

0BIT15

Independent control through door

1

The company factory setting32 . Some may choose to use other functions. Specific

functional description please refer to the following instructions:

The driver features: If you do not select this function, the lift does not have a driver

function;

Fire back to the base station functions: selecting this function, the user can board

or main control board terminal (fire signal) back into the fire base station

functionality, in this case, if the elevator is running, the layer nearest parking floor

is not open through the display, and then directly drove the base station, to the

base station after holding the door. If it became a firefighter input signal, the

elevator will enter fireman running.

Re-leveling: high floor lift or heavy load, the load changes when the car door is

large, the elevator car will above (or below) the sill. If this function is selected, the

elevator door would be in the case of a very low speed and then leveling

operation. This feature requires a peripheral sealing contact with the door, and be

sure to use3A leveling inductor (upper and lower planar door area);

Advance door opening function: When the lift is automatic (normal) operation, the

process speed is slower than the parking0.1m / s, And in the door zone signal is

valid, we need Lock contactor short lock signal, then open the door in advance, so

that the highest efficiency of the elevator;

Hall call blocking Removal: Under normal circumstances, if the hall call button

adhesions can cause heavy lift has been carried out this layer to open the door,

the elevator does not work. After using this function,NICE3000Automatic

identification information landing call button, if abnormal findings, this button is

automatically removed, does not affect the use of the elevator;

Night security layer functions, Down selective service peak, peak services, time-

sharing service layer functions: seeF6Parameter description; and

withF6Corresponding set of parameters with the use.

Independent operation: the non-parallel (group control) by independent

operation switches within the car enters the independent operation state, does not

respond to an elevator hall call at this time, as when the driver door operating

state, i.e. not close automatically, automatic door closing is not complete. If in the

parallel (control group), the system automatically off the parallel (group control);

Run straight ahead: In the state of the driver, before the place closed, press the

elevator button until the end of the run, the system does not respond to outside

move between the current floor and the destination floor.

Maintenance automatic close door: When the engine room for maintenance

operations, if the car door is not closed, causing the elevator door blocked, not

run. If this function is selected, in the case of maintenance, according to the

DOWN button, the elevator will automatically close, if not press on the down

button, the door close signal is not output.

Within the church call miss delete: If you are ready to delete instruction has been

registered within the church, continuously press the call button twice

(interval0.5sOr so), the system will cancel the call. However, if the elevator is

locked within the church call, you can not delete this call.

Hall call call miss delete: If you are ready to delete the registered external call

instruction, continuously press the call button twice (interval0.5sOr so), the system

will cancel the call.

Emergency auto-running car: in the case of application of the permanent magnet

synchronous motor, can rely on locking contactor achieve self-running car power

failure, when it slides to the position of the leveling door. Selecting this function

can be implemented in case of emergency rescue work very economical.

Emergency Survival overtime protection: emergency rescue, if the car is balanced

load or drive power capacity is insufficient rescue, emergency rescue will result in a

very long time, may be dangerous, this function can auto-running car over

rescue100Seconds, drive over the rescue50After the second stop the rescue.

Lock short detection: Automatic elevator case (normal) operation, if the OD is

short, the door is detected, the systemE53Alarm.

OD holding open: this function is selected, the elevator door open signal is output

even after the door is opened;

Closing operation is not output: this function is selected, the elevator door closing

signal is not output during operation;

Maintenance closed closing bit detection: this function is selected, the system

determines the CD signal Maintenance automatic closing function, or only to close

the door locking signal to determine the place where the elevator;

Automatic reset contact adhesion: brake detection, feedback contact running

contactor, contacts exception is foundE36,E37Fault tips, and does not

automatically reset, this feature will appear in the case of these two faults, if the

fault disappears automatically reset, up to three times.

Blocking detection forced deceleration switch: This function always supervise the

lift is running forced deceleration switch, if it is forced to reduce the adhesion

found.

Locking contactor synchronous machine shutdown output: the synchronous

machine locking contactor can ensure high-speed slip does not occur even if the

elevator car in case of failure Brake,NICE3000Output terminal

options12(Synchronous motor auto) is automatically stopped when the output at

this functional role. If the selected contact input feedback (F5-01~F5-24Function

code in function code is set to have30or62),NICE3000The feedback monitor

contacts application when a synchronous machine, once the abnormal, theE29Call

the police. Note: We now use the running contactor comes enclosed star

contactor function, there is no need to set parameters.

Locking contactor normally closed type: In synchronous motor, locking contactor

control switch normally closed type. Note: The Company does not use, do not set.

Weighing analogue input uses10PlaceADsampling:Weighing analogue input

uses10PlaceADsampling:"0", Weighing analogue employed8PlaceADSampling; for

the"1", Weighing analogue employed10PlaceADsampling. Need to re-weighing

self-tuning after selecting this function. The factory default8PlaceADsampling.

Car door close command is not output after lights: in the energy saving state, the

elevator does not need to continue to output commands to close, so as not to

work long hours door.

No stopping non-serving anti leveling function selection: elevator applications in

the field, may be due to some reason no longer is part of the floor where the

service layer, and the process returns in a flat elevator required layer can not be

resting on the floor . Users canFE-33ofBIT12To choose,

ifBIT12for1ThenNICE3000The control system determines the process returns to

leveling leveling whether the current service level, and can stop at the service

layer.

High-speed elevators protection options: the current high-speed synchronous

traction machine elevators (more than2.5m / s) More and more

applications,NICE3000For applications where high-speed elevators, an increase of

special protection, to prevent further accidents elevator (for example, hoisting)

occurs. This function has no less than2.5m / sDo not use the elevator.

