Professional Documents

Culture Documents

Fabricacion Inteligente de Moldes

Uploaded by

Carlo Villar CaniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fabricacion Inteligente de Moldes

Uploaded by

Carlo Villar CaniCopyright:

Available Formats

Session VA5

Intelligent Manufacturing Process Tool For Plastic Injection Molding

Aravind Kumbakonam, Terrence L. Chambers, Suren N. Dwivedi

Department of Mechanical Engineering

University of Louisiana, Lafayette

Bill Best

Ash Industries

Abstract

This paper presents an overview of ongoing research aimed at the development of a Computer-

Based Intelligent Manufacturing Process Tool, at the University of Louisiana at Lafayette. The

Manufacturing Process Tool is a computer program, which would help the manufacturer in

solving problems associated with Injection Molding. These problems include long process set up

time, non-optimized cycle time, and poor control of the molding process. The Manufacturing

Process Tool would eventually help the machine operator (who need not be an expert) in setting

up, optimizing, and controlling the Injection Molding Process; thus maximizing the production

rate on that particular Injection Molding machine.

Introduction

Plastic Injection Molding is the world’s most common method of producing complex

commercial plastic parts with excellent dimensional tolerance. According to the C-mold design

guide, 32% by weight of all plastics processed go through Injection Molding machines, making

Plastic Injection Molding one of the most important manufacturing processes2. It is seen that the

final molded part quality is chiefly dependent on the type of material, mold design and the

molding process settings. Once the material and the mold to be used are specified, the part

quality basically depends on the molding process. The molding process is quite complex

involving many variable process parameters like pressure, temperature and time settings. These

process parameters have to be optimally set in order to improve part quality and maximize the

production capacity of the Injection Molding machine. Educated and experienced individuals

are required to set up and optimize such a complex process. These individuals control the

molding process on a trial and error basis, which is usually time consuming. This method of

controlling the molding process relies heavily on operator intuition and a few “rules of thumb,”

which the operator develops over a period of time while working with different materials,

pressures, temperatures and time settings.

This paper presents an outline of ongoing research at the University of Louisiana at Lafayette

involving the development of Intelligent Knowledge-Based Engineering Modules (IKEM) for

Proceedings Of 2002 ASEE Gulf- Southwest Annual Conference,

The University of Louisiana at Lafayette, March 20-22,2002

Copyright @ 2002, American Society for Engineering Education

the Injection Molding process. IKEM has different modules, namely: Parsing, Mold Design,

Cycle Time and the Manufacturing module, which are linked to each other. This paper mainly

concentrates on the Manufacturing module, which involves the development of an Intelligent

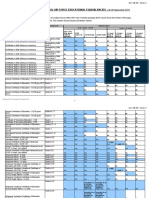

Manufacturing Process Tool called “The Optimizer.” Figure 1 and 2 show the transfer of data

between the different modules of IKEM.

Material MOLD DESIGN

Database MODULE

PARSING

MANUFACTURING DATA TRANSFER MODULE

MODULE

Machine

CYCLE TIME

database

MODULE

Expert system

Figure 1.Intelligent Knowledge Base Engineering Modules For Plastic Injection Molding

Figure 2. Data Flow Diagram

Proceedings Of 2002 ASEE Gulf- Southwest Annual Conference,

The University of Louisiana at Lafayette, March 20-22,2002

Copyright @ 2002, American Society for Engineering Education

The Optimizer captures non-deterministic knowledge in the Injection Molding process from an

expert in this field, and also uses deterministic knowledge available in the form of relations, look

up tables, etc. The Optimizer is written in Visual Basic, and would assist the machine operator

in setting up, optimizing and controlling the Injection Molding Process and thus maximize the

production rate on that particular Injection Molding machine. As shown in Figure3, The

Optimizer helps the manufacturer in the set up of the molding machine, by giving him the initial

optimal process parameter values. These values could be later fine tuned for personal benefits

by the operator using his intuition and guesswork.

Final Product

Time

Fine-tuning

Initial Process

Setup

Design stage Manufacturing stage

Product Development

Figure 3. Product Development Vs Time

Knowledge-Based Engineering Modules

An expert system, or a knowledge-based system, is defined as “a model and associated procedure

that exhibits, within a specific domain, a degree of expertise in problem solving that is

comparable to that of a human expert5.” Of the different kinds of expert systems available,

which have their individual advantages and disadvantages, the “Rule Based” type of knowledge-

based system is the one that is most commonly used. It basically consists of a knowledge base,

containing a set of “IF-THEN” statements, called “rules.”

