Professional Documents

Culture Documents

EART-02-003 Issue B - Earthing and Bonding at Secondary Subs

Uploaded by

kapil aryaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EART-02-003 Issue B - Earthing and Bonding at Secondary Subs

Uploaded by

kapil aryaCopyright:

Available Formats

DISTRIBUTION CONSTRUCTION MANUAL

SECTION 4 - SUBSTATIONS

ISSUE B

4.4.4

SEPT 1996

EARTHING AND BONDING AT SECONDARY SUBSTATIONS

1 SCOPE

This section of the Distribution Construction Manual lays down the standard for

earthing and bonding of plant and apparatus at secondary substations to comply with

Regulations.

2 GENERAL

Earth is defined as the general mass of earth.

Earthed means connected to the general mass of earth in such a manner as shall ensure

at all times, an immediate discharge of the electrical energy without danger.

An Earth Electrode comprises a metal rod or system of rods or other conducting

objects, such as copper tape, providing an effective connection with the general mass of

earth.

Earth Electrode Systems

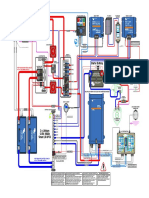

At every secondary substation two earth electrode systems are necessary i.e. Equipment

Earthing (HV Earth) and System Neutral Earthing (LV Earth). The two systems shall

be installed with suitable segregation and can only be connected together when the

combined value of the systems in less than 1 ohm.

Equipment Earthing and Bonding of all the metalwork associated with the electrical

equipment (other than parts which are normally current carrying) ensures effective

operation of the HV fuse or switchgear controlling the circuit, where the potential of

such metalwork, with respect to the general mass of earth or other adjacent metalwork

could rise to a value which could cause danger to life or risk of fire.

System Neutral Earthing is necessary to preserve security of systems, to ensure that

the voltage on each live conductor is restricted to such a value with respect to the

potential of the general mass of earth as is consistent with the insulation level of the

system.

DCM 4.4.4 ISSUE B SEPTEMBER 1996 PAGE 1 OF 8

D.C.M. 4.4.4

3 HV STEELWORK EARTH

3.1 The HV steelwork in the substation shall be connected with earth by bonding an

un-insulated copper conductor (in accordance with Table 1) from the earth terminal on

the transformer tank or switchgear to an earth electrode system, Reference Section 6,

with an ohmic resistance value as low as economically practicable, and of such a value

that when contact is made between a line conductor and earthed metalwork, the

resulting leakage current shall be not less than twice the current required to operate the

device which will make the line dead. The earth electrode system resistance value,

measured independently shall not exceed 40 ohms. The sheaths of any metallic

sheathed cables shall subsequently be bonded to that established system.

3.2 The routing and position of the earth electrode system should be such as to form

an equi-potential mat beneath the operating position of any of the apparatus so that the

operator is protected, so far as reasonably possible, from any voltage gradient arising

from an HV fault.

3.3 Where secondary substations are surrounded by metallic structures e.g. palisade

fencing, all separate sections of the surround shall be bonded to the HV earth electrode

system. Care should be taken to keep the earth electrode and their bonding leads as far

as possible from nearby non-related metal fences, metal buildings etc., so as to avoid

these becoming charged during a fault on the HV system. A distance of 3 metres is

recommended if this is possible.

4 LV NEUTRAL EARTH

4.1 The LV neutral shall be connected to an earth electrode system separate from the

HV earth electrode system, reference Section 6, by running a PVC insulated cable (in

accordance with Table 1), from the neutral busbar in the LV pillar or fuse cabinet to an

earth electrode system. The resistance of the LV neutral earth electrode system at the

substation measured independently shall not exceed 40 ohms. The combined resistance

of all the LV neutral electrodes, including any contribution from any metallic sheathed

cables, shall not exceed 20 ohms.

4.2 Care shall be exercised to place the neutral earth electrode system outside the

influence of the HV steelwork earthing system. A distance of not less than 3 metres is

recommended from the nearest steelwork earth electrode or earth mat but this distance

may require to be increased in cases of abnormally high resistances.

