Professional Documents

Culture Documents

HIP Turbine Erectioin Sequence LPA Turbine Erection Sequence

Uploaded by

Mukesh Bhandakkar0 ratings0% found this document useful (0 votes)

471 views8 pagesLPB Turbine Erection sequence Bolt level measurement Concrete surface chipping Preparation of the grout pad with sole plate bottom. Placement of 4 LP outer casings for leveling and joining LP casing centering should be done Now Considering Pedestal-2 as master level LPB After leveling start blue matiching of the Bearing Meanwhile top casing placement and joining should be done rotor Placement, seal bore and rotor level checking rotor centering and checking to be completed.

Original Description:

Original Title

48441403-Turbine-erection-manoj

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentLPB Turbine Erection sequence Bolt level measurement Concrete surface chipping Preparation of the grout pad with sole plate bottom. Placement of 4 LP outer casings for leveling and joining LP casing centering should be done Now Considering Pedestal-2 as master level LPB After leveling start blue matiching of the Bearing Meanwhile top casing placement and joining should be done rotor Placement, seal bore and rotor level checking rotor centering and checking to be completed.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

471 views8 pagesHIP Turbine Erectioin Sequence LPA Turbine Erection Sequence

Uploaded by

Mukesh BhandakkarLPB Turbine Erection sequence Bolt level measurement Concrete surface chipping Preparation of the grout pad with sole plate bottom. Placement of 4 LP outer casings for leveling and joining LP casing centering should be done Now Considering Pedestal-2 as master level LPB After leveling start blue matiching of the Bearing Meanwhile top casing placement and joining should be done rotor Placement, seal bore and rotor level checking rotor centering and checking to be completed.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

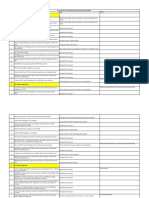

HIP Turbine Erectioin sequence LPA Turbine Erection sequence

Bolt level measurement

Concrete surface chipping

Blue matching of sole plate with surface plate

Preparation of the grout pad for

Pedestal1 & 2 Preparation of the grout pad

Blue matching of the grout pad with sole plate

Blue matching of pedestal to soleplate bottom

Blue matching of the sole plate top to the LP

outer casing

LP casing to casing blue matching

Sole plate positioning & leveling (Remember not

to do for LPB)

Placement of 4 LP outer casings for leveling &

joining

LP casing centering should be done

Now Considering Pedestal-2 as master level

LPA

After leveling start blue matiching of the Bearing

Meanwhile top casing placement & joining

should be done

Rotor Placement, seal bore & rotor level

checking

Rotor centering & checking to be completed

HIP/LPA & LPA/ LPB Alignment

Sole plate to outer casing key fixing should be

done

Inner casing positioning, centering & leveling

Horn drop test of inner casing to be done

All the temporary keys to be placed

Diaphram placement & centering to be done

Steam Seal & diaphragm seals clearance

correction to be carried out

Diffuser & gland steam seal to be placed

Gland steam seal centering to be completed

Top diaphram to be placed

LPB Turbine Erection sequence Generator Erection sequence

Bolt level measurement Bolt level measurement

Concrete surface chipping Concrete surface chipping

Preparation of the grout pad Preparation of the grout pad for

Blue matching of the grout pad with

sole plate bottom Blue matching of the grout pads with the sole plate

Blue matching of the sole plate top to

the LP outer casing Sole plate top face blue matching with the master plate

LP casing to casing blue matching Generator leg supports to be attached after blue matching

Sole plate positioning & leveling

(Remember not to do for LPB) generator Lifting & placement

Placement of 4 LP outer casings for

leveling & joining End shelid blue matching

LP casing centering should be done Removal of the end sheild cover from gen.

Now Considering Pedestal-2 as

master level LPB Placement of end sheild

After leveling start blue matiching of

the Bearing Hydro test of the H2 coolers

Meanwhile top casing placement &

joining should be done Placement of H2 coolers

Rotor Placement, seal bore & rotor

level checking

Rotor centering & checking to be

completed

HIP/LPB & LPA/ LPB Alignment

Sole plate to outer casing key fixing

should be done

Inner casing positioning, centering &

leveling

Horn drop test of inner casing to be

done

All the temporary keys to be placed

Diaphram placement & centering to

be done

Steam Seal & diaphragm seals

clearance correction to be carried out

Diffuser & gland steam seal to be

placed

Gland steam seal centering to be

completed

Top diaphram to be placed

LPA Turbine Erection Activity llel jobs can be started Duration tools

Before starting the erection procedure, we

should have proper references i.e centerline of

TG & proper elevation reference.

