Professional Documents

Culture Documents

Shiva and Bannari Gap Study

Uploaded by

Raj KumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shiva and Bannari Gap Study

Uploaded by

Raj KumarCopyright:

Available Formats

Gap Study

Subject : GAP STUDY

Place & : Shiva TexYarn Limited, Dindigul.

Date 04th,5th and 18th Feb 2008 at Mills, 13th Feb 2008 at H.O.

Participants : Mr. D.L. Jeevandass KALPATHARU Software Ltd,

Mr. M. Kannan 1023, Avanashi Road,

Mr. S. Sasikumar Coimbatore – 641 018.

Ph: 0422 2212561

: At Mills: Shiva Texyarn Limited /

Mr. K. Prabakaran, GM Bannari Amman Spg Mills Ltd.

Mr. Mathavan, EDP Trichy Road,

Mr. Sivakumar, EDP Dindigul .

Mr. A.Sankar, Accounts

Mr. Kumaresan,Accounts

Mr. Venkatasubramanian,Stores

Mr. Ragunathan , Stores

Mr. Manikandan, Time office

Ms.Thilagavathi, Time office

Mr. Raj kumar, QC

Mr. Vasudevan, Electrical

Mr. Sagayaraj, Electrical

Mr. Saravanakumar, Despatch

Mr. Raja , Despatch

Mr. Dinesh Kumar, BASML I

Mr. Ramasamy, BASML I

At H.O: Shiva Texyarn Limited /

Mr. S. Seshadri, GM (Finance) Bannari Amman Spg Mills Ltd.

Mr. C.S. Balakumar, GM (Accounts) MTP Road,

Mr. Sankar Kumar, GM (Marketing) Coimbatore.

Mr. R. Rajasekar, EDP

Mr. Veera raj, EDP

Mr. Duraisamy

Mr. Natarajan

Mr. Gnanavelu

Mr. Sakthivel

Objective:

The main objective of the gap study is to understand the current mills practices and

procedures vis a vis Kalsofte ERP system. Every individual process followed by mills is

detailed and mapped to the procedures in the system during the gap study.

Result:

The gaps between the mills practices and existing system are captured and documented.

The captured details, module wise and process wise, are tabulated. Gaps and activities to

be carried out by mills / Kalpatharu during implementation have been highlighted.

Please go through the details for correctness and inform us of any variance or mis-

interpretation to enable us modify it accordingly.

Kalpatharu Software Limited Page 1 of 21

Gap Study

Organisation Hierarchy

Company 1 : Shiva Texyarn Limited. (Level 1)

Division 01 : Shiva Texyarn Limited, Unit I. (Level 2)

Division 02 : Shiva Texyarn Limited, Unit II. (Level 2)

Division 03 : Shiva Texyarn Limited, Wind Mill Division. (Level 2)

Division 04 : Shiva Texyarn Limited, H.O. (Level 2)

Company 2 : Bannari Amman Textiles Limited. (Level 1)

Division 01 : Bannari Amman Textiles Limited, Unit I. (Level 2)

Division 02 : Bannari Amman Textiles Limited, Unit II. (Level 2)

Bannari Amman Textiles Limited, Unit II – A Unit. (Level 3)

Bannari Amman Textiles Limited, Unit II – B Unit. (Level 3)

Division 03 : Bannari Amman Textiles Limited, Wind Mill Division. (Level 2)

Division 04 : Bannari Amman Textiles Limited, H.O. (Level 2)

Division 05 : Bannari Amman Textiles Limited, Weaving Division. (Level 2)

Division 06 : Bannari Amman Textiles Limited, Technical Textiles. (Level 2)

Note: Weaving and Technical Textiles divisions have not been considered in the

current scope.

Kalpatharu Software Limited Page 2 of 21

Gap Study

1.1 STORES PURCHASE:

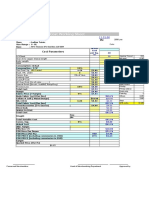

Mill System Kalsote ERP System

Supplier master details. Exhaustive details with latest updated information

( Data migration / export from the existing on supplier are available.

software to be done )

## Option to maintain more than one address for

supplier required with effective date.

Supplier addresses effective date validation to be

done while processing.

Supplier-Item / Item-Supplier Database. Up-to-date Supplier wise purchased items & its

## details and item wise supplier details with their

recent supplied details are readily available on line.

Purchase Indent Purchase Indent to be raised through the system

by the department. The indent follow up will be

done through the system.

Indent approval required before raising Purchase

Order - Mills require 2 Levels of approval. First

level by HOD / FM and second level by GM.

Order approval before Order printing is required.

PO enquiry PO Enquiry would be sent from the system, for the

items in the indent register. Suppliers list will be

prompted and the user can select the suppliers to

whom the enquiry can be sent.

Quotation entry and comparison being Quotation(s) from the multiple suppliers will be

done in one format. compared in the comparative quotation statement

(maximum of 5) is available. Apart from comparing

the present quotation, provision is there to compare

the price from previous supplies (price comparison

statement).

PO types are Cash and Credit purchases. Cash, Credit and Capital purchase options are

available.

Provision to raise PO directly from approved indent

skipping enquiry and quotation for regular items.

Receipt without PO option is available - To be

Blocked.

PO Amendment / Cancellation PO amendments are allowed through authorized

persons on selective criteria, like delivery schedule,

quantity, rate, specification etc. Items cannot be

changed.

PO cancellations are done through authorized

persons. Provision to close orders that are partly

supplied is available.

Kalpatharu Software Limited Page 3 of 21

Gap Study

Mill System Kalsote ERP System

Purchase Budget provision done manually Department wise and Item Group wise budget

provisions are available.

PO Reports Quotation comparison, Budget utilization are some

of the specific reports other than the regular reports

like pending PO, PO Register supplier / Item / Cost

Centre wise, Pending Indent status etc.

PO Reminder Multi options of PO Reminder done automatically

ie. Supplier wise / Aging wise.

