Professional Documents

Culture Documents

Welding Procedure Specification (WPS) Welding Procedure Specification No Supporting PQR Welding Process Preheat Applicable Code

Uploaded by

anon_499770Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specification (WPS) Welding Procedure Specification No Supporting PQR Welding Process Preheat Applicable Code

Uploaded by

anon_499770Copyright:

Available Formats

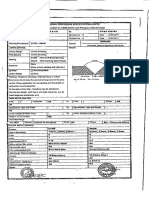

WELDING PROCEDURE SPECIFICATION ( WPS ) APPLICABLE CODE

AWS-D 1.1

REVISION 0

WELDING PROCEDURE SPECIFICATION NO MISCO -WPS-SM-11-0

SUPPORTING PQR PREQUALIFICATION PAGE 1 OF 1

SEMI

WELDING PROCESS SMAW TYPE MANUAL

AUTOMATIC

AUTOMATIC

JOINT DESIGN PREHEAT

PREQUALIFIED PREHEAT TEMPERATURE ( min ) 20 ◦C

( REFER TO FIG 3.3 TO FIG 3.11 OF

AWS D 1.1 ) INTERPASS TEMPERATURE ( max ) 225 ◦C

PREHEAT MAINTENANCE NONE

OTHRES N/A

POST WELD HEAT TREATMENT

TEMPERATURE RANGE N/A

TIME RANGE N/A

OTHER N/A

TECHNIQUE

ORIFICE TO GAS CUP DISTANCE N /A

BASE METAL CONTACT TUBE TO WORK DISTANCE N /A

BASE METAL SPECIFICATION OSCILLATION N /A

A36 GROUP P1 SRINGER √

WEAVE √

METHOD OF CLEANING

FILLER METAL BRUSHING √

AWS SPECIFICATION A 5.1 GRINDING √

AWS CLASSIFICATION E 7018 OTHER VARIABLE

SIZE ( IN MM ) 2.5 , 3.2 , 4.0 NUMBER OF ELECTRODES SINGLE

POSITION METHOD OF BACKGOUGING GRINDING

REF FIG 3.3 SINGLE OR MULTIPASS MULTIPLE

POSITION OF GROOVE & FILLET

TO FIG 3.11 PEENING N /A

PROGRESSION UPHILL GAS SHIELDING

FILLER / ELECTRODE CHARACTERISTICS CLASSIFICATION GAS FLOW RATE

METAL TRANSFER MODE N /A SHIELDING N /A N /A

TUNGSTEN ELECTRODE TYPE N /A BACKING N /A N /A

FLUX TYPE N /A TRAILING N /A N /A

LAYER NO PROCESS F- NO FILLER METAL ELECT CURRENT / VOLT TRAVEL SPEED ( HEAT INPUT (

SIZE POLARITY RANGE cm/min ) kj /cm )

Root SMAW 4 E7018 2.5 DCRP 80-120 6 to 10 ………

Hot SMAW 4 E7018 3.2 DCRP 90-130 6 to 20 ………

FILL SMAW 4 E7018 3.2 DCRP 90-130 6 to 20 ………

Remaining SMAW 4 E7018 4 DCRP 140-180 8 to 20 ……….

REV PREPARED BY REVIEWED BY APPROVED BY

DINESH SOMWANSHI DINESH SOMWANSHI

WELDING INSPECTOR WELDING INSPECTOR

0

0

WELDING PROCEDURE SPECIFICATION ( WPS ) APPLICABLE CODE

AWS-D 1.1

REVISION 0

WELDING PROCEDURE SPECIFICATION NO MISCO -WPS-FC-11-0

SUPPORTING PQR PREQUALIFICATION PAGE 1 OF 1

SEMI

WELDING PROCESS FCAW-GS TYPE MANUAL

AUTOMATIC

AUTOMATIC

JOINT DESIGN PREHEAT

PREQUALIFIED ( PREHEAT TEMPERATURE ( min ) 20 ◦C

REFER TO FIG 3.3 TO FIG 3.11 OF AWS D 1.1 )

