Professional Documents

Culture Documents

Bridge Pics

Uploaded by

Sandeep SinghOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bridge Pics

Uploaded by

Sandeep SinghCopyright:

Available Formats

A RECORD SEGMENTAL SPAN

KANAWHA RIVER BRIDGE

by Santiago Rodriguez, T.Y. Lin International

A 760-ft-long A record concrete box girder span over

the Kanawha River will soon complete

The existing I-64 bridge over the

Kanawha River between Dunbar and

main span is the longest the widening of a 4.3-mile section of South Charleston is a steel plate girder

I‑64 located in Kanawha County, West structure with a 440-ft-long main span

concrete box girder span Virginia. T. Y. Lin International’s bridge that was completed in 1974 to carry

designers, working with the West four lanes of traffic. The preliminary

in the United States. Virginia Department of Transportation, design studies evaluated several

Division of Highways (WVDOH), were alternatives for increasing the capacity

confronted with the challenge of of the existing Kanawha River Bridge to

creating a low-cost, durable, and six lanes, including widening the existing

aesthetically pleasing structure that bridge, complete bridge replacement,

would alleviate traffic congestion for and construction of a new eastbound

commuters in the Charleston area. bridge. The alternative selected was

The resulting eight-span segmental the construction of a new eastbound

bridge design is the first long-span structure on an improved nonparallel

segmental box girder structure built by alignment carrying three travel lanes and

the balanced cantilever method in West one auxiliary lane. The existing bridge

Virginia. will be modified to maintain four lanes

of westbound traffic.

The Kanawha River Bridge shown in this rendering

has the record span in the United States for a

concrete box girder at 760 ft. All photos and

renderings: T.Y. Lin International.

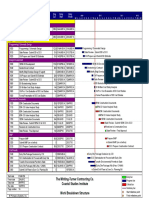

profile Kanawha River Bridge / Kanawha County, West Virginia

Engineer: T.Y. Lin International, Alexandria, Va.

Geotechnical Engineer: Triad Engineering Inc., St. Albans, W. Va.

Prime Contractor: Brayman Construction Corporation, Saxonburg, Pa.

Construction Engineers: Finley Engineering Group Inc., Tallahassee, Fla., and Michael Baker Corporation,

Charleston, W. Va.

Concrete Supplier: Arrow Concrete, Winfield, W. Va.

Formwork Supplier: DOKA, USA Ltd., Baltimore, Md.

Awards: 2007 West Virginia Division of Highways Engineering Excellence Award in the Large Bridge Category

30 | ASPIRE, Winter 2009

The twin-walled

piers support the

main span. While

strong enough

to support the

cantilevered

construction, they

are adequately

flexible to

accommodate

longitudinal

deformations.

The bridge types evaluated for the 760, 540, and 209 ft for a total length depth varies along the main span from

new eastbound structure included a between centerlines of abutment 38 ft at the piers to 16 ft at midspan.

segmental concrete box girder, steel bearings of 2950 ft. Spans 1, 2, 3, 4, The bottom slab thickness is variable

tied arch, steel box girder, concrete 5, 7, and 8 have a curved alignment with a maximum thickness of 5 ft at the

cable-stayed bridge, and a steel truss. including a circular curve with a 1910 ft main span piers and a minimum of 9 in.

The segmental concrete box girder radius and a spiral transition. The main at midspan. The approach spans have a

and steel arch alter natives were span has a tangent alignment. constant depth of 16 ft and a constant

selected for the type, size, and location bottom slab thickness of 9 in., with the

study. After evaluating construction A continuous concrete box girder exception of the pier tables where the

costs, maintenance requirements, superstructure, using cantilever con- bottom slab thickness transitions to 1 ft

and constructability, final plans were struction, was chosen for the full length 9 in. The webs have a constant thickness

developed for a segmental concrete box of the bridge. This allowed for longer of 1 ft 6 in.

girder bridge. approach spans, which reduced the

bridge’s environmental impact. The top slab has constant dimensions

Bridge Layout for the full length of the bridge. Its

With a total length of 2975 ft, the Given the size and urban setting of thickness varies transversely from a

Kanawha River Bridge will span a the project, bridge aesthetics were minimum of 9 in. to a maximum of 2

railroad track operated by Norfolk an important design consideration. ft at the intersection with the webs.