Indent Status Automatic updation of indent status after every

transactions, i.e an indent will pass through the

status of Enquiry / quotation / order / Received /

inspected / Stock.

Vendor Rating Vendor rating done more accurately based on

rating criteria.

Supplier Assessment (ISO purpose) ISO Requirement of supplier assessment is done

through the system.

Bill entry done by accounts Bill entry will be done in stores only. As requested,

bill approval will be done by accounts.

Mills to insist with suppliers on receiving

the Bills along with the DC / delivery so as

to close the PO then & there.

Materials received as Sample, on Sample handling provision without PO is available

verification sometimes accepted by raising in the system.

necessary PO if mills need them. This provision will be modified and mapped

Otherwise rejected sample is sent back. according to the mills requirement. Required

modification to the existing process will be done

during implementation.

Annexure for PO Printing required with Will be customised as per mills requirement.

comparison details.

Advance payment Supplier advance payments are linked to Financial

Accounting and it is referred against Bill Payments.

NOTE:

## - Templates for respective modules will be sent before commencement of implementation.

Mills need to collect necessary data and keep it ready to enable faster user training and

implementation.

Kalpatharu Software Limited Page 4 of 21

Gap Study

1.2 STORES INVENTORY

Mill System Kalsote ERP System

Every item is identified by its code / name Following additional features are available in the

( Data migration / export from the existing Item Master:

software to be done ) • Visual Image of the item

## • Goods Receipt Tolerance for every item – eg.

Packing materials / paper cones / nuts and

bolts we can fix some tolerance. If 2% is the

tolerance and the ordered qty is 100 Nos. it will

accept up to 102 without the requirement of

approval.

• Self – Indent. Eg. For less value items, stores

indent process need not be followed. The store

keeper himself can give the items without

approved indents.

• Auto alert message for indenting when the

stock reaches Re-Order Level.

• Category Classification – Capital Items, Repairs

& Maintenance, Spares, Consumables, Civil

etc. with linking to Budgets and Accounts.

GRN Preparation Goods Receipt Note (GRN) at Stores will be

prepared against the Gate Inward entry only.

When party is selected, system will list all pending

POs against this party. Provision available to

prepare single GRN against multiple POs.

Provision also available to prepare GRN without

PO also. However provision available to restrict

this facility.

GRN Inspection intimation is manual Automatic alert message is given to the indenter for

inspection, once the material is received and GRN

is prepared.

Purchase Rejections Rejected Materials in Inspection would be sent

back to supplier through Returnable Gate Pass

(RGP) or Non-Returnable Gate Pass (NRGP)

prepared automatically by the software along with

Gate pass slip. The exact time of outward will be

entered against the gate pass at the Gate. This

improves operational efficiency.

System has the provision to segregate reason wise

rejections. For eg. 25 cones are rejected. Out of

25, 10 may be dimension not ok, 5 color not ok, 10

cone weight not ok as per sample. Segregation of

rejections will be helpful for effective Vendor

Analysis.

Kalpatharu Software Limited Page 5 of 21

Gap Study

Mill System Kalsote ERP System

Material Issue request & approval. • Pro active approach for Material Issue -

Requisition is made on-line by the user.

Stock updation is based on reactive • Then Requisition approval on-line by HOD /

approach. FM. This can be made optional.

• Approved Requisition goes to store-keeper for

Issue of Materials.

• While issuing the material issue to the end-

user, Issue slip to be printed and store-keeper

to get the signature from the user on the slip.

Signed Issue slip is maintained as a record for

the transaction.

Stock Adjustments Receipt Adjustment - in the case of variance

between book stock and physical stock, excess

material received against 0% tolerance, Free

spares / sample items are accounted.

Similarly Issue Adjustment – in the case of variance

between book stock and physical stock, excess

material issued to floor or more consumption than

the estimated qty.

Inter unit transfers are done manually. By Having a Wide Area Network (WAN), System

has the provision for inter unit transfer of items

either RGP / NRGP method. Re-entry of data at

another unit is avoided.

Bill passing is done manually Bills entry / passing and approval against GRN are

automatic. When the party bill details are entered,

if there is any difference between the PO value and

the Bill value, automatic Debit / Credit Note

generation is possible and FA posting done

automatically.

Sub store concept Sub-store concept is followed in the system. Items

issued are transferred to sub-stores like

Maintenance, Electrical and Packing etc. Then on

actual consumption, based on maintenance Job

Card/ Packed Production, the item is considered as

consumed.

Gate Pass Process ERP provides various types of Gate pass system

like Returnable / Non-Returnable for Stores items

as well for Job order items. RGP reminders are

generated automatically. For eg. A material sent

out for service and the same has to come back in

15 days. If material not received within 15 days

from the date of RGP, system generates reminder.

Kalpatharu Software Limited Page 6 of 21

Gap Study

Mill System Kalsote ERP System

Job Order Maintenance Job order sent outside is tracked by preparing the

Returnable Gate Pass (RGP).

Work Order Concept Worked order concept - for all repair works inside

the mill premises are maintained.

Per spindle consumption is monitored System helps to compare with industry norms.

manually

VAT accounting CENVAT and State VAT are handled through

system with the required reports.

Freight Accounting Provision to do the Freight accounting along with

the bill and or separately.

Bin Numbering System Provision available in ERP to have specific bin

number for individual items.

Stock Valuation Stock valuation is done in First In First Out (FIFO)

Mills are following the weighted average method for better accuracy.

method - agreed to switch over to FIFO

Method.

Reports: Multilevel consumptions reports like item /

Analytical reports department / machine / cost center wise.

System provides ABC Analysis (Consumption),

XYZ Analysis (Stock value), FSN movement

reports.

Various exceptional reports like, Excess stock, Age

wise stock, EOQ analysis done effectively.