5 COMBINED HV STEELWORK AND LV NEUTRAL EARTHS

5.1 Where the earth resistance of the combined earths (HV steelwork + neutral earth

+ connections with earth associated with the cables connected to the substations via

their sheaths) is 1 ohm or less, then the separate HV and LV earth electrode systems

shall be bonded together. This is the preferred state and when this condition prevails

the link provided in the LV pillar between the neutral earth bar and the pillar shell shall

be closed.

DCM 4.4.4 ISSUE B SEPTEMBER 1996 PAGE 2 OF 8

D.C.M. 4.4.4

5.2 Where it is not technically and economically justified to reduce the combined earth

resistance value to 1 ohm or less, the HV steelwork earth electrode system shall remain

segregated from the neutral earth electrode system. In this condition, where a link is

provided between the neutral earth and the LV metalwork, it shall be left in the open

position. A notice shall be installed in a conspicuous position within the pillar

showing that this condition prevails.

6 EARTH ELECTRODE SYSTEMS

6.1 Earth electrode systems shall normally be comprised of conductors as detailed in

Table 1 and earth rods complying with EA Technical Specification 43-94 Issue 3 and

ScottishPower Procurement Specification No. 4389/10,000 which includes non

extensible galvanised steel tubes 20 mm dia., non extensible copper clad 9 mm dia. rods

and extensible copper clad 15 mm dia. rods. The rods shall be driven into the ground

vertically until their tops are at least 600 mm below the surface. This depth is

necessary to prevent appreciable voltage gradient on the surface of the ground in the

vicinity of the electrode. The HV earth electrode system can be installed within the

substation and shall cross the area on which an operator will be required to stand while

operating the switchgear. The LV earth electrode system can be installed along an LV

cable trench but shall not make contact with a cable or come within 3m of an HV cable.

Paper insulated metallic sheath, jute or hessian served cables laid direct in the ground

shall not be used as the main HV steelwork or LV neutral earth electrode system but

shall be bonded to the relative systems.

6.2 Where more than one rod is necessary, then a number of rods may be installed at

a distance of approximately, but not less than, 3 metres from each other. The resistance

of N rods at 3 metre spacing, connected in parallel, is approximately 1.5 x R/N where

R is the resistance in ohms of one rod. The connections between earth rods, where

more than one are installed shall always be made using copper conductor in accordance

with Table 1. The connections from the neutral/earth bar to the neutral earth electrode

system shall be insulated until they are outwith the sphere of influence of HV steelwork

earth system (not less than 3 metres separation).

6.3 All connections between the earth rods and the earth leads must be carefully made

up, using approved clamps, adequately protected by wrapping with denso or other

approved tape or cast in bitumen compound. Where connections are made using lugs

and bolts then two bolt fixings shall be used.

6.4 Means must be provided for disconnecting the earth electrode system at

substations for testing, and this can normally be achieved by having a bolted connection

where the earth electrode system is connected on to the equipment or neutral busbar

which can be undone and the lead disconnected. These disconnections must always be

at copper to copper or copper to brass joints. Aluminium joints shall not be

disconnected for testing.

DCM 4.4.4 ISSUE B SEPTEMBER 1996 PAGE 3 OF 8

D.C.M. 4.4.4

6.5 In areas of high soil resistivity, low electrode resistances are difficult to achieve

and dangerous potential gradients could occur over and around the site unless adequate

steps are taken to prevent this. These potential gradients may also be imposed on the

entire LV distribution system. Increasing the number of electrodes will reduce the

overall earth resistance value but may result in extending the earth system outwith the

confines of the substation and produce potential gradients between nearby metallic

objects, e.g. metal framed buildings or fences. A lower resistance value may often be

achieved by driving extensible earth electrodes deep into the ground without extending

the earth system outside the substation. In rocky soil, copper tape in accordance with

Table 1 may be installed.