INTERPASS TEMPERATURE ( max ) 225 ◦C

PREHEAT MAINTENANCE NONE

OTHRES N/A

POST WELD HEAT TREATMENT

TEMPERATURE RANGE N/A

TIME RANGE N/A

OTHER N/A

TECHNIQUE

ORIFICE TO GAS CUP SIZE 20mm-22 mm

BASE METAL CONTACT TUBE TO WORK DISTANCE 12-16 mm

BASE METAL SPECIFICATION OSCILLATION N /A

A36 GROUP P1 SRINGER √

WEAVE √

METHOD OF CLEANING

FILLER METAL BRUSHING √

AWS SPECIFICATION A 5.20 GRINDING √

AWS CLASSIFICATION E 71T-C OTHER VARIABLE

SIZE ( IN MM ) 0.8 , 1.2 NUMBER OF ELECTRODES SINGLE

POSITION METHOD OF BACKGOUGING GRINDING

SINGLE OR MULTIPASS ( PASS PER SIDE ) MULTIPLE

POSITION OF GROOVE & FILLET REF FIG 3.3 TO FIG

3.11 PEENING N /A

PROGRESSION UPHILL GAS SHIELDING

FILLER / ELECTRODE CHARACTERISTICS CLASSIFICATION GAS FLOW RATE

METAL TRANSFER MODE N /A SHIELDING CO-2 16-20 lpm

TUNGSTEN ELECTRODE TYPE N /A BACKING N /A N /A

FLUX TYPE N /A TRAILING N /A N /A

ELECT FILLER WIRE VOLTAGE CURRENT / AMPS TRAVEL SPEED ( OSCILLATION

LAYER NO PROCESS SPEED

SIZE METAL (cm/min) RANGE POLARITY RANGE cm/min ) WIDTH (mm)

Root FCAW-GS 1.2 E 71T-C 4.5 - 7.0 24-27 DCRP 180-220 14 to 40 STRING

Hot Pass FCAW-GS 1.2 E 71T-C 4.5 - 7.7 24-27 DCRP 185-220 13 TO 30 3.5 -5

Filling FCAW-GS 1.2 E 71T-C 4.5 - 8.5 24-27 DCRP 185-230 13 TO 30 12 max

Caping FCAW-GS 1.2 E 71T-C 4.5 - 8.5 24-27 DCRP 190-230 15 TO 40 12 max

REV PREPARED BY REVIEWED BY APPROVED BY

DINESH SOMWANSHI DINESH SOMWANSHI

WELDING INSPECTOR WELDING INSPECTOR

0

0

You might also like

- Smaw PQR FinalDocument3 pagesSmaw PQR Finalsheikmoin100% (1)

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- Fit Up Welding Visual Inspection ReportDocument2 pagesFit Up Welding Visual Inspection Reportgst ajah100% (1)

- Quality Plan For Vessel Structural ModificationDocument9 pagesQuality Plan For Vessel Structural ModificationEbuka NwankwoNo ratings yet

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- QA-R-04 - Visual Inspection ReportDocument1 pageQA-R-04 - Visual Inspection ReportvinothNo ratings yet

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Welder ID Card BRE KarahaDocument5 pagesWelder ID Card BRE KarahaHerruSetiawan100% (1)

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- Blasting & Painting Inspection Report Format For Bottom Plate 01Document7 pagesBlasting & Painting Inspection Report Format For Bottom Plate 01ABEC Trombay siteNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 01 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 01 DateAmjad PathanNo ratings yet

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinNo ratings yet

- Asme Sec Ix, Wps-Welding Variables and Data (Smaw-Saw-Gtaw)Document7 pagesAsme Sec Ix, Wps-Welding Variables and Data (Smaw-Saw-Gtaw)Saran Kumar100% (1)

- Dokumen - Tips Wqt-FormatDocument2 pagesDokumen - Tips Wqt-FormatMr Pie100% (1)

- P91 ProfileDocument6 pagesP91 ProfilesrinivasanNo ratings yet

- WPS PQR-05Document10 pagesWPS PQR-05Ranjan KumarNo ratings yet

- Welding Report For Tank 1Document1 pageWelding Report For Tank 1Rifki HasyaNo ratings yet

