Professional Documents

Culture Documents

Jha New Format-Painting Revision)

Uploaded by

Kenny HassanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jha New Format-Painting Revision)

Uploaded by

Kenny HassanCopyright:

Available Formats

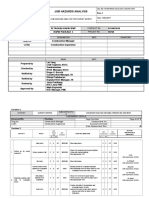

JHA WORKSHEET

HOW TO USE THIS FORM Installation/Facility

1. Crew performing task reviews ALL generic JHA considerations. Location

2. Review previous JHA updates for useful information which will help this task. Associated Work Permit Type

3. Create new JHA update with generic form and ALL considerations for this task. Associate Work Permit Number

4. Carry out tasks as per plan. If any conditions change - STOP AND RE-ASSESS Electrical Isolation Certificate Number

5. File JHA update for future reference. Physical Isolation Certificate Number

Work Description PAINTING JHA Cross Reference Number

JOB HAZARDS ANALYSIS

Job Potential Control Recovery

Description of Job Steps Potential Hazards L S R L S R Result

Step Impact Measures Measures

Applicant, Authorizing,

Approval Signatories

be familiar with the

Fail to

Incident may job.

identify all the

occur and Competent Personal Medical treatment

1 Preparation of PTW potential hazard 1 2 2 1 1 1 Acceptable

personnel may to conduct the Constantly updating JHA

associated with

get injured operations

the activity

Personnel applying

PTW must have PTW

training

Correct tools and third

party certified lifting

gears to be used (e.g

Walkway pulley, trolley)

obstructions at Safety briefing during

Head / body

low positions or Tool Box meeting.

injury due to slip

Tools & Equipment Preparation overhead Placing the barricade

and fall

2 / Mobilization Improper lifting of 3 2 6 tape. Medical treatment 1 2 2 Acceptable

Back injury

(Manually) loads Emergency response

Materials damage

Slip and fall procedure in place &

Paint spill tested.

Falling object

Use proper lifting

techniques.

More than one person

to be assigned to lift

heavy loads into

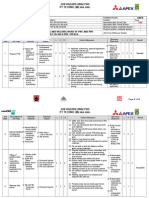

JHA WORKSHEET

position.

Heavy items to be

transferred to work

area by crane (not

hand carried).

Check surrounding

work area for any

obstructions and

Personnel may fall remove/barricade/plac

and get body e warning signs.

Slip/Trip/Fall injured Ensure safety harness

from height or Man overboard is secured.

overboard may happen Buddy system.

3 Protect Painting Area 3 3 9 Medical treatment 1 2 2 Acceptable

Sharp object Personnel may get If on scaffolding,

Congested hand / finger injury ensure that it has

work area Incorrect body been checked and

posture can cause approved by

backache Scaffolding Inspector

Use complete PPE

Use correct body

movement techniques

Application of paint 3 3 9 Medical treatment 1 2 2 Acceptable

4 Supervisor to ensure

o Mixing Paint Obstructions in Head / body no overhead activities

o Application of Paint work path injury due to slip take place while

Blocking escape and fall personnel on location.

route Erect barriers where

Slip and fall due required. Keep work

to slippery surface area clear of

Congested area unnecessary

Strong wind materials & assign

Water splash at personnel to monitor

splash zone area activities.

Bad weather Ensure approved

procedure in place

and reviewed.

Emergency response

procedure in place &

tested.

Materials to be

JHA WORKSHEET

transferred to working

area in sealed / intact

containers.

Use proper body

posture technique

Use proper PPE

Personnel need to

double check the

erected scaffolding

Weather forecast

need to be available

Lung damage 2 3 6 Full Chemical Medical treatment 1 2 2 Acceptable

Excess inhalation Internal injury Protective Equipment

of paint vapor Eye injury Worn During Mixing &

Ingestion of paint Skin Irritation Dispensing.

Splash into eyes Finger injury Barrier creams to be

Splash onto skin used on all exposed

Sharp edges skin areas.