6.6 Great care should be exercised when installing the earth electrode system

particularly when hammering rods into the ground, to avoid accidents due to piercing

cables or other utilities services already laid in the ground, e.g. gas, water, telephone,

sewage, etc. Before commencing installation of electrodes an up-to-date plan of the site

should be prepared showing the exact position of all cables and other services including

cables recently laid in conjunction with the project under construction and the cables in

question should be positively located, if necessary by excavating trial holes, before

driving the earth rods. So far as possible, persons should avoid direct contact with

earth rods being driven into the ground by using an insulated tool to steady the rod or

by the use of rubber gloves.

7 BONDING

7.1 The size and type of bonding conductors to be used are set down in

Table 1.

7.2 All steelwork within touching distance (2 metres) shall be bonded together, so that

no potential difference can arise between units. This includes the transformer, HV

switchgear, HV cables, LV feeder pillar shells, fences, exposed total enclosure

metalwork and any other apparatus installed.

The bond shall be made using conductors shown in Table 1. Where theft of copper is

likely, aluminium conductors are recommended for above ground with terminations

similar to those in Section 4.3.3 Appendix 2 of this manual.

8 SUBSTATION EARTH POTENTIAL RISE (HOT EARTHS)

8.1 Under system earth fault conditions the neutral or earth potential near a

substation rises above the true earth potential and can adversely affect

telecommunications equipment in that zone. Engineering Recommendation ER G60

recommends that where the rise of potential exceeds 430 volts at Distribution

substations, the substation is deemed "HOT" and additional protection is required for

telecommunications equipment in the vicinity of the substation.

DCM 4.4.4 ISSUE B SEPTEMBER 1996 PAGE 4 OF 8

D.C.M. 4.4.4

8.2 For all new substations, or when requested to do so, it is incumbent upon

ScottishPower to calculate the 430 volt contour radius using Engineering

Recommendation S34, "A Guide for Assessing the Rise of Earth Potential at Substation

Sites" and advise BT or other companies involved. Additional precautions for

telecommunications equipment will only be needed in the calculated "HOT" zone. This

will normally be done at the design stage, reference Section 13.8 of the Distribution

Design Manual, but must be confirmed at the construction stage.

9 LV SYSTEM EARTHING

9.1 At network pillars and link boxes remote from substations or at other

disconnecting points on the LV system, the cable neutral and earth shall be securely

bonded together using 35 mm2 or 70 mm2 conductor depending on the cable size. The

framework of the pillar shall be bonded to the cable neutral/earth and shall be connected

with a 35 mm2 conductor to an earth electrode.

10 INSTALLATION EARTHING

The earthing of installations shall comply with the Code of Practice "Earthing of LV

Distribution Networks". Where a new installation is being connected to a separate

neutral and earth (SNE) network, preference should be given to adopting protective

multiple earthing (PME). In certain circumstances, however, it may be technically and

economically justified to extend the existing SNE earthing system.

11 TECHNICAL NOTES

11.1 In situations of high earth resistivity, there may be difficulty in obtaining the

required earth electrode system resistance. This would cause high potential gradients to

occur in and around the substation, which could be impressed on the whole of the LV

distribution system supplied from the substation or on telecommunications equipment.

The earth resistance can be reduced by inserting more electrodes, until a low enough

total resistance is achieved. This may, however, result in extending the earth system

beyond the confines of the substation, and may produce dangerous proximities between

the earth leads and external metal objects. It may be better in certain locations to use

extensible deep driving earth electrodes, within or near the substation to obtain the same

results. The LV neutral earth electrode system should always have an insulated lead,

and be at least 3 metres separate from the HV steelwork earth electrode system or any

metalwork bonded thereto. This is particularly important in high resistivity areas.

Special care must be taken to ensure that all metalwork, including the fence and LV

pillars, is bonded, and connected to the HV steelwork earth electrode system to avoid

potential differences between items of apparatus, when within touching distance, i.e.

within 2 metres proximity.