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoNo ratings yet

- Welder Diameter Limitation ASME SEC IXDocument1 pageWelder Diameter Limitation ASME SEC IXkumarNo ratings yet

- Welding Procedure Welding Procedure Specification SpecificationDocument2 pagesWelding Procedure Welding Procedure Specification SpecificationHamid MansouriNo ratings yet

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- Circularity Inspection Report: Shell Course (LW) CW CWDocument14 pagesCircularity Inspection Report: Shell Course (LW) CW CWaszlizaNo ratings yet

- Welding Procedure Specification (WPS) : in The Outer TubeDocument1 pageWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaNo ratings yet

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- Asme WPS Demo PWHT PDFDocument3 pagesAsme WPS Demo PWHT PDFGanesh rohitNo ratings yet

- Weld Repair Rate - MFJO542Document2 pagesWeld Repair Rate - MFJO542Salahuddin Farooqui100% (1)

- Mechanical Test 1Document21 pagesMechanical Test 1Manoranjan sharmaNo ratings yet

- Asme Ix 2013 PTDocument1 pageAsme Ix 2013 PTRonel John Rodriguez CustodioNo ratings yet

- WPS Format For Asme Ix - Wps - Fcaw GmawDocument1 pageWPS Format For Asme Ix - Wps - Fcaw GmawThe Welding Inspections CommunityNo ratings yet

- ASME IX - How To Prepare A WPS! - Shipbuilding KnowledgeDocument3 pagesASME IX - How To Prepare A WPS! - Shipbuilding KnowledgeRamakrishnan AmbiSubbiahNo ratings yet

- TopCoreBelco 101 FCDocument9 pagesTopCoreBelco 101 FCCesar ArellanoNo ratings yet

- PQR Is7307Document1 pagePQR Is7307Tridib Dey100% (1)

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFDocument11 pagesEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaNo ratings yet

- AWS Classification System SAWDocument5 pagesAWS Classification System SAWperungguNo ratings yet

- Wps 7018 SmawDocument1 pageWps 7018 SmawErick VazquezNo ratings yet

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocument9 pages2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanNo ratings yet

- NSH-DALM-JERP-WPS-11-P2 Rev.00Document10 pagesNSH-DALM-JERP-WPS-11-P2 Rev.00Alam MD SazidNo ratings yet

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- D T LabDocument30 pagesD T LabMahmoud Alwasif100% (1)

- Acceptable Grade of Plate Material (API 650)Document1 pageAcceptable Grade of Plate Material (API 650)juantamad02No ratings yet

- Qap 8000ce Reactor - Repat - 1Document2 pagesQap 8000ce Reactor - Repat - 1AliasgarNo ratings yet

- Test Pack Clearance FormatDocument2 pagesTest Pack Clearance FormatKarthikNo ratings yet

- Process Piping Inspection and Test PlanDocument6 pagesProcess Piping Inspection and Test Planmanoj thakkarNo ratings yet

- Magnetic Particle Testing ReporDocument2 pagesMagnetic Particle Testing ReporGabriela MotaNo ratings yet

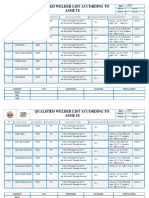

- Qualified Welder List According To Asme IxDocument5 pagesQualified Welder List According To Asme IxAhmad Nabil ElsharkawyNo ratings yet

- WPS FGPDocument1 pageWPS FGPShabbir HussainNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- 16 - SGU - RT - ASME - 16 - Radiographic - REV - 00Document53 pages16 - SGU - RT - ASME - 16 - Radiographic - REV - 00pankrasius herbudiNo ratings yet

- WPS Api 1104Document3 pagesWPS Api 1104miguelNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- Gtaw 106Document2 pagesGtaw 106ganeshkumarg_1No ratings yet

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- GMCo - WPSDocument8 pagesGMCo - WPSMohamed AtefNo ratings yet

- IRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Document4 pagesIRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Mostafizur RahmanNo ratings yet

- WPS PQR XLSXDocument4 pagesWPS PQR XLSXMd Sahabul IslamNo ratings yet

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (1)