1 Bolt level measurement

Foundation bolt eleevation & bolt to bolt

1.1 distance has to measure

2 Concrete surface chipping

Chip 15-20mm top concrete surface to have a

good bonding with the Gp-2 pads with the top

2.2 concrete surface

3 Positioning of the sole plates

Initially fix any one base plate as master & level

it 1mm or 0.6mm more than reference level, so

that if any is bubble form during the pad making

3.1 will be removed while Blue matching.

3.2 Place other plates & level them with master.

4 Preparation of the grout pad

After leveling of the plate start prepation for

grout pad. Prepare the plywood cutouts fitting to

the grout pad size. Before pouring the Grout

cement check its batch nos & expiry date. Make

the grout mixture with clean water & mix the

4.1 water with proper ratio.

5 Blue matching of gout pad with sole plate

Check the grout pad surface whether on its

surface is smooth with few bubbles accepted

with less than 1mm depth, if more bubbles or air

pokets with greater depths are present then

5.1 reject the block & make a new pad

Apply blue on the surface of the plate & place

on the pads, check the blue on pads &

accordingly start grinding of the surface, till we

geet more than 80% matching. Don’t grind

thethe surface more than 1mm as we have

prepared the block 1-0.7mm higher than the

required elevation. Also we require few shim

above the pads for shim adjustment. during

5.2 alignment.

6 Blue matching of sole plate with LP casing

Once all the grout pads are cleared, we can

start matching of the base plate top surface with

6.1 the LP outer casing surface

7 LP casing to casing blue matching

LP casing come in 4 different parts, blue

matching of all the 4 different casing surface

with eachother has to be done with the master

plate. After blue matching of all the surface,

preassembly of all the casing has to be done

out-side with half bolt placing & also check all

bolts freeness in the holes. Casing to casing

parting plane level has to be 0.03 & filler of

0.03mm has to checked at the joing faces.

7.1

Sole plate positioning & leveling (Remember not

to do for LPB)

Placement of 4 LP outer casings for leveling

8 & joining

All the outer casing has be to placed on the sole

plates & again surface leveling 0.03 has to be

checked, after that we have to remove 2nd &

3rd part & apply STAG-B on the joining surface

8.1 & on 1st & 4th joing surface.

9 LP casing centering should be done

Radial Centering of the casing should be done

with the piano wire at the bearing seal bore,

axial centering will be done with the pedestal to

9.1 casing distance as per drg

Now Considering Pedestal-2 as master level

LPA

After leveling start blue matiching of the

10 Bearing

leveling of the casing will be checked at all the

10.1 cornes & on bearing housings

Mark brg nos, left, right, front & rear on the

bearing surface & on yoke surface. Now start Meanwhile top casing

matching the bearing pads of the yoke to the placement & joining should

10.2 casing be done

Rotor Placement, seal bore & rotor level

11 checking

Check the rotor level on the journal.

After bluematching completion of the bearing,

11.1 place the rotor & check the seal bore.

Rotor centering & checking to be completed

HIP/LPA & LPA/ LPB Alignment

Sole plate to outer casing key fixing should be

done

Inner casing positioning, centering & leveling

Horn drop test of inner casing to be done

All the temporary keys to be placed

Diaphram placement & centering to be done

Steam Seal & diaphragm seals clearance

correction to be carried out

Diffuser & gland steam seal to be placed

Gland steam seal centering to be completed

Top diaphram to be placed

manpower manpower for llel jobs checks acceptability

You might also like

- Cibse TM65 (2020)Document67 pagesCibse TM65 (2020)Reli Hano100% (1)

- 02.SIPP-PP-07-M02 - IFC - 0 - Steam Turbine and Main Valves Installation ProcedureDocument422 pages02.SIPP-PP-07-M02 - IFC - 0 - Steam Turbine and Main Valves Installation ProcedureBadr MoutassarefNo ratings yet

- L-134 Static TimingDocument17 pagesL-134 Static TimingMax Steffe100% (1)

- GT Inspection PDFDocument88 pagesGT Inspection PDFMuhammad Hamza Naveed100% (2)

- Horn Drop TestDocument5 pagesHorn Drop Testptiwari2808100% (2)

