Professional Documents

Culture Documents

Hazard Profile Pipe Laying (Water Sewer) January 2010

Uploaded by

Mumtaz Ahmed GhummanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazard Profile Pipe Laying (Water Sewer) January 2010

Uploaded by

Mumtaz Ahmed GhummanCopyright:

Available Formats

Hazard Profile – Pipe Laying (Water and Sewer)

Preamble

This Hazard Profile (the Profile) has been prepared by Hunter Water Corporation for the purpose of assisting Principal Contractors with the

identification of occupational health and safety (OHS) hazards associated with the laying of pipe line for water and sewer maintenance and

construction and the subsequent preparation of Safe Work Method Statements. Although the Profile is reasonably detailed, it is not intended to

be exhaustive. The Profile provides examples of some of the hazards associated with maintenance and construction of pipelines. There may

be other hazards associated with the work depending upon the site(s) and the maintenance and construction techniques proposed by the

Principal Contractor.

The Principal Contractor must:

• undertake their own hazard identification and risk assessment for the particular site(s) at which the work under the contract will be carried

out,

• determine the appropriate actions which must be taken to eliminate or satisfactorily control all identified hazards,

• provide Safe Work Method Statement(s) for approval of Hunter Water for employees and contractors which include the specific

requirements of the contract,

• comply with all applicable OHS legislation.

For the purpose of the Profile, Principal Contractor means a person who is, under Clause 210 of the OHS Regulation 2001, for the time being

appointed or taken to be the Principal Contractor for the construction work.

The Profile applies to all activities relating to the laying of pipe line for water and sewer whether a contract is in existence or not.

A digital copy of the Profile (Word document) will be provided on request to debbie.croft@hunterwater.com.au.

Note: Revisions to previous version are shown in Bold type.

Brian Grady

Manager Contracts

Hunter Water Corporation

HW2006-1845/35/2 Version : January 2010 Page 1 of 11

Hazard Profile – Pipe Laying (Water and Sewer)

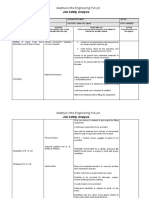

TYPICAL WHAT CAN HARM YOU WHAT CAN HAPPEN (Risks) TYPICAL SAFETY CONTROLS TO BE CONSIDERED AND

ACTIVITY (Hazards) IMPLEMENTED WHERE APPROPRIATE

Delivery and Pipes may move/roll or be Injury to persons generally Provide secure stockpile area for pipes and fittings.

unloading of tampered with by others

Unload and stack pipes strictly in accordance with the

pipes

manufacturers’ recommendations (contact manufacturer for

recommendations where necessary).

Minimise height of pallets / stockpile.

Pipes and fittings Lifting injury Correct manual handling techniques.

Swinging load Use mechanical aids where possible.

Maintain control of loads when lifting & moving.

Carry pipes close to ground while moving.

Secure Site Public safety Injury to a member of the public Provide the appropriate fencing and/or barricades as per site risk

assessment.

Apply appropriate signage and pedestrian control.

Devise and implement system for site inspection and security.

Ensure security and equipment suitable to minimise vandalism.

Traffic Personal injury to members of the public, Traffic Control Plan (TCP) as per RTA regulations.

contractors and employees

Keep area clean & clear of obstacles.

Vehicle Accidents

Inadequate access/egress Slips, trips and falls, abrasions, strains and Conduct site inspection to ensure access/egress is adequate for

sprains; manual handling injuries such as back the task activities.

damage

HW2006-1845/35/2 Version : January 2010 Page 2 of 11

Hazard Profile – Pipe Laying (Water and Sewer)

TYPICAL WHAT CAN HARM YOU WHAT CAN HAPPEN (Risks) TYPICAL SAFETY CONTROLS TO BE CONSIDERED AND

ACTIVITY (Hazards) IMPLEMENTED WHERE APPROPRIATE

Locate Existing underground services Explosion, electrocution, damage service, Use Dial Before You Dig (www.dialbeforeyoudig.com.au or phone

existing asbestos pipe 1100).

services

Check relevant Authority (e.g. power, water, gas, council) records

for location of services.

