Professional Documents

Culture Documents

BoltMethod Check

Uploaded by

actstyrolOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BoltMethod Check

Uploaded by

actstyrolCopyright:

Available Formats

BOLT MATL:

1001 REDHILL INDUSTRIAL ESTATE #04-01 / 06 JALAN

BUKIT MERAH, SINGAPORE 159455. FLANGE MATL: ASTM A105 BOLT SIZE:

FAX:(65) 6273-3121 / 6273-9670 FLANGE SIZE: NO. OF BOLT:

TEL:(65) 6271-0800 JOINT REF: NUT SIZE (A/F):

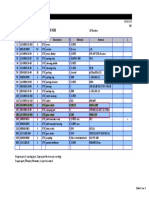

ASME VIII BOLT LOADS AND SYSTEM PRESSURES TO ASME VIII 1996 DIVISION 1

METHOD OF STATEMENT (BOLT TENSIONING) AND CHECK SHEET

GASKET TYPE: BOLT TENSIONER MODEL:

TOOL COVERAGE : 100% of Stubs per bolting exercise NUMBER OF BOLT TENSIONER:

The following procedure shall be carried out with reference to the appropriate "BOLT TENSIONING DATA SHEET".

Required Bolt Load: lbf.

Bolt Stress at: psi Check " √ "

STEP 1 Assemble 50% of the tensioning tools to one side of the joint equally spread

with the remaining 50% on the opposite adjacent stub bolts

STEP 2 Ensure all hydraulic hose are connected from both side of the tensioners

STEP 3 Then apply 2nd pass pressure as specified on the "Bolt Tensioning Data".

while maintaining the pressure, turn down all nuts using tommy bar.

2nd Pass Pressure psi

STEP 3 Release the system pressure and repeat the STEP 3,

until there is no further nut movement.

Final Pass Pressure psi

STEP 4 Using a hammer, "ring" each nut to ensure that no slack bolts are remain.

At this stage the tensioning operation is said to be completed.

SAFETY * All necessary safety precautions have been carried out.

CHECK

* Personnel involved in bolt tensioning are competent and fully

trained in the use of bolt tensioners and tightening techniques.

REMARKS

Client: Work preformed by:

Contract No.:

Attention to: Work checked by:

Date:

BOLT MATL:

1001 REDHILL INDUSTRIAL ESTATE #04-01 / 06 JALAN

BUKIT MERAH, SINGAPORE 159455. FLANGE MATL: ASTM A105 BOLT SIZE:

FAX:(65) 6273-3121 / 6273-9670 FLANGE SIZE: NO. OF BOLT:

TEL:(65) 6271-0800 JOINT REF: NUT SIZE (A/F):

ASME VIII BOLT LOADS AND SYSTEM PRESSURES TO ASME VIII 1996 DIVISION 1

METHOD OF STATEMENT (BOLT TENSIONING) AND CHECK SHEET

GASKET TYPE: BOLT TENSIONER MODEL:

TOOL COVERAGE : 50% of Stubs per bolting exercise NUMBER OF BOLT TENSIONER:

The following procedure shall be carried out with reference to the appropriate "BOLT TENSIONING DATA SHEET".

Required Bolt Load: lbf.

Bolt Stress at: psi Check " √ "

STEP 1 Number all bolts in consecutively order, 1, 2, 1, 2, 1, 2, etc… and in

a clockwise direction.

STEP 2 Assemble tensioning tools to 50% of the bolts (example all number 1 bolts)

and apply nominal pressure for box up. Then apply 1st pass pressure as

specified on the "Bolt Tensioning Data".

1st Pass Pressure psi

STEP 3 Move tensioning tools to the next 50% of the bolts (example all number 2 bolts)

and apply 2nd pass pressure as specified on the "Bolt Tensioning Data".

2nd Pass Pressure psi

STEP 4 Move tensioning tools to the previously tightened in STEP 2 (all the number

1 bolts) and apply 2nd pass pressure as a final check.

Final Pass Pressure psi

STEP 5 Using a hammer, "ring" each nut to ensure that no slack bolts are remain.

At this stage the tensioning operation is said to be completed.

SAFETY * All necessary safety precautions have been carried out.

CHECK

* Personnel involved in bolt tensioning are competent and fully

trained in the use of bolt tensioners and tightening techniques.