- Behaviour Modification Testbank PDFDocument118 pagesBehaviour Modification Testbank PDFjade tagabNo ratings yet

- Presentation of Turbine Erection 1Document42 pagesPresentation of Turbine Erection 1Trung Quan Vo100% (1)

- 700 MW TurbinDocument42 pages700 MW TurbinWisnu NugrahaNo ratings yet

- 150 MW TG Erection Sequence.Document30 pages150 MW TG Erection Sequence.Pradeep Yallanki100% (1)

- LP Prilling Bucket For UreaDocument4 pagesLP Prilling Bucket For UreaNour Saad EdweekNo ratings yet

- L-06 Erection Guide Line of 500 MW Turbine Anp-4Document20 pagesL-06 Erection Guide Line of 500 MW Turbine Anp-4Sam100% (4)

- Lis Job MechanicalDocument6 pagesLis Job MechanicalAya Veer NadiTyaNo ratings yet

- Daily Progress TB & BG 24 Feb 2021Document37 pagesDaily Progress TB & BG 24 Feb 2021angga andi ardiansyahNo ratings yet

- Presentation of Turbine Erection 1Document42 pagesPresentation of Turbine Erection 1Anubhav Singhal75% (4)

- Presentation On VibrationDocument24 pagesPresentation On VibrationSethuRamalingamNo ratings yet

- Ealing and Anti Seizing Compound Used in Turbine As Per BHELDocument99 pagesEaling and Anti Seizing Compound Used in Turbine As Per BHELAnonymous 7ZYHilD100% (1)

- Final AOH Report - TMD 060818Document15 pagesFinal AOH Report - TMD 060818sanmukhaNo ratings yet

- Erection Sequence of Steam TurbineDocument4 pagesErection Sequence of Steam Turbinefatima_khadra380960% (5)

- RM85,125,250K6 '06 Race Preparation ManualDocument17 pagesRM85,125,250K6 '06 Race Preparation ManualNikolas KarrerNo ratings yet

- Installation Procedure of Turbine +generatorDocument7 pagesInstallation Procedure of Turbine +generatoryeddidyonatanNo ratings yet

- Bhel Horn Drop TestDocument4 pagesBhel Horn Drop Testarindam misra8No ratings yet

- LP Turbine Assembly ProcedureDocument8 pagesLP Turbine Assembly Procedurebhushanbharat_843298No ratings yet

- Preventive Maintenance Schedule For Bowl Mill & Coal Feeder of "U# 8, D.P.P.S."Document7 pagesPreventive Maintenance Schedule For Bowl Mill & Coal Feeder of "U# 8, D.P.P.S."mrinal mandalNo ratings yet

- Erection Sequence: (For 500 MW Fixed Pedestal Type Turbine With Spring Loaded Foundation)Document4 pagesErection Sequence: (For 500 MW Fixed Pedestal Type Turbine With Spring Loaded Foundation)rohit_me083100% (1)

- Z03 AersqDocument6 pagesZ03 AersqPhilip PetersonNo ratings yet

- Sequence of Turbine Erection Upto BaringDocument6 pagesSequence of Turbine Erection Upto BaringPeter Antony100% (2)

- Steam Turbine 500 MW Erection Erection SequenceDocument4 pagesSteam Turbine 500 MW Erection Erection Sequencelovelyshree100% (1)

- SR No Equipments Action Taken by Process: MUW-1/2 FSSAI Related Job ListDocument2 pagesSR No Equipments Action Taken by Process: MUW-1/2 FSSAI Related Job ListPushpendra YadavNo ratings yet

- Mold Drop Check SheetDocument1 pageMold Drop Check SheetRS MANIKANDANNo ratings yet

- BHEL Feed BackDocument58 pagesBHEL Feed BackelrajilNo ratings yet

- Erection Procedure For Floating Roof TankDocument10 pagesErection Procedure For Floating Roof Tankabdul1207100% (2)

- Presented By: Bill Brayton ATRA Senior Research TechnicianDocument39 pagesPresented By: Bill Brayton ATRA Senior Research TechnicianDavid Lacunes100% (1)

- Turbine Punch Point Closeout Status-For HURLDocument7 pagesTurbine Punch Point Closeout Status-For HURLpriyajit sahooNo ratings yet

- Constraint For Hydro Test DocumentationDocument1 pageConstraint For Hydro Test DocumentationjalNo ratings yet

- PML 087a - PMS - EngineDocument70 pagesPML 087a - PMS - EngineFidriNo ratings yet