With the increased use of plastic covered cables it is essential to achieve sufficiently low

DCM 4.4.4 ISSUE B SEPTEMBER 1996 PAGE 5 OF 8

D.C.M. 4.4.4

earth electrode system resistance values.

The requirement for the electrode systems to dissipate fault current must be achieved by

installing a minimum of five earth rods in every system even if a lesser number could

achieve the required ohmic value of resistance.

11.2 LV Neutral/HV Metalwork Earth System

Should a potential gradient exist in the vicinity of a substation during an HV fault there

is a risk of this being impressed on the LV system if the neutral and HV steelwork

earths are connected together, and the earth system resistance is high. It is considered

safe to join the two earth systems together when their combined resistance is 1 ohm or

less. Where it is impracticable to achieve this resistance, care should be taken to ensure

that the LV neutral is connected by an insulated lead to the electrode system which is

well clear of the estimated potential gradient of the HV earth system. This may require

a greater distance than the stipulated minimum of 3 metres.

11.3 PVC Over Sheathed Cables

In the past, advantage has been taken of the effectiveness of the sheaths of lead-covered

hessian protected cables as an earth. It should be noted that PVC over sheathed cables

do not contribute to the earth electrode system in this way.

11.4 Substations Supplied by HV Overhead Lines Only

Where substations are supplied from a metallic sheathed underground cable system, the

major part of the earth fault current returns to the source (the primary substation) via

the sheath, whereas in the case of an overhead line fed substation there is no metallic

return path and all of the fault current must return via the earth electrode system and the

general mass of earth. In these circumstances, it is most important to make sure that

the earth electrode system and the earth leads have a low enough resistance and an

adequate current-carrying capacity to dissipate the whole of the fault current.

11.5 Metal Objects Adjacent to Substations

Where there are metal structures or fences adjacent to a substation, potential differences

may occur between them and the metal parts of the substation or the fences, which may

be within touching distance. On the other hand, if such structures are bonded, or in

contact with the substation steelwork, then the potential may be carried a considerable

distance from the substation, e.g. along the wires of a fence with wooden posts and

create a danger elsewhere. Substations must be designed and sited so as to avoid these

situations.

11.6 Gates on Steel Fences or Total Enclosure Steel Doors

DCM 4.4.4 ISSUE B SEPTEMBER 1996 PAGE 6 OF 8

D.C.M. 4.4.4

Where gates exist in steel fences or the doors of a total enclosure are of sheet steel,

particularly if the fence or door is discontinuous, they shall be bonded on both sides of

the gate or door to avoid the possibility of a potential developing across the gate or

door.

DCM 4.4.4 ISSUE B SEPTEMBER 1996 PAGE 7 OF 8

D.C.M. 4.4.4

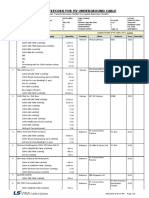

TABLE 1 - EARTHING AND BONDING CONDUCTORS TO BE USED AT

SECONDARY SUBSTATIONS

Bonding of S/Stn. HV Steelwork LV Neutral

Type of Conductor Apparatus Earth Leads Earth Leads

Solid Alum. PVC

insulated cable to

BS 6791: 1969

600

1000 V Grade 120 mm2 - -

Copper Strip to

BS 1432: 1970 20 mm x 4 mm 20 mm x 4 mm -

Alum. Strip to

BS 2898: 1970 (EIE.M)

30 mm x 4 mm - -

Bare Copper Conductor Not less than Not less than

Solid or Stranded 70 mm2 70 mm2 -

Insulated Copper Wire Not less than Not less than

70 mm2 - 70 mm2

DCM 4.4.4 ISSUE B SEPTEMBER 1996 PAGE 8 OF 8

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingFrom EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingNo ratings yet

- 1435028754370-Earthing GSDocument89 pages1435028754370-Earthing GSprembiharisaranNo ratings yet

- Earthing and TestingDocument5 pagesEarthing and TestingdestawNo ratings yet

- Bonding & EarthingDocument75 pagesBonding & EarthingPrachir Shrivastava0% (1)

