Professional Documents

Culture Documents

NRT105F061

Uploaded by

nawazcOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NRT105F061

Uploaded by

nawazcCopyright:

Available Formats

43.

034/1

NRT 105: Electronic fan-coil controller

How energy efficiency is improved

ECO meter for displaying instantaneous energy consumption and digital input for switching between

presence and absence.

Areas of application

Individual single room dwelling and zone temperature control in 2- or 4-pipe systems for heating, cool-

ing or heating/cooling with automatic activation of valves (heating/cooling), as well as 3-stage fan coil.

Properties

• Recording of room temperature with choice of integrated or external temperature detector

• High level of operating convenience thanks to buttons on front and large LCD display

• Modern design

Technical description

• Housing made of flame-retardant, pure white thermoplastic (RAL9010)

• Input for c/o signal

• P-controller with pulse-pause or analogue (0...10 V) output T

• 3-stage fan coil activation with parameterisable on/off points for individual stages

• Frost/overheating protection function P

• Hours run meter

• Suitable for fitting on walls or recessed junction boxes Y06755

• Electrical connection in base with screw terminals for wires up to 2,5 mm²

• Rear cable infeed

T

• Electronics in snap-on housing

Typ Range 1) Control behaviour Power Weight P

°C [kg]

NRT 105 F011 8...37 P, quasi-continuous 110...230 V~ 0,27 Y06756

NRT 105 F061 8...37 P, continuous 0...10 V 24 V~ 0,27

F011 (switched) F061 (continuous)

Type of installation 2- and 4-pipe Type of installation 4-pipe

Outputs for ventilator relay, 3 step Outputs for ventilator relay, 3 step

Outputs for value relay Outputs for value 0...10 V, load > 4 kΩ,

max. switch rating max. 2,5 mA

Internal sensor (NTC) 2(1.6) A, 250 V~ max. switch rating

External sensor (Ni1000) 5(3) A, 250 V~ Internal sensor (NTC) 2(1.6) A, 250 V~

Switching period 4...30 min External sensor (Ni1000) 5(3) A, 250 V~

Control factor shown in 10 levels

Minimum pulse 30 s

Tolerance in power supply ± 15%; 50...60 Hz Ambient temp. 0...50 °C

Power consumption < 1 VA Ambient humidity 5...95 %rh

Parameters non-volatile non-condensing

P-band Xp 1...20 K Degree of protection IP 30 (EN 60529)

Dead zone N/R 0...10 K / 0...12 K Protection class II (IEC 60730)

Temperature levels normal/reduced (N/R)

Anti-frost temperature 8 °C (heating OFF) Conformity EN 12098 and CE

Anti-overheat temperature 38 °C (cooling OFF) EMC immunity EN 61000-6-1, 2

Range shown, actual temp. –8...+50 °C EMC irradiation EN 61000-6-3, 4

Time constant 22 min Safety EN 60730-1

Dead time 2 min Quality ISO 9001

Documentation: F011 F061

Wiring diagrams A06646 A06647

Dimension drawing M04773 M04773

Fitting instructions MV 505484 MV 505489

Operating instructions 2) BA 505579 BA 505579

Accessories

-AXT, AXM Valves with thermal or continuous drive; see Sections 55

-EGT . . . External Ni1000 temperature sensor; see Section 36

-ZDR . . . Memotime central time-switch; see Section 12

0303124 000* Recessed junction box

*) Dimension drawing or wiring diagram are available under the same number

1) Depending on parameters P05, P08

2) Supplied with each controller; in five languages (Ger., Fre., Eng., Ital., Span.)

Sauter Components 7143034003 04

43.034/2 NRT 105

Operation

The room temperature is measured by a precision temperature sensor and compared to the prevailing

setpoint. Depending on the control offset and control characteristic, the room is heated up or cooled

down in order to keep the desired room temperature constant. The fully automatic control system pro-

vides optimum comfort.

For your own individual temperature profile, use the time-limited and the time-unlimited manual mode

to obtain the absence or presence functions.

The plant's operating status is shown on the LCD by means of pictograms and the numeric field. To

match the controller to the plant, use the service mode. It is possible to parameterise control behaviour,

the switching points of the fan stages, anti-frost and anti-overheating functions, valve anti-jamming

function, setpoint limitation etc.