The IKEM project deals with creating an expert system containing a set of IF-THEN rules

collected from the human expert with the help of knowledge engineers. Two of the most

important issues that are essential to the reliability of this rule-based type expert system are, the

Knowledge Acquisition and Knowledge Representation.

Proceedings Of 2002 ASEE Gulf- Southwest Annual Conference,

The University of Louisiana at Lafayette, March 20-22,2002

Copyright @ 2002, American Society for Engineering Education

Knowledge Acquisition

This is the initial approach wherein the knowledge engineers extract the rules from the human

expert. This step is quite labor intensive, and has been considered the bottleneck in the expert

system development process. Knowledge acquisition mainly depends on the skills of the

knowledge engineer. His primary aim is to extract strategies or rules of thumb from the human

expert(s) and transfer it to the knowledge base. Care has to be taken during the knowledge

acquisition process, as it directly affects the knowledge representation scheme, later. It’s seen

that there are two basic types of Knowledge Acquisition:

1. Knowledge Acquisition directly from the human expert (non deterministic knowledge)

2. Knowledge Acquisition thorough previous cases, relations, look up tables (deterministic

knowledge).

The Intelligent Manufacturing Tool being developed intends to capture non–deterministic

knowledge which is gained by experience in the field, as well as more deterministic knowledge

available in the form of relations, look up tables, etc.

A student knowledge engineer from the University of Louisiana at Lafayette has been working in

conjunction with Ash Industries, Lafayette, which is primarily a Plastic Injection Molding plant.

The knowledge engineer interviews the human expert at Ash Industry. He then organizes this

extracted data in a logical fashion. This knowledge extracted from the expert is in the form of

heuristics, or more precisely “rules of thumb.” The expert develops these heuristics or rules of

thumb intuitionally and from his prior experience in this field. These “rules of thumb” act as the

guidelines, using which; the molding process is operated for the most optimal product quality.

A typical example of a set of “rules of thumb” or heuristics developed by the expert useful

in the calculation of clamp tonnage is:

Rule 1: IF part wall thickness >= 0.04 inch

And material = crystalline

THEN clamp tonnage = 2.0 ton/ inch2 *

Rule 2: IF part wall thickness < 0.04 inch

And material = crystalline

THEN clamp tonnage = 2.6 ton/inch2

Rule 3: IF part wall thickness >= 0.04 inch

And material = amorphous

THEN clamp tonnage = 3.0 ton/inch2

Rule 4: IF part wall thickness < 0.04 inch

And material = amorphous

THEN clamp tonnage =3.6 ton/inch2

* Inch2 represents the cross sectional area of the total number of parts in the mold that are

perpendicular to the nozzle of the injection molding machine.

Proceedings Of 2002 ASEE Gulf- Southwest Annual Conference,

The University of Louisiana at Lafayette, March 20-22,2002

Copyright @ 2002, American Society for Engineering Education

To this rule set we add a couple more rules, to determine whether the material selected is

amorphous or crystalline. Using these six rules the expert system calculates the required clamp

tonnage.

Rule 5: IF mold shrink, linear flow rate** of the material < 12

THEN material = amorphous.

Rule 6: IF mold shrink, linear flow rate of the material >= 12

THEN material = crystalline.

Knowledge Representation

Knowledge Representation is the second stage of the knowledge engineering process, wherein

the knowledge acquired is coded into the Knowledge Base. The heuristics obtained by the

knowledge engineer from the human expert are represented in the knowledge base using IF-

THEN rules so that conclusions can be drawn by the expert system. These IF-THEN rules are

then coded in VISUAL BASIC. A separate material database is created in Microsoft Access

and then linked with the Visual Basic program. This is shown in Figure 4.

Figure 4. Access to Visual Basic Linkage

** Mold shrink, linear flow rate obtained from the material database.

Proceedings Of 2002 ASEE Gulf- Southwest Annual Conference,

The University of Louisiana at Lafayette, March 20-22,2002

Copyright @ 2002, American Society for Engineering Education

The Outputs

The Optimizer gives out the most optimized values of different parameters affecting the Injection

Molding process, which have to be controlled in order to ensure that a high quality part is

produced in the most economical way. The outputs of The Optimizer could be confined to four

different categories, namely: the Temperature, Pressure, and Time And Distance. Each of these

outputs are represented in Figure 5 and discussed in detail below.

