Professional Documents

Culture Documents

Strategiclayoutplanningandsimulationforleanmanufacturing 2

Uploaded by

beebunny0 ratings0% found this document useful (0 votes)

37 views5 pagesThis tutorial describes the LayOPT methodology and presents an overview of the software's features and capabilities. LayOPT is an improvement algorithm that starts with an existing block layout and attempts to improve it by exchanging the locations of defined departments. It generates solutions that are generally 50% to 80% more efficient than their starting points.

Original Description:

Original Title

strategiclayoutplanningandsimulationforleanmanufacturing_2

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis tutorial describes the LayOPT methodology and presents an overview of the software's features and capabilities. LayOPT is an improvement algorithm that starts with an existing block layout and attempts to improve it by exchanging the locations of defined departments. It generates solutions that are generally 50% to 80% more efficient than their starting points.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

37 views5 pagesStrategiclayoutplanningandsimulationforleanmanufacturing 2

Uploaded by

beebunnyThis tutorial describes the LayOPT methodology and presents an overview of the software's features and capabilities. LayOPT is an improvement algorithm that starts with an existing block layout and attempts to improve it by exchanging the locations of defined departments. It generates solutions that are generally 50% to 80% more efficient than their starting points.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

STRATEGIC LAYOUT PLANNING AND SIMULATION FOR LEAN MANUFACTURING

A LAYOPTTM TUTORIAL

Ramu Narayanaswamy

Production Modeling Corporation

3 Parklane Boulevard, Suite 910 West

Dearborn, Michigan 48126, U.S.A.

ABSTRACT results obtained from these algorithms may lead to

inferior solutions. LayOPT overcomes these limitations

LayOPT™ is an innovative facilities layout analysis and and generates solutions that are generally 50% to 80%

optimization software package which can be used by more efficient than their starting points.

layout planners and engineers in the optimal solution of LayOPT is a Windows-based software system with all

single and multiple floor facility layout problems. the amenities of a user-friendly interface, including pull-

LayOPT is ideal for the re-design of the overall layout down menus, toolbars, status bars, user-defined window

for an existing facility or the development of a block sizes, and an on-line help system. It comes with a User's

layout for a new building. It can be applied to Guide/Reference and a Training Manual.

manufacturing, warehouse, office, and various service

facility layout problems. This tutorial describes the 1.1 The LayOPT Algorithm

LayOPT methodology and presents an overview of the

software's features and capabilities. LayOPT is an improvement algorithm for developing

alternative and efficient block layouts from an initial

1 INTRODUCTION TO LAYOPT block layout provided by the user. The initial layout is

typically either the existing or a proposed layout. In the

The importance of space allocation in contributing to absence of an initial layout, one may also be randomly

productivity and efficiency has long been recognized in generated by the program. The seed algorithm used in

many contexts, such as factories, offices, and warehouses LayOPT is based on the algorithm developed by Bozer,

(Vollman, Nugent, and Zutler 1968). LayOPT is a Meller, and Erlebacher (1994).

facilities layout optimization software package which can LayOPT's algorithm is a steepest-descent, two-way

be used by layout planners and engineers to solve single exchange optimization routine (Winston 1994). In each

and multiple floor facility layout problems. It can be iteration, the algorithm picks the department pair whose

applied to manufacturing, warehouse, office, and various exchange leads to the largest reduction in the objective

service facility layout problems. LayOPT allows the function. It then automatically exchanges the pair to

layout planner to generate alternative layout plans proceed to the next iteration. The objective function

quickly and easily and to find the optimal layout among minimized by the LayOPT algorithm is the sum of the

these alternatives. parts flows multiplied by the appropriate costs and

LayOPT is an improvement algorithm that starts with expected distances between all department pairs with

an existing block layout, and given the flow and cost non-zero parts flow between them.

data, attempts to improve it by exchanging the locations

of defined departments. While several available 1.2 LayOPT Terminology

improvement algorithms perform basically the same

function, many are severely limited by the kinds of Before we describe the steps in creating and analyzing a

exchanges they could perform. Not uncommon among layout problem in LayOPT, a brief discussion of

them are constraints either on the layout itself or on the commonly used terms is presented below.

type of exchanges that could be considered (for instance,

only equal area or adjacent departments). Consequently, 1.2.1 Building and Grids

The building is the actual physical facility whose layout The space filling curve (SFC) is a device entered by the

is being determined. It may consist of a single floor or user and used by LayOPT to construct the layout. The

more than one floor, including partial floors (mezzanines SFC is a continuous line that visits all the assignable

or loft areas with limited vertical access). The building grids in a particular floor in the facility. To construct the

footprint defines the actual shape (rectangular or layout, a set of departments whose areas fit in the floor

irregular) of the building when viewed from the top. To defined by the SFC is sequenced along that curve. An

represent a non-rectangularly shaped building in SFC guarantees that no department is split because a

LayOPT, the smallest enclosing rectangle is drawn to separate curve is used for each floor and, within each

surround the building footprint. As in most computer- floor, the curve visits the neighbors of a grid before

based layout algorithms, layouts in LayOPT are visiting other grids.

represented as a matrix. Each element of the matrix Space filling curves can be drawn through virtually

corresponds to a grid square (or simply, grid) of any building with obstacles and fixed departments as

specified area. long as an obstacle or fixed department does not split the

building into two or more disjointed pieces.