Under no circumstances call after parking, the elevator does not show direction:

This feature requires byFE-33ofBIT14To choose. This function is

selected,NICE3000Detecting each time the current running down the elevator if

there are other call, if not, the direction of the elevator will immediately show

cancellations, no shows direction.

Through independent control gate comprising the following functions:

A, Open delay: in the case of an elevator extension button to open the door by

the elevator after the close of this function is not used. Remains open state, the

time need not be set. If you do not press the button to open delay, the closing

function and the closing function of the same standard.

B, door1,door2Control: IncreaseMCTC-CCB-AofJP16Function, this timeJP16As

the door1,door2Control switch. By way of the switch button, is performed each

time the door1,door2Control switching section1On power-up default times for the

door1control. If the layer is only one door, the door1,door2Switch ineffective; if

there are two doors, this button is selected, but the two doors will not open

simultaneously. Click the button once the door1,door2Switching control, each

time interval required by3Sec.

C, This call door outer layer: the elevator closed, this layer has a function to open

the door again;

D, Open parking: parking, according to several circumstances to determine: If only

one side of the hall call call, the elevator stopped, opened a side door that calls;

call if there are external call on both sides, after the elevator stopped, according to

door1,door2A control switch to determine which side door open; If there is no

external call call only move within the call, the elevator stopped, according to the

door1,door2A control switch to determine which side door open;

E, After using this function, the highest floor is15F (physical floor), external call

address1 to 15correspond1floorTo 15Loumen1External call, external call

address17 to 31correspond1floorTo 15Loumen2External call.

l Elevator debugging

Commissioning phase of the elevator, make sure you do well and under

unattended in the car! In order to avoid accidents.

1. Mechanical installation, electrical connection check

Correct installation of the components is important to ensure the installation

elevator ensure the comfort, the door system,PADMating the card with the

inductor, the switch terminal fitting bow frame and the striker and the like. In strict

accordance with the correct wiring system wiring and cabling, especially

2. Encoder check: Firmly mounted, shielded cable, and power wiring line must be

arranged in the sub-tank, take separate metal protective tube, the pulse signal

encoder feedback is important to ensure the realization of control accuracy.

3. Power check: Check the bus capacity, three-phase five-wire system; voltage

fluctuation within the standard range.

4. Check the ground: The ground wirePEShould be infinite resistance with the

power supply terminals, check all the electrical components of the terminal and

the elevator control cabinet into the linePEThe resistance should be as small as

possible.

5. The electrical inspection: drawing corresponding to each of the control power

supply voltage measurement; CheckF5Set point parameters and functional

requirements of each drawing are the same. an

examinationF0group,F1group,F6group,F8Group parameter settings are

consistent with the requirements of the contract.

6. Maintenance test run: check the input and output signals, running direction,

encoder counting, the communication is normal.

7. Door system debugging: manual testing whether normal control door, the door

should be smooth, there should be no impact closing, crawling speed may be

adjusted, or if deceleration time. To consider the mechanical door from the

complex, with the size croquet door with a knife each door, to ensure that each

landing door to run freely.

8. Debug Express: well to ensure smooth flow, mechanical and electrical

components installed in each end, no short wires; each connection and electrical

parameters are set correctly. Hoistway self-learning; weighing self-tuning; MPU

keypadF1Function or keypadF7Test function, into the single test run, whether the

door system and observing the run performed as required. When properly

completed, then the other functional tests. Finally, the whole comfort debugging.

l In addition to the Commissioning Manual"Fault Diagnosis and

Countermeasures"In addition, we add some common troubleshooting guide.

1, Storey2 How to complete the elevator shaft self-learning?

Description field: elevator shaft since the completion of learning, high-speed

operation can be carried out, but after the power on

again,NICE3000appearE35Can not be high-speed operation.

Problem Cause: The elevator only2Layer, shaft self-learning is1Floor leveling

began. Thus the hoistway self-learning is performed, the number of pulses

obtained leveling plateF4-05for0. And the system will be on the floor efficacy

pulses in a case where each power found pulse number flapper0The promptE35.

Remedy: out of the bottom of the elevator, from the door zone, and then re

hoistway can be self-learning.

2, Synchronous motor-pumped self-learning reportE35

Description field: elevator shaft self-tuning after each time to the first2A leveling

plate, immediately reportedE35prompt.

problem causes:NICE3000In addition to synchronous machinePGcard(MCTC-PG-

B), Both connections (byCN6) Is based on the system records rotary encoder

pulse, but notAcorrespondPGA;BcorrespondPGBOn it, this related to the

installation of the unit. Thus the control system during the self-learning of the

hoistway, section2When the arrival of a leveling plate, the number of pulses of the

recording system if the internal0Or negative immediately promptE35.

Remedy: AdjustPGCard toCN6Wiring. With maintenance operation, seeF4-

03Confirmed the elevator up, the number of pulses increases; downlink, the

number of pulses is reduced.

appendix:E35All the causes

Before starting:1,F4-01The current floor dataF6-01The bottom of the elevator

inconsistent data.2, Under a forced deceleration is invalid.3,F0-00 = 0, The open-

loop mode. If the overhaul, has been effective or down button to open the door,

close the door will not be able to enter button has been effective self-learning

operation.

Operation:1, Inspection switch is not in service position.2If theF9-02In the same

direction within the set time operation, receive door zone signals, the elevator will

reportE35. This parameter setting is less than3SThis function does not detect. If

you have long landing of the hoistway self-learning, should beF9-02Parameter is

set to less than3S, Since the study is completed, then changed45S.3, Floor height

is less than500mm.4When learning from the top end of the current floor and

inconsistent.