Temperature:

Approximately 80% of the plastic products produced today are made of thermoplastics.

Thermoplastics could be defined as “ plastic materials which, when heated, undergoes physical

change1.”

The different types of thermoplastics are:

• Amorphous materials, “ which basically soften as the temperature is increased and get

softer and softer as more heat is absorbed, until they degrade1.”

• Crystalline materials, “ these don’t have a softening stage but they stay firm until they are

heated to a particular point at which they start to melt and later degrade if more heat is

added1. ”

INPUTS

OUTPUTS

Clamp tonnage

User input

• Machine data

• Material etc Injection pressure

Hold pressure

Parsing program

•Part surface area Melt, Mold, Nozzle,

Barrel temperatures

•Part dimensions

Shot size

Mold design MANUFACTURING

•Flow length PROCESS Distance between 2

OPTIMIZER halves of the mold

•Type of Gate

•Gate dimensions Screw Speed &

•Sprue dimensions Screw recovery time

Cooling time

Cycle time

Back Pressure

Figure 5. The Optimizer.

Proceedings Of 2002 ASEE Gulf- Southwest Annual Conference,

The University of Louisiana at Lafayette, March 20-22,2002

Copyright @ 2002, American Society for Engineering Education

Considering the differences in the properties of amorphous and crystalline materials, we set the

different temperatures in the Injection Molding machine.

1. Melt temperature: The temperature to which plastic material has to be heated before it is

injected into the mold. Optimizing the melt temperature results in controlling the flow

rate of the material, material degradation, brittleness and flashing.

2. Barrel temperatures: The different temperatures to be set at the rear, middle and the front

end of the barrel of the injection-molding machine.

3. Nozzle temperature: The temperature set at the machine nozzle, which is right in front of

the heating zone (barrel) of the plastic.

4. Mold temperature: The temperature at which the injection mold has to be set to obtain a

plastic part of high quality with a lower cycle time. The optimized mold temperature

helps in obtaining reduced cycle time and better part quality having a glossy finish, less

warp and less shrinkage.

Pressure:

There are various pressures to be optimized in the Injection-Molding machine.

1. Clamp Pressure: The amount of pressure to hold the injection mold tightly against the

injection pressure. The optimal clamp pressure prevents the mold from flashing due to

less clamp tonnage. It even saves energy and the mold from collapsing due to high clamp

tonnage.

2. Injection Pressure: The amount of pressure required to produce the initial filling (95%)

of the mold cavity. The optimized injection pressure helps to attain a part of high quality,

less shrinkage, less warp, and that is easy to eject.

3. Holding Pressure: The second stage of the injection pressure, and usually fills up the

remaining 5% of the mold cavity. It is usually needed to hold the plastic in the mold,

from flowing back into the barrel.

4. Back Pressure: The pressure exerted by the plastic on the screw spindle. Optimized

backpressure helps in obtaining a part of better density and fewer voids.

Time:

• Cooling time: It is the amount of time required by the plastic part in the mold cavity to

solidify and get ejected safely. The optimized cooling time helps in achieving better

cycle time.

Distance:

• Mold open distance: The distance for the mold halves to open apart in order to eject the

part safely. Optimal mold open distance is necessary for better cycle time.

Proceedings Of 2002 ASEE Gulf- Southwest Annual Conference,

The University of Louisiana at Lafayette, March 20-22,2002

Copyright @ 2002, American Society for Engineering Education

Conclusion

The Manufacturing Process Tool, which has been discussed in this paper, is being developed at

the University of Louisiana at Lafayette. When completed this Tool will be able to give the

initial optimal process parameter values, which are crucial to start off the injection molding

process. These values could be later fine tuned for personal benefits by the operator using his

intuition and guesswork.

References

1. Douglas M.B., Fundamentals of Injection Molding: Material Selection and Product Design Fundamentals,

Vol. 2, Society of Manufacturing Engineers.

2. C-MOLD Design Guide. - A Resource for Plastic Engineers.

3. Dym. J. B., Injection Molds and Molding, 2nd edition, Van Nostrand Reinhold.

4. Xinming Jin, Xuefeng Zhu, “Process Parameters Setting Using Case-Based and Fuzzy Reasoning for

Injection Molding.” Proceedings of the 3rd World Congress on Intelligent Control and Automation. June

28-July 2, 2000, Hefei, P.R. China.