Southern, Dunbar Avenue, the Kanawha The bridge concept was developed to The maximum 2-ft depth of the top

River back channel, Wilson Island, the be compatible with both the existing slab is required to accommodate the

Kanawha River main channel, Riverside steel plate girder bridge that will carry cantilever tendons needed for the

Drive, and MacCorkle Avenue. A westbound traffic and a future twin main span. The box girder cross section

760-ft-long main span—the longest parallel westbound bridge. has variable superelevation from plus

concrete box girder span in the United to minus 8%. The specified concrete

States—resulted from the need to locate Superstructure compressive strength is 6500 psi at 28

the main piers outside the main channel The bridge cross-section accommodates days. For mass concrete, the acceptance

of the Kanawha River in order to avoid three travel lanes, one auxiliary lane, age was extended to 56 days.

interference with barge traffic. and shoulders for a total roadway

width of 64 ft. The cross section of the The concrete box section is post-

The eight-span structure has span superstructure consists of a single cell tensioned longitudinally, transversely,

lengths of 144, 247, 295, 295, 460, box with inclined webs. The structural and vertically. The longitudinal post-

Cast-in-Place Segmental Box Girder Bridge / West Virginia Department of Transportation, Owner

Bridge Description: 2975-ft-long box girder bridge

Structural Components: 66-ft-wide single-cell box girder in eight spans ranging from 144 to 760 ft built by balanced cantilever.

Five single shaft approach piers and two twin-walled main span piers. Drilled shaft foundations.

Form Travelers: STRUKTURAS, Langesund, Norway

Bearings: R. J. Watson Inc., Amhurst, N.Y.

Expansion Joints: Watson Bowman Acme Corporation, Amhurst, N.Y.

Post-Tensioning: VSL, Dallas, Tex.

Grouts: BASF, Shakopee, Minn.

Bridge Construction Cost: $75 Million ($379/ft2)

ASPIRE, Winter 2009 | 31

The foundations consist of reinforced

concrete footings and concrete drilled

shafts socketed in the underlying hard

sandstone. The average length of

drilled shafts is about 45 ft. Two pre-

construction drilled shaft load tests,

using the Osterberg method, were

performed prior to final design. These

tests verified the ultimate end bearing

and side shear capacity to be used.

In addition to the Kanawha River, the bridge

crosses three roads and a railroad.

Photo: Ahmed Mongi, WVDOT.

Construction

This project was advertised in February

2007 using competitive bidding

between the segmental concrete box

tensioning consists of two sets of l o n g i t u d i n a l d i s p l a c e m e n t s . Tw o girder alternative designed by T. Y. Lin

tendons. The cantilever tendons, located bearings are provided at each pier with International and a steel box girder

in the top slab, are stressed during vertical service capacities up to 6900 superstructure with the same span

cantilever construction shortly after a new kips. The bearings will be blocked during arrangement that was developed by

segment is added. The span tendons, construction and the superstructure will another consultant.

located in the bottom slab, are used in be temporarily fixed to the approach

the central part of the spans to provide piers. A large modular expansion joint The contract was awarded to Brayman

continuity between adjacent cantilevers. with a displacement capacity of 30 in. Construction Corp. with a low bid for

Transverse post-tensioning is utilized in accommodates displacements caused the concrete alternative of $82,864,247.

the top slab. Vertical post-tensioning by temperature, creep, and shrinkage The low bid for the steel box alternative

consisting of high strength 1 3/ 8-in.- at the west abutment. The east was $112,910,000. The construction

diameter bars is required in the webs, abutment requires a joint with a 16-in.- contract includes a small amount of

in the proximity of the piers, where the displacement capacity. roadway work, MSE walls, and minor

shear forces are high. The post-tensioning changes to the existing bridge. These

was designed to limit the principal tensile Substructure items were the same for the steel and

stresses in the webs. The main span piers—Piers 5 and concrete alternatives. The segmental box

6—consist of twin concrete walls, which girder superstructure was designed to be

The continuous box girder will have frame into the superstructure. The built by the balanced cantilever method

expansion joints at the abutments only. twin pier walls provide the necessary using cast-in-place segments supported

The advantages of this design approach strength and stiffness during cantilever by two pairs of form travelers. The

are to reduce maintenance, improve construction and, at the same time, are project has a total of 160, 16-ft-long,

serviceability, and simplify construction, longitudinally flexible to accommodate cast-in-place segments in seven pairs of

as intermediate hinges are not needed. d e f o r m a t i o n s c a u s e d b y c re e p , cantilevers. Falsework is required to cast

The superstructure is fixed at the main shrinkage, and temperature changes. the pier tables and the end segments

piers and is supported on unidirectional The approach piers—Piers 1, 2, 3, 4, near the abutments.

bearings at the approach piers and and 7—have a rectangular section with

abutments. The bearings restrain the 45-degree chamfers. Bridge construction—scheduled to

transverse displacements while allowing be completed by the end of 2010—

has sparked local attention, which is

expected to peak in the summer of

2009 with the closure of the main

Aesthetics span cantilevers. When completed,

The proposed segmental box girder bridge is a harmonious design with simple area commuters will enjoy significant

and consistent forms with the same basic cross section between abutments. improvements in safety and traffic

The selected cross section, with long overhangs and inclined webs, will result capacity in this segment of I-64.

in a light appearance. The shadow created by the overhang will reduce the ____________

perceived superstructure depth. The inclination of the webs will lessen the

volume of the superstructure. The curved approach spans will give a sense of Santiago Rodriguez is an associate

vice president of T.Y. Lin International,

openness and continuity with the graceful main span. The edges of the main Alexandria, Va., and served as project

span piers embrace the webs of the superstructure, thus subdividing the box manager and lead bridge designer for the

girder depth. The piers have a modified rectangular section, with 45-degree Kanawha River Bridge Project.

chamfers, which reduce the perceived width of the columns in skewed views.