If in doubt uses experienced/accredited service locators.

When using hand prodders to locate pipes, prodders must never

be driven in to the ground by hammers or other implements.

Confirm location of services by “Pot holing” techniques.

Comply with the OHS Regulation 2001 (Part 8.7 and Part 11.2)

including the Code of Practice for Safe Removal of Asbestos

[NOHSC: 2002 (1988)] and Guide to the Control of Asbestos

Hazards in Buildings and Structures [NOHSC: 3002(1988)].

Excavate Working plant & equipment Noise, falling objects Operations of plant by WorkCover accredited personnel.

Refer – WCA Damage to existing surfaces Personal Protective Equipment (PPE) – hardhat, high visibility

Safety Guide vest, hearing protection etc.

Moving plant Material spillage

on construction Maintain a safety working area around moving plant.

Hit by moving plant

sites, and

Protect surfaces from plant movements.

WCA Code of

Practice Ensure appropriate plant noise control.

Excavation Maintain clean-up equipment on site.

Work

Maintain (specified) appropriate spillage control equipment.

Employ observer where appropriate.

Storage of materials Falling objects No materials to be placed or stacked near the edge of any

excavation.

No load to be placed or moved near the edge of excavation where

it is likely to cause collapse of side of work.

No load handling/movement across excavation.

No rollable objects stored uphill from excavation.

HW2006-1845/35/2 Version : January 2010 Page 3 of 11

Hazard Profile – Pipe Laying (Water and Sewer)

TYPICAL WHAT CAN HARM YOU WHAT CAN HAPPEN (Risks) TYPICAL SAFETY CONTROLS TO BE CONSIDERED AND

ACTIVITY (Hazards) IMPLEMENTED WHERE APPROPRIATE

Overhead & underground power Electrocution Determine location of underground services.

cables

If underground power cables are located in the vicinity, exercise

extreme care while excavating.

Consider any restriction on kinds of tools and equipment that may

be required.

Consult with local authority distributor (e.g. Energy Australia 13

1525, Integral Energy 13 1081, Country Energy 13 2356) and

comply with requirements.

Locate and keep clear of overhead services (3m up to 132kv, 6m

over 132kv up to 330kv). If distances cannot be maintained, plant

operator and observer must be trained and assessed as

competent in crane and plant electrical safety.

Gas mains Explosion Check Authority records for location of services.

If in doubt use experience service locators.

When using hand prodders to locate pipes, prodders must never

be driven in to the ground by hammers or other implements.

“Pot holing” techniques.

Extreme care to be exercised when working near gas mains.

No smoking or mobile phone use within defined radius.

Sloping ground Falling, rolling objects Maintain good house keeping (remove debris, trip hazards, site

tidiness).

Select locations to minimise potential for movement.

Stack materials at level below excavation.

Appropriate plant chosen for sloping ground.

Secure/retain potential falling/rolling objects.

HW2006-1845/35/2 Version : January 2010 Page 4 of 11

Hazard Profile – Pipe Laying (Water and Sewer)

TYPICAL WHAT CAN HARM YOU WHAT CAN HAPPEN (Risks) TYPICAL SAFETY CONTROLS TO BE CONSIDERED AND

ACTIVITY (Hazards) IMPLEMENTED WHERE APPROPRIATE

Accessing trenches/conduits Collapse of trench, falling objects Support / bench / batter excavation.

Keeping safe distance from edge of trench (Refer Clause 3.10 of

WCA Code of Practice Excavation Work).

Materials not to be placed or stacked near the edge of trench.

No load to be placed or moved near the edge of trench where it is

likely to cause collapse of the trench.

All trenches to have safety barricades when left open for a period

of time.

Provide submersible pump to dewater trenches where ground is

water-charged.

PPE – hardhats.

No load/personnel movement across trench.

Falling into Installation of shoring system (Ref Clause 3.3 of WCA Code of

Practice Excavation Work).

Where possible backfill trenches.

Erect 1.8 metre (min) security fence if open excavation is to be

left unattended,

or

Cover open excavation with suitable steel plating if left

unattended.

No personnel movement across trench.

Other risks associated with confined spaces such Where trench/conduit is considered to be a confined space, use

as gases etc accredited trained personnel.