5. Ignizio J. P., Introduction to Expert Systems: The Development and Implementation of Rule-Based Expert

Systems, Mc Graw Hill.

6. Bob Hatch, On the Road with Bob Hatch: 100 Injection Molding problems solved by IMM’s

Troubleshooter, Injection Molding Magazine.

7. Mok S.L, Kwong. C.K,Lau. W.S “ Review of research in the determination of process parameters for

plastic injection molding.” Advances in Polymer Technology, V 18, n 3, 1999, p 225-236.

8. Shelesh-Nezhad. K, Siores, E. “Intelligent system for plastic injection molding process design.”

Proceedings of 1996 3rd Asia Pacific Conference on Materials Processing, Nov 12-14 1996, Hong Kong,

Hong Kong, p 458-462

9. Yeung.V.W.S., Lau.K.H., “ Injection Molding, ‘C-MOLD’ CAE package, Process Parameter Design and

Quality Function Deployment: A case study of intelligent materials processing.” Published in Journal of

Materials Processing Technology.

ARAVIND KUMBAKONAM

Mr. Kumbakonam is a graduate student of the Mechanical Engineering Department at the University of Louisiana at

Lafayette. He had done his B.S. form Bangalore Institute of Technology, Bangalore, India. His areas of research

include Design, Solid Modeling, Artificial Intelligence and Supply Chain Management.

SUREN N. DWIVEDI

Dr. Dwivedi is the Endowed chair Professor of Manufacturing in the Mechanical Engineering Department at the

University of Louisiana at Lafayette. His research interests include Integrated Product and Process Development

(IPPD), Concurrent Engineering, Manufacturing Systems, and CAD/CAM.

TERRENCE L. CHAMBERS

Dr. Chambers is an Assistant Professor and the Mechanical Engineering/LEQSF Regents Professor in Mechanical

Engineering at the University of Louisiana at Lafayette. His research interests include design optimization, artificial

intelligence. He is a member of ASME and ASEE, and is currently serving as the Vice-President of the ASEE Gulf-

Southwest Section. Prof. Chambers is a registered Professional Engineer in Texas and Louisiana.

BILL BEST

Mr. Bill Best is currently working as a plant manager at Ash Industries in Lafayette, LA. He is an expert in the field

of injection molding having an experience of more than 40 years in this field.

Proceedings Of 2002 ASEE Gulf- Southwest Annual Conference,

The University of Louisiana at Lafayette, March 20-22,2002

Copyright @ 2002, American Society for Engineering Education

You might also like

- Presentación1 - Pecha KuchaDocument3 pagesPresentación1 - Pecha KuchaCarlo Villar CaniNo ratings yet

- Content ServerDocument21 pagesContent ServerOmar TerraNo ratings yet

- Presentación1 - Pecha KuchaDocument3 pagesPresentación1 - Pecha KuchaCarlo Villar CaniNo ratings yet

- Hameed2018 PDFDocument35 pagesHameed2018 PDFCarlo Villar CaniNo ratings yet

- Can Making EquipmentDocument12 pagesCan Making EquipmentCarlo Villar Cani100% (1)

- From The SAGE Social Science Collections. All Rights ReservedDocument7 pagesFrom The SAGE Social Science Collections. All Rights ReservedCarlo Villar CaniNo ratings yet

- Hameed2018 PDFDocument35 pagesHameed2018 PDFCarlo Villar CaniNo ratings yet

- Automatic Detection of Surface Defects by Using A Vision System On FruitDocument9 pagesAutomatic Detection of Surface Defects by Using A Vision System On Fruitelgarsn14No ratings yet

- The Communication Secrets of Executive CoachesDocument3 pagesThe Communication Secrets of Executive CoachesCarlo Villar CaniNo ratings yet

- Matlab NumerAnalyis BookDocument159 pagesMatlab NumerAnalyis BookLucas CavalcanteNo ratings yet

- Data Acquisition in MATLAB PDFDocument30 pagesData Acquisition in MATLAB PDFjaneprice100% (1)

- 6sigma DummiesDocument362 pages6sigma DummiesAChomNo ratings yet

- BlackBelt Manual SampleDocument25 pagesBlackBelt Manual Samplehim2000himNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 0- Syllabus HIST 112 - HIST 102 (1)Document3 pages0- Syllabus HIST 112 - HIST 102 (1)mohmmedawad24No ratings yet