A textured architectural treatment is used in the transverse faces of all piers

and abutments. An applied concrete finish will be used on the surfaces of the

substructure and superstructure elements

For more information on this or other

projects, visit www.aspirebridge.org.

32 | ASPIRE, Winter 2009

American Coal Ash Association

The American Coal Ash Association (ACAA) is devoted to educating engineers, concrete professionals, standards organizations, and others

about coal combustion products or “CCPs”—materials produced by coal-fueled power plants. These include fly ash, bottom ash, boiler slag,

and flue gas desulfurization materials. Fly ash concrete has been specified because of its high strength and durability for numerous bridge

projects worldwide, including the longest cable-stayed bridge in North America, the John James Audubon Bridge near Baton Rouge, La.

The I-35W bridge near Minneapolis, Minn. has been reconstructed using a unique mix design that included fly ash concrete to ensure

a long-lasting, high performance structure. Caltrans required high volume fly ash mixes for the largest bridge project in its history—the

San Francisco-Oakland Bay Bridge. Using innovative specifications and blending techniques, Caltrans was able to improve its workability,

hardening, and permeability properties of the bridge’s concrete. A number of engineering standards and specifications define CCP

applications, thus ensuring high quality performance and products.

Though these materials’ properties vary according to coal composition and power plant operating conditions, experts can advise on

quality and determine the best mix design for most any condition and project. Mix designs exceeding 40 percent fly ash have proven

successful in many projects. Experts with first-hand experience may be located by contacting ACAA. The technical, environmental and

commercial advantages of CCPs contribute to global sustainability.

In addition to a myriad of core performance attributes in sustainable construction, CCP use can conserve natural resources, reduce

greenhouse gas emissions and eliminate need for additional landfill space. For more information, contact ACAA at info@acaa-usa.org

or call 720-870-7897.

Bridge Monitoring

Know more about your bridges.

At Campbell Scientific, we design rugged, stand-alone data

acquisition systems for any size of bridge. From short-term testing

to long-term monitoring, our systems can provide you

with valuable decision-making data.

(435) 750-9692

www.campbellsci.com/bridges

ASPIRE, Winter 2009 | 33

KANAWHA RIVER BRIDGE / WEST VIRGINIA

The concrete box girder in the approach spans measures

64 ft wide and 16 ft deep. Photo: T.Y. Lin International.

The segmental box girder bridge is a harmonious design.

Comprising a total of seven approach spans, the bridge’s total length is 2975 ft. Illustration: T.Y. Lin International.

Web | ASPIRE, Winter 2009

KANAWHA RIVER BRIDGE / WEST VIRGINIA

Photos: T.Y. Lin International.

ASPIRE, Winter 2009 | Web

KANAWHA RIVER BRIDGE / WEST VIRGINIA

Photos: T.Y. Lin International.

Web | ASPIRE, Winter 2009

KANAWHA RIVER BRIDGE / WEST VIRGINIA

Photo: Ahmed N.K. Mongi, of the WVDOT.

Work continues on the Kanawha River Bridge with completion expected

by the end of 2010. Photo: Ahmed N.K. Mongi, of the WVDOT.

ASPIRE, Winter 2009 | Web

KANAWHA RIVER BRIDGE / WEST VIRGINIA

Photo: Ahmed N.K. Mongi, of the WVDOT.

Web | ASPIRE, Winter 2009

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Railway Code Rdso CatlogDocument54 pagesRailway Code Rdso CatlogSandeep SinghNo ratings yet

- CorbelDocument2 pagesCorbelSandeep SinghNo ratings yet

- Openstaad PDFDocument9 pagesOpenstaad PDFSurendran MurugesanNo ratings yet

- Openstaad PDFDocument9 pagesOpenstaad PDFSurendran MurugesanNo ratings yet

- Structural Sections BS4Document42 pagesStructural Sections BS4ahmadove1No ratings yet

- 2400 Surface and Sub Surface Geotechnical ExplorationDocument15 pages2400 Surface and Sub Surface Geotechnical ExplorationimamtaNo ratings yet

- Calculation For SpliceDocument15 pagesCalculation For SpliceSandeep Singh0% (1)