Follow confined space entry procedures as per OH&S Regulation

2001 (Clauses 66-78).

No smoking/mobile phone use, avoid sparking.

HW2006-1845/35/2 Version : January 2010 Page 5 of 11

Hazard Profile – Pipe Laying (Water and Sewer)

TYPICAL WHAT CAN HARM YOU WHAT CAN HAPPEN (Risks) TYPICAL SAFETY CONTROLS TO BE CONSIDERED AND

ACTIVITY (Hazards) IMPLEMENTED WHERE APPROPRIATE

Storage of fill Trip hazard Secure fill stockpile.

Dust – eye injury Provide a dedicated area for fill.

Environmental damage Watering of material.

Provide necessary environmental protection measures.

Cover fill when unattended or unable to be watered.

Manual handling (shovelling) Strains and sprains; injuries such as back Manual handling awareness.

damager

Adequate rest periods allowed, job rotation, minimise repetitious

twisting and shovelling.

Contaminated soil Impact on health of persons generally Refer Section 4 of WCA Code of Practice Excavation Work

Materials Defective materials Risk of various injuries Visual inspection of materials.

Checking

Refer Australian Standards and WorkCover guidelines used

where appropriate.

Storage of Hazardous Materials Risk of various injuries and illnesses Handling and storage to be done according to Materials Safety

Data Sheets (MSDS).

Lay bedding Earth mounds Engulfment Control operation of mobile plant by competent person.

Dust – eye injury Watering of material.

Control slopes.

Delineate earth mounds appropriately.

Warning signage.

Cover when unattended or unable to be watered.

HW2006-1845/35/2 Version : January 2010 Page 6 of 11

Hazard Profile – Pipe Laying (Water and Sewer)

TYPICAL WHAT CAN HARM YOU WHAT CAN HAPPEN (Risks) TYPICAL SAFETY CONTROLS TO BE CONSIDERED AND

ACTIVITY (Hazards) IMPLEMENTED WHERE APPROPRIATE

Stringing Pipes may move/roll or be Injury to persons generally Provide secure stockpile area for pipes and fittings.

Pipes tampered with by others

Unload and stack pipes strictly in accordance with the

manufacturers’ recommendations (contact manufacturer for

recommendations where necessary).

Minimise height of pallets / stockpile.

Secure pipes to prevent movement irrespective of slope of

surface, secure pipes to prevent movement e.g sand bags, star

pickets, place against fixed objects which will prevent the

movement of pipes.

Orientate/select position to minimise potential for movement e.g

place pipes normal to slope of ground.

Place pipes in secure compound if site left unattended.

Minimise waiting time for pipes on site prior to laying.

Identify high risk or unsuitable stringing locations in advance, eg

sloping or soft ground.

Ensure availability of sand/gravel bags/pegs/timber or other

suitable materials for retaining or securing pipes.

Install pipe Accessing trenches/conduits Collapse of trench, falling objects Use shoring system (Ref Clause 3.3 of WCA Code of Practice

and fittings Excavation Work).

Electrocution if using power tools in water-

on bed

charged environment String only sufficient pipes for day’s work.

Return all pipes not laid at end of day to secure stockpile

areas.

HW2006-1845/35/2 Version : January 2010 Page 7 of 11

Hazard Profile – Pipe Laying (Water and Sewer)

TYPICAL WHAT CAN HARM YOU WHAT CAN HAPPEN (Risks) TYPICAL SAFETY CONTROLS TO BE CONSIDERED AND

ACTIVITY (Hazards) IMPLEMENTED WHERE APPROPRIATE

Working plant & equipment Personal injury Use only maintained equipment fitted with yellow flashing lights

and reversing alarms.

Maintain a safe distance from working plant.

Wear appropriate PPE including high visibility clothing and hard

hat etc.

Perimeter fencing where appropriate.

Place trained personnel on look-out.

Pipes and fittings Lifting injury Correct manual handling techniques.

Swinging load Use mechanical aids where possible.

Maintain control of loads when lifting & moving.

Carry pipes close to ground while moving providing mechanical

aid is used.