1.2.2 Floors and Lifts

1.2.6 Flows and Weight Factors

A floor in LayOPT corresponds to a floor level in a

facility. It may either be an actual floor or a mezzanine. Flow represents parts, information, or people that are

Lifts are vertical material handling devices that allow for transported from one department to another. These may

the transport of materials and people from one floor to be in the forms of actual part pieces, pallets, boxes,

another in a multi-floor facility. These may include racks, bins, etc. The From-To chart is a table containing

elevators, vertical reciprocating conveyors (VRCs), flow values from one department to another in a form

gravity chutes, etc. similar to a mileage chart.

Weight factors represent either the actual unit costs

1.2.3 Departments associated with the individual flow values in the From-

To chart or simply relative weights. Relative weights (on

Departments are the smallest planning units that a user-defined scale) may represent such intangible

comprise a facility. A department may be an actual factors as difficulty of the material moves, environmental

process department, a product cell, a single machine, a and safety issues on various parts flows, or preferences

group of machines, or any part of the facility (offices, for specific material handling containers. LayOPT

cafeteria, rest rooms, shipping and receiving docks, etc.) minimizes either the layout cost expressed in dollars per

whose location relative to other departments is being unit time or the overall weighted sum of parts travel in

determined. the facility.

A fixed department is one whose location is

designated in the initial layout and is not allowed to 1.2.7 Layout Assessment

change during optimization. Fixed departments are not

considered when evaluating pairwise departmental Layout assessment is the value of the objective function

exchanges. A free department is one whose location is calculated by LayOPT : the sum of the flows multiplied

allowed to change during optimization. All free by the appropriate weights and expected distances

departments are considered when evaluating pairwise between all department pairs with non-zero parts flow

departmental exchanges. between them. A lower layout assessment generally

means a better layout.

1.2.4 Obstacles

2 METHODOLOGY

An obstacle is a general term used to describe any

unusable part of a facility. Such obstacles include Creating a project in LayOPT involves defining the basic

building columns, safety areas, freight elevators, etc. input data required to describe an initial layout and

Obstacles may also be used to depict non-existing execute an optimization run, namely: (a) the building or

building areas as when representing a non-rectangularly facility, (b) departments and departmental properties, (c)

shaped building with an enclosing rectangle, or when flow and cost values, and (d) an initial departmental

representing a mezzanine with an entire floor. block arrangement.

1.2.5 The Space Filling Curve 2.1 Defining the Building

LayOPT can capture virtually any building shape and obstacles because flows exist between them and the other

size. The grid size used in the matrix representation of departments.

the building shape is entirely dependent on the needs of A space filling curve may then be drawn through the

the user. In general, a finer grid size can more accurately rest of the grids, i.e., those not assigned to either

represent departmental areas and shapes, though, at the obstacles or fixed departments. The user may

expense of faster computational run times. The opposite experiment with several types (in terms of orientation,

is true for a larger grid size -- less precision but faster run density, or path) of curves either to obtain alternative

times. Depending on the grid size selected by the user, layouts or to correct some department shapes.

LayOPT can represent a department or an obstacle 5 ft. To complete the layout, the free departments are then

by 5 ft. in size, or even smaller. drawn either by sequencing them automatically along the

Multi-level facilities are easily represented by defined space filling curve or by laying them out

assigning multiple floors to the building. In this regard, individually. See Figure 1. Boundaries may also be

floor separation heights may or may not be the same drawn to outline individual department block footprints.

across all floors. Vertical material handling equipment

to transport parts, people, or products to and from

departments on different floors can be placed anywhere

on a floor and are assumed to service all defined floors.

LayOPT concurrently optimizes the layouts of all the

floors, i.e., each floor's layout is not developed

independently of the others.

2.2 Defining Departments

A department is uniquely identified by its number and

description. Defining a department also includes

specifying its area requirements in square distance units

(sq. ft. or sq. meters) or grids and designating it as free or

fixed. Additionally, floor restrictions may be defined --

floors where the department may not be located at any

time during and after the optimization run.

LayOPT does not limit department shapes to

rectangles or squares. Departments can assume virtually Figure 1: Partially Completed Initial Layout

any shape as long as they remain a single piece (i.e., not

disjointed) and do not contain an enclosed void.