REMARKS

Client: Work preformed by:

Contract No.:

Attention to: Work checked by:

Date:

BOLT MATL:

1001 REDHILL INDUSTRIAL ESTATE #04-01 / 06 JALAN

BUKIT MERAH, SINGAPORE 159455. FLANGE MATL: ASTM A105 BOLT SIZE:

FAX:(65) 6273-3121 / 6273-9670 FLANGE SIZE: NO. OF BOLT:

TEL:(65) 6271-0800 JOINT REF: NUT SIZE (A/F):

ASME VIII BOLT LOADS AND SYSTEM PRESSURES TO ASME VIII 1996 DIVISION 1

METHOD OF STATEMENT (BOLT TENSIONING) AND CHECK SHEET

GASKET TYPE: BOLT TENSIONER MODEL:

TOOL COVERAGE : 33-1/3% of Stubs per bolting exercise NUMBER OF BOLT TENSIONER:

The following procedure shall be carried out with reference to the appropriate "BOLT TENSIONING DATA SHEET".

Required Bolt Load: lbf.

Bolt Stress at: psi Check " √ "

STEP 1 Number all bolts in consecutively order, 1, 2, 3, 1, 2, 3, 1, 2, etc… and in

a clockwise direction.

STEP 2 Assemble tensioning tools to 33-1/3% of the bolts (example group A, all number

1 bolts) and apply nominal pressure for box up. Then apply 1st pass pressure

as specified on the "Bolt Tensioning Data".

1st Pass Pressure psi

STEP 3 Move tensioning tools to the next 33-1/3% of the bolts (example group B, all

number 2 bolts) and apply 1st pass pressure as specified on the "Bolt

Tensioning Data".

1st Pass Pressure psi

STEP 4 Move tensioning tools to the next 33-1/3% of the bolts (example group C, all

number 3 bolts) and apply 2nd pass pressure as specified on the "Bolt

Tensioning Data".

2nd Pass Pressure psi

STEP 5 Due to the number of passes required load loss will have occurred in bolts

tightened in STEP 2 and STEP 3. Therefore, assemble tensioning tools

to bolts previously tightened in STEP 2 (group A) and STEP 3 (group B)

and apply final checked pass (2nd pass pressure).

Final Pass Pressure psi

STEP 6 Using a hammer, "ring" each nut to ensure that no slack bolts are remain.

At this stage the tensioning operation is said to be completed.

SAFETY * All necessary safety precautions have been carried out.

CHECK

* Personnel involved in bolt tensioning are competent and fully

trained in the use of bolt tensioners and tightening techniques.

REMARKS

Client: Work preformed by:

Contract No.:

Attention to: Work checked by:

Date:

BOLT MATL:

1001 REDHILL INDUSTRIAL ESTATE #04-01 / 06 JALAN

BUKIT MERAH, SINGAPORE 159455. FLANGE MATL: ASTM A105 BOLT SIZE:

FAX:(65) 6273-3121 / 6273-9670 FLANGE SIZE: NO. OF BOLT:

TEL:(65) 6271-0800 JOINT REF: NUT SIZE (A/F):

ASME VIII BOLT LOADS AND SYSTEM PRESSURES TO ASME VIII 1996 DIVISION 1

METHOD OF STATEMENT (BOLT TENSIONING) AND CHECK SHEET

GASKET TYPE: BOLT TENSIONER MODEL:

TOOL COVERAGE : 25% of Stubs per bolting exercise NUMBER OF BOLT TENSIONER:

The following procedure shall be carried out with reference to the appropriate "BOLT TENSIONING DATA SHEET".

Required Bolt Load: lbf.

Bolt Stress at: psi Check " √ "

STEP 1 Number all bolts in consecutively order, 1, 2, 3, 4, 1, 2, 3, 4, 1, etc… and in

a clockwise direction.

STEP 2 Assemble tensioning tools to 25% of the bolts (example group A, all number

1 bolts) and apply nominal pressure for box up. Then apply 1st pass pressure

as specified on the "Bolt Tensioning Data".

1st Pass Pressure psi

STEP 3 Move tensioning tools to the next 25% of the bolts (example group B, all

number 2 bolts) and apply 1st pass pressure as specified on the "Bolt

Tensioning Data".

1st Pass Pressure psi

STEP 4 Move tensioning tools to the next 25% of the bolts (example group C, all

number 3 bolts) and apply 2nd pass pressure as specified on the "Bolt

Tensioning Data".

2nd Pass Pressure psi

STEP 5 Move tensioning tools to the next 25% of the bolts (example group D, all

number 4 bolts) and apply 2nd pass pressure as specified on the "Bolt

Tensioning Data".

2nd Pass Pressure psi

STEP 6 Moving tensioning tools to bolts previously tightened in STEP 2 (group A) and

STEP 3 (group B) and apply final checked pass (2nd pass pressure).