Respiratory Protection

Device to be used

All Personnel to be

clear of landing area

when paint is being

applied

MSDS or CSDS to be

available on site and

personnel briefed on

possible health risk

during Tool Box

Meeting.

Awareness of location

of safety shower &

eye wash station from

site.

Appropriate First Aid

Equipment to be

available on site.

Wrap with cotton rags

for all identify sharp

edges

Unauthorized

personnel not allowed

JHA WORKSHEET

to enter the working

area

Use proper PPE with

work vest.

Certified scaffolding

erected

Working at Note: Every scaffold

Injury due to

height / splash zone 3 3 9 has to have handrails Medical treatment 1 2 2 Acceptable

fall

area (level 2) and attached

to a toe board to block

personnel or

equipment from falling

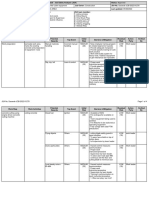

down.

Secured every hose

connection with

whiplash (safety

May cause

cable) and safety

the paint to

Hose pins

splash all over 3 3 9 Medical treatment 1 2 2 Acceptable

detachment Awareness of location

the place

of safety shower &

eye wash station from

site.

Tie-up / secure hoses

with ropes to the

nearest still structure.

May cause

Loose hoses Awareness of location

injury to 2 3 6 Medical treatment 1 2 2 Acceptable

connection of safety shower &

personnel

eye wash station from

site.

May cause injury 3 2 6 Medical treatment 1 2 2 Acceptable

Burst hose to personnel Pre-inspection of all

hoses.

Awareness of location

of safety shower &

eye wash station from

JHA WORKSHEET

site.

Protect the area with

canvas

Equipment Replace new

Overspray other 2 3 6 Supervisor need to 1 2 2 Acceptable

damage equipment

components inspect of any expose

area

Hoses crossing Roll in the blasting

work path Body injury due hoses away from work

Slip and fall to slip and fall path. Medical

5 Inspection 3 2 6 1 2 2 Acceptable

due to slippery Skin irritation Wash down the area treatment

surface and inflammation prior to inspection

Wet paint Use proper PPE

6 Housekeeping Improper Body injury 2 2 4 Medical 1 2 2 Acceptable

handling of Back injury Secure the material treatment

materials Finger injury with rope or put inside

Personnel box and seal it

carrying properly.

excessive load Carry load

Slip and fall proportionate with

Pinch point physical ability.

Paint spill Observe proper

posture while carrying

heavy load.

Carry load with one

hand free to grip

handrail.

Clear work path from

any obstruction

Limit the loads carried

per person

Use proper PPE

Secure and close

properly paint

container after used

Label the used

chemical (e.g paint,

thinner, etc.) prior to

sent back to onshore

JHA WORKSHEET

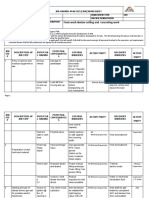

L - LIKELIHOOD S - SEVERITY R - RATING RESULT

S

CATEGORY DEFINITION CATEGORY DEFINITIONS E H 3 6 9 6-9 UNACCEPTABLE

LOW 1 Remote LOW 1 No Injury No Damage No Pollution V M 2 4 6 3-4 TOLERABLE

E

MEDIUM 2 Possible MEDIUM 2 First Aid Minor Damage Minor Pollution R L 1 2 3 1-2 ACCEPTABLE

HIGH 3 Probable HIGH 3 Lost Time Injury Major Damage Major Pollution I L M H

JHA WORKSHEET

IS THERE A SAFER WAY TO COMPLETE THE JOB ? ARE THERE ALTERNATIVES WITH LESS RISK ? LIKELIHOOD

T

JHA Number Date This JHA Created :

TASK SAFETY MANAGEMENT OUTLINE

Date JHA Last Revised : 22nd Oct 2010

WORK ACTIVITY EQUIPMENT

Type of Equipment Manufacturer Tag No Precise Work Site

WORK ACTIVITY PARTICIPANTS THIS JHA CREATED BY

Performed Job

Name Discipline Position Name Discipline Position

Before?