Engineering and fitting notes

Because of the anti-frost, anti-overheating and valve anti-jamming functions, the controller should be

permanently connected to the power supply. The controller should be fitted at approx. 1,5 metres

above floor level and away from direct insolation, draughts and sources of heat or cold.

Additional technical data

Temperature setpoint 23 °C (factory setting)

Time-limited change

to the operating mode: 2 to 9 hours (with countdown)

SERV parameters EEPROM non-captive

Temperature measurement: NTC sensor (internal)

Input for external temperature sensor Ni1000; internal/external (excludes dew-point switch/change-over input)

Zero-point correction,

e.g. influence of wall ±6K

Graduation for setpoint entry 0,5 K

Graduation for display of actual value 0,1 K

Accuracy 0,3 K at 20 °C

Limitation setpoint minimum and maximum values (Tmin, Tmax) limitable via SERV;

factory setting not limited

Universal input PROG for external, potential-free, gold-plated contacts. Up to 20 controllers

can be activated in parallel

from one set of contacts if the diameter of the (copper) cable is

≥ 0,5 mm2 and the distance

from the contacts to the controller is ≤ 100 m

Suitable for one of the following functions:-

Absence energy-saving mode with reduced temperature level

Presence normal temperature level (N)

Window contact reduced temperature level (R)

External timer extended dead zone (reduced temperature level, R)

Remote control stand-by, normal mode

Fault (e.g. filter contaminated) indicated by a warning symbol

Keys disabled (key-operated switch) indicated by a symbol

Input TEMP for external, potential-free, gold-plated contacts:-

Dew point cooling OFF (excludes external temperature sensor and change-over)

Change-over (c/o) for two-pipe system, F011 only (excludes external temperature sensor

and dew-point sensor)

Anti-jamming function for valve After one week, the valve outputs are activated for 0....15 minutes

(variable), if none of the valves has been activated beforehand.

Anti-frost & anti-overheating functions selectable via SERV; setpoint not shown

Childproof function enabled/disabled by special key sequence; indicated by symbol

Valve output with indication of switching condition

Ventilator control levels 0, 1, 2, 3 automatically; manual override with levels 1, 2, 3;

with indication of switching condition; heating without fan is possible, but

manual

fan control for ventilation purposes still has priority.

Min. fan speed: stage 0 or 1 optional (or duct controller)

Method of operation as per EN 60730: type 1C; normally-open contacts, partly potential-loaded; see wiring

diagrams

Hours-run counter for fan retrievable via SERV, 0...9990 h, not deletable

Mechanical switching operations > 5 million

Sauter Components 7143034003 04

NRT 105 43.034/3

T Off (anti-frost or anti-overheating function, where applicable)

Tmin Limitation of the minimum temperature setpoint

Tmax Limitation of the maximum temperature setpoint

Xs Temperature setpoint; factory setting 23 °C

T ≤ Tmin+Xp/2 +Xt/2 ≤ Xs ≤ Tmax–Xp/2 –Xt/2 ≤ T

SERV parameters with factory setting (range)

P01:000 Input TEMP 0 = temp external, 1 = dew point: active when cooling 2 = c/o (F011 only)

see table below 1)

P02:000 Type of sensor: 0 = NTC, 1 = Ni1000 1)

P03:000 Influence of wall, NTC (–60...+60 = ± 6 K)

P04:000 Influence of wall, Ni1000 (–60...+60 = ± 6 K)

P05:020 2 K P-band Xp, heating and cooling valve (010...200)

P06:004 4 min. period duration tp, heating and cooling valve (004...030)

P07:008 0,8 K dead zone normal Xtn (002...98)

P08:100 10.0 K dead zone extended Xtr (004...120) Xtr > Xtn

st

P09:030 30 % cut-in point for 1 fan speed G1 as a percentage of the P-band (005...040)

nd

P10:090 90 % cut-in point for 2 fan speed G2 as a percentage of the P-band (020...120)

120 % cut-in point for 3 fan speed G3 as percentage of P-band (040...160); G1 ≤ G2 ≤ G3

rd

P11:120

P12:015 15 % switching difference of fan XSdG as a percentage of the P-band (005...040)