- 6-Earting TN - TT MDocument21 pages6-Earting TN - TT MAhdab ElmorshedyNo ratings yet

- MOS Integrated Circuit DesignFrom EverandMOS Integrated Circuit DesignE. WolfendaleNo ratings yet

- LV Cable InstallationDocument20 pagesLV Cable Installationkailasamvv100% (1)

- Bonding & Earthing (Final)Document67 pagesBonding & Earthing (Final)Vardaa Impex100% (2)

- Earthing in SubstationDocument14 pagesEarthing in SubstationArun SukumarNo ratings yet

- Electric Distribution LinesDocument7 pagesElectric Distribution LinesluisepasNo ratings yet

- Insulation Co-ordination in High-voltage Electric Power SystemsFrom EverandInsulation Co-ordination in High-voltage Electric Power SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- Earthing System 26 05 26 PDFDocument5 pagesEarthing System 26 05 26 PDFozsenerNo ratings yet

- Rajasthan Rajya Vidyut Utpadan Nigam Limited 2 X 660 MW Suratgarh Supercritical Tps Unit # 7 & 8Document41 pagesRajasthan Rajya Vidyut Utpadan Nigam Limited 2 X 660 MW Suratgarh Supercritical Tps Unit # 7 & 8rohitctppNo ratings yet

- BRUSH BDAX GE - 62 - 170ERT Data CurvesDocument18 pagesBRUSH BDAX GE - 62 - 170ERT Data Curvescogen100% (4)

- Earthing of Power Supply Installations - 1Document6 pagesEarthing of Power Supply Installations - 1mshahidshaukatNo ratings yet

- EHV HV Cable Sheath EarthingDocument20 pagesEHV HV Cable Sheath EarthingSachinNo ratings yet

- Circular Rotor Windmill (Wind Turbine)Document105 pagesCircular Rotor Windmill (Wind Turbine)SanjaySherikarNo ratings yet

- Earthing PracticesDocument16 pagesEarthing PracticesPraveen KumarNo ratings yet

- SECTION 16450 Grounding Part 1 - GeneralDocument5 pagesSECTION 16450 Grounding Part 1 - GeneraljosemartinpenatorresNo ratings yet

- Bonding and Grounding: What? Why? How?Document45 pagesBonding and Grounding: What? Why? How?chibssa alemayehu100% (1)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- HV Cable Sheath EarthingDocument15 pagesHV Cable Sheath EarthingjuliancansenNo ratings yet

- EHVHV Cable Sheath EarthingDocument12 pagesEHVHV Cable Sheath EarthingHimdad Tahir100% (1)

- Sustainable Power Systems: Nava Raj Karki Rajesh Karki Ajit Kumar Verma Jaeseok Choi EditorsDocument186 pagesSustainable Power Systems: Nava Raj Karki Rajesh Karki Ajit Kumar Verma Jaeseok Choi Editorsnop phornnaraNo ratings yet

- Conduit - Electrical Design GuideDocument4 pagesConduit - Electrical Design GuidezeliteNo ratings yet

- OM 6-5-A Earthing PracticesDocument16 pagesOM 6-5-A Earthing PracticesAnurag PugaliaNo ratings yet

- Sec06 - GroundingDocument6 pagesSec06 - GroundingYusufNo ratings yet

- Design Condition For Earthing SystemDocument4 pagesDesign Condition For Earthing SystemRashad SarwarNo ratings yet

- Code of Practice For Earthing - Railway SpecDocument16 pagesCode of Practice For Earthing - Railway Specsuresh kumarNo ratings yet

- Specifications of Typical Substation Earthing SystemDocument5 pagesSpecifications of Typical Substation Earthing SystemYahya Faiez WaqqadNo ratings yet

- E 7 Ear Thing RequirmentsDocument8 pagesE 7 Ear Thing RequirmentsJohn Arllan DiestroNo ratings yet

- Power Substatio-WPS OfficeDocument9 pagesPower Substatio-WPS OfficeJessa NavarrosaNo ratings yet