- Composite Span FOB On 1 JUNE 2012Document7 pagesComposite Span FOB On 1 JUNE 2012Sandeep SinghNo ratings yet

- Steel Table SectionsDocument26 pagesSteel Table SectionsSandeep SinghNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Shafeeq 123Document136 pagesShafeeq 123Maaz Uddin SiddiquiNo ratings yet

- Causes of Distress and Deterioration of Concrete, EM 1110-2-2002 1995-06-30Document14 pagesCauses of Distress and Deterioration of Concrete, EM 1110-2-2002 1995-06-30RONALD MUELLERNo ratings yet

- Pgsuper Design GuideDocument77 pagesPgsuper Design GuideLuis OrdoñezNo ratings yet

- IUST v9n4p611 en PDFDocument18 pagesIUST v9n4p611 en PDFmehdi taheriNo ratings yet

- Structural Designer JobDocument1 pageStructural Designer JobDina AvdićNo ratings yet

- Project Construction Management: Data SheetDocument8 pagesProject Construction Management: Data SheetyfcbrandonNo ratings yet

- E Poster PresentationDocument15 pagesE Poster Presentationdhruv soniNo ratings yet

- Method Statement For Pipe Culvert Anil SahabDocument2 pagesMethod Statement For Pipe Culvert Anil SahabAsad AshfaqNo ratings yet

- Faculty - Civil Engineering - 2022 - Session 1 - Degree - Ecs416Document4 pagesFaculty - Civil Engineering - 2022 - Session 1 - Degree - Ecs416Sarah ZulaikhaNo ratings yet

- Timeline of ConcreteDocument7 pagesTimeline of ConcreterabeeabuahmadNo ratings yet

- CON4334A2TO130523BL Ch1 IntroductionDocument27 pagesCON4334A2TO130523BL Ch1 IntroductionLeung Wai YipNo ratings yet

- Columns and Shear Walls Means Vertical Elements Form Work We Cane Remove After24 Hours But Slab Form Work Depend On Span Same Like ThisDocument16 pagesColumns and Shear Walls Means Vertical Elements Form Work We Cane Remove After24 Hours But Slab Form Work Depend On Span Same Like ThisImam ShakilNo ratings yet

- PM WBS Construction Schedule PDFDocument10 pagesPM WBS Construction Schedule PDFXozanNo ratings yet

- Sequence of WorksDocument5 pagesSequence of WorksmohdNo ratings yet

- Group 1 - Goldin Finance 117 Structure (Revised)Document5 pagesGroup 1 - Goldin Finance 117 Structure (Revised)rishikaNo ratings yet

- Cobicif-Reportdescription Eng PDFDocument700 pagesCobicif-Reportdescription Eng PDFĐạt Nguyễn TuấnNo ratings yet

- Cast-In-Place and Pre-Cast: Flat Type General NotesDocument4 pagesCast-In-Place and Pre-Cast: Flat Type General NotesGelineGayleUgasNo ratings yet

- RC Column Strengthened with Ferrocement JacketDocument8 pagesRC Column Strengthened with Ferrocement JacketChelemen MaryaNo ratings yet

- PROD - Technical FloorDocument1 pagePROD - Technical FloorsupportLSMNo ratings yet

- Capacity Spectrum MethodDocument8 pagesCapacity Spectrum MethodJashwin UllalNo ratings yet

- Ringwall ExampleDocument1 pageRingwall ExampleJorge Lovera HurtadoNo ratings yet

- Flier - Refresher Course On Prestressed Concrete DesignDocument3 pagesFlier - Refresher Course On Prestressed Concrete DesignMano HarNo ratings yet

- TN-326 Average Pre CompressionDocument3 pagesTN-326 Average Pre CompressionPartha Pratim RoyNo ratings yet

- Ikundji Divin Cumulative Fyrdp ReportDocument83 pagesIkundji Divin Cumulative Fyrdp ReportDivin IkundjiNo ratings yet

- Stainless Steel in Fire Final Summary Report March 08 PDFDocument121 pagesStainless Steel in Fire Final Summary Report March 08 PDFjovanaNo ratings yet

- Muhammad Tunggal Rifat Case StudyDocument5 pagesMuhammad Tunggal Rifat Case StudyAdib RizqullohNo ratings yet

- Seismic RC BuildingDocument33 pagesSeismic RC BuildingDario Manrique GamarraNo ratings yet

- Masonry Work Productivity RateDocument13 pagesMasonry Work Productivity RateLito EstimosNo ratings yet

- High Strength Concrete: Enabling Taller, Lighter ConstructionDocument9 pagesHigh Strength Concrete: Enabling Taller, Lighter Constructionneethu26No ratings yet

- CE 71 DRB Internal-2-Answer Key (Student Copy)Document22 pagesCE 71 DRB Internal-2-Answer Key (Student Copy)PaulNo ratings yet