P13:002 2 min. fan lag tG (000...010) when fan switches off automatically

P14:000 Fan function when heating and cooling = 0, when cooling only = 1

2)

P15:000 Minimum fan speed, stage G1: 0 = inactive; 1 = active

P16:000 Contacts input PROG: see table below

P17:000 Anti-frost/anti-overheating function

0 = active 8 °C 1 = active : 38 °C

2 = active and 3 = inactive

P18:000 Valve anti-jamming function (0 = inactive, 1...15 = active minutes)

P19:014 Minimum limitation, range, temperature setpoint Tmin (009...035) 3)

P20:032 Maximum limitation, range, temperature setpoint Tmax (011...037) 3)

P21:000 Hours-run counter for fan, in units of 10 hours; not deletable

P22:10× Software version

1) Dew-point sensor or c/o input and Ni1000 sensor are mutually exclusive!

2) Except for P17:003 and when P16:004 contacts input closed (stand-by mode)

3) Dependent on P-band and dead zone

Input functions

Input functions Possible mode when Activated by Symbols when

contacts are closed contacts are closed

000 Absence PROG N R R Absence sensor

001 Presence PROG R N N Occupancy detector

002 Window contacts PROG N R R Window contacts

P16 003 External time-switch PROG N R R External timer

004 Remote control PROG N Telephone

005 Fault indicator PROG N N Fault contacts

006 Keys disabled PROG N N Key-operated sw.

1)

P01

001 Dew point 1) TEMP N N OFF Dew-point monitor

002 Change-over 2) TEMP C/o

SERV

B06645b

N = Temperature setpoint for normal (normal comfort and energy requirement)

R = Temperature setpoint for reduced (reduced comfort and energy requirement)

1) When the dew point is exceeded, the cooling valve closes; control is no longer possible; actual value is shown as: ---

2) F011 only.

Sauter Components 7143034003 04

43.034/4 NRT 105

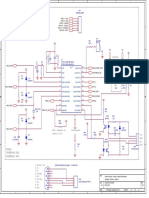

Wiring diagrams

NRT 105 F011 / F901

NTC P-controller

< 7 AT pulse/ pau se

L 1

110...230 V~

N 2

Rel 3

Rel 4

Rel 0

Rel 1

Rel 2

PROG

TEMP

3 4 5 6 7 8 9 10 11

I II III

N Ni1000

3 4 5 6 7 8 9 10 11

I II III

c/o

N A06646f

NRT 105 F061

NTC

P-controller

1

24 V~

2

Rel 0

Rel 1

Rel 2

PROG

TEMP

3 4 5 6 7 8 9 10 11 8 9 10 11

I II III

M M

Ni1000

L L

N N

A06647e

III III

125

II 100 % II

F011 F061 F061 F011

75

50

I I

25

XsdG

-3 -2 -1 Xs +1 +2 +3 ΔT

Xtn Xp

B06648a

Sauter Components 7143034003 04

NRT 105 43.034/5

Examples of application

- +

T

P

B06649a

T

P

B06954a

- +

T

2P

F011

B07020a

+-

c/o

T

2P

F011

B07809

Sauter Components 7143034003 04

43.034/6 NRT 105

Dimension drawing Accessories

76 303124

70,5

38

9,2

Ø 60

65

60

7

3,4

136

152

8

53

114

3,6

84

9

60

M00815

8

M04773

Printed in Switzerland

Right of amendment reserved

N.B.: A comma between cardinal

numbers denotes a decimal point

© Fr. Sauter AG, CH-4016 Basle

7143034003 04 Sauter Components

You might also like

- Multi Zone Outdoors Service ManualDocument56 pagesMulti Zone Outdoors Service Manualcmorley505775% (4)

- CATALOGO DE VALVULAS OsvatDocument218 pagesCATALOGO DE VALVULAS OsvatGabriel Piñon Conde67% (3)

- Strategic Planning ToolkitDocument19 pagesStrategic Planning ToolkitStephen OliekaNo ratings yet

- Cambridgehistory008599mbp PDFDocument439 pagesCambridgehistory008599mbp PDFDhiman NathNo ratings yet