WORK ACTIVITY RESPONSIBILITY JHA SUBMITTED BY JHA ACCEPTED BY JHA ENDORSED BY

WORK LEADER RECEIVING AUTHORITY APPROVING AUTHORITY AREA AUTHORITY

Name Name Name Name

Signature Signature Signature Signature

Date Date Date Date

JHA WORKSHEET

Time Time Time Time

You might also like

- Hot Work: Job Hazard Analysis PT Technic (M)Document4 pagesHot Work: Job Hazard Analysis PT Technic (M)ShahrizatSmailKassim100% (1)

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Document6 pagesJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNo ratings yet

- JSA For Cutting, Grinding and Welding in AtmosphereDocument21 pagesJSA For Cutting, Grinding and Welding in AtmosphereThái Đạo Phạm Lê100% (1)

- JSA Erection of Gathering TentDocument12 pagesJSA Erection of Gathering TentMuhammad Tariq100% (2)

- CPF-JSA-022 Welding Cutting and Drilling of Underground and Above Pipes Night ShiftDocument3 pagesCPF-JSA-022 Welding Cutting and Drilling of Underground and Above Pipes Night Shiftaioudi100% (1)

- Habitat JHADocument4 pagesHabitat JHAEdha AliNo ratings yet

- Manual Tig Welding (RRC) - Job ProcedureDocument3 pagesManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- SINOPEC JSA For HDPE PIPE & ACCESSORIES INSTALLATIONDocument12 pagesSINOPEC JSA For HDPE PIPE & ACCESSORIES INSTALLATIONtusharDJNo ratings yet

- Job Safety Analysis: Page 1 of 4Document4 pagesJob Safety Analysis: Page 1 of 4RakeshkasarlaNo ratings yet

- Tool Box Talk: House KeepingDocument1 pageTool Box Talk: House KeepingAli Alqaisy100% (1)

- JSA FORMAT For Materials LoadingDocument2 pagesJSA FORMAT For Materials LoadingVikky KumarNo ratings yet

- 1 (Hazard Analysis) For Earth Works Gurun Jsa G 001 Rev 002Document3 pages1 (Hazard Analysis) For Earth Works Gurun Jsa G 001 Rev 002nurul sarahNo ratings yet

- Jsa Pipe Cutting at Fire PumpDocument5 pagesJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdNo ratings yet

- Glass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETDocument3 pagesGlass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETusman rasheed100% (1)

- JSA FOR Using The LadderDocument4 pagesJSA FOR Using The Laddertnssbhaskar100% (1)

- JHA - Survey WorksDocument3 pagesJHA - Survey WorksNazirul Syazwan100% (3)

- JSA Fitting and Welding Work For Pipe Trench InstalationDocument6 pagesJSA Fitting and Welding Work For Pipe Trench InstalationAzmi Fauzi78% (9)

- Laydown Area Civil WorksDocument4 pagesLaydown Area Civil WorksMohammed MinhajNo ratings yet

- Step No. Sequence of Activities Hazard Who or What May Be Harmed? Control Measures / Recovery Measures Action / Responsible PartyDocument7 pagesStep No. Sequence of Activities Hazard Who or What May Be Harmed? Control Measures / Recovery Measures Action / Responsible PartyameeraliNo ratings yet

- Job Activity Hazard Effect Control Measures: Project in ChargeDocument3 pagesJob Activity Hazard Effect Control Measures: Project in Chargeperquino oasanNo ratings yet

- JHA Scaffolding - ApprovedDocument15 pagesJHA Scaffolding - ApprovedLuqman OsmanNo ratings yet

- Job Hazard Analysis Welding Operations: Job Title: Work Place LocationDocument18 pagesJob Hazard Analysis Welding Operations: Job Title: Work Place Locationmuhammad imtiaz100% (1)