1.3 RAW MATERIAL INVENTORY - SPINNING

Mill System Kalsote ERP System

Mills are currently using 100% Cotton as System has the provision to handle any materials

raw material. like Cotton, Synthetic & Melange. Both Local and

Import purchases of raw material covered.

Contract and Order Confirmation Contract / Order Confirmation processing is

Individual lot of 100 bales considered as a available.

separate Contract.

Order Confirmation Report (OCR) is

issued for each lot.

Lot Arrival – Individual bale weighing Sample and Purchase automatically from weighing

procedure is not in practice. Average bale machine and prepares bale wise weight report. If

weight on arrival is taken into account. the individual bales are not weighed, average

Kalpatharu Software Limited Page 7 of 21

Gap Study

Mill System Kalsote ERP System

weight is distributed to all the bales. Material

accounting based on FOR / Spot Basis.

Lot Approval System provides for sample receipt, testing of lot

samples, quality details of lot arrivals. After

inspection, system compares sample test values

with the actual received material, and gives

deviation report. Provision to interface with HVI

testing and AFIS machine is available.

Issue to Mixing Mixing wise / Mix Number wise issues are

accounted. Provision to issue bales from multiple

lots of same variety also available.

Multiple Godown Stock Maintenance System will maintain multiple godown stock and

when the stock is moved from one godown to

another. Stock valuation is on landing cost basis.

Weight Difference accounting System generates a report on bale wise weight

difference recorded during receipt and issue.

Waste stock accounting Stock of different wastes produced is handled

separately and sale of different waste is also

accounted in the system. Sales details are

automatically transferred to Finance module.

Bill entry and payment is manual Bills entry / passing and approval against Lot

receipt is automatic. When the party bill details are

entered, if there is any difference between the

contract value and the Bill value, automatic Debit /

Credit Note generation is possible and FA posting

done automatically. Similarly for any allowances /

Premium also Debit / credit note are generated.

The new value after debit / credit note value is

added to mill lot value for costing purpose.

Reports: Other than the regular reports, following important

Reports are manually prepared. reports generated through this module are:

♦ Lot wise / variety wise stock

♦ Lot Reconciliation

♦ Supplier / Broker Assessment

♦ Mixing Cost

Kalpatharu Software Limited Page 8 of 21

Gap Study

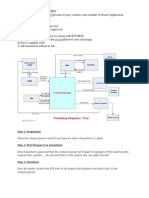

2.1 PRODUCTION - SPINNING

Mill System Kalsote ERP System

Scope of Spinning Division Scope covers from Blow Room to Packing.

Production Planning: Spin plan and balancing of machines are prepared

by the system depending on the product mix /

count change.

Mixing identification is with Mix number Unique mix number right from Blow room to

and Lot Number. winding for quality monitoring.

Transactions: Software has option of both automatic data transfer

Shift wise machine wise production, and manual feeding.

stoppage% and waste % are manually

entered and followed in stand alone Note – Automatic transfer from RIDA can be done,

software. provided the data are available in ASCII Form.

All Ring frames are linked with RING

DATA (RIDA).

Waste data maintenance System provides facility to enter the waste details

department wise, shift wise, type of waste like

salable / usable.

Process stock: Process stock is arrived at end of every day and

Process stock is manually arrived by 1st can be physically compared and verified.

of every month.

Contamination Monitoring

Contaminations collections & Rejections To be developed according to Mills Requirement.

are followed Manually. Mills to provide detailed requirement and freeze the

requirement at the earliest.

Reporting: Shift wise production status is monitored at the end

Shift wise production status is reported at of every shift for better control, in the case of

the end of 3 shifts, on the following day. manual data entry. If on-line data capture facility is

made available, the software will produce on-line

production for effective production monitoring.

Shift wise stoppage details and reason wise

analysis are maintained for analysis.

Standard reporting is made available Exhaustive production reporting is made available

for analytical purpose. For eg. Make wise

production, supervisor performance, workers

performance, Comparison of multiple frames mix

wise performance etc.

Yarn conditioning Yarn conditioning details are maintained in the

system.

Kalpatharu Software Limited Page 9 of 21

Gap Study

Mill System Kalsote ERP System

Production comparison with mill own Provision available to compare actual production

standards and SITRA norms followed. with Mill Standards and SITRA norms.

Packing Production: Electronic weighing scale interface can also be

Are entered manually and stock reports provided to monitor actual pack weight and also to

are maintained. arrive at exact kgs of production so that more

accurate yarn realization can be arrived at.

Quality Control: ERP will provide interfaces with Quality control

Study details are gathered and reports are equipments which has computer connectivity for

prepared manually. online monitoring of quality data at the user

terminals. This would save hard copy printout and

reporting to Managerial staff through Quality

Control staff.

Quality Checking schedule also prepared System generated schedule will have a close

manually. monitor on Machines.

Linking with UT5, mills to organize for data

downloading to PC from the UT5 vendor. This is

applicable for all equipments in the testing lab.

Customer Complaints tracking. System will track the Lot number from the Invoice

details given in the customer complaint. Lot

tracking is to identify the nature of complaint given

by the customer and verify with the test results.

Limited QC study details / reports are Exhaustive study provision and reporting are

practiced available. Studies include the best practices

followed across the industry vertical.

QC Reporting: Report views and graphical representation for

Hard copy printouts and displays better analysis control. Any Schedule deviations

are also highlighted.

Conformance Status available in ERP based on the

predefined Norms and Tolerances.

Integration with Maintenance Automated interaction with Maintenance schedule

schedules. is available.

Manual interaction with Maintenance

schedules followed.

Production Incentive: Production incentive calculated on different

Employee wise incentives are calculated categories of employees in each department and

manually. linked to payroll software automatically. This gives

lot of accuracy and time saving during OT

calculation, weekly payments, incentive payments

and monthly payroll processing.