- PC - VRF - Systems - PART IDocument18 pagesPC - VRF - Systems - PART Icarlos vasquezNo ratings yet

- Ef3602 9Document2 pagesEf3602 9AwanNo ratings yet

- Workover Kill Fluid Density CalculationDocument3 pagesWorkover Kill Fluid Density CalculationSanny Astari100% (1)

- LG-Component Level Repair Y-Z Board IPMDocument3 pagesLG-Component Level Repair Y-Z Board IPMcaseysamNo ratings yet

- Haier Esa-3065-3085 hwr08xc5 Window-Type Air Conditioner 2004 SM PDFDocument21 pagesHaier Esa-3065-3085 hwr08xc5 Window-Type Air Conditioner 2004 SM PDFhernandez.josedomingo6804No ratings yet

- Solar Storage System Comp GUIDEGTM 2 1Document10 pagesSolar Storage System Comp GUIDEGTM 2 1harosalesvNo ratings yet

- Inverter Multi Split System (60Hz, R22)Document58 pagesInverter Multi Split System (60Hz, R22)Педро СлеваNo ratings yet

- TC - Rcue 40 - 240 WG2 (TCGB0045 (12-06)Document88 pagesTC - Rcue 40 - 240 WG2 (TCGB0045 (12-06)arif1993100% (1)

- Service Manual Bora Gwh28aae-K3nna1aDocument67 pagesService Manual Bora Gwh28aae-K3nna1aElena TanevaNo ratings yet

- Appendix I - AirDocument155 pagesAppendix I - AirTown of Colonie LandfillNo ratings yet

- 256 Copeland Scroll Motor Technical Information PDFDocument11 pages256 Copeland Scroll Motor Technical Information PDFDianichtrNo ratings yet

- HCD DX9Document70 pagesHCD DX9PALAGUERRA LENIS EVERNo ratings yet

- Termostato Robertsaw AnsalDocument7 pagesTermostato Robertsaw Ansalcapacitacion bomberos voluntarios sarmientoNo ratings yet

- WT500Document16 pagesWT500M. Abdullah Reza D.HNo ratings yet

- CopelandDocument3 pagesCopelandJesús R. Zárraga100% (1)

- Star Cool Short Form Manual CIM 5 Version 3 PDFDocument38 pagesStar Cool Short Form Manual CIM 5 Version 3 PDFOmar Sangrona100% (2)

- (TDB) Free Joint Multi For Brazil (R410A, 50 - 60Hz, HP) Ver.1.0 - 210624Document383 pages(TDB) Free Joint Multi For Brazil (R410A, 50 - 60Hz, HP) Ver.1.0 - 210624Elivandro Vicente VicenteNo ratings yet

- RHXYQ8-66AYL: Heat Pump 60HzDocument508 pagesRHXYQ8-66AYL: Heat Pump 60HzClayton VeronezNo ratings yet

- JP-QR203 User ManualDocument162 pagesJP-QR203 User ManualEng. Edelson MartinsNo ratings yet

- Codigos de Error Samsung PDFDocument18 pagesCodigos de Error Samsung PDFOscar LinoNo ratings yet

- LG MultiV III - CatalogueDocument13 pagesLG MultiV III - CatalogueMuhidin KozicaNo ratings yet

- Samsung Ar Condicionado Virus Doctor Manual PDFDocument2 pagesSamsung Ar Condicionado Virus Doctor Manual PDFrogerfbezerraNo ratings yet

- Stepper 23bb h202 14Document9 pagesStepper 23bb h202 14niltonces100% (1)

- Intelligent Incubator Controller User ManualDocument7 pagesIntelligent Incubator Controller User ManualDairon GamezNo ratings yet

- Lsc07n65lse07n65lsf07n65v6 0Document8 pagesLsc07n65lse07n65lsf07n65v6 0Kenneth Navarro ChavarriaNo ratings yet

- Ae4456e Es1bDocument1 pageAe4456e Es1bWellton PecanhaNo ratings yet

- Mugen MBX5TDocument1 pageMugen MBX5Tbc24flNo ratings yet

- Kirisun PT8100-Service-ManualDocument35 pagesKirisun PT8100-Service-ManualRobertino100% (1)

