Professional Documents

Culture Documents

Lincolnweld 888 & LA-85

Uploaded by

Pablo PazCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lincolnweld 888 & LA-85

Uploaded by

Pablo PazCopyright:

Available Formats

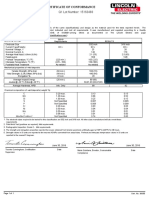

The Lincoln Electric Company

22801 St. Clair Avenue

CERTIFICATE OF CONFORMANCE

Cleveland, Ohio 44117-1199 (APPLIES ONLY TO U.S. PRODUCTS)

Product: Lincolnweld® 888™ Flux / [1Year]

Lincolnweld® LA-85 (LNS 165) Electrode

Classification: F8A6-ENi5-Ni5-H4

Specification: AWS A5.23:2011, ASME SFA-5.23

Date December 04, 2014

This is to certify that the product named above and supplied on the referenced order number is of the same classification, manufacturing process, and material

requirements as the material which was used for the test that was concluded on the date shown, the results of which are shown below. All tests required by the

specifications shown for classification were performed at that time and the material tested met all requirements. It was manufactured and supplied according to

the Quality System Program of the Lincoln Electric Company, Cleveland, Ohio, U.S.A., which meets the requirements of ISO9001, NCA3800, AWS A5.01, and

other specification and Military requirements, as applicable. The Quality System Program has been approved by ASME, ABS, and VdTUV.

F8A6-ENi5-Ni5-H4

Operating Settings Requirements RESULTS

Electrode Size 241in

5/32 5/321inch

Polarity DC+

Voltage, V 27 - 30 28

Wire Feed Speed, cm/min (in/min) 107 (42)

Current, A 475 - 575 525

Contact Tip to Work Distance, mm (in) (1 - 1.5) 32 (1.25)

Travel Speed, cm/min (in/min) (15 - 17) 41 (16)

Pass/Layers 19/9

Preheat Temperature, °C (°F) (275 - 325) 150 (300)

Interpass Temperature, °C (°F) (275 - 325) 150 (300)

Postweld Heat Treatment As-welded As-welded

Mechanical properties of weld deposits

Tensile Strength, MPa (ksi) (80 - 100) 610 (89)

Yield Strength, 0.2% Offset, MPa (ksi) (68 min.) 520 (75)

Elongation % 20 min. 27

Average Impact Energy (20 min.) 82 (61)

Joules @ -51 °C (ft-lbs @ -60 °F) 69,82,96 (51,60,71)

Average Hardness, HRB Not Required 93

Chemical composition of weld deposits (weight %)

C 0.12 max. 0.06

Mn 1.60 max. 1.44

Si 0.80 max. 0.44

S 0.025 max. 0.002

P 0.030 max. 0.010

Ni 0.70 - 1.10 0.85

Mo 0.10 - 0.35 0.20

Cu 0.35 max. 0.10

B Not Required 0.004

Electrode composition (weight %) F8A6-ENi5-Ni5-H4 Electrode

Requirements Results

C 241 0.12 max. 1 0.08

Mn 1.20 - 1.60 1.39

Si 0.05 - 0.30 0.23

S 0.020 max. 0.002

P 0.020 max. 0.008

Ni 0.75 - 1.25 0.95

Mo 0.10 - 0.30 0.22

Total Cu 0.35 max. 0.11

B Not Required 0.000

F8A6-ENi5-Ni5-H4

Diffusible Hydrogen (per AWS A4.3) Requirements RESULTS

Electrode Size 241 1 5/32 inch

Polarity DC+

Diffusible Hydrogen, mL/100g 4 max. 3

Absolute Humidity (grains moisture/lb dry air) 63

1. This certificate complies with the requirements of EN 10204, Type 2.2.

2. The electrode size required to be tested for this classification is 5/32 inch. All other sizes manufactured will also meet these requirements.

3. Test assembly constructed of ASTM A537 steel.

4. Radiographic Inspection: Met requirements.

5. Results below the detection limits of the instrument or lower than the precision required by the specification are reported as zero. Strength values in SI

units are reported to the nearest 10 MPa converted from actual data. Preheat and interpass temperature values in SI units are reported to the nearest

5 degrees.