Kalpatharu Software Limited Page 10 of 21

Gap Study

Mill System Kalsote ERP System

Monthly MIS reports are prepared by the Production MIS reports is available on date and on

department during 1st week of every the 1st day of every month without any manual data

month. adjustment. Production data cannot be altered for

designed results. The software will report 100 %

actual information.

Customer complaint and follow up actions. Quality complaints and follow up actions are

monitored on-line and the reports are as per ISO

requirement. Complete ISO requirement

maintained through the software.

QC Study actions: Software has provision to capture predictive

Based on QC study results machine maintenance activities to be carried out for any

setting changes are instructed manually deviations in quality standards. Alert messages on

and carried out. quality deviations are provided immediately to

control the quality.

3.1 MACHINERY MAINTENANCE

Mill System Kalsote ERP System

Scope All productive machineries in the plant for which

maintenance are done in Preventive, Break Down

and Predictive methods - based on worked days /

production kgs or fixed time period.

Machinery and Maintenance Details are System gives detailed predefined maintenance

maintained in stand alone software activities and its frequency decided by the mills.

##

Daily Schedule is followed. System generates machine wise preventive

Frequency based on “number of days” maintenance schedule with the items required for

only followed in Mechanical maintenance the maintenance activity.

Mills to work out the previous throughput Schedule frequency based on production tonnage

data for those items tonnage option is also possible for required schedules like card wire

recommended – e.g Card Wire. change.

##

Job Card Maintenance Daily Job Entry and completion are captured In the

job completion the items actually consumed will be

deducted from the sub-store and taken into account

for consumption reports.

Breakdown calls System allows entering the Break down request

and alert message is given to Maintenance

department for necessary action. Once the break

down completion is entered the items replaced for

the Break Down also captured. This will give the

actual Break down consumption value.

Kalpatharu Software Limited Page 11 of 21

Gap Study

Mill System Kalsote ERP System

Third party AMC details System allows entering all the third party AMC

## details and their service bill details when the call is

attended.

Machine history System provides complete machine history details

## with all the calls attended and spares replaced.

Maintains Preventive / Breakdown / Predictive

activities list under each machine with the remarks

on each job.

Predictive Maintenance System allows for Predictive Maintenance based

on quality study observations.

Reports: • MTBF / MTTR – Mean Time Between

Failure / Mean Time To Repair.

• Per spindle Maintenance cost

• Budget vs Actual are some of the important

reports generated through the system

3.2 ELECTRICAL MAINTENANCE

Mill System Kalsote ERP System

Scope Scope includes for motors, compressors,

Generators and other panels and electronic

equipments. The schedules are done based on

running hours and in days

Preventive Maintenance: System generates Equipment wise preventive

## maintenance schedule with the items required for

the maintenance activity.

Job Card Entry Daily Job Entry and completion are captured. In

the job completion the items actually consumed will

be deducted from the sub-store and taken into

account for consumption reports.

Breakdown Calls: System allows entering the Break down request

## and alert message is given to Maintenance

department for necessary action. Once the break

down completion is entered Machine History details

are updated.

Third party AMC details: System allows entering all the third party AMC

## details and their service bill details when the call is

attended.

Kalpatharu Software Limited Page 12 of 21

Gap Study

Mill System Kalsote ERP System

Machine history System provides detailed equipment history with

## the calls attended and spares replaced.

Predictive Maintenance: System allows for Predictive Maintenance based

on quality study observations.

Reports: • MTBF / MTTR – Mean Time Between

Failure / Mean Time To Repair.

• Per spindle cost

• Budget vs Actual are some of the important

reports generated through the system

3.3 POWER Module:

Mill System Kalsote ERP System

At present the data from the energy System has the provision for on-line data capture

meters were collected manually. from energy meters

Power Consumptions System generated EB bill similar to the original bill

submitted by EB Dept. System also generates EB

estimation from the actual units consumed.

Scope of Transactions This Power Audit Module will cover the Power

## Consumption, Generator Set Reading, H.T.Meter

Reading, Water Consumption, and Vehicle Diesel

Consumption.

FA Posting: The above information is automatically transferred

to Finance for P&L purpose as provisional entry.

Wind Mill Monitoring of the Wind power data through the

system to be developed after detailed study of the

accounting procedure of wind power generation.

Reports: Few important reports generated through this

module are:

♦ Power Consumption

♦ UKG report

♦ H.T.Meter Reading

♦ Water Consumption

♦ Diesel Consumption

♦ EB Bill Estimation

♦ Diesel Stock statement

Kalpatharu Software Limited Page 13 of 21

Gap Study

4.1 Marketing : Yarn :

Mill System Kalsote ERP System

Marketing Activity:: Software has a separate marketing module for

enquiry handing, Proforma invoice and follow up till

the contract is made. Lot of information can be

provided from this module to the management for

strategic planning.

Scope System gives a full flow of marketing activities of

## Yarn.

Enquiries are registered

Technical feasibility is done.

If sample is required, sample request is generated

and given to production to produce the same as per

the technical specification.

Quotation is sent along with / without samples

Once the quotation is accepted, sales order /

contract is generated.

If we receive any customer complaints against this

sale, the sample yarn details / technical feasibility is

automatically linked to the customer complaint.

Various Reports are generated like enquiry

generated in a month, Region wise / Broker wise,

Enquiry vs Sales Order ratio etc.

EXIM transactions are carried out Exports related transactions and documentation

manually. are available separately under Exports sub-module

of Sales. A view on the same to be provided under

marketing.

Import related transactions and documentation to

be developed as per mills requirement.

4.2 SALES - Yarn :

Mill System Kalsote ERP System

Sales activities System provides facility for Yarn, Waste & Scrap

## Invoicing.

Sales Status Specific customer order, production status is made

available online for meeting effective deliveries.

Excise documents System provides all excise related and VAT related

registers like RG1, ER-1, MO3 (Hank Yarn

Obligation) reports. The State VAT Returns are

Kalpatharu Software Limited Page 14 of 21

Gap Study

Mill System Kalsote ERP System

generated as per the new act. This facilitates the

mill to switch over to State VAT system easily.