Pressure testing pipe work Delivery pipe/joint failure may cause body injuries Use only competent person to perform the task.

Adequately secure connecting pipes (safety pins for lever

couplings).

To prevent joint or pipe section failure, fix brackets close enough

together to prevent excessive movement.

Don’t exceed pipe operating pressure, ensure pipe is correct

diameter.

Ensure pipe not damaged.

Ensure adequate support where a change in direction or reducer

occurs.

Pressure for air testing must not exceed 32kPa.

Set up laser Laser Eye injury Use only competent person to perform the task.

for line and

Follow manufactures safety guidelines.

grade

Erect warning signs.

HW2006-1845/35/2 Version : January 2010 Page 8 of 11

Hazard Profile – Pipe Laying (Water and Sewer)

TYPICAL WHAT CAN HARM YOU WHAT CAN HAPPEN (Risks) TYPICAL SAFETY CONTROLS TO BE CONSIDERED AND

ACTIVITY (Hazards) IMPLEMENTED WHERE APPROPRIATE

Cut-in to Failure of existing pipeline Injury from high pressure Use PPE.

existing under pressure

Ensure adjacent stop valves are operational / closed.

pipeline

Secure adjacent valves against movement.

Relieve pressure in system.

Reconnecting High pressure water Injury from high pressure Use PPE.

house

Relieve pressure in system.

services

Welding Burns Care with torch and PPE.

House services Electrocution Earth straps and insulating gloves to be used as services are

used for household earthing. Always ensure pipes are cleaned

back to bare metal prior to fitting the bridging straps to ensure a

direct electrical contact between the pipes and the strap.

Restoration Inadequate compaction Public hazard Compaction to specified standard.

of site

Construction refuse Public hazard Site cleared of debris and refuse.

Inadequate re-surfacing Public hazard Re-surface appropriately.

Do not leave gaps in turf or leave uneven surface.

Erect fence around hazardous areas until restored and safe.

High hydraulic/pneumatic Injury from high pressures in pipelines blowouts of Ensure plugs and compressors are installed and secured against

pressures plugs movement.

Release air before removing plugs.

Clear area of pipe ends being tested.

HW2006-1845/35/2 Version : January 2010 Page 9 of 11

Hazard Profile – Pipe Laying (Water and Sewer)

TYPICAL WHAT CAN HARM YOU WHAT CAN HAPPEN (Risks) TYPICAL SAFETY CONTROLS TO BE CONSIDERED AND

ACTIVITY (Hazards) IMPLEMENTED WHERE APPROPRIATE

General Inadequate training, consultation, Task specific injuries due to inexperience, All personnel on-site to be appropriately inducted.

Activities planning and improvisation inadequate consultation or failure to provide

All personnel on-site to be suitably qualified.

appropriate equipment

Refer WCA

Competent supervision to be provided on-site.

Code of

Practice

Occupational

health and

safety

induction

training for

construction

work

Misuse of equipment/fire hazards Fire/Explosion Care to be taken when refuelling machinery with petrol to ensure

engines aren’t running and there are no naked flames in the

vicinity.

Oxy Acetylene and gas equipment must be used strictly in

accordance with the manufacturers safe operating procedures.

All personnel working on the site are to be trained in the correct

operation of the tools and equipment they are using.

All tools and equipment are to be serviceable and in safe

condition.

All electrical tools are to be fitted with current test tags.

Fire extinguishers are to be located on site.

No work during high fire danger unless dry vegetation is cleared

and/or watered down prior to carrying out hot work.

Avoid driving or parking motor vehicles on long dry grass as the

heat generated by the exhaust could start a fire.

Exposure to ultra violet light, glare Skin cancer, sunburn, eye damage Protective clothing, sunscreen, flap on hard hat. AS rated

sunglasses.

HW2006-1845/35/2 Version : January 2010 Page 10 of 11

Hazard Profile – Pipe Laying (Water and Sewer)

TYPICAL WHAT CAN HARM YOU WHAT CAN HAPPEN (Risks) TYPICAL SAFETY CONTROLS TO BE CONSIDERED AND

ACTIVITY (Hazards) IMPLEMENTED WHERE APPROPRIATE

Weather Conditions (e.g. hot, cold Dehydration and dizziness Supply adequate drinking water in work area.

wet, flooding/inundation, electrical

Provide protection from UV rays.

storms, high winds)

PPE.