Page 1 of 2 Cert. No. 58860

The Lincoln Electric Company

22801 St. Clair Avenue

CERTIFICATE OF CONFORMANCE

Cleveland, Ohio 44117-1199 (APPLIES ONLY TO U.S. PRODUCTS)

Product: Lincolnweld® 888™ Flux / [1Year]

Lincolnweld® LA-85 (LNS 165) Electrode

Classification: F8A6-ENi5-Ni5-H4

Specification: AWS A5.23:2011, ASME SFA-5.23

Date December 04, 2014

December 04, 2014 December 04, 2014

Toronto Cunningham, Certification Supervisor Date Dave Fink, Manager, Compliance Date

Engineering, Consumable R&D

Page 2 of 2 Cert. No. 58860

You might also like

- Non-Metallic Materials - Selection and ApplicationDocument53 pagesNon-Metallic Materials - Selection and ApplicationKUMAR100% (1)

- Dep 30.10.60.32 - Welding of Metals, Based On Iso StandardsDocument76 pagesDep 30.10.60.32 - Welding of Metals, Based On Iso StandardsPablo PazNo ratings yet

- Plates Steel MetalDocument12 pagesPlates Steel MetalAnonymous aWpx7nENo ratings yet

- Prepare and Interpret Technical DrawingDocument5 pagesPrepare and Interpret Technical DrawingDwin Rosco75% (4)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Refinery TankagesDocument4 pagesRefinery Tankagesmayuresh1101100% (1)

- Offer of Appointment Contract LetterDocument4 pagesOffer of Appointment Contract LetterPablo PazNo ratings yet

- BS 3059-2Document11 pagesBS 3059-2abhiNo ratings yet

- Excalibur 11018M MR CertDocument2 pagesExcalibur 11018M MR CertAminNo ratings yet

- Certificate of Conformance: Q1 Lot Number: 15163483Document1 pageCertificate of Conformance: Q1 Lot Number: 15163483interx00No ratings yet

- L-50 Lincolnweld 980Document1 pageL-50 Lincolnweld 980geloram66No ratings yet

- 1 - Primacore LW71 1.2 E208038900Document1 page1 - Primacore LW71 1.2 E208038900Suli HartoNo ratings yet

- Q1 DisplayDocument1 pageQ1 DisplayOscar BasantesNo ratings yet

- Pipeliner® NR®-208-XP: (Applies Only To U.S. Products)Document2 pagesPipeliner® NR®-208-XP: (Applies Only To U.S. Products)Pablo PazNo ratings yet

- Lincoln (Data Sheet) Murex E7024Document2 pagesLincoln (Data Sheet) Murex E7024PubcrawlNo ratings yet

- Q1 Lot Number: 14997588: Certificate of ConformanceDocument3 pagesQ1 Lot Number: 14997588: Certificate of ConformanceOscar BasantesNo ratings yet

- Certificate of ConformanceDocument1 pageCertificate of ConformanceedwinNo ratings yet

- Q1 Lot Number: 15888757: Certificate of ConformanceDocument2 pagesQ1 Lot Number: 15888757: Certificate of ConformanceDesdeAquiHastaAllaNo ratings yet

- Certificado Lote Er70s-6Document1 pageCertificado Lote Er70s-6willariasNo ratings yet

- Hobart 9LDocument1 pageHobart 9LFelipe montanaNo ratings yet

- Q1Display 15843280Document3 pagesQ1Display 15843280Oscar BasantesNo ratings yet

- Chemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRDocument2 pagesChemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRQuality teamNo ratings yet

- Chemical Composition Raw Material Grade: Ref - No JSPL/ANGUL/TDC-003493C Rev. 1 Date of Issue 11/11/2022Document3 pagesChemical Composition Raw Material Grade: Ref - No JSPL/ANGUL/TDC-003493C Rev. 1 Date of Issue 11/11/2022MAHESH BELENo ratings yet

- CertMaterialTestReport E6010 Fletweld SP 1-8Document1 pageCertMaterialTestReport E6010 Fletweld SP 1-8gerosuca800No ratings yet

- Pipeliner 7P+: Conformances Key FeaturesDocument2 pagesPipeliner 7P+: Conformances Key FeaturesAnand GNo ratings yet

- Böhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileDocument1 pageBöhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileRaviTeja BhamidiNo ratings yet

- DatasheetDocument2 pagesDatasheetStuxnetNo ratings yet

- TPS Series: Low EsrDocument13 pagesTPS Series: Low EsrJoão Paulo Lucas BarbosaNo ratings yet

- Surface-Mount Fuses: 2410 Very Fast-Acting Chip FusesDocument4 pagesSurface-Mount Fuses: 2410 Very Fast-Acting Chip Fusesreza yousefiNo ratings yet

- DatasheetDocument2 pagesDatasheetStuxnetNo ratings yet

- Ficha Tecnica Esab Electrodos EspecialesDocument1 pageFicha Tecnica Esab Electrodos EspecialesStanley RamirezNo ratings yet

- Data - Sheet 2H Grade 50Document3 pagesData - Sheet 2H Grade 50sagitroseNo ratings yet

- Ultracore 360 C71: Conformances Key FeaturesDocument3 pagesUltracore 360 C71: Conformances Key FeaturesYousab CreatorNo ratings yet

- Technical Data: 02014W104KATDocument9 pagesTechnical Data: 02014W104KATndfgdfs oishdfNo ratings yet

- Diodo SS110-A PDFDocument5 pagesDiodo SS110-A PDFcamiloNo ratings yet

- CDBC520-G Thru936922. CDBC5100-G RevC-268425Document5 pagesCDBC520-G Thru936922. CDBC5100-G RevC-268425georgerouseNo ratings yet

- Certificado Pipeliner 6P+Document2 pagesCertificado Pipeliner 6P+Eric RamirezNo ratings yet

- Capacitor PanasonicDocument6 pagesCapacitor PanasonicdenisharkNo ratings yet

- Catalogue - 71-T8 (Rev06)Document7 pagesCatalogue - 71-T8 (Rev06)Suntech Testing Limited STLNo ratings yet

- K24 SchottkyDocument3 pagesK24 SchottkyLeon MartinezNo ratings yet

- 04042016000000A Avesta 2205 Covered ElectrodesDocument1 page04042016000000A Avesta 2205 Covered Electrodesmeckup123No ratings yet

- Capacitor ELEDocument2 pagesCapacitor ELEJhoscky L. DuttiNo ratings yet

- Supercored 71H technical data sheetDocument9 pagesSupercored 71H technical data sheetPongwitt BoonayamaneeNo ratings yet

- Lasdraad HTS 70 PRIORDocument1 pageLasdraad HTS 70 PRIORCem DufourNo ratings yet

- Applicable Standards: ASTM A792 ASTM A792 EN10215Document14 pagesApplicable Standards: ASTM A792 ASTM A792 EN10215ersinNo ratings yet

- Material Data Sheet Thermally Broken Steel USADocument2 pagesMaterial Data Sheet Thermally Broken Steel USAYungfang HuangNo ratings yet

- DC 01Document1 pageDC 01sobheysaidNo ratings yet

- Data Sheet API 2W Grade 50 2017Document2 pagesData Sheet API 2W Grade 50 2017Tiến Bách PhạmNo ratings yet

- Technical Specifications - Pipes API 5L X65 PSL 2Document2 pagesTechnical Specifications - Pipes API 5L X65 PSL 2isan.structural TjsvgalavanNo ratings yet

- C10200 (Cu-OF) : ) Incl. AgDocument2 pagesC10200 (Cu-OF) : ) Incl. AgJosue Crespo GonzalezNo ratings yet

- Test Device: Excitation CurveDocument2 pagesTest Device: Excitation CurveNagaraj VjNo ratings yet

- ENiFe CIDocument1 pageENiFe CIakashmalayiNo ratings yet

- A064-0S-000159 2n7002W PANJITDocument7 pagesA064-0S-000159 2n7002W PANJITChiapin LeeNo ratings yet

- B - Boehler EMK 6 - de - en - 5 PDFDocument1 pageB - Boehler EMK 6 - de - en - 5 PDFburakNo ratings yet

- NIC Components NRLRW SeriesDocument11 pagesNIC Components NRLRW SeriesNICCompNo ratings yet

- Resistencias SMD WIN-1524917Document4 pagesResistencias SMD WIN-1524917Ignacio Barriga NuñezNo ratings yet