3, After the synchronous machine parking brake, the elevator car slide

Site description: Live in synchronous machine debugging process, we found each

parking brake at the same time, there is the feeling of the car rolling away.

Problem Cause: synchronous and asynchronous machines machines differ in the

parking brake moment. Maintain the same moment of time is not enough.

Because there is no transmission damping synchronous machine, if you do not

extend the time to maintain zero-speed torque in an instant brake, it is easy to

slip.

Remedy: TheF8-11 = 0.2S default parameters, to change the scene0.4second.

4, Elevator appearE38prompt

Site description: Elevator door sports car does not start area, newspaperE38Failure

to open the door. Charles failure information records and found fault speed has

reached the rated speed, the current can exceed the rated current.

Cause of the problem: the elevator when the door zone activated, the brake is not

fully open,F1-13PG signal is not received within the set time detected by the

encoder, and at this time the elevator speed and the drive current command has

been issued reaches the rated value.

Remedy: Check brake power is normal; check whether the auxiliary brake circuit

controlled all point contact is abnormal. Check the encoder is used correctly.

Increasing the brake opening detection switch detects be determined, if not

detected immediately reported byE37malfunction.

appendix:E38All the causes

1, F0-00 = 02, A pulse control system to collect the running direction opposite to

a large error or

3, Operation of the encoder pulse has not changed

4, Encoder pulsesF1-12Set incorrectly

5, Synchronous drive control system, if the brake can not be opened may

reportE20orE38Code disk failure.

5, Elevator oftenE48,E49

Site description: Elevator door area newspaperE48,E49malfunction.

problem causes:E48A door open error, the cause of that is open during OD signal

is not received, after repeated door, when the door exceeds the number ofFB-

09After TipsE48;E49Is closed fault, it causes the lock-on signal is not received

after the closing time, after several closed overFB-09After TipsE49.

Remedy: Find terms doors, locks, etc., if setFB-9 = 0. You will not prompt such a

failure, but the door will not stop the door.

6, Parallel ladder oftenE51

Site description: appear in the parallel application of occasionsE51prompt

Cause of the problem: the problem is the systemCanbusCommunications

interference affecting the normal communication data.

Remedy: ground finish again; terminal resistor operated correctly; check DIP

switch, is solid, can be re-allocated once; shielded twisted pair communication

lines or whether the correct use; communication line can not inline with the power

line; dial code switch in a parallel form of ladder set correctly.

7, Method to reduce the elevator speed

Site description:1.6m / sThe elevator will speed down1m / s.NICE3000It has been

shown1m / s, But it feels elevator speed is also very high.

Problem Cause: The wrong interpretation of the sceneF0-03(Maximum lift

speed),F0-04(Elevator rated speed) meaning,

The wrongF0-04 = F0-03 = 1m / sSo although shown as elevator1m / sBut the

actual speed of the elevator is still1.6m / s.F0-04Is the nominal rated speed

elevators, the elevator machine parameter is determined and the hoisting

machine, so this parameter can not be changed. To change the spin-down run

onlyF0-03.

Remedy: TheF0-04 = 1.6m / s;F0-03 = 1m / s. At this time, the elevator is

running1m / s.

8, Input type CTBF5-25Does not set

Site description :NICE3000Input point type car top plate Settings (F5-25) May

define screens, and other signal OD is normally open or normally closed type, and

then press Binary Decimal, but commissioning personnel often not the count

parameter.

Remedy: In this case, in fact, we already provided, in addition to full load switch is

set to"1"Often away, the rest of the inputs, e.g. overloading, off screen, OD,

closing place (default must normally closed) etc. set normally closed at this

timeF5-25 = 64. Check if the problem switch wiring (inverted open or closed). For

special machine door open connection mode can only take place normally open,

soF5-25 = 76.

9, Occasional elevatorE03,E04

Description field: Even children appear elevator in normal operationE03,E04Fault

tips.

Problem Cause: The lift can operate normally, indicatingNICE3000Integrated

system is normal, in this case in general, an encoder may cause loose or broken or

loose integration output power wiring.

Remedy: contactor connection, the entire main circuit connection re-connected.

produceE02,E03,E04Of all the reasons:

ACheck the motor parameters are correctF1-01 ~ 05Setting the motor nameplate.

BCheck encoder parameters are correct, the number of pulses per revolution is set

correctly.

C, The encoder checks the learning point parameters are correct, the value of

learning times are equal.

D, Check the encoder wiring is correct.

EMeasuring the resistance is no motor three phase phase failure, phase resistance

substantially equal.

F, Model parametersFF-01Settings are correct.

10, Elevator appear uneven layer, occasionally reportedE02,E03,E04The driving

force is not enough

Site description: synchro lift is uneven layer, occasionally reportedE02,E03,E04The

driving force is not enough, etc.

Problem Cause: When the elevator maintenance or replacement of the

motherboard factory, on the motherboardFF-01Power setting and the drive itself

and the power settings do not match.

Remedy: Check the nameplate power with internal motherboardFF-01Power

settings are consistent.

FF-01Corresponding to the power:11 correspond3.7KW;12correspond5.5KW;

13correspond7.5KW; 14correspond11KW; 15correspond15KW;

16correspond18.5KW; 17correspond22KW; 18correspond30;

19correspond37KW11, Asynchronous lift is running with a grievance layer

Site description:Run flat layer multilayer,However, single elevator run uneven

layer,difference5-6Millimeter

problem causes:

Method of exclusion: A,Check the motor nameplate, re-Motor self-learning; B,an

examinationF2Set of parameters, high-speedINot more than0.7; C,Increase the

deceleration end segmentF3-06time; D,Appropriate settingF3-09Parameters5 .