Slippery surfaces Slips and falls Non-slip safety footwear to be worn on all worksites.

Extreme care when working in wet and slippery areas.

Personnel should never run on worksite.

Untidy site Slips and falls Keep worksite clean and tidy at all times.

Storage of materials Materials may be dislodged and fall onto people Materials to be stored in a safe manner.

or property particularly when site is unattended

Stockpile of pipes, drums (rolling Pipes or drums may roll onto the roadway causing All materials to be secured by suitable chocks, sandbags or other

objects) an accident or may be rolled by unauthorised means. All pipes not laid during the course of a day are to be

persons particularly when site is unattended returned to the stockpile and secured appropriately.

causing injury to persons

Storage of plant Public Safety Store/park plant & equipment off site & in a secure area.

HW2006-1845/35/2 Version : January 2010 Page 11 of 11

You might also like

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document5 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair Vanmazhy100% (1)

- OCP Confined Space ShahiDocument4 pagesOCP Confined Space ShahiVishal SrivastavaNo ratings yet

- Discharge Rod 11kv 3phaseDocument1 pageDischarge Rod 11kv 3phasewaytobhushan100% (1)

- GroutingDocument1 pageGroutingraphael damanikNo ratings yet

- EXCAVATION BY HAND (Live Electrical) (Known & Unknown) : Job Safety AnalysisDocument2 pagesEXCAVATION BY HAND (Live Electrical) (Known & Unknown) : Job Safety Analysisfrancis100% (1)

- Safety Campaign-Working at Height Final (May-2022)Document6 pagesSafety Campaign-Working at Height Final (May-2022)HSE99 BHDC100% (1)

- Vaultex CatelogDocument218 pagesVaultex Catelogprabu prasad0% (1)

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDocument2 pagesJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNo ratings yet

- SRB-02-2011 - (Welding of Pipes) For Thrust BoringDocument4 pagesSRB-02-2011 - (Welding of Pipes) For Thrust BoringkkalviNo ratings yet

- Emergency Drill Fall From HeightDocument5 pagesEmergency Drill Fall From HeightBinay100% (1)

- MEIL Rigging Plan For Unloading LoaderDocument4 pagesMEIL Rigging Plan For Unloading LoaderGyanendra Narayan NayakNo ratings yet

- JSA Fitting and Welding Work For Pipe Trench InstalationDocument6 pagesJSA Fitting and Welding Work For Pipe Trench InstalationVishnu VijayanNo ratings yet

- Corroseal TE 321 Rev 01Document1 pageCorroseal TE 321 Rev 01Ashif AkhtarNo ratings yet

- JSA Building WorksDocument9 pagesJSA Building WorksMon Trang Nguyễn100% (1)

- BargeDocument4 pagesBargeanon_222140886No ratings yet

- Eil Permit For Energy Isolation & De-IsolationDocument1 pageEil Permit For Energy Isolation & De-IsolationAvesh ChauahanNo ratings yet

- Hydro Blasting 3Document6 pagesHydro Blasting 3Robinson Ysasis100% (1)

- HIRA-Metalic Pipe ErectionDocument13 pagesHIRA-Metalic Pipe ErectionShams Tabrez100% (2)

- Nitoproof 230Document2 pagesNitoproof 230Balasubramanian Ananth50% (2)

- Jsa Ndt-BuildingDocument5 pagesJsa Ndt-BuildingFirdaus RidzuanNo ratings yet

- Jsa CompressorDocument9 pagesJsa CompressorRavi thokalNo ratings yet

- Risk Assessment On Demolition Work - CompressDocument8 pagesRisk Assessment On Demolition Work - CompressAbegail Manuel GatusNo ratings yet

- Jsa D. G. INSTALLATIONDocument5 pagesJsa D. G. INSTALLATIONRavi thokalNo ratings yet

- Abrasive Blasting Check ListDocument2 pagesAbrasive Blasting Check ListSaravanan JambunathanNo ratings yet