The ITC taken into account from various purchases

and tax due by Sales accounts are reconciled.

Accounts Receivable is maintained in In the ERP environment accounts receivable is

sales and in accounts. There is a maintained based on sales and collection details at

duplication of work. one location which could be viewed by sales and

accounts department. There is no need for

maintaining it in two departments and doing the

reconciliation.

Reports Exhaustive reports are made available like pending

contracts, product ranking, customer ranking, auto

reminders to parties etc.

Formal procedure in handing contract This facility is handled very effectively through the

amendment and cancellation is needed. software.

Stock Valuation is done based on market Finished goods stock could be valued by COGM

rate or last contract / dispatch rate (Cost of Goods Manufactured) through effective

costing for accurate P&L.

Movement of stock is monitored manually. Stock aging by bag number wise is arrived at for

controlling the stock and reporting the stock value

age wise.

Scrap sales Scrap sales also part of sales and Distribution

module.

Scope includes local and waste sales. Scope includes Local, (Direct / Depot /

Consignment and Merchant export), waste and

scrap sales.

Data from depot and consignment are In ERP Depot and consignment sales can be

gathered manually over a period of time collected through mail on a daily basis and effective

dispatch and stock details by individual depot and

consignment agents are monitored.

Invoice serial number ERP is having separate serial number for different

category of sales, As per mills requirement suitable

modification to be done during implementation.

Reports Pending Contract Registers, Pending LC, Agent

wise / count wise / Country wise sales are

generated through the system.

Kalpatharu Software Limited Page 15 of 21

Gap Study

Mill System Kalsote ERP System

Stock ageing for bags - Manually Available in the system.

maintained

Sales return Sales return transaction will be carried out in Sales

Module and the necessary credit posting will be

Credit notes are raised in accounts only. automatically done. Credit note to be raised in FA

system in reference with corresponding sales

return / credit posting.

Waste sales Provision to track by Kilograms, No of bag / borah

is available.

Allotment system in waste sales is being

followed. Will be customised according to mills requirement.

For export sales – documentation is Following export documentation is done through

prepared manually. ERP software.

• Quotation/Proforma Invoice

Provision to adjust the value of export on • Contract/Sales Order

negotiating the LC on submission of • Letter of Credit

shipping documents • Pre shipment Invoice

• Packing List

• Shipping Instructions

• Post Shipment Invoice/Packing List

• Shipping Details

• Insurance Details

• Quality Claims

• Debit/Credit Notes

Any additional requirements to be developed during

implementation. Provision for adjustment on LC

Negotiation to be made available.

5.1 HUMAN RESOURCE MODULE:

Mill System Kalsote ERP System

Bio Data collected and maintained System allows you to enter the Bio-Data and

manually database is maintained. This will facilitate to

## search for experience wise / job post wise, and

send interview letter automatically.

Training details are maintained manually System provides a comprehensive Training module

where we can maintain Training Schedule, list of

participants, feed back from the participants / Head

of Department after the training is attended. This

will facilitate whether some more training is

required for the employee or improve the quality of

the training etc.

Kalpatharu Software Limited Page 16 of 21

Gap Study

Mill System Kalsote ERP System

Awards and Fine systems are manual System maintains the details of awards given to an

employee whether it is single award or group

award, reason for the award.

Promotions and Increments are System maintains the periodical promotions /

maintained manually. increments given to the employee so that we can

view the entire history of the employee from his

Date of Joining till date.

Family – Dependent details System facilitates to maintain the employee’s

dependent details, their relationship and nominee

for PF / Gratuity ESI.

Experience and Educational Qualification System has the provision to update the educational

qualification / other external training attended by

the employee, previous experience details

company wise.

5.2 PAYROLL:

Mill System Kalsote ERP System

Scope of the Module Scope includes Attendance, over-time, incentive

and complete payroll accounting records for all

individual Divisions.

Staff and worker attendance is maintained We suggest using any Attendance Recording

Partially in software. System which could be linked to our payroll. This

## will automate all the attendance activities.

Shift change for all categories System handles any shift rotation – clock wise / anti

clock wise – on a particular day or every 7th day.

Leave details System provides complete Leave register with

various types of Leaves like LWW / LOP / CL / PL

etc and generates Form15 leave card yearly.

Payroll System handles various types of worker categories

for payroll. System provides a versatile payroll

system to suite most of the textile mills.

Statutory Reports Statutory reports like Form3A, Form6, 6A, Form15,

ESI Form 6, Form 7 are generated through system.

Yearly Benefits Bonus, Gratuity, Scheme Settlement are taken care

in the system.

Visitors’ entries are manually maintained. System handles complete movements of Men /

Vehicles / Materials and provides various analysis.

Kalpatharu Software Limited Page 17 of 21

Gap Study

Mill System Kalsote ERP System

4 types of Salary statement are being

followed

1. Earnings statement

2. Net Salary inclusive of all Additional reports will be developed.

deductions, OT, Incentive and

Deductions statement

3. Incentive statement

4. OT Statement

The following systems / activities has

been identified.

1. Van – Route link for employees Suitable modifications will be done.

2. GM advance

3. Attendance modification for

previous days within a month

4. Canteen Token

5. Guest House expense

6. Medicare

Staff advance at present is not linked to System handles employee wise advance given / re-

FA and HR department handles the same. payment details in Accounts when the payroll is

processed and authorized.

6.1 FINANCIAL ACCOUNTING:

Mill System Kalsote ERP System

Accounting is done in a stand alone ERP has a versatile Accounting package linked to

software. all its modules wherever it is necessary and avoids

manual entry. Only cash and bank vouchers and

## journal entries are to be done. The system is very

proactive in the following areas:

• Document generation (Voucher printing /

cheque printing / covering letter) Receipt

Printing / Dr/ Cr Printing

• Provisional entry

• Automatic Closing stock

• Online P&L and Balance Sheet (BS)

• Expenses Analysis – cost center wise

• Ratio analysis

• Budget monitoring.