Other related reasons: When replacing the motherboard,Make sure the

motherboard inside the program version,Synchronous and asynchronous versions

of the board can not be interoperable,please checkFA-04,FA-05version number.

12, Lift inspection speed is greater than0.1msImmediately

reportedE02,E03malfunction

Field Description: inspection speed is greater than0.1msTimesE02,E03. When the

speed is reduced to less than0.1msYou can run.

Cause of the problem: the elevator can run normally, indicating that the system is

no problem. But with the overcurrent detection point. Inverter according to the

system load is determined in the case where the emergency power supply signal is

valid220VOvercurrent point is based on the power determination.

Remedy: Check the elevator is in normal use, if there isMCTC-MCB-

AboardupsInput detection signal is valid. ViewF5Is there a defined set of input

parametersupsParameters, or redefine signal is negated.

13, Asynchronous lift operating normally, but in doing110%Kai fixed overload test

Site description: Elevator everything is normal, but the technical supervision at the

time of testing, overload testing do not start up.

Cause of the problem: the motor drive controller is not sufficient recognition, no

truly closed-loop control, motor control many parameters can not be detected

and controlled. Thus affecting the start-up and operational comfort.

Remedy: do a static tuning the motor control system. The controller obtainsF1-

06ToF1-10The specific parameters.

14, Weighing compensation, starting unstable effects, changes depending on

various conditions

Field Description: weighing compensation, starting unstable effects, changes

depending on various conditions

solution:

A, To ensure that changes linearly with load weighing signal.

(1)ObservedF8-05Values, to see if the load sensor is mounted correctly, if the

setFE-33Using eightADSampling distance is adjusted so that the sensor loadF8-05

= 80 ~ 90Around for the best. After loading full self-learning, observationF8-07To

ensure Not reached the upper limitADValue Sampling255. Or can not report

overload prompt.

(2)To ensure that the weighing signal of the applied load in the car changes the

position. Check the load sensor is mounted in the center position of the platforms,

and the four rubber uniform change.

(3)Check whether the weighing signal changes with the change of floors.

For higher floor elevator, if the compensation chain channel fixed on the

platforms, the installation location of reasons, with the growth of the platforms

compensation chains may cause distortion of the deformation of the platforms

channel, since the sensor is also mounted on the platforms on the beam, the

channel distortion may cause a change in the measured values of the sensor.

Weighing apparatus may be considered a little further away from the

compensating chain lever is mounted, re-weighed study.

BCheck the platforms rubber deformation stroke is large enough, too small to

affect the accuracy of strain measurement. Self-learning should ensure that

finishedF8-07versusF8-06The difference20the above.

C,an examinationF8-05Whether the change in time with load, i.e., to check

whether the platforms can be freely and rapidly restoring compressed with load

changes. Check the car and can be considered a straight beam gantry frame

clamp mounting rubber appropriateness possible to install an external force

should not, go beyond. Otherwise, not only affect the start, and the entire high-

speed operation is not comfortable.

D, If the above conditions are met when the start of the effect varies with load lift,

few people start a good effect, many people start effect is not good, not good or

less good people, for theF8-02Not adjusted correctly, please cooperateF8-03,F8-

04, Pressing the middle floor adjustment, calculate the correctF8-02.

E, If you start with the floor effect change, please check whether the

compensation chain in place, because of the weight caused by the rope, wire rope

and due compensation chain weight difference caused by the effect of an unstable

start, unable to resolve the problem at source. Start effect can be adjusted

according to the top, to the greatest extent make up for the weight difference of

the impact. Deformation due to the underlying effect of a large rope length can

ease the impact started.

15, Security, petty through the door, the elevator can not run fast, slow

Problem Description: Security, Suo through the door, the elevator can not run fast,

slow

solution:

A,byF5-35Observation CD signal is valid, closing normally closed default place, the

default connection is not valid, then if the CD signal is set according to the type of

door closing correctly placeF5-25The CD signal is valid

B,byF5-35Observation open input signal is valid, if valid range gate opening signal

area. In the elevator, the door close signal to be output when the input is active to

open the door, the elevator can not close the output signals, the elevator can not

be run. Solution: To observe the door enter a valid reason, to check whether dead

or faulty command button card board input points, or short-circuit command

board itself.

16, How freight elevator overload switch wiring wiring in the engine room

Field Description: freight load switch installed in the engine room because, like

directly connected to the control system in the machine room.

Solution:AIf the switch is in the form of a normally closed, it is a common point to

the control cabinet301Another access pointMCTC-MCBThe spare board

pointX24The function codeF5-24 Set to46 . Weighing input selectionF6-36This

is0. B, If a switch output in the form of magnetic induction, then increase to a set

of24Vpower supply(301,302). A normally closed switch, with the wiring methodA.

17, Proper useupsSlip car rescue

Site description: non-synchronous machine elevator stopped at the gate area,

rescue mode switch to manual state, cut off electricity after,JUPAfter the pullupsIt

has the power to the control system, but can not achieve self-leveling elevator

rescue function. Switch to an emergency power again, press the up or down

elevator coaster.

Problem Cause: AlthoughJUPClosing the contactor, but also by the

inverterupsThe power supply. MPU but not detectedJUPThe feedback signal

orJUPThere feedback signal, but within the system is not set correctly. That is, the

control system does not consider entering the emergency touch-type state.