Final Pass Pressure psi

STEP 7 Using a hammer, "ring" each nut to ensure that no slack bolts are remain.

At this stage the tensioning operation is said to be completed.

SAFETY * All necessary safety precautions have been carried out.

CHECK

* Personnel involved in bolt tensioning are competent and fully

trained in the use of bolt tensioners and tightening techniques.

REMARKS

Client: Work preformed by:

Contract No.:

Attention to: Work checked by:

Date:

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Veg Dum Biryani - Hyderabadi Veg Biryani Recipe - Hyderabadi Biryani - Hebbar's KitchenDocument2 pagesVeg Dum Biryani - Hyderabadi Veg Biryani Recipe - Hyderabadi Biryani - Hebbar's KitchenmusicalcarpetNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Lesson Notes Lecture 14Document5 pagesLesson Notes Lecture 14Quantum SaudiNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Legend Of Symbols: Chú Thích Các Ký HiệuDocument9 pagesLegend Of Symbols: Chú Thích Các Ký HiệuKiet TruongNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Course On Quantum ComputingDocument235 pagesCourse On Quantum ComputingAram ShojaeiNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Spina 2002Document10 pagesSpina 2002hasantapNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Geology of Johannesburg ReadingDocument2 pagesGeology of Johannesburg ReadingKavish DayaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 1.1 Introduction To KennametalDocument40 pages1.1 Introduction To KennametalVig PankajNo ratings yet

- Aesa Based Pechay Production - AbdulwahidDocument17 pagesAesa Based Pechay Production - AbdulwahidAnne Xx100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Farmhouse Style Plans - Farm & CountryDocument6 pagesFarmhouse Style Plans - Farm & Countryhanif azriNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Introduction: Science and Environment: Brgy - Pampang, Angeles City, PhilippinesDocument65 pagesIntroduction: Science and Environment: Brgy - Pampang, Angeles City, PhilippinesLance AustriaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Medical CodingDocument5 pagesMedical CodingBernard Paul GuintoNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Benefits of OTN in Transport SDNDocument9 pagesBenefits of OTN in Transport SDNGhallab AlsadehNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Nema MG10 PDFDocument27 pagesNema MG10 PDFManuel Antonio Santos VargasNo ratings yet

- ESM-4810A1 Energy Storage Module User ManualDocument31 pagesESM-4810A1 Energy Storage Module User ManualOscar SosaNo ratings yet

- HPE 3PAR StoreServ 20000 Storage Service and Upgrade Guide Service EditionDocument282 pagesHPE 3PAR StoreServ 20000 Storage Service and Upgrade Guide Service Editionben boltNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Aci 522R-06 PDFDocument25 pagesAci 522R-06 PDFaldi raimon100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Good Practices in Tray DesignDocument7 pagesGood Practices in Tray Designmehul10941100% (2)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Titan GelDocument6 pagesTitan GelVladi Salas100% (1)

- SVR Neuro Quote 2 PROvidoDocument3 pagesSVR Neuro Quote 2 PROvidoChejarla Naveen KumarNo ratings yet

- ADC ManualDocument47 pagesADC ManualRavi ShuklaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Nitofloor NDocument3 pagesNitofloor Nkiranmisale7No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- CM Bu9000 Eng Bushings 3Document36 pagesCM Bu9000 Eng Bushings 3ing.dmanriq27100% (1)

- Pertanyaan TK PDBDocument4 pagesPertanyaan TK PDBHardenNo ratings yet

- Etl 213-1208.10 enDocument1 pageEtl 213-1208.10 enhossamNo ratings yet

- Kulkarni Shilpa A.Document148 pagesKulkarni Shilpa A.MSKCNo ratings yet

- LINEAR INDUCTION MOTOR 6981660.ppsxDocument56 pagesLINEAR INDUCTION MOTOR 6981660.ppsxFalley FasterNo ratings yet

- Dwnload Full Psychology Core Concepts 7th Edition Zimbardo Test Bank PDFDocument13 pagesDwnload Full Psychology Core Concepts 7th Edition Zimbardo Test Bank PDFcomfortdehm1350100% (7)

- Wet Chemical Pre E PresentationDocument310 pagesWet Chemical Pre E PresentationEdwardAlexanderGarciaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Burst Abdomen 3Document12 pagesBurst Abdomen 3Satvik BansalNo ratings yet

- Pediatric Gynecology BaruDocument79 pagesPediatric Gynecology BaruJosephine Irena100% (2)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)