- Composition and Film Scoring - Degree: Catalog Year Fall 99 - Sum 01Document1 pageComposition and Film Scoring - Degree: Catalog Year Fall 99 - Sum 01lucio0rebelloNo ratings yet

- Individual Development Plan - Kimberly M. CoominguezDocument2 pagesIndividual Development Plan - Kimberly M. CoominguezJeraldine MayolNo ratings yet

- Class ViiiDocument1 pageClass ViiiInnovate With AnweshaNo ratings yet

- Smoothie Lesson Plan 2Document3 pagesSmoothie Lesson Plan 2api-324980546No ratings yet

- Ceramics I - Slab ConstructionDocument7 pagesCeramics I - Slab Constructionapi-267189611No ratings yet

- English For Young LearnersDocument3 pagesEnglish For Young LearnersYoskapelaNo ratings yet

- in What Language Was The Text, Maga Agos Sa Disyerto Written2. What Did The Text Aim To - Brainly - inDocument1 pagein What Language Was The Text, Maga Agos Sa Disyerto Written2. What Did The Text Aim To - Brainly - intakanesimbulasNo ratings yet

- Code 8601Document12 pagesCode 8601عائشہ حسینNo ratings yet

- Information Sheet: Home AddressDocument3 pagesInformation Sheet: Home AddressRooking Ewondo SfuutNo ratings yet

- Unit III: Creativity in DesignDocument61 pagesUnit III: Creativity in Designpalaniappan_pandianNo ratings yet

- Research Cliniquing 2023Document5 pagesResearch Cliniquing 2023FrengieBotoyNo ratings yet

- The Official Study Guide For All SAT Subject TestsDocument1,051 pagesThe Official Study Guide For All SAT Subject TestsAUSTRANo ratings yet

- Ctet Syllabus 2020 PDF DownloadDocument9 pagesCtet Syllabus 2020 PDF DownloadDeepak SoniNo ratings yet

- 4EA1 01R Que 20200305Document28 pages4EA1 01R Que 20200305Noël Perera100% (2)

- Customer Satisfaction Study of Himalaya ProductsDocument7 pagesCustomer Satisfaction Study of Himalaya ProductsR. SuryaNo ratings yet

- An Overview of AssessmentDocument10 pagesAn Overview of AssessmentnikjadhavNo ratings yet

- Guide For Students - ISE I PDFDocument16 pagesGuide For Students - ISE I PDFChristopher BrittNo ratings yet

- COA Upto CS 301 UpdatedDocument148 pagesCOA Upto CS 301 UpdatedMuhammad AyubNo ratings yet

- Term 1: View Course DescriptionsDocument2 pagesTerm 1: View Course DescriptionsPreet ParmarNo ratings yet

- Kidzplay Pumpkin Activity BoxDocument6 pagesKidzplay Pumpkin Activity BoxEllaNo ratings yet

- Grade 9 Math Lessons on Direct VariationDocument14 pagesGrade 9 Math Lessons on Direct VariationJulie Ann ArellanoNo ratings yet

- Towards Resistant Geostatistics - Cressie2Document586 pagesTowards Resistant Geostatistics - Cressie2Dilson David Ramirez ForeroNo ratings yet

- b1 Preliminary Information For CandidatesDocument15 pagesb1 Preliminary Information For CandidatesElyelson dos Santos Gomes100% (1)

- Common Core State Standards: National Glencoe Math, Course 2, © 2015Document14 pagesCommon Core State Standards: National Glencoe Math, Course 2, © 2015ahmed5030 ahmed5030No ratings yet

- MollyMcNulty ResumeDocument2 pagesMollyMcNulty ResumeMolly McNultyNo ratings yet

- 20170927-Ap3391 Vol3 Lflt205 Education Annex C-UDocument8 pages20170927-Ap3391 Vol3 Lflt205 Education Annex C-URiannab15No ratings yet

- 10 1 1 867 152 PDFDocument146 pages10 1 1 867 152 PDFDavid Simon Hoyos GonzalezNo ratings yet

- Bgcse Maths Pp3 2022Document11 pagesBgcse Maths Pp3 2022Kaone LakayNo ratings yet

- Concept of Motivational Training To AthletesDocument14 pagesConcept of Motivational Training To AthletesShailNo ratings yet