Remedy: ConfirmX20Signal sampling is correct andF5-20Set as59(Using signal is

normally closed). confirmF5-31Set as13Emergency operation automatically

switches power failure, automatic power outputY6effective.

Correct methods of operation:1Rescue mode is the Manual: elevator stops NAND

gate region, the elevator is in a normal state (non-maintenance) Total power

down;JUPAutomatic pull power to the control system; the control system

detectsJUPEffective feedback signal, the brake automatically open, leaving the

region to the leveling, open release, waiting for a call. 2, Rescue mode

automatically when: a NAND gate region elevator stops, the elevator is in a

normal state (non-maintenance) Total power down;JUPWill drop through the

system bus voltage250VOr soY6After the automatic pull output power to the

control system; the control system detectsJUPEffective feedback signal, the brake

automatically open, leaving the region to the leveling, open release, waiting for a

call.

upsRequire regular testing and maintenance. Must be maintained once a month,

no discharge when a power outage3minute.

Reference the following timely maintenance or replacement batteries

Ambient temperature

Battery Life

Inspected once every six months

Once monthly maintenance

20℃

2-3year

buy1Within a half years

Monthly discharge uninterruptible3minute

30℃

1.5year

buy10Within months

Monthly discharge uninterruptible3minute

18, The door after the door is electrically Slow

Site description:NSFC01-01The door after the door is electrically Slow

Cause of the problem: problematic bistable down switch

Remedy: Check whether the bistable switch wiring loose or broken; check whether

the bistable switching operation is reversed in polarity, the magnet can have a

spare turn refresh adjustment. Hand plate way to determine the deceleration

signal is correct.

19, Shen Ling door closed with Panasonic controls are in place to be knocking

Site description:NSFC01-01There are striking phenomenon organs door when the

door is in place

Cause of the problem: the deceleration position away from the door closed in too

close, closing the final crawl speed is too high.

Remedy: To solve this problem you must first install confirm every hall croquet

mechanically in a vertical line, and on both sides of the door blade and the

distance should ensure croquet5 ~ 8mmSo that elevator is safe and will not cause

failure Sassafras croquet. The adjustment in this case again the deceleration

bistable switch or reduce creep speedD27frequency.

20, Elevator will open the door to other floors, floor or attic is not open in the end

Field Description: elevator to the bottom floor or top layer is not open

Cause of the problem: the normal operation of the elevator to the bottom of the

compression limit switch, and should reportedE44Fault tips

Remedy: re-adjust the upper and lower terminal switch frame, re-write data storey.

twenty one, Run to the end station elevator frequent rapid deceleration

phenomenon

Site Description: Run to the end station elevator frequent rapid deceleration

phenomenon

Problem Cause: After writing storey elevator, although the express run. However,

in order to lift safer use of high-speed operation every time the operation of

detecting the position and state of the switch frame. This problem is when the

elevator reaches the end station decelerate switch has two possible actions.

Remedy: re-adjust with the switch from the rack and hit the bow. It is necessary to

check whether the play bow bent.

twenty two, Lift out for newspaperE20How fault

Description field: the synchronous motor in a stopped state, continued to

reportE20malfunction.

Cause of the problem: becausedspAngle of the received signal is determinedU +/-

;V +/-;W +/-Three-phase signals are all high level or low level all.

Remedy: measured with a multimeterPGCard terminals,U +versusU-Voltage (red

pen amount between+And the black amount-, Note that the measured voltage is

positive or negative);V +versusV-Voltage between;W +versusW-Voltage between.

Measuring out the need for a negative voltage is different from the other two, if

compared with the same positive and negative-phase signal encoder feedback

wrong should be reported20malfunction. The amplitude should be

measured3Vabout

Additional ways: If measured correctly encoder feedback signal, first check or

replace thepgCard to the bottom of the flat cable, since the cable connector is

tight, there is more likely to cause the internal plug disconnected. There is no

problem if the flat cable, then replacepgThe card also can not be determined

before replacing the bottom. Currently damage caused by goods20Fault, more,

due to the discharge line encoder followed,PGCard or the underlying cause of a

very small number.

twenty three, Brake (brake) switch on how to set

Site description:NICE3000Brake system is necessary to detect open switch does

not know how to set.

solution:NICE3000This defines the input terminal has set. Or two wiring

methods.1, Two normally closed switch and is coupled, one endMCTC-

MCBboardX21, The other end of the terminal block301, System SettingsF5-21Set

as58.2, Two series connected normally open switch, a terminationMCTC-

MCBBoardX21, The other end of the terminal block301. System SettingsF5-21Set

up26. whenF5-21Set as0 We will not use this feature.

twenty four, Panasonic door controller (NSFC01-01)

Site Description: Panasonic Door ControllerNSFC01-01 Bistable deceleration. No

deceleration of the door process.

Solution: check control modeP09Is correct; checkP43Logic input signal

Report/ Report

You might also like

- SM5000 Serial Control System Functions and Parameters GuideDocument73 pagesSM5000 Serial Control System Functions and Parameters GuideAndrew Sison82% (11)

- TK 103 UserManualDocument8 pagesTK 103 UserManualYusuf OzkayNo ratings yet

- ACCUVIX V10 Error Code TableDocument45 pagesACCUVIX V10 Error Code TableTroubleshooting100% (2)

- AS380 Machine On-Site DebuggingDocument5 pagesAS380 Machine On-Site DebuggingTroubleshooting100% (1)

- Motion Programming For ComauDocument318 pagesMotion Programming For ComauEddie Scarpa100% (1)

- NVAS380 Integrated Parameter GuideDocument30 pagesNVAS380 Integrated Parameter GuideMoises PerelloNo ratings yet