P&L and BS generated for all Divisions and

consolidated statements generated for the

company. For unit level, only operational details

comparison statements can be generated – P&L

and BS cannot be generated at the unit level.

Kalpatharu Software Limited Page 18 of 21

Gap Study

Mill System Kalsote ERP System

Accounts Receivables AR is comprehensive in the following areas and

automatic from Sales module:

• Customer wise / Invoice Wise / Broker wise

• Payment reminder printing

• Over due Interest calculation

• Ageing analysis

• Customer ranking

• Confirmation of Balances at the financial year

end.

AR view to be made available to both Sales and

Finance departments.

Accounts Payable: Accounts payable has the following features;

• Party wise / Bill wise

Manually age wise / party wise payable • Ageing analysis

statement is sent for Director’s approval. • TDS / TCS Deduction and Form 16 Printing

Voucher / Payments are prepared as per • Option of accounting account wise and specific

Director’s instructions. bill wise

• Form XVII / C Form Issue and Annexure

printing.

• Form 8 / 10 for C Form Register

Party wise / Age wise payables to be made

available on-line for Director’s approval to effect

payment on approval.

Fixed Assets and Depreciation are System has the following provision in FAD module:

manually maintained. • Asset Register

• Depreciation Method – Company Rate / IT Rate

• Asset valuation – SLM / WDV

• Depreciation projection

• Profit / Loss on sale of asset

• Queries on asset value.

Financial Control statements Other Salient features are:

• FBT

• Cash Flow

• Funds Flow

• Ratio analysis

Bank Reconciliation is done manually System has the provision for automatic BRS with

the soft copy of the statement received from

bankers or downloaded directly by mills.

Consignment / depot invoices Updates from depots to be obtained more

frequently (daily basis is suggested and ideal for

ERP environment) in order to have the Accounting

more accurate. Also all transactions of a month, to

Kalpatharu Software Limited Page 19 of 21

Gap Study

Mill System Kalsote ERP System

be completed within the respective month.

Cheques on hand (Pre-signed) are Provision to be made available for handling this.

handled.

Service Tax being collected and Returns Necessary provision for the service tax to be made

filled manually. available for those items considered for service tax

by mills.

EPCG Licences, Terminal Excise Duty on Provision to be made available in the system to

capital goods and Duty Draw Back details update relevant details automatically and track

are tracked manually. them effectively.

Quarters Power Bill: Basic units paid by Provision to be made in Payroll.

mills and excess units borne by staff.

Insurance Policies for Employees, To be developed as per mills requirement.

Vehicles and Electrical Instruments and its

claims tracking is done manually.

Only Main cash book is currently being Multiple cashbooks can be maintained in the

practised. system.

6.2 COSTING :

Mill System Kalsote ERP System

Scope • To have a closer costing figure of count

wise/sort wise per kg. cost

• System collects all the required data from

various modules to arrive the costing factors.

• Different cost profiles are maintained for all

manufactured counts/sorts.

• Various reports for conversion cost on

estimation and actual.

• Contribution Report based on Ex-Mill Rate /

Net Rate / Profit per Kg.

Reports and Variance analysis manually System has the provision for automated

comparison of estimated and actual P&L

statements based on costing estimates. Revised

costing estimates are arrived and used for next

estimation. So variance gap would be made

minimum/nil over few iteration.

On-line query for Decision making System has the provision for on-line query of

costing estimates for yarn, comparison of

contribution statements on-line.

Kalpatharu Software Limited Page 20 of 21

Gap Study

7.0 MIS MODULE:

Mill System Kalsote ERP System

Scope of the Module To provide On-line MIS information to

Management.

This module reports are customized as per Mill

MIS Reports formats in practice. Various MIS reports

specimen are available and mills to select

reports required for them as per Mill

Management’s requirement.

ERP has a versatile MIS Reporting. There is no

need to enter any details manually. All the

modules are inter-linked and required details are

consolidated automatically.

Following few reports are generated in the MIS

Module :

• Daily Management Information Report

- a one page summary of mill activities.

• Management Information Details on

Production – complete production, efficiency,

utilization abstracts.

• Department wise Performance Details

• Finished Goods Stock(Yarn & Cloth) Abstract

• Raw Material Stock for Spg. & Wvg.

• Attendance abstract:: Shift / Day wise

• Financial Status Report

• Over all Mill Performance

Kalpatharu Software Limited Page 21 of 21

You might also like

- Costing For A Spinning MillDocument14 pagesCosting For A Spinning MillSakthivel JegarajanNo ratings yet

- X Bar and R ChartDocument12 pagesX Bar and R ChartSENTHIL KUMARNo ratings yet

- Rubber Cots ComparisionDocument5 pagesRubber Cots Comparisionhassan SardarNo ratings yet

- Seminar 3Document40 pagesSeminar 3Solomon Solostar JacobNo ratings yet

- Production Parameters for Viscose DepartmentDocument5 pagesProduction Parameters for Viscose DepartmentPra93No ratings yet

- Fabric Processing and Garments Testing SolutionsDocument16 pagesFabric Processing and Garments Testing SolutionsVarsha SinghNo ratings yet

- Cost Sheet STDDocument1 pageCost Sheet STDSabbir Hossain ImranNo ratings yet

- Talha Spinning Mills Limited Mulaid, Sreepur, Gazipur.: Carding DrawingDocument1 pageTalha Spinning Mills Limited Mulaid, Sreepur, Gazipur.: Carding DrawingShoreless ShaikatNo ratings yet

- Conventional and Modern ProcessDocument16 pagesConventional and Modern ProcessAshiqueNo ratings yet

- Knit Fabric Production ParametersDocument10 pagesKnit Fabric Production Parameterssuvrodev812No ratings yet