- Jha For RoadworksDocument15 pagesJha For RoadworksHenry RajahNo ratings yet

- Copy (4) of JSA For HDPE Liner Fusion Welding Includes Night WorksDocument7 pagesCopy (4) of JSA For HDPE Liner Fusion Welding Includes Night WorksMohammed Minhaj80% (5)

- JHA PaintingDocument9 pagesJHA Paintingperquino oasan100% (1)

- Jsa Tank CleaningDocument5 pagesJsa Tank CleaningASLAM MULANINo ratings yet

- JSA For Material ShiftingDocument3 pagesJSA For Material ShiftingMohammed Minhaj100% (1)

- JSA WeldingDocument2 pagesJSA WeldingSigint Sides0% (3)

- JHA LiftingDocument4 pagesJHA Liftingsyamimi balkhisNo ratings yet

- Mie Hse Jha 002 - Welding, Cutting, Fabrication WorkDocument4 pagesMie Hse Jha 002 - Welding, Cutting, Fabrication WorkLuqman Osman100% (1)

- JSA-Use of Temporary Energization (Power Generator)Document4 pagesJSA-Use of Temporary Energization (Power Generator)MajdiSahnoun100% (1)

- Jha RebarsDocument7 pagesJha RebarsJaycee QuinNo ratings yet

- JOB HAZARD ANALYSIS - Cable TrayDocument10 pagesJOB HAZARD ANALYSIS - Cable TrayJayson Escamillan100% (1)

- Coring: Job Safety Analysis (JSA)Document2 pagesCoring: Job Safety Analysis (JSA)Nishad Muhammed100% (1)

- Concrete Cutting JsaDocument4 pagesConcrete Cutting JsaMohammad Irfan Kiki IsmailNo ratings yet

- JSA GC-5 Mobile ScaffoldingDocument6 pagesJSA GC-5 Mobile Scaffoldinggrande100% (2)

- SWMS - Hot WorkDocument14 pagesSWMS - Hot WorkParasNo ratings yet

- Concrete Surface Coating JSA-027Document5 pagesConcrete Surface Coating JSA-027shivgovind pal100% (1)

- Pha ExcavationDocument13 pagesPha ExcavationirshadNo ratings yet

- JSA Unloading & SHIFTING by Manually 10-01-2017Document16 pagesJSA Unloading & SHIFTING by Manually 10-01-2017PAVANKUMAR100% (1)

- JHA Pump CreteDocument2 pagesJHA Pump CretePopo EaldamaNo ratings yet

- JSA E&I 4.earthing Bonding InstallationDocument3 pagesJSA E&I 4.earthing Bonding InstallationAmyNo ratings yet

- Installation of Pannel JSADocument6 pagesInstallation of Pannel JSAOFFSHORE OFFSITENo ratings yet

- Project No. 074-10 JHA No. 1Document20 pagesProject No. 074-10 JHA No. 1Adel SukerNo ratings yet

- Halliburton: Mobilize Equipment Job Safety AnalysisDocument1 pageHalliburton: Mobilize Equipment Job Safety Analysisaneshse100% (2)

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocument17 pagesSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh0% (1)

- Demolition PDFDocument2 pagesDemolition PDFvinothNo ratings yet

- Method Statement For Painting of All Metallic Piping: Form 000.653.F0100Document9 pagesMethod Statement For Painting of All Metallic Piping: Form 000.653.F0100narmathaNo ratings yet

- Lim Meng Heck (SR - Operation Manager) : ISK Ssessment ORMDocument2 pagesLim Meng Heck (SR - Operation Manager) : ISK Ssessment ORMVaradaraju ThirunavukkarasanNo ratings yet

- Jsa PaintDocument2 pagesJsa PaintKhalid NaseemNo ratings yet

- Copy (2) of JSA For Removal of MS Sheet For E&P ShedDocument12 pagesCopy (2) of JSA For Removal of MS Sheet For E&P Shedmidozoty50% (2)