- Toshiba Spacel IIIDocument11 pagesToshiba Spacel IIITran Huy50% (2)

- Nova Ev3200 ManualDocument25 pagesNova Ev3200 ManualCarolina Sansón100% (1)

- Atlas TechNotes - Complete Set Rev Nov 2011Document50 pagesAtlas TechNotes - Complete Set Rev Nov 2011caod1712No ratings yet

- Harmonic Oscillator & Rigid Rotor ModelsDocument14 pagesHarmonic Oscillator & Rigid Rotor ModelsJisu RyuNo ratings yet

- NICE3000new Elevator Controller FeaturesDocument209 pagesNICE3000new Elevator Controller Featureskolwin .chindwin100% (1)

- FC 3000s PDFDocument60 pagesFC 3000s PDFAgnelo FernandesNo ratings yet

- Bg101 User Manual1Document22 pagesBg101 User Manual1MikeNo ratings yet

- Operation and Maintenance Manual For WYJ 250 Series Permanent-Magnet Synchronous Gearless Traction MachineDocument20 pagesOperation and Maintenance Manual For WYJ 250 Series Permanent-Magnet Synchronous Gearless Traction MachineJULIONo ratings yet

- FILE 20221010 095658 X11joDocument22 pagesFILE 20221010 095658 X11joNguyễn ThànhNo ratings yet

- Asanor Compact Iran 2 PDFDocument71 pagesAsanor Compact Iran 2 PDFSatisNo ratings yet

- STVF5 Trouble REV0 PDFDocument42 pagesSTVF5 Trouble REV0 PDFUpien Ayah MahardikaNo ratings yet

- Jarless Con Door DriveDocument1 pageJarless Con Door Drivewakeel ahmedNo ratings yet

- Do3000x Oim enDocument49 pagesDo3000x Oim enAlexNo ratings yet

- Ic卡制卡软件使用说明 EnDocument42 pagesIc卡制卡软件使用说明 EnASIA PTS ELEVATOR INCNo ratings yet

- 19010493-SC - A00 - 19010493 - ME320LNnew Series Elevator AC Drive - 20161121Document145 pages19010493-SC - A00 - 19010493 - ME320LNnew Series Elevator AC Drive - 20161121Ks BharathiyarNo ratings yet

- Operation Manual NSFC01-02 Lift Door ControllerDocument39 pagesOperation Manual NSFC01-02 Lift Door ControllerHƯNG NGUYỄN THANHNo ratings yet

- 02 IRIS2 - NV - Controller-ENDocument36 pages02 IRIS2 - NV - Controller-ENAhmedNo ratings yet

- Yaskawa L1000A Quick Start Guide TOEPC71061638Document204 pagesYaskawa L1000A Quick Start Guide TOEPC71061638younesNo ratings yet

- Plano Mikrolift Ml50sDocument61 pagesPlano Mikrolift Ml50sJavier MartínezNo ratings yet

- Gearless JSA07910E-AA BST BG201 Adjust Manual PDFDocument33 pagesGearless JSA07910E-AA BST BG201 Adjust Manual PDFHamza KefayahNo ratings yet

- ARES Escalator BDocument2 pagesARES Escalator BGutmonarchNo ratings yet

- System Diagram Ec3000a 5r5 011 4 (Ups Epm S)Document24 pagesSystem Diagram Ec3000a 5r5 011 4 (Ups Epm S)Tuân HoàngNo ratings yet

- HB As380 E20 PDFDocument70 pagesHB As380 E20 PDFjonathanNo ratings yet

- Manual Book Esc - Pillar PLC PDFDocument27 pagesManual Book Esc - Pillar PLC PDFWinNo ratings yet

- Escalator Control Panel MTCC-E1Document13 pagesEscalator Control Panel MTCC-E1yoen_anNo ratings yet

- Steel W Orks Products (Thailand) : Elevator Controller SystemDocument4 pagesSteel W Orks Products (Thailand) : Elevator Controller Systemtran xobonNo ratings yet

- CX/ELF Series Lift Control System: User ManualDocument26 pagesCX/ELF Series Lift Control System: User ManualMohamed Saad100% (1)

- A6000 Integrated Elevator Controller: QMA (Shanghai) Electric Co., LTDDocument197 pagesA6000 Integrated Elevator Controller: QMA (Shanghai) Electric Co., LTDJesús David Diaz MontesNo ratings yet

- Mitsuindo Jaya Teknik M3P1 Wering PDFDocument18 pagesMitsuindo Jaya Teknik M3P1 Wering PDFWinNo ratings yet

- Control panel layoutDocument9 pagesControl panel layoutpatoNo ratings yet

- Ahsmrw30dam SD101Document48 pagesAhsmrw30dam SD101ibrahimNo ratings yet

- 78 Fuji SanyoDocument4 pages78 Fuji SanyoBAAAK100% (2)

- Right choice for maximum yieldDocument223 pagesRight choice for maximum yieldRobert Mohovic100% (1)

- Inovance Monarch Nice3000 Elevator User Manual 7 enDocument184 pagesInovance Monarch Nice3000 Elevator User Manual 7 enMehedi HasanNo ratings yet

- Serial Control System ManualDocument232 pagesSerial Control System Manualrendy kurniawanNo ratings yet

- Description of Common Fault Codes For Fujitec CP28 Controller Elevator p2Document3 pagesDescription of Common Fault Codes For Fujitec CP28 Controller Elevator p2thanggimme.phanNo ratings yet

- MicroZed v35 CatalogDocument32 pagesMicroZed v35 CataloghabibullaNo ratings yet