- Wet Processing 1Document47 pagesWet Processing 1Rahul ThomasNo ratings yet

- Determination of Loop Length, Tightness Factor and Porosity of Single Jersey Knitted FabricDocument6 pagesDetermination of Loop Length, Tightness Factor and Porosity of Single Jersey Knitted FabrictanveerhusseinNo ratings yet

- Uster Yarn Standard Table For Knitting Yarn: Coun T (N E) Y Arn Char Ctris TicsDocument1 pageUster Yarn Standard Table For Knitting Yarn: Coun T (N E) Y Arn Char Ctris Ticslalit kashyap0% (1)

- Sky Textile rejection analysis reportDocument2 pagesSky Textile rejection analysis reportsky textiles300No ratings yet

- 9 After Print Washing Printing Training 1&2Document55 pages9 After Print Washing Printing Training 1&2yadi haryadiNo ratings yet

- Spin Plan 3Document209 pagesSpin Plan 3Harsimran SinghNo ratings yet

- Barre Causes and PreventionDocument19 pagesBarre Causes and PreventionReal SheriffNo ratings yet

- Finishing MachinariesDocument46 pagesFinishing MachinariesBodiuzzaman BodiNo ratings yet

- Calculation of Package Density in Yarn Dyeing - Textile CalculationDocument3 pagesCalculation of Package Density in Yarn Dyeing - Textile CalculationHodNo ratings yet

- Cotton Grading ChartDocument4 pagesCotton Grading Charthassan Sardar100% (1)

- Machine Load CalculationDocument3 pagesMachine Load Calculationস্মৃতিরছেড়াপাতাNo ratings yet

- Lot Wise Yarn RealizationDocument12 pagesLot Wise Yarn RealizationArif ApuNo ratings yet

- The Heart of Spinning: Understanding the Key Operating Principles and Tasks of Carding MachinesDocument101 pagesThe Heart of Spinning: Understanding the Key Operating Principles and Tasks of Carding MachinesUmår F ÃfriDiNo ratings yet

- Sample Report 34th CPQ StudyDocument21 pagesSample Report 34th CPQ StudySundaram Climate Institute Office100% (2)

- Assignment ON: Eco-Textiles Chemical Processing of Textile MaterialsDocument10 pagesAssignment ON: Eco-Textiles Chemical Processing of Textile Materialsila03No ratings yet

- Publications: Fibre & YarnDocument14 pagesPublications: Fibre & YarnvigneshbalajirsNo ratings yet

- Lenzing Tencel - Courtesy: LenzingDocument38 pagesLenzing Tencel - Courtesy: LenzingSENTHIL KUMARNo ratings yet

- SO # - 000 GM Hosiery - 09.12.2022Document3 pagesSO # - 000 GM Hosiery - 09.12.2022sky textiles300No ratings yet

- Costing of FabricDocument2 pagesCosting of Fabricahsen_hasanNo ratings yet

- Cost Analysis: Quality Comes First, Rest Are ConsequencesDocument5 pagesCost Analysis: Quality Comes First, Rest Are ConsequencesAl AminNo ratings yet

- ExelDocument9 pagesExelThu NguyễnNo ratings yet

- Study On Reduction of Air Consumption On Air-Jet Weaving MachinesDocument11 pagesStudy On Reduction of Air Consumption On Air-Jet Weaving MachinesNatraj kanaharajNo ratings yet

- Objective of SizingDocument2 pagesObjective of Sizingnow4jadu100% (1)

- Dyeing and Printing DefectsDocument25 pagesDyeing and Printing DefectsMustafa Cuneyt GezenNo ratings yet

- Modern Developments in WeavingDocument13 pagesModern Developments in WeavingRakeahkumarDabkeyaNo ratings yet

- Sky Textiles ETP RO MEE Cost ReportDocument1 pageSky Textiles ETP RO MEE Cost Reportsky textiles300No ratings yet

- Final Mill Tariniggng ReportDocument53 pagesFinal Mill Tariniggng ReportPriyanka VishnoiNo ratings yet

- Spin Plan - Synthetic YarnDocument1 pageSpin Plan - Synthetic Yarnardhendu1No ratings yet

- Practice of Cotton Fibre Selection For Optimum MixingDocument7 pagesPractice of Cotton Fibre Selection For Optimum Mixingviswa5263100% (3)

- Industrial Attachment of Shohagpur Textile Mills Ltd.Document88 pagesIndustrial Attachment of Shohagpur Textile Mills Ltd.Anonymous ZH6tcBQNo ratings yet

- WFT BRK CNTRLDocument17 pagesWFT BRK CNTRLसोमदत्त शर्म्माNo ratings yet

- Costing Sheet Retail Price Calculation SheetDocument2 pagesCosting Sheet Retail Price Calculation SheetitskashifNo ratings yet

- POY TroubleshooterDocument2 pagesPOY TroubleshooterKağan Ayşe AyanNo ratings yet

- Denim Washing DetailDocument108 pagesDenim Washing DetailMudassar AliNo ratings yet

- Management Information System Project: Sri Karpagam Spinning Mills LTDDocument5 pagesManagement Information System Project: Sri Karpagam Spinning Mills LTDPradeep DurairajNo ratings yet

- Cost-Effective Touch Screen Controller for Automated Dyeing MachinesDocument2 pagesCost-Effective Touch Screen Controller for Automated Dyeing Machinesanon_612425549100% (1)

- SMEDA Fabric Dyeing & Finishing Unit (Knit Fabric)Document27 pagesSMEDA Fabric Dyeing & Finishing Unit (Knit Fabric)Nisar AhmadNo ratings yet

- Uster: Measuring PrinciplesDocument48 pagesUster: Measuring Principlesnminhtuan88No ratings yet

- Garden Silk Mills Ltd.: India's Leading Polyester Yarn ManufacturerDocument19 pagesGarden Silk Mills Ltd.: India's Leading Polyester Yarn ManufacturerParitosh VermaNo ratings yet