- FE2.1 Data Sheet 1.4 PDFDocument23 pagesFE2.1 Data Sheet 1.4 PDF3degreesNo ratings yet

- Liebert-Pex-Condenser LSF-user-manual PDFDocument21 pagesLiebert-Pex-Condenser LSF-user-manual PDFEmmanuel MunozNo ratings yet

- Catalogo Separador de Óleo AF EmersonDocument2 pagesCatalogo Separador de Óleo AF EmersonAndre VargasNo ratings yet

- Fic MR055 MR056 - Rev 0.2Document53 pagesFic MR055 MR056 - Rev 0.2GrafrjNo ratings yet

- GPS PPK Kit-CompressedDocument13 pagesGPS PPK Kit-CompressedRicardo A. Cotrina AlbercaNo ratings yet

- Sp431 High Voltage Adjustable Precision Shunt RegulatorsDocument11 pagesSp431 High Voltage Adjustable Precision Shunt Regulatorsagmnm1962No ratings yet

- Lava e Seca LG WD9WE6Document46 pagesLava e Seca LG WD9WE6Jose Airton TirakowskiNo ratings yet

- LGMV Total ENG PDFDocument42 pagesLGMV Total ENG PDFJorge alfredo Villarreal triviñoNo ratings yet

- Using Slic3r With The XYZprinting DaVinci 1.0Document6 pagesUsing Slic3r With The XYZprinting DaVinci 1.0anonymoose47150% (2)

- Single CAC Outdoor PDB Feb 2013 PDFDocument161 pagesSingle CAC Outdoor PDB Feb 2013 PDFkadir kaya100% (1)

- 160 81-O1 PDFDocument110 pages160 81-O1 PDFAnandNo ratings yet

- SRC 1203Document4 pagesSRC 1203Rony panggabeanNo ratings yet

- AOC 212Va+SERVICE+MANUAL PDFDocument60 pagesAOC 212Va+SERVICE+MANUAL PDFMarcos RangelNo ratings yet

- UPS700 657Document6 pagesUPS700 657Marcio Antonio MachadoNo ratings yet

- Copeland CF and Cs Compressor Catalogue PDFDocument88 pagesCopeland CF and Cs Compressor Catalogue PDFJhonatan Martínez100% (1)

- KR AHU Comm - Kit 220V, 5060Hz EU MFL68924303 0CAA0-02H June.2022Document74 pagesKR AHU Comm - Kit 220V, 5060Hz EU MFL68924303 0CAA0-02H June.2022antonio gaitan100% (1)

- Manual de Instalação ASBA24JFCDocument19 pagesManual de Instalação ASBA24JFCSCS AssistenteNo ratings yet

- Compressor EGAS80CLPDocument5 pagesCompressor EGAS80CLPSamuel OsmagNo ratings yet

- 42LUCA018 Vista ExplodidaDocument1 page42LUCA018 Vista ExplodidaLuciano GoncalvesNo ratings yet

- Esquema Gigabyte GA-945GZM-S2 V3.0Document33 pagesEsquema Gigabyte GA-945GZM-S2 V3.0tecboard100% (1)

- HECTRONIC Heconomy EN PDFDocument4 pagesHECTRONIC Heconomy EN PDFFilimone ThumboNo ratings yet

- OH44E-svg44e Data SheetDocument3 pagesOH44E-svg44e Data SheetharshaNo ratings yet

- Washer Extractors: W4130S, W4180S, W4250SDocument2 pagesWasher Extractors: W4130S, W4180S, W4250SHanif Harun100% (1)

- 35N06 PDFDocument4 pages35N06 PDFMy LifeNo ratings yet

- Control Digital para FB TransportDocument4 pagesControl Digital para FB TransportLudwig RosasNo ratings yet

- Stp7Nc70Z - Stp7Nc70Zfp STB7NC70Z - STB7NC70Z-1Document13 pagesStp7Nc70Z - Stp7Nc70Zfp STB7NC70Z - STB7NC70Z-1Maz Roful100% (1)

- Catalogo Compresores Hermeticos Piston CR CopelandDocument6 pagesCatalogo Compresores Hermeticos Piston CR Copelandmaximo fuenmayorNo ratings yet