- How To Order A Gauge: Above Ground Under GroundDocument15 pagesHow To Order A Gauge: Above Ground Under Groundأسامة حمدونىNo ratings yet

- Steam Turbine ChecklistDocument5 pagesSteam Turbine ChecklistVlanic StudioNo ratings yet

- Steamturbineintroductionmaintenanceppt 170211165058Document101 pagesSteamturbineintroductionmaintenanceppt 170211165058praditya100% (1)

- ERECTION MANUAL LDT 225 - 1000 Cooling Tower Liang Ho PDFDocument9 pagesERECTION MANUAL LDT 225 - 1000 Cooling Tower Liang Ho PDFMohammad IqbalNo ratings yet

- Assembly Instructions For GS DOUBLE Chamber Pumps-2013Document33 pagesAssembly Instructions For GS DOUBLE Chamber Pumps-2013arasNo ratings yet

- 06 - Rubbing Detection in A Synthesis Gas CompressorDocument10 pages06 - Rubbing Detection in A Synthesis Gas CompressorSeresdfrtNo ratings yet

- Fine Tuner TD181 - Iss A - Illustrated Troubleshooting and Set Up Guide For EL PositionersDocument7 pagesFine Tuner TD181 - Iss A - Illustrated Troubleshooting and Set Up Guide For EL PositionerskaleesuwariNo ratings yet

- Presentation On Constructional Features of 57.02Mw Steam Turbine at Aes KelanitissaDocument27 pagesPresentation On Constructional Features of 57.02Mw Steam Turbine at Aes KelanitissaSagar BahirjeNo ratings yet

- 4l60e Reaction Carrier Shaft and 5 Pinion PlanetsDocument1 page4l60e Reaction Carrier Shaft and 5 Pinion Planetscyber_nauticaNo ratings yet

- NB 41AS Honda 5 Speed Installation GuideDocument8 pagesNB 41AS Honda 5 Speed Installation GuideJuan LunaNo ratings yet

- Preventive Maintenance Checklist Drafted Q34 Q44 1Document152 pagesPreventive Maintenance Checklist Drafted Q34 Q44 1shani5573100% (1)

- 01 QC Preventive Maintenance Checklist Drafted Q34 Q44 1Document153 pages01 QC Preventive Maintenance Checklist Drafted Q34 Q44 1shani5573No ratings yet

- Swing CheckDocument3 pagesSwing CheckSuresh RamanujaluNo ratings yet

- Shut in Procedures PDFDocument71 pagesShut in Procedures PDFRichard Reiersen100% (3)

- Condenser Sequential Erection ProcessDocument6 pagesCondenser Sequential Erection ProcessbairagimohitNo ratings yet

- Trick Flow Camshaft Degreeing Kit: Instructions ForDocument4 pagesTrick Flow Camshaft Degreeing Kit: Instructions ForROYALNo ratings yet

- Dodge Ram 2006 SRM Includes SRT-10 & Diesel Factory Service Manual - SteeringDocument116 pagesDodge Ram 2006 SRM Includes SRT-10 & Diesel Factory Service Manual - SteeringLuis Ramon Arguello RealNo ratings yet

- Aop Jop Eop InterlocksDocument27 pagesAop Jop Eop InterlocksAbhishek Prakash SrivastavaNo ratings yet

- Yamaha R6 Service ManualDocument394 pagesYamaha R6 Service ManualJohn Michael HonradaNo ratings yet

- Ruturaj ED11B032 PPT 1 PDFDocument25 pagesRuturaj ED11B032 PPT 1 PDFRuturaj BargalNo ratings yet

- E & C ManaulDocument57 pagesE & C ManaulnikerNo ratings yet

- Presentation On Simhadri Unit-2 High VibrationDocument21 pagesPresentation On Simhadri Unit-2 High VibrationVIBHAV100% (1)

- CementDocument44 pagesCementPawan SinghNo ratings yet

- HIP Turbine Erectioin Sequence LPA Turbine Erection SequenceDocument8 pagesHIP Turbine Erectioin Sequence LPA Turbine Erection SequenceMukesh BhandakkarNo ratings yet

- Pressure Chart ConvertorDocument8 pagesPressure Chart ConvertorMukesh BhandakkarNo ratings yet

- Pressure Chart ConvertorDocument8 pagesPressure Chart ConvertorMukesh BhandakkarNo ratings yet