- Updated JSA For SAPMTofficeDocument30 pagesUpdated JSA For SAPMTofficeShaikh Abu bakarNo ratings yet

- Hira - Mov Valve Inspection & MaintenanceDocument8 pagesHira - Mov Valve Inspection & MaintenanceAbzad HussainNo ratings yet

- Jsa - Cable Termination: Job Step No. Step Description Hazards Control Measure(s) Responsible PersonDocument7 pagesJsa - Cable Termination: Job Step No. Step Description Hazards Control Measure(s) Responsible PersonMon Trang NguyễnNo ratings yet

- Jsa For PCCDocument6 pagesJsa For PCCCICON EngineersNo ratings yet

- RAPID-P0027-0005-CON-JHA-3215-0005 - Rev. A JHA of Blasting and PaintingDocument4 pagesRAPID-P0027-0005-CON-JHA-3215-0005 - Rev. A JHA of Blasting and Paintingshaiful annuarNo ratings yet

- 10 Percent Acid Washing SOP TemplateDocument5 pages10 Percent Acid Washing SOP TemplatekofinyameNo ratings yet

- JSA For Dewatering PumpDocument1 pageJSA For Dewatering Pumpwahyu nugrohoNo ratings yet

- Al-Khafji Joint Operation (Kjo) Upgrade of Kjo'S Public Address and General Alarm System Contract# Gt629It19Document7 pagesAl-Khafji Joint Operation (Kjo) Upgrade of Kjo'S Public Address and General Alarm System Contract# Gt629It19Numan SaleemNo ratings yet

- Powder Actuated ToolsDocument1 pagePowder Actuated ToolsJayvee Baradas ValdezNo ratings yet

- Risk Assessment Record: Page 1 of 4Document4 pagesRisk Assessment Record: Page 1 of 4Abdul HadiNo ratings yet

- JSA For PVC FlooringDocument4 pagesJSA For PVC FlooringJavedNo ratings yet

- Method Statement & Risk Assessment Hydrostatic Leak TestDocument7 pagesMethod Statement & Risk Assessment Hydrostatic Leak TestWalid AmdouniNo ratings yet

- Risk Assesment Installation Testing For Fire Fighting Piping System and AccessoriesDocument8 pagesRisk Assesment Installation Testing For Fire Fighting Piping System and AccessoriesGopinath SekarNo ratings yet

- Ewrc SHP Gen Hse Jsa 00040Document12 pagesEwrc SHP Gen Hse Jsa 00040Rickz CabaloNo ratings yet

- 07 - Tata Power Scaffold Safety ProcedureDocument24 pages07 - Tata Power Scaffold Safety Procedurehse bsjNo ratings yet

- Work Method Statement For Structure ErectionDocument12 pagesWork Method Statement For Structure ErectionMuhammad TeguhNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument3 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- HIRA Reference Bearing & StopprtDocument51 pagesHIRA Reference Bearing & StopprtPlanning C7100% (1)

- Job Safety Analysis: Work at HeightDocument3 pagesJob Safety Analysis: Work at Heightmarlon armamentoNo ratings yet

- JSA For Erection Modification QSTECDocument7 pagesJSA For Erection Modification QSTECMohamed NouzerNo ratings yet

- Bar Bending Checklist: Contractor NameDocument1 pageBar Bending Checklist: Contractor NameAfroz AlamNo ratings yet

- TUV Certificate 2015Document7 pagesTUV Certificate 2015zahid_497100% (1)

- Hse JsaDocument22 pagesHse JsaAnonymous y1pIqcNo ratings yet

- Emergency Rescue Procedure KM 200+655/200+857: Occupational Health and SafetyDocument4 pagesEmergency Rescue Procedure KM 200+655/200+857: Occupational Health and Safetyabhinav djNo ratings yet

- Window CleaningDocument1 pageWindow CleaningSanthoshKumarNo ratings yet

- Fatigue Management ProcedureDocument12 pagesFatigue Management ProcedureWakarusa CoNo ratings yet

- SOP For Gas Cutting Amp WeldingDocument12 pagesSOP For Gas Cutting Amp WeldingRmr ReyesNo ratings yet