- Cha 1Document40 pagesCha 1Yahya Faiez WaqqadNo ratings yet

- Lecture 08 - EarthingDocument12 pagesLecture 08 - Earthingsethdesilva.clNo ratings yet

- Importance of Earthing & PracticesDocument26 pagesImportance of Earthing & PracticesPraveen KumarNo ratings yet

- Nec 250 Part IV EnclosureDocument6 pagesNec 250 Part IV Enclosurevladimir rosas ayalaNo ratings yet

- Service Entrance Grounding: 1.0 INDEXDocument6 pagesService Entrance Grounding: 1.0 INDEXSaurabh HimkarNo ratings yet

- Chapter 4Document38 pagesChapter 4alembrhanNo ratings yet

- Design and Construction Standards Cornell UniversityDocument9 pagesDesign and Construction Standards Cornell UniversitygarysNo ratings yet

- Electrical Regulations: 7 Earth ConnectionsDocument3 pagesElectrical Regulations: 7 Earth ConnectionsVijay PatelNo ratings yet

- Earthing OF Impulse Voltage StationsDocument6 pagesEarthing OF Impulse Voltage StationsYahya Faiez WaqqadNo ratings yet

- 3.3 EMC Solutions in SubstationDocument21 pages3.3 EMC Solutions in SubstationnicheworldNo ratings yet

- Earthing SystemDocument5 pagesEarthing SystemPrashna ShresthaNo ratings yet

- Spec EarthingDocument10 pagesSpec EarthingDolyNo ratings yet

- Article 2Document64 pagesArticle 2mark ianNo ratings yet

- Distribution System Earthing Guidelines PDFDocument15 pagesDistribution System Earthing Guidelines PDFasexyguyNo ratings yet

- Wiring ProtocolDocument5 pagesWiring ProtocoljeannineNo ratings yet

- Tablas Nec InglesDocument24 pagesTablas Nec InglesJavier Encalada100% (1)

- Earthing SystemDocument6 pagesEarthing SystemsallammohamedNo ratings yet

- Design Considerations For Arctic - Grounding SystemsDocument5 pagesDesign Considerations For Arctic - Grounding SystemsicastongNo ratings yet

- Chapter Four Earthing Systems and Lightning ProtectionDocument7 pagesChapter Four Earthing Systems and Lightning Protectionyibelta abebeNo ratings yet

- What Is EarthingDocument4 pagesWhat Is EarthingGopesh NakraNo ratings yet

- Earthing & Bonding SystemDocument6 pagesEarthing & Bonding Systemsaravana3kumar3ravicNo ratings yet

- (FT) (FT) I. (FT) : Part 2. Safety Rules For Overhead LinesDocument1 page(FT) (FT) I. (FT) : Part 2. Safety Rules For Overhead LinesSj Comp UtaNo ratings yet

- Conductor Puesta A TierraDocument1 pageConductor Puesta A TierraKevin MontoyaNo ratings yet

- Electric Gas Lighting How to Install Electric Gas Ignition ApparatusFrom EverandElectric Gas Lighting How to Install Electric Gas Ignition ApparatusNo ratings yet

- Relevant Characteristics of Power Lines Passing through Urban AreasFrom EverandRelevant Characteristics of Power Lines Passing through Urban AreasNo ratings yet

- An Essential Guide to Electronic Material Surfaces and InterfacesFrom EverandAn Essential Guide to Electronic Material Surfaces and InterfacesNo ratings yet

- Transformer PDFDocument70 pagesTransformer PDFumair rashidNo ratings yet

- Why Electric Power Transmission Is Multiple of 11 I.E 11kV - 22kV - 66kV EtcDocument8 pagesWhy Electric Power Transmission Is Multiple of 11 I.E 11kV - 22kV - 66kV EtcSushil NamoijamNo ratings yet

- Electrical Resistance Lecture 2Document5 pagesElectrical Resistance Lecture 2bigbang0% (1)