- Unit 2Document16 pagesUnit 2danishmaniNo ratings yet

- 4687 - Carrier 30 GF 120Document36 pages4687 - Carrier 30 GF 120ชัยณรงค์ เทียนบุตรNo ratings yet

- Data Sheet Batería 3.7 VoltiosDocument1 pageData Sheet Batería 3.7 VoltiosEdisonMartinezNo ratings yet

- BCS Italia SRLDocument9 pagesBCS Italia SRLIsaac LopbenNo ratings yet

- Optim of APDDocument9 pagesOptim of APDAyaz AhmadNo ratings yet

- KB Electronics KBPC 240d Manual de UsuarioDocument21 pagesKB Electronics KBPC 240d Manual de UsuarioAndrés Gregorio de las Heras YanzonNo ratings yet

- Electromagnetic FormingDocument8 pagesElectromagnetic Formingxcvs40No ratings yet

- Assignment On Conductors and InsulatorsDocument16 pagesAssignment On Conductors and Insulatorsaliasad aliasad100% (1)

- Media Communications: Test Booklet Electrical Engineering Paper IiDocument20 pagesMedia Communications: Test Booklet Electrical Engineering Paper IiRaghuNo ratings yet

- 3 Phase Power GenerationDocument9 pages3 Phase Power Generationjaythakar8887No ratings yet

- Kafd Systra PHB Te All LST 4020 A1 Master Vol 2 Part 2 EpcoDocument496 pagesKafd Systra PHB Te All LST 4020 A1 Master Vol 2 Part 2 EpcoJuan Dela CruzNo ratings yet

- Automated Solar Powered Pumping Systems For IrrigationDocument10 pagesAutomated Solar Powered Pumping Systems For IrrigationfarizalNo ratings yet

- User Manual For Flexible Solar Panel 2021Document3 pagesUser Manual For Flexible Solar Panel 2021DaNo ratings yet

- Basic Sentence PatternsDocument21 pagesBasic Sentence PatternsSarah NasihahNo ratings yet

- Ca3086 3Document1 pageCa3086 3EDWIN NICOLAS SILVA FERNANDEZNo ratings yet

- Referance Book ListDocument2 pagesReferance Book ListAsif Al Faisal0% (1)

- PH EZO DatasheetDocument67 pagesPH EZO DatasheetdilipNo ratings yet

- Arcing Fault: Electric ArcDocument3 pagesArcing Fault: Electric Arcsandeep_chauhan3770No ratings yet

- Delight EnterprisesDocument25 pagesDelight Enterprisesmotol9iNo ratings yet

- Meldas 65S RS232 Port1 - Port2Document1 pageMeldas 65S RS232 Port1 - Port2Mohammad AhmadNo ratings yet

- Draka - UC500 23 Cat6a - UFTP LSZH - Sales - 240301 - 143717Document5 pagesDraka - UC500 23 Cat6a - UFTP LSZH - Sales - 240301 - 143717badrquestNo ratings yet

- WWW - Thinkiit.in: Important DefinitionsDocument37 pagesWWW - Thinkiit.in: Important Definitionsthinkiit100% (2)

- Medical Physics PresentationDocument18 pagesMedical Physics Presentationsamavia sohailNo ratings yet

- Frick 090 020 M QLX 2013 11 Rev 2014 08 PDFDocument172 pagesFrick 090 020 M QLX 2013 11 Rev 2014 08 PDFnachoNo ratings yet

- Service: LCD-TVDocument69 pagesService: LCD-TVJavier Ventura ValenciaNo ratings yet

- ISOLATOR (Scame) PDFDocument16 pagesISOLATOR (Scame) PDForient qatarNo ratings yet

- Phoenix Contact 3004362 enDocument58 pagesPhoenix Contact 3004362 enBambang AmingNo ratings yet

- Etd PDFDocument158 pagesEtd PDFRasibNo ratings yet

- Circuit Breaker RatingsDocument75 pagesCircuit Breaker Ratingsyibelta abebeNo ratings yet

- Sharp - CDBA3000 PDFDocument60 pagesSharp - CDBA3000 PDFSergioNo ratings yet