- MCTC Ard C English 1Document11 pagesMCTC Ard C English 1Khaled ZakariaNo ratings yet

- NICE 1000 Elevator Integrated Controller User Manual PDFDocument172 pagesNICE 1000 Elevator Integrated Controller User Manual PDFMoh Aya100% (1)

- PU3200 English ManualDocument71 pagesPU3200 English Manualعلاء صقرNo ratings yet

- Ctrl70a V101 2019 3 15Document53 pagesCtrl70a V101 2019 3 15Ali DiabNo ratings yet

- Nice 9000Document91 pagesNice 9000Samuel AcevedoNo ratings yet

- CX User ManuelDocument26 pagesCX User ManuelSafi100% (2)

- Hotel Santika - Tmii 4LTDocument24 pagesHotel Santika - Tmii 4LTGogik AntoNo ratings yet

- DiSi (210) TroubleshootingDocument4 pagesDiSi (210) TroubleshootingFERNSNo ratings yet

- 05 - Test-Run in High SpeedDocument8 pages05 - Test-Run in High SpeedAndiosoNo ratings yet

- GSD SM Instruction Book PDFDocument15 pagesGSD SM Instruction Book PDFMitro100% (1)

- A NICE3000new 2018Document203 pagesA NICE3000new 2018Bahodur ToshevNo ratings yet

- 默纳克原理图KNWC-KZG插件板 - 英文 PDFDocument22 pages默纳克原理图KNWC-KZG插件板 - 英文 PDFMitroNo ratings yet

- IRIS1 NV (New) Spec Data SheetDocument3 pagesIRIS1 NV (New) Spec Data SheetJaydi ZambranoNo ratings yet

- Nice 3000Document98 pagesNice 3000NAIMUR RAHAMANNo ratings yet

- 01 SNP PCBs r0Document28 pages01 SNP PCBs r0Renee CarranzaNo ratings yet

- Jarless Con Door Drive - CompressDocument16 pagesJarless Con Door Drive - Compressexequiel cordobaNo ratings yet

- Manual Guide For Thysseen Door Controller IMS-DS20P2B1540370583512Document14 pagesManual Guide For Thysseen Door Controller IMS-DS20P2B1540370583512aziz faizNo ratings yet

- DOC-FE - IE.IN.014156.EN Fermator Programming ToolDocument13 pagesDOC-FE - IE.IN.014156.EN Fermator Programming Toolguturi satyanarayana murthyNo ratings yet

- Door Dive: User ManualDocument67 pagesDoor Dive: User ManualRoyal AkashNo ratings yet

- Elevador SWORD HAMCB Tipo OtisDocument41 pagesElevador SWORD HAMCB Tipo OtisRaul GutierrezNo ratings yet

- Wireless Door Lock System RegistrationDocument12 pagesWireless Door Lock System RegistrationChaim FriedNo ratings yet

- Always On Duty: The Automatic Emergency Lowering System That'SDocument2 pagesAlways On Duty: The Automatic Emergency Lowering System That'STroubleshootingNo ratings yet

- Codes of Practice for Fire Service InstallationsDocument187 pagesCodes of Practice for Fire Service Installationswholook275No ratings yet

- Sky AcDocument62 pagesSky AcTroubleshootingNo ratings yet

- NICE7000 DebuggingDocument4 pagesNICE7000 DebuggingTroubleshootingNo ratings yet

- fS1cV4Ar PDFDocument1 pagefS1cV4Ar PDFTroubleshootingNo ratings yet

- Application Note AN-LM2A-0005v120EN: Vector Control With Peripheral PG (Synchronous Motor)Document12 pagesApplication Note AN-LM2A-0005v120EN: Vector Control With Peripheral PG (Synchronous Motor)TroubleshootingNo ratings yet

- Inquiry Form: Floors/Stops/DoorsDocument1 pageInquiry Form: Floors/Stops/DoorsTroubleshootingNo ratings yet

- Lift Inverter Series L A: For Modernization and New InstallationDocument12 pagesLift Inverter Series L A: For Modernization and New InstallationTroubleshootingNo ratings yet

- Ard For Elevator: Model SOJI10 SOJI15 SOJI25 Using For Traction Machine 5.5kW 7.5-9kW 11-16kWDocument2 pagesArd For Elevator: Model SOJI10 SOJI15 SOJI25 Using For Traction Machine 5.5kW 7.5-9kW 11-16kWTroubleshootingNo ratings yet

- Major elevator and escalator brands: origins and notesDocument7 pagesMajor elevator and escalator brands: origins and notesTroubleshootingNo ratings yet

- Mitsubishi Elevator GPS-III Fault Code - A Water Logging - Netease BlogDocument7 pagesMitsubishi Elevator GPS-III Fault Code - A Water Logging - Netease BlogTroubleshootingNo ratings yet

- BL 2000 STB PDFDocument131 pagesBL 2000 STB PDFTroubleshooting100% (2)

- Usb To Serial Module.Document3 pagesUsb To Serial Module.TroubleshootingNo ratings yet

- Jalan KayoonDocument3 pagesJalan KayoonTroubleshootingNo ratings yet

- On-Site Common ProblemDocument9 pagesOn-Site Common ProblemTroubleshootingNo ratings yet

- Usb To Serial Module.Document3 pagesUsb To Serial Module.TroubleshootingNo ratings yet

- AC Dynamic Lowering Hoist Control: Scott35Document10 pagesAC Dynamic Lowering Hoist Control: Scott35TroubleshootingNo ratings yet