- Project No. 074-10 JHA No. 1Document20 pagesProject No. 074-10 JHA No. 1Adel SukerNo ratings yet

- 3.ceiling Installation JSA ADocument2 pages3.ceiling Installation JSA APijah AhmadNo ratings yet

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 pageJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNo ratings yet

- SandblastingDocument2 pagesSandblastingAL SALEH ELECTRONo ratings yet

- JSA For HOT JobDocument1 pageJSA For HOT JobEquipment MaterialsNo ratings yet

- JSA Mobile CranesDocument2 pagesJSA Mobile CranesAmanya DickallansNo ratings yet

- JSA-Confined Space Activity - 05Document4 pagesJSA-Confined Space Activity - 05babjihanumanthuNo ratings yet

- Piling Hazards and RisksDocument5 pagesPiling Hazards and Risksnagesh1234No ratings yet

- Piling Hazards and RisksDocument4 pagesPiling Hazards and RisksAbhishek Gupta100% (2)

- Amines For Steam Condensate Treatment PDFDocument8 pagesAmines For Steam Condensate Treatment PDFMumtaz Ahmed GhummanNo ratings yet

- Best Practice Manual Hvac ChillersDocument69 pagesBest Practice Manual Hvac ChillersraajaahNo ratings yet

- Iwc 2011 Final Paper Peer ReviewedDocument10 pagesIwc 2011 Final Paper Peer ReviewedMumtaz Ahmed GhummanNo ratings yet

- The Treatment of Cooling Water With Chlorine Dioxide PDFDocument10 pagesThe Treatment of Cooling Water With Chlorine Dioxide PDFMumtaz Ahmed GhummanNo ratings yet

- Hloramines: 6.1 Chloramines ChemistryDocument35 pagesHloramines: 6.1 Chloramines ChemistryMumtaz Ahmed GhummanNo ratings yet

- Water Quality Control PDFDocument7 pagesWater Quality Control PDFpurna100% (1)

- Dave Christophersen - Crown Solutions, Subsidiary of Veolia - 1-27-11Document48 pagesDave Christophersen - Crown Solutions, Subsidiary of Veolia - 1-27-11Mumtaz Ahmed GhummanNo ratings yet

- Boiler - Problems and SolutionDocument44 pagesBoiler - Problems and SolutionNguyen HoaNo ratings yet

- Bop Bop: Call Bop, We're The Trusted Water Treatment Plant. Call Bop, We're The Trusted Water Treatment PlantDocument2 pagesBop Bop: Call Bop, We're The Trusted Water Treatment Plant. Call Bop, We're The Trusted Water Treatment PlantMumtaz Ahmed Ghumman100% (1)

- 19 - Pulv - SDSDocument11 pages19 - Pulv - SDSBoon ChewNo ratings yet

- Trasar TRAC102: Traced Closed System TreatmentDocument3 pagesTrasar TRAC102: Traced Closed System TreatmentMumtaz Ahmed Ghumman100% (7)

- 3D Trasar PDFDocument10 pages3D Trasar PDFOussama Sissaoui100% (1)

- Product Bulletin 3DT104 PDFDocument3 pagesProduct Bulletin 3DT104 PDFMumtaz Ahmed Ghumman100% (1)

- Awt 11Document13 pagesAwt 11Mumtaz Ahmed GhummanNo ratings yet

- NPSHHHHDocument5 pagesNPSHHHHMumtaz Ahmed Ghumman100% (1)

- ASME Steam Purity ProblemsDocument48 pagesASME Steam Purity ProblemsMumtaz Ahmed GhummanNo ratings yet

- Selection of ProcessesDocument8 pagesSelection of ProcessesMumtaz Ahmed GhummanNo ratings yet

- HSE-Iran Power PlantDocument40 pagesHSE-Iran Power PlantDivya Sankaranarayanan100% (1)

- Pipe Manufacturer's Data Sheet 1Document231 pagesPipe Manufacturer's Data Sheet 1Mumtaz Ahmed Ghumman100% (1)

- Module 2 - The Fibonacci SequenceDocument7 pagesModule 2 - The Fibonacci SequenceCommish ZoneNo ratings yet