- Cost Sheet - SkyDocument8 pagesCost Sheet - Skysky textiles300No ratings yet

- P04734 PDFDocument120 pagesP04734 PDFOdd BoyNo ratings yet

- Industrialattachmentofnazbangladeshltd 140515042508 Phpapp02Document198 pagesIndustrialattachmentofnazbangladeshltd 140515042508 Phpapp02Ripon SayanNo ratings yet

- Automation in WeavingDocument7 pagesAutomation in Weavingsalsabila fuNo ratings yet

- Shahi Export (Final Report)Document72 pagesShahi Export (Final Report)Kartikey JangraNo ratings yet

- COTTON USA Global Fax Update - November 2010Document2 pagesCOTTON USA Global Fax Update - November 2010mlganesh666No ratings yet

- Circular Singeing MachineDocument4 pagesCircular Singeing Machineيحيى عياشNo ratings yet

- Process Flow of Dye HouseDocument47 pagesProcess Flow of Dye HouseAakashNo ratings yet

- Mr. R.R. Sharma M/s Baerlocher India Additives Pvt. LTD, Dewas 455 001 Tel 098268 12407Document5 pagesMr. R.R. Sharma M/s Baerlocher India Additives Pvt. LTD, Dewas 455 001 Tel 098268 12407aditya_khandelwalNo ratings yet

- ACCNU Advanced Cloud Solution QuotationDocument6 pagesACCNU Advanced Cloud Solution QuotationEmphorasoft gmailNo ratings yet

- Accnu Advanced Cloud Solution - Aquatech EngineersDocument6 pagesAccnu Advanced Cloud Solution - Aquatech EngineersEmphorasoft gmailNo ratings yet

- E Commerce Part2Document4 pagesE Commerce Part2Mark John PeñaNo ratings yet

- Drill Down Documentation Jul2019Document89 pagesDrill Down Documentation Jul2019mbajeesh007No ratings yet

- NotesDocument17 pagesNotesAnonymous WJR06O3OTpNo ratings yet

- Nir Code, 1997Document64 pagesNir Code, 1997benzylicNo ratings yet

- Accounting System-Special Journals Accounting System - Special JournalsDocument27 pagesAccounting System-Special Journals Accounting System - Special JournalsShane Jesuitas100% (1)

- Assessment Cover Sheet: Sitxinv001 - QuizDocument35 pagesAssessment Cover Sheet: Sitxinv001 - QuizAmis2018 Amis2018No ratings yet

- View Bitcoin transaction detailsDocument1 pageView Bitcoin transaction detailsJean BlockchainNo ratings yet

- Amkpp1500c 2018Document4 pagesAmkpp1500c 2018chinna rajaNo ratings yet

- FBS M PinkyDocument75 pagesFBS M PinkyEmmerNo ratings yet

- Ed - PPP - COA Circular 2012 001Document148 pagesEd - PPP - COA Circular 2012 001Melissa Mae GumaposNo ratings yet

- Common Problems and Solutions - AutoApply of ReceiptsDocument7 pagesCommon Problems and Solutions - AutoApply of ReceiptsHimanshu GosainNo ratings yet

- Oracle Purchase Order CycleDocument21 pagesOracle Purchase Order Cyclepaletir6593No ratings yet

- Walmart Black Magic Buy One, Get One FREEDocument1 pageWalmart Black Magic Buy One, Get One FREESunita NairNo ratings yet

- Tax Invoice Cum Acknowledgement Receipt of PAN Application (Form 49A)Document1 pageTax Invoice Cum Acknowledgement Receipt of PAN Application (Form 49A)M Computer & TravelsNo ratings yet

- Detailed Comparison Between Various Version of TallyDocument34 pagesDetailed Comparison Between Various Version of TallyMahendra KushwahaNo ratings yet

- SBO - Solution - Brief - Jaffer Business Systems (EN)Document15 pagesSBO - Solution - Brief - Jaffer Business Systems (EN)zulfiqar26No ratings yet

- WeRadio Malta Erasmus Project InfoPack June 2022Document20 pagesWeRadio Malta Erasmus Project InfoPack June 2022Naughty HarborNo ratings yet

- Explanatory Notes For AEO-Self Assessment QuestionnaireDocument40 pagesExplanatory Notes For AEO-Self Assessment QuestionnaireGIRITHARANNo ratings yet

- BF Log MM Ci 2 Ehp3 enDocument3 pagesBF Log MM Ci 2 Ehp3 enEvandro Pontes PereiraNo ratings yet

- Subsidiary BooksDocument15 pagesSubsidiary BooksJohnPrajwalMendoncaNo ratings yet

- Exchange Companies Manual Updated 2019Document126 pagesExchange Companies Manual Updated 2019Syed Zahid ShahNo ratings yet

- Tenders Invited for Sale of Waste MaterialsDocument2 pagesTenders Invited for Sale of Waste MaterialsGohilakrishnan ThiagarajanNo ratings yet

- Inventory Costing ConsiderationsDocument37 pagesInventory Costing ConsiderationsresiddiquiNo ratings yet

- Sop Accounts and FinanceDocument6 pagesSop Accounts and FinanceShivam Gaur100% (1)

- Russian oil and fuel products from LukoilDocument5 pagesRussian oil and fuel products from LukoilLuis Enrique Romero100% (4)

- GeM Bidding 2910226Document4 pagesGeM Bidding 2910226Sulvine CharlieNo ratings yet

- Taxation: 4. Other Percentage TaxDocument6 pagesTaxation: 4. Other Percentage TaxMarkuNo ratings yet

- Vat Seatwork - NeDocument3 pagesVat Seatwork - NeMarvin San JuanNo ratings yet

- Item Master TemplateDocument6 pagesItem Master TemplatenrupenvarthyNo ratings yet

- Chapter23 Audit of Cash BalancesDocument37 pagesChapter23 Audit of Cash BalancesAnita NytaNo ratings yet