- SC-71MSR Flux Cored Wire Spec SheetDocument7 pagesSC-71MSR Flux Cored Wire Spec SheetRaviTeja BhamidiNo ratings yet

- Switching Diode: 1N4148 / 1N4150 / 1N4448 / 1N914BDocument2 pagesSwitching Diode: 1N4148 / 1N4150 / 1N4448 / 1N914BEmilio GarcíaNo ratings yet

- 1%Ni Low Alloy Steel for Improved ToughnessDocument4 pages1%Ni Low Alloy Steel for Improved Toughnessmohamed AdelNo ratings yet

- Test Device: Excitation CurveDocument2 pagesTest Device: Excitation Curveidhaya vickyNo ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- Chinese Steel Material ManualDocument41 pagesChinese Steel Material Manualuday RaviNo ratings yet

- Product Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument2 pagesProduct Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB Swedentungau87No ratings yet

- BOHLER E 71T-1C/1M: GMAW Rutile Flux Cored WireDocument2 pagesBOHLER E 71T-1C/1M: GMAW Rutile Flux Cored WirebrayanNo ratings yet

- NIC Components NRLM SeriesDocument5 pagesNIC Components NRLM SeriesNICCompNo ratings yet

- Dep 30.10.02.17 - Wet H2S Requirements For DownstreamDocument24 pagesDep 30.10.02.17 - Wet H2S Requirements For DownstreamPablo PazNo ratings yet

- Registering For PING ID On A Mobile PhoneDocument4 pagesRegistering For PING ID On A Mobile PhonePablo PazNo ratings yet

- Catalogo General RaychemDocument6 pagesCatalogo General RaychemPablo PazNo ratings yet

- API 510 Exam Publications Effectivity Sheet - : May and September 2016 and January 2017Document1 pageAPI 510 Exam Publications Effectivity Sheet - : May and September 2016 and January 2017mohamedeldeeb88No ratings yet

- KPP-Polly Pigs-P1-02Document1 pageKPP-Polly Pigs-P1-02Pablo PazNo ratings yet

- Registering For PING ID On A DesktopDocument6 pagesRegistering For PING ID On A DesktopPablo PazNo ratings yet

- API 510 Exam Publications Effectivity Sheet - : September 2019 and January 2020Document1 pageAPI 510 Exam Publications Effectivity Sheet - : September 2019 and January 2020Inspection EngineerNo ratings yet

- Pipeliner® NR®-208-XP: (Applies Only To U.S. Products)Document2 pagesPipeliner® NR®-208-XP: (Applies Only To U.S. Products)Pablo PazNo ratings yet

- API 510, 570 and 653 exam tutorial guideDocument25 pagesAPI 510, 570 and 653 exam tutorial guideEswaran100% (1)

- Pipeliner 80S-GDocument1 pagePipeliner 80S-GPablo PazNo ratings yet

- Pipeliner® NR®-208-XP: (Applies Only To U.S. Products)Document2 pagesPipeliner® NR®-208-XP: (Applies Only To U.S. Products)Pablo PazNo ratings yet

- Pipeliner 16PDocument2 pagesPipeliner 16PPablo PazNo ratings yet

- Pipeliner 70S-GDocument1 pagePipeliner 70S-GPablo PazNo ratings yet

- Pipeliner 17PDocument1 pagePipeliner 17PPablo PazNo ratings yet

- c550 PDFDocument54 pagesc550 PDFSamiYousifNo ratings yet

- It's Annie's 1st Birthday PDFDocument1 pageIt's Annie's 1st Birthday PDFPablo PazNo ratings yet

- Pipeliner® NR®-208-XP: (Applies Only To U.S. Products)Document2 pagesPipeliner® NR®-208-XP: (Applies Only To U.S. Products)Pablo PazNo ratings yet

- 600ti PDFDocument3 pages600ti PDFPablo PazNo ratings yet

- ALE Between Two SAP SystemsDocument24 pagesALE Between Two SAP Systemsraghava nimmala100% (1)

- Guaranteed Restore Points Oracle 11g - Flash Back to SCN or RP (39Document2 pagesGuaranteed Restore Points Oracle 11g - Flash Back to SCN or RP (39PraveenNo ratings yet