- Bhopali Gosht KormaDocument1 pageBhopali Gosht KormaZahid GolandazNo ratings yet

- Carbohydrate Counting SP Handout 1 1Document1 pageCarbohydrate Counting SP Handout 1 1api-286765982No ratings yet

- Wood Technology Topic - IntroductionDocument25 pagesWood Technology Topic - IntroductionCalinescu CristinaNo ratings yet

- Blood Circulation and Transport ModuleDocument15 pagesBlood Circulation and Transport ModuleIella's Rashid100% (1)

- Tips and Tricks To Crack PMTDocument3 pagesTips and Tricks To Crack PMTNeyaz HasnainNo ratings yet

- Aquarium PDFDocument34 pagesAquarium PDFsksingl350No ratings yet

- Exercises Like or As PDFDocument2 pagesExercises Like or As PDFwahidNo ratings yet

- Sunder NurseryDocument2 pagesSunder NurserynishNo ratings yet

- English Paper 1 SJK Set 2Document15 pagesEnglish Paper 1 SJK Set 2Murely PonnusamyNo ratings yet

- Bamboo Poles For Engineered BambooDocument12 pagesBamboo Poles For Engineered BambooDanize Kate GimenoNo ratings yet

- RIEGO POR GOTEO Libro Cap24bibliografiaDocument107 pagesRIEGO POR GOTEO Libro Cap24bibliografiaIng. Luis Felipe Ferreras GuerreroNo ratings yet

- Monthly Narrative ReportDocument14 pagesMonthly Narrative ReportDing CadavisNo ratings yet

- Introduction To Cryptogams Course 2020-2021Document19 pagesIntroduction To Cryptogams Course 2020-2021habumugishajaeanpierre45No ratings yet

- Epp 6 q2 Wk3-4 Quiz 2Document3 pagesEpp 6 q2 Wk3-4 Quiz 2JAIFE ERIVE MACARAEGNo ratings yet

- 4192 EnglishDocument25 pages4192 EnglishChelyn Yessi Sarah0% (1)

- Chapter 6 - Tissues Revision NotesDocument4 pagesChapter 6 - Tissues Revision NotesAbhishek100% (1)

- Evolutionary Taxonomy - WikipediaDocument3 pagesEvolutionary Taxonomy - Wikipediaskline3No ratings yet

- Menu ProjectDocument1 pageMenu Projectapi-357256089No ratings yet

- RHH Family Mealtime ToolkitDocument79 pagesRHH Family Mealtime ToolkittherealhappyhourNo ratings yet

- Pokemon Platinum WalkthroughDocument66 pagesPokemon Platinum WalkthroughSachin HegdeNo ratings yet

- Section B: Site Works: 2.1 Soft Landscaping / Page 1Document1 pageSection B: Site Works: 2.1 Soft Landscaping / Page 1Mohammed WasiuddinNo ratings yet

- 2020 08 05 Iv Evs 0Document3 pages2020 08 05 Iv Evs 0Vijay KumarNo ratings yet

- Everyday Roses How To Grow Knock Out and Other Easy-Care Garden Roses PDFDocument194 pagesEveryday Roses How To Grow Knock Out and Other Easy-Care Garden Roses PDFSafeta100% (1)

- 20170918140947SBC 3023 - TBB 2033beditednew4Document36 pages20170918140947SBC 3023 - TBB 2033beditednew4Leena MuniandyNo ratings yet

- Effect of Aqueous and Ethanolic Extracts of Pimpinella Anisum L. Seeds On Milk Production in RatsDocument6 pagesEffect of Aqueous and Ethanolic Extracts of Pimpinella Anisum L. Seeds On Milk Production in RatsDaniWijayantoNo ratings yet

- Nakshatra Vatika Recharging HumanDocument4 pagesNakshatra Vatika Recharging HumanramanjyotNo ratings yet

- FRANCISCO Manosa (TheoryDocument19 pagesFRANCISCO Manosa (TheoryShaira Reyes100% (10)

- KakteenDocument68 pagesKakteenWalter Johan Paco GonzalesNo ratings yet

- Mugg and BeanDocument16 pagesMugg and BeanCog ChemyNo ratings yet