- Caracteristici UPSDocument6 pagesCaracteristici UPSVerdesh VladNo ratings yet

- 1 2 Chapter1 Basic Concept of EM w1Document12 pages1 2 Chapter1 Basic Concept of EM w1Paramaet TamNo ratings yet

- Vd412.06.13e GTP 1vyn400990-009Document5 pagesVd412.06.13e GTP 1vyn400990-009Jatupol PongsirisartNo ratings yet

- Unit 7 - Week 6: Assignment 6Document4 pagesUnit 7 - Week 6: Assignment 6venugopal pudurNo ratings yet

- Module 1 - BASIC ELECTRICAL QUANTITIES AND RELATED CONCEPTSDocument19 pagesModule 1 - BASIC ELECTRICAL QUANTITIES AND RELATED CONCEPTSJohn Mark CabitacNo ratings yet

- Name of The Transmission Lines Voltage (KV) : AG (1) AG (1) AG (1) AG (1) AG (1) AG (1) AG (1) AG (1) AGDocument5 pagesName of The Transmission Lines Voltage (KV) : AG (1) AG (1) AG (1) AG (1) AG (1) AG (1) AG (1) AG (1) AGBinode SarkarNo ratings yet

- Nec 10 11 12Document9 pagesNec 10 11 12Marie Grace DollentasNo ratings yet

- Final Documentation Drawings CS0928Document91 pagesFinal Documentation Drawings CS0928Gunji Venkata Srinivasa BabuNo ratings yet

- ABB Wind Turbine Converters: ACS880, 800 KW To 8 MWDocument12 pagesABB Wind Turbine Converters: ACS880, 800 KW To 8 MWEdgardNo ratings yet

- 4 Phoenix Charger and InverterDocument1 page4 Phoenix Charger and InverternevkatNo ratings yet

- S.M.Academy: Physics Project OnDocument16 pagesS.M.Academy: Physics Project OnSarvesh Kumar SinghNo ratings yet

- Product Overview: MC33151: High Speed Dual MOSFET DriverDocument1 pageProduct Overview: MC33151: High Speed Dual MOSFET Driversp300bNo ratings yet

- W9 1489436 10 11Document82 pagesW9 1489436 10 11Matthew MonroeNo ratings yet

- Up Eei Inverter 09 24Document1 pageUp Eei Inverter 09 24Earl IneNo ratings yet

- Current Transfomers, 5A Output: Unique Dual-Hinge Split-Core DesignDocument2 pagesCurrent Transfomers, 5A Output: Unique Dual-Hinge Split-Core DesignCata CatalinNo ratings yet

- Nava Bharat Ventures Limited Power Plant (Orissa) : Unit ProfileDocument8 pagesNava Bharat Ventures Limited Power Plant (Orissa) : Unit ProfileashifNo ratings yet

- PDFDocument17 pagesPDFAnonymous 1grFXHMG100% (1)

- EEPCO Directive On Clearance & Volt 98engDocument6 pagesEEPCO Directive On Clearance & Volt 98engMelese SefiwNo ratings yet

- 1.6KVA 12V MultiPlus 230 Volt System Example 4 PIN VE Bus BMS Lithium Orion TRDocument1 page1.6KVA 12V MultiPlus 230 Volt System Example 4 PIN VE Bus BMS Lithium Orion TRAlba Car MarNo ratings yet

- ME267 Assignment01Document1 pageME267 Assignment01InsaneNo ratings yet

- Syllabus For Wireman Examination - 07.2015Document2 pagesSyllabus For Wireman Examination - 07.2015James NyamwayaNo ratings yet

- Supply Record For HV Underground Cable: (For Seam Type/Continuously Welded Corrugated Aluminium Sheath)Document8 pagesSupply Record For HV Underground Cable: (For Seam Type/Continuously Welded Corrugated Aluminium Sheath)GalihNo ratings yet

- 7 STC TRS Con 02 I Relays & SwitchesDocument47 pages7 STC TRS Con 02 I Relays & Switchesmikkumar5No ratings yet