- ICE ECUA90-240 ECUDA180-360 Rev16 PDFDocument25 pagesICE ECUA90-240 ECUDA180-360 Rev16 PDFAbel L. LopezNo ratings yet

- 03-CCM09 - Instal-Operation Manual (A-07-19)Document20 pages03-CCM09 - Instal-Operation Manual (A-07-19)Vitor BuenoNo ratings yet

- PBL10 Project Compal Confidential: LA-6731P Schematic REV1.0Document45 pagesPBL10 Project Compal Confidential: LA-6731P Schematic REV1.0Assiseletro100% (2)

- E5cs PDFDocument4 pagesE5cs PDFRick AvilNo ratings yet

- Omron E5cj-Q2hb DatasheetDocument6 pagesOmron E5cj-Q2hb Datasheet王俊發No ratings yet

- Omron E5CWL PDFDocument12 pagesOmron E5CWL PDFmaloyNo ratings yet

- Over Voltages 6Document2 pagesOver Voltages 6ekaNo ratings yet

- Arco Solar Inc.: Case Analysis OnDocument12 pagesArco Solar Inc.: Case Analysis OnAnish RajNo ratings yet

- Sap Accrual EngineDocument2 pagesSap Accrual Enginerohit12345aNo ratings yet

- Role of Technology in AdvertisementtDocument29 pagesRole of Technology in AdvertisementtShalini ChatterjeeNo ratings yet

- Plunger Pump Service Manual: Installation and Start-Up InformationDocument6 pagesPlunger Pump Service Manual: Installation and Start-Up InformationDark CenobiteNo ratings yet

- Final Project Miguel Santana GallegoDocument44 pagesFinal Project Miguel Santana GallegoDaniel PereiraNo ratings yet

- Molded Case Circuit Breakers Section 6: Spectra RMSDocument1 pageMolded Case Circuit Breakers Section 6: Spectra RMSArslan LashariNo ratings yet

- AOO Personal Information FDocument8 pagesAOO Personal Information FOdhiambo OwinoNo ratings yet

- TDS 9-11SA Mechanical TroubleshootingDocument34 pagesTDS 9-11SA Mechanical Troubleshootingahmed.kareem.khanjerNo ratings yet

- SAP BW Basic Configuration SettingsDocument29 pagesSAP BW Basic Configuration SettingsSIKANDARNo ratings yet

- Dism Repair Tools PDFDocument21 pagesDism Repair Tools PDFprashant4455No ratings yet

- List of International and National Professional Bodies - PECDocument4 pagesList of International and National Professional Bodies - PECerumerNo ratings yet

- Case Study #3 ThermodynamicsDocument6 pagesCase Study #3 ThermodynamicsColeene Forteza100% (1)

- DE GUZMAN - Module 2 Activity No. 2Document4 pagesDE GUZMAN - Module 2 Activity No. 2Alvin De GuzmanNo ratings yet

- Admit Card: Examination Centre: Centre CodeDocument1 pageAdmit Card: Examination Centre: Centre CodekrishnaNo ratings yet

- MclogitDocument19 pagesMclogitkyotopinheiroNo ratings yet

- BX Tuner ManualDocument4 pagesBX Tuner ManualdanielthemanNo ratings yet

- Diesel GateDocument41 pagesDiesel Gateanon_934477879100% (1)

- Eminence Deltalite II 2515Document1 pageEminence Deltalite II 2515Suto BandNo ratings yet

- GRT655 GRT655L Product Guide ImperialDocument20 pagesGRT655 GRT655L Product Guide ImperialDanilo UrruchurtoNo ratings yet

- 690 2004Document19 pages690 2004RahilaHammadNo ratings yet

- Dilg-Mbcrpp Isf Q2 2023Document2 pagesDilg-Mbcrpp Isf Q2 2023Mallari GabrielNo ratings yet

- Solucionario Libro Infotech 4th EditionDocument32 pagesSolucionario Libro Infotech 4th EditionGisella Espinoza BarberenaNo ratings yet

- Biochemical Oxygen DemandDocument18 pagesBiochemical Oxygen DemandUnputdownable Bishwarup100% (1)