- JSA For Civil Work and MDocument22 pagesJSA For Civil Work and MSyed Yousuf Ali100% (1)

- JSA Electrical WiringDocument10 pagesJSA Electrical WiringWeru Morris100% (1)

- Job Hazard Analysis Form (Shutdown Activites)Document4 pagesJob Hazard Analysis Form (Shutdown Activites)MARK ARQUE LACANARIA100% (1)

- jesa-INSTALLATION OF Toilet Cubicle PartitionDocument5 pagesjesa-INSTALLATION OF Toilet Cubicle PartitionLeo PascualNo ratings yet

- JSA For Screeding With MeshDocument4 pagesJSA For Screeding With MeshMohammed Minhaj100% (1)

- Jsa Working at Height (Maintenance & Cleaning)Document2 pagesJsa Working at Height (Maintenance & Cleaning)Nur Syafiqah Mat Rapie100% (1)

- JSA-Manual Lifting of MaterialsDocument3 pagesJSA-Manual Lifting of Materialsfrancis_e_tan75% (4)

- JRA No 11-195 Field Calibration For Valves & Transmitters at FEC AreaDocument5 pagesJRA No 11-195 Field Calibration For Valves & Transmitters at FEC AreaAijaz AhmedNo ratings yet

- 09.2014-Install Formwork, Re-Bar Setting and HousekeepingDocument8 pages09.2014-Install Formwork, Re-Bar Setting and Housekeepingاسامه محمد راضي جعفرNo ratings yet

- Loan CompareDocument1 pageLoan CompareKenny HassanNo ratings yet

- View NetDocument2 pagesView NetvielardzNo ratings yet

- Type of HeadDocument1 pageType of HeadKenny HassanNo ratings yet

- Am-C-T (B) (Bi)Document7 pagesAm-C-T (B) (Bi)Kenny HassanNo ratings yet

- 570 Publications Effectivity Sheet Dec 1 2010asDocument1 page570 Publications Effectivity Sheet Dec 1 2010asFabio MiguelNo ratings yet

- ERAS Protocols For Thyroid andDocument9 pagesERAS Protocols For Thyroid andOskar MartinezNo ratings yet

- Kassean & Juwaheer 26Document15 pagesKassean & Juwaheer 26Noush BakerallyNo ratings yet

- Pro-Oxidant Strategies - Cancer Treatments ResearchDocument71 pagesPro-Oxidant Strategies - Cancer Treatments ResearchSpore FluxNo ratings yet

- Predicting and Controlling Influenza Outbreaks - Published Article - IJERSTE - Vol.12 Issue 2, Feb 2023Document4 pagesPredicting and Controlling Influenza Outbreaks - Published Article - IJERSTE - Vol.12 Issue 2, Feb 2023dimple kharwarNo ratings yet

- Pathophysiology of Neonatal Sepsis Secondary To Neonatal PneumoniaDocument4 pagesPathophysiology of Neonatal Sepsis Secondary To Neonatal Pneumoniapaul andrew laranjo asuncion80% (5)

- IMCI Chart BookletDocument66 pagesIMCI Chart Bookletnorwin_033875No ratings yet

- 2016 10 12 Members Letter-HHS OCR Organ Transplant DiscriminationDocument4 pages2016 10 12 Members Letter-HHS OCR Organ Transplant DiscriminationMike Honda100% (2)

- Prilosec (Omeprazole) MoreDocument3 pagesPrilosec (Omeprazole) MoreLuis Arturo Andrade CoronadoNo ratings yet

- Acute HepatitisDocument14 pagesAcute Hepatitisapi-379370435100% (1)

- ReferencesDocument2 pagesReferencesapi-451063936No ratings yet

- Covid-19 RT-PCR Test Report & Certification: Certificate IssuedDocument1 pageCovid-19 RT-PCR Test Report & Certification: Certificate IssuedJerome OliverosNo ratings yet