- 12VDC To 230VAC 60W Inverter CircuitDocument1 page12VDC To 230VAC 60W Inverter CircuitTroubleshootingNo ratings yet

- Chapter 5 GlossaryDocument4 pagesChapter 5 GlossaryTroubleshootingNo ratings yet

- 12VDC To 230VAC 60W Inverter CircuitDocument1 page12VDC To 230VAC 60W Inverter CircuitTroubleshootingNo ratings yet

- K10616 V01 35 00 English 111208 HK PDFDocument81 pagesK10616 V01 35 00 English 111208 HK PDFTroubleshootingNo ratings yet

- SIGMA S8 Quick Debugging GuideDocument14 pagesSIGMA S8 Quick Debugging GuideTroubleshootingNo ratings yet

- PDFDocument239 pagesPDFSodov Odbaatar80% (5)

- 128 Beams Elevator Light Curtain LDocument2 pages128 Beams Elevator Light Curtain LTroubleshootingNo ratings yet

- 2.0 User Manual Ipswiss Nr. 1011299Document35 pages2.0 User Manual Ipswiss Nr. 1011299TroubleshootingNo ratings yet

- 1 14 C011 SpecificationsDocument162 pages1 14 C011 SpecificationsTroubleshootingNo ratings yet

- 166Document12 pages166TroubleshootingNo ratings yet

- L-3/T-2/CE Date: 07/08/2016Document30 pagesL-3/T-2/CE Date: 07/08/2016নীল জোছনা0% (1)

- Maths IA IntroDocument20 pagesMaths IA Introshakthi aravinthNo ratings yet

- Data Sheet Monocristalino Chint Astronergy PDFDocument2 pagesData Sheet Monocristalino Chint Astronergy PDFPaulo SousaNo ratings yet

- Chapter - 3.2 - Finale Internal Forced ConvectionDocument18 pagesChapter - 3.2 - Finale Internal Forced ConvectioneirinaNo ratings yet

- EssayDocument5 pagesEssayRobert MariasiNo ratings yet

- How To Mathematics Organize Patterns in The World?Document3 pagesHow To Mathematics Organize Patterns in The World?johnmartin sabiliNo ratings yet

- I. Turek Et Al - Exchange Interactions, Spin Waves, and Transition Temperatures in Itinerant MagnetsDocument36 pagesI. Turek Et Al - Exchange Interactions, Spin Waves, and Transition Temperatures in Itinerant MagnetsTellusz4532No ratings yet

- Engineering Failure Analysis: Ayad Subhy, Davide Lo Presti, Gordon AireyDocument11 pagesEngineering Failure Analysis: Ayad Subhy, Davide Lo Presti, Gordon AireyMohamed BoudabbousNo ratings yet

- Filter Vessel Calculations Per As Me Viii 1Document40 pagesFilter Vessel Calculations Per As Me Viii 1Anonymous J1vjrU2No ratings yet

- Master1 AM CoursesDocument3 pagesMaster1 AM CoursesParokotil MidhunNo ratings yet

- Molykote Greases For Subsea ApplicationsDocument1 pageMolykote Greases For Subsea ApplicationsProject Sales CorpNo ratings yet

- Radar Systems Range Equation PDFDocument6 pagesRadar Systems Range Equation PDFSanjid ElahiNo ratings yet

- STAAD Service Stage and Seismic Analysis ResultsDocument14 pagesSTAAD Service Stage and Seismic Analysis ResultsVikasNo ratings yet

- BEYOND SYLLABUS: CURVED, COMPOSITE, UNSYMMETRICAL BEAMSDocument11 pagesBEYOND SYLLABUS: CURVED, COMPOSITE, UNSYMMETRICAL BEAMSVignesh VickyNo ratings yet

- Zetex HandbookDocument8 pagesZetex HandbookbolermNo ratings yet

- Slope ND DeflectionDocument19 pagesSlope ND DeflectionprashantbaraskarNo ratings yet

- Maxwell Stress Tensor ExplainedDocument6 pagesMaxwell Stress Tensor ExplainedSyeda Tehreem IqbalNo ratings yet

- Resistivity and Saturation in ShalesDocument6 pagesResistivity and Saturation in ShalesAngelMesoNo ratings yet

- Evaluation of Structural Efficiency of Steel Diagrid Systems For Multi-Storey BuildingsDocument4 pagesEvaluation of Structural Efficiency of Steel Diagrid Systems For Multi-Storey BuildingsPrateek ModyNo ratings yet

- Thesis MainDocument144 pagesThesis MainIvan GrkajacNo ratings yet

- Composite Beams & Columns To Eurocode 4Document155 pagesComposite Beams & Columns To Eurocode 4dfdfdfasd324sad100% (2)

- Adjoint Rans With Filtered Shape Derivatives For Hydrodynamic OptimisationDocument11 pagesAdjoint Rans With Filtered Shape Derivatives For Hydrodynamic Optimisationvolo87No ratings yet

- 08 Energy 03 Complementary Strain Energy PDFDocument2 pages08 Energy 03 Complementary Strain Energy PDFjack_hero_56No ratings yet

- Antimicrobial Properties of Silver NanoparticlesDocument37 pagesAntimicrobial Properties of Silver NanoparticlesbasavarajitnalNo ratings yet

- Performance-Based Plastic Design and Energy-Based Evaluation of Seismic Resistant RC Moment FrameDocument7 pagesPerformance-Based Plastic Design and Energy-Based Evaluation of Seismic Resistant RC Moment FrameARJafariNo ratings yet

- Literature SurveyDocument6 pagesLiterature SurveyAnonymous j0aO95fgNo ratings yet