- Missouri Department of Transportation: Standard Inspection and Testing Plan (ITP)Document32 pagesMissouri Department of Transportation: Standard Inspection and Testing Plan (ITP)mohamedamine.zemouriNo ratings yet

- Unit B: What Is Customer-Based Brand Equity?Document3 pagesUnit B: What Is Customer-Based Brand Equity?So-Nam Dorji Dr-UKpaNo ratings yet

- Adiba Final Activity CousellingDocument29 pagesAdiba Final Activity Cousellingadiba KhanNo ratings yet

- Star WarsDocument28 pagesStar Warsalex1971No ratings yet

- Pilot Implementation of The Limited Face-to-Face Class Program at Librada Avelino Elementary SchoolDocument10 pagesPilot Implementation of The Limited Face-to-Face Class Program at Librada Avelino Elementary SchoolCher GeriNo ratings yet

- ( (2004) Yamamuro & Wood) - Effect of Depositional Method On The Undrained Behavior and Microstructure of Sand With SiltDocument10 pages( (2004) Yamamuro & Wood) - Effect of Depositional Method On The Undrained Behavior and Microstructure of Sand With SiltLAM TRAN DONG KIEMNo ratings yet

- Chart and Compass (London Zetetic Society)Document8 pagesChart and Compass (London Zetetic Society)tjmigoto@hotmail.comNo ratings yet

- Word Formation ListDocument8 pagesWord Formation ListpaticiaNo ratings yet

- Robit Forepoling Catalogue ENG 03-2015Document36 pagesRobit Forepoling Catalogue ENG 03-2015Purwadi Eko SaputroNo ratings yet

- MMC 16101 - Positive Displacement Pump - 01Document19 pagesMMC 16101 - Positive Displacement Pump - 01HET DEDHIANo ratings yet

- Mindfulness For Two An Acceptance and Commitment TDocument5 pagesMindfulness For Two An Acceptance and Commitment TNilton SantosNo ratings yet

- Geometallurgical Modelling of The Collahuasi Flotation CircuitDocument6 pagesGeometallurgical Modelling of The Collahuasi Flotation CircuitFrancisco CampbellNo ratings yet

- Eng Essay For PresentationDocument8 pagesEng Essay For Presentationctn batrisyiaNo ratings yet

- Mds SM13CRM 110 enDocument5 pagesMds SM13CRM 110 enColinNo ratings yet

- Conversation Class - Video GamesDocument4 pagesConversation Class - Video GamesMaíra MouraNo ratings yet

- Digital Thermometer Using Arduino: Mini Project Report ONDocument5 pagesDigital Thermometer Using Arduino: Mini Project Report ONNeha PintoNo ratings yet

- ISO IEC 11801-5 - IT - Generic Cabling For Data CentreDocument63 pagesISO IEC 11801-5 - IT - Generic Cabling For Data Centreshazwanshaiful1No ratings yet

- CSE 473 Pattern Recognition: Instructor: Dr. Md. Monirul IslamDocument57 pagesCSE 473 Pattern Recognition: Instructor: Dr. Md. Monirul IslamNadia Anjum100% (1)

- Daftar Isian 3 Number Plate, Danger Plate, Anti Climbing DeviceDocument2 pagesDaftar Isian 3 Number Plate, Danger Plate, Anti Climbing DeviceMochammad Fauzian RafsyanzaniNo ratings yet

- Assignment-2: 1) Explain Classification With Logistic Regression and Sigmoid FunctionDocument6 pagesAssignment-2: 1) Explain Classification With Logistic Regression and Sigmoid FunctionpraneshNo ratings yet

- New Techniques of Predictions # 1Document5 pagesNew Techniques of Predictions # 1bhagathi nageswara raoNo ratings yet

- FWD Week 47 Learning Material For Alaric YeoDocument7 pagesFWD Week 47 Learning Material For Alaric YeoarielNo ratings yet

- ISMR B-School BrochureDocument28 pagesISMR B-School Brochurerahul kantNo ratings yet

- Lesson 15 Validity of Measurement and Reliability PDFDocument3 pagesLesson 15 Validity of Measurement and Reliability PDFMarkChristianRobleAlmazanNo ratings yet

- Oct2020 GCE Final PDFDocument30 pagesOct2020 GCE Final PDFGavinNo ratings yet

- Chapter Two Sector Analysis: (MBAM)Document23 pagesChapter Two Sector Analysis: (MBAM)Ferlyn PelayoNo ratings yet