- Final Project DescriptionDocument6 pagesFinal Project DescriptionCahyani DamawatiNo ratings yet

- Module 1 DiversityDocument33 pagesModule 1 DiversityCatherine A. PerezNo ratings yet

- Prescribing For Transgender Patients ELHEDocument4 pagesPrescribing For Transgender Patients ELHEGe YgayNo ratings yet

- TEACHER Healthy Diet American English Upper Intermediate Advanced GroupDocument4 pagesTEACHER Healthy Diet American English Upper Intermediate Advanced GroupMarcus SabiniNo ratings yet

- Public Health Internship Cover LetterDocument8 pagesPublic Health Internship Cover Letterf5dct2q8100% (2)

- Set C QP Eng Xii 23-24Document11 pagesSet C QP Eng Xii 23-24mafiajack21No ratings yet

- Pengaruh Metode Pengeringan Terhadap Karakter Mutu Fisik Dan Kimia Serbuk Minuman Instan Kulit Buah NagaDocument9 pagesPengaruh Metode Pengeringan Terhadap Karakter Mutu Fisik Dan Kimia Serbuk Minuman Instan Kulit Buah NagaHadi Yusuf FaturochmanNo ratings yet

- Risk Assessment of Heavy LiftingDocument5 pagesRisk Assessment of Heavy Lifting채종언100% (3)

- (Yabanci Dil Testi) : T.C. Millî Eğitim Bakanliği Ölçme, Değerlendirme Ve Sinav Hizmetleri Genel MüdürlüğüDocument22 pages(Yabanci Dil Testi) : T.C. Millî Eğitim Bakanliği Ölçme, Değerlendirme Ve Sinav Hizmetleri Genel Müdürlüğücem kayaNo ratings yet

- Musculoskeletal Clinical Translation FrameworkDocument1 pageMusculoskeletal Clinical Translation FrameworkRafaelNo ratings yet

- Pappas Bikhazi 2023 Babe Ruth S Anaplastic Epidermoid Carcinoma of The NasopharynxDocument5 pagesPappas Bikhazi 2023 Babe Ruth S Anaplastic Epidermoid Carcinoma of The NasopharynxVinoster ProductionNo ratings yet

- Roma Therapy IN Yurveda: N.SrikanthDocument89 pagesRoma Therapy IN Yurveda: N.SrikanthAkshay TandleNo ratings yet

- Arterial Events, Venous Thromboembolism, Thrombocytopenia, and Bleeding After Vaccination With Oxford-Astrazeneca Chadox1-S in Denmark and Norway: Population Based Cohort StudyDocument10 pagesArterial Events, Venous Thromboembolism, Thrombocytopenia, and Bleeding After Vaccination With Oxford-Astrazeneca Chadox1-S in Denmark and Norway: Population Based Cohort StudyFemale calmNo ratings yet

- 1120161049855Document16 pages1120161049855Ruchi SharmaNo ratings yet

- Effects of Sprint Interval Training and Body.24Document8 pagesEffects of Sprint Interval Training and Body.24Maxwell MartinsNo ratings yet

- IELTS 03 - Listening 01 & Reading 01 - Transcripts & KeysDocument8 pagesIELTS 03 - Listening 01 & Reading 01 - Transcripts & KeysLe Hoang KhaNo ratings yet

- Evidence-Based Practice in Pediatric Physical Therapy by BarryDocument14 pagesEvidence-Based Practice in Pediatric Physical Therapy by BarryFe TusNo ratings yet

- Domestic Violence Cycle of Violence Types of Families-2Document22 pagesDomestic Violence Cycle of Violence Types of Families-2api-340420872No ratings yet

- Calories Needed For A 17 Year Old, 70 KG MaleDocument7 pagesCalories Needed For A 17 Year Old, 70 KG Maleboom boomNo ratings yet