- Podar International School Chinchwad STD Xi - (I Unit Test) Subject: Computer Science Date: 8-9-2020 Marks: 40Document3 pagesPodar International School Chinchwad STD Xi - (I Unit Test) Subject: Computer Science Date: 8-9-2020 Marks: 40Shriniwas KulkarniNo ratings yet

- SteganographyDocument13 pagesSteganographyIgloo JainNo ratings yet

- UMTS Chap6Document33 pagesUMTS Chap6NguyenDucTaiNo ratings yet

- Truth Without ObjectivityDocument4 pagesTruth Without ObjectivityMetafisco Parapensante0% (1)

- PEA ClocksDocument50 pagesPEA ClocksSuresh Reddy PolinatiNo ratings yet

- Kidney AnatomyDocument55 pagesKidney AnatomyMohammad zreadNo ratings yet

- Full Paper Template IRC 2020Document3 pagesFull Paper Template IRC 2020Mobina AbdulRaufNo ratings yet

- Hargreaves 2007Document15 pagesHargreaves 2007Sam GonçalvesNo ratings yet

- It Tigear2Document2 pagesIt Tigear2rrobles011No ratings yet

- Sensitive Albuminuria Analysis Using Dye-Binding Based Test StripsDocument24 pagesSensitive Albuminuria Analysis Using Dye-Binding Based Test StripsВалерия БедоеваNo ratings yet

- Physics Assignment 1Document4 pagesPhysics Assignment 1Trí Võ PhạmNo ratings yet

- Si™ Command Language (SCL) Software Manual: For 1240I 3540I 7080I Bl7080I Blsi7080 Si-100 Si2035 Si3540 Si5580Document23 pagesSi™ Command Language (SCL) Software Manual: For 1240I 3540I 7080I Bl7080I Blsi7080 Si-100 Si2035 Si3540 Si5580Agenor CarvalhoNo ratings yet

- Nextion InstructionDocument53 pagesNextion InstructionMacp63 cpNo ratings yet

- CFG Grammar: Context Free Grammar BasicsDocument34 pagesCFG Grammar: Context Free Grammar BasicsEd MolloNo ratings yet

- OMC 140 Operator Manual v1.08Document38 pagesOMC 140 Operator Manual v1.08Anderson DuarteNo ratings yet

- Thinsat®300 Installation and User'S Manual: Thinkom Solutions, IncDocument39 pagesThinsat®300 Installation and User'S Manual: Thinkom Solutions, IncHiep Mai Van100% (1)

- Auditing The Usage of Therapeutic Footwear in Diabetic Foot Patients Through Amit Jain's Extended SCC' Classification For Therapeutic FootwearDocument6 pagesAuditing The Usage of Therapeutic Footwear in Diabetic Foot Patients Through Amit Jain's Extended SCC' Classification For Therapeutic FootwearJosé MorenoNo ratings yet

- Linux OS LabDocument2 pagesLinux OS LabSubaNo ratings yet

- Introduction To Business Statistics: ProbabilityDocument2 pagesIntroduction To Business Statistics: ProbabilityNghĩa PhùngNo ratings yet

- Energy Criteria in GRIHA PDFDocument71 pagesEnergy Criteria in GRIHA PDFAnisha Prakash100% (1)

- Kollidon 30 Technical InformationDocument10 pagesKollidon 30 Technical InformationhomarearisugawaNo ratings yet

- Grade 6 Term1 Properties of 2-D Shapes Lesson 7Document4 pagesGrade 6 Term1 Properties of 2-D Shapes Lesson 7Ayanda Siphesihle NdlovuNo ratings yet

- Computational Intelligence in Communications and Business AnalyticsDocument369 pagesComputational Intelligence in Communications and Business AnalyticsSourasish NathNo ratings yet

- Activity No. 5 Capacitive Circuit ObjectivesDocument4 pagesActivity No. 5 Capacitive Circuit ObjectivesJohn Paul BaquiranNo ratings yet

- State Standards: Common CoreDocument24 pagesState Standards: Common CoreEddy R. VélezNo ratings yet

- CC5291-Design For Manufacture Assembly and Environments QBDocument11 pagesCC5291-Design For Manufacture Assembly and Environments QBYuvaraj Yuvi0% (1)