Individual department shapes can be controlled through a 2.4 Defining Weight Factors and Flows

user-defined shape parameter, one which compares the

department's perimeter-to-area ratio to that of the ideal The objective function minimized by LayOPT is the sum

shape, e.g. a square. of parts flows multiplied by unit costs and the distances

over which these parts travel. Having defined the

2.3 Drawing an Initial Layout departments and an initial layout from which distances

can be calculated, the From-To chart may be entered

Drawing the initial layout involves doing four basic directly by the user. Parts flow values entered in this

steps: (a) drawing obstacles, (b) placing fixed chart may be expressed in different units, e.g., pieces,

departments, (c) drawing the space filling curve, and (d) pallets, trips, racks, etc. However, they should represent

placing free departments. parts flow between departments over the same time

The user has unlimited freedom in designating period.

unusable space in the facility. Defining obstacles is the The user may also enter from-to information using

first step in drawing the layout because grids assigned to process flow charts. Here, the user graphically specifies

obstacles may not be visited by the space filling curve. departments visited in sequence by each subassembly or

Another set of grids not visited by the space filling component that make up the end products. The quantity

curve is that of fixed departments. Fixed departments of each component that goes into the end product as well

should also be drawn before the space filling curve. as transfer batch sizes are defined for each department

While fixed departments never move during the pair in the process sequence. LayOPT then

optimization run, they are nevertheless different from

automatically generates the From-To chart from these 2.6 Massaging the Final Layout

process charts.

In addition to the From-To chart, the user also It is expected that the user will perform multiple runs

supplies a cost or weight factor matrix which represents starting with different initial layouts or space filling

either: (a) the actual unit cost of moving the parts curves. This enables the generation of several alternative

between the departments, or (b) user-defined relative layouts that in general, satisfy the overall layout

weights. The resulting layout assessment can therefore development objective. During these runs and in the

be either the total material movement cost or the resulting layouts, some departments may assume

weighted sum of parts travel in the facility. irregular shapes. LayOPT allows the user to 'massage'

the layout by smoothing out or refining department

2.5 Executing an Optimization Run shapes and make them more practical and usable.

Department shapes can be adjusted through either of

A LayOPT optimization run can be executed in one of the following layout massaging features: (a) even (no

two modes: automatic and interactive. In its true area loss/gain) grid exchange between departments, or

steepest-descent two-way exchange form, the automatic (b) grid reassignment from one department to another.

run searches all possible departmental exchange pairs Departmental input and output points can also be

based on space, shape, floor, and other restrictions and assigned anywhere within departmental boundaries to

selects the best exchange at each iteration. The designate actual parts pick-up and drop-off points. This

department location exchange is made and it proceeds allows for a more realistic calculation of the layout

iteratively until no further improvement in the objective assessment summary when presenting actual material

function is realizable, at which point the optimal layout handling costs for the final layout.

has been reached.

The interactive run mode allows the user to execute 3 LAYOPT AND SIMULATION

incremental 2-way departmental exchanges on the

current layout. LayOPT presents the top 10 exchanges at For many facilities layout design or improvement tasks,

each iteration in descending order of layout assessment conventional practice suggests arranging departments in

savings and lets the user select the most appropriate (not a new plant in the same manner as has been done in

necessarily the best) exchange. See Figure 2. Once the similar plants in the past. While this easy approach saves

user selects one of the top ten exchanges, LayOPT time, it nevertheless runs the risk of inheriting the

switches the locations of those two departments and inefficiencies and shortcomings of the previous layout.

proceeds to the next iteration. A new list of top ten On the other hand, most simulation studies attempt to

exchanges is then constructed from the 'new' layout. The determine satisfactory plant operating parameters based

user interactively participates in this process until no on an existing layout (Harnell and Tumay 1995).

further exchanges can reduce the current layout Increasingly, analysts all too quickly jump to the micro-

assessment. level simulation of a proposed system laid out

inefficiently and perhaps show 10%-15% improvements

in WIP levels or material handling costs. In the process,

they may have missed a larger window of opportunity to

save up to 80% in material movement and handling costs

had they first optimized the layout. The importance of

synergy between layout optimization and simulation has

been emphasized by Tumay 1992.

The ills of simulating a bad layout are numerous and

common. In many simulation studies, the objectives are

operational and local: (a) how many carriers should a

power and free system have to adequately service the

needs of the assembly area? (b) how many forklifts does

the shipping and receiving area need? (c) what is the best

speed to run a particular transfer conveyor? (d) which of

two possible temporary staging areas should WIP be sent

to and what should the capacity of those staging areas

Figure 2: Interactive Run be?

All these objectives focus on the one thing that lean

manufacturing is all about: reducing non-value added

time spent on material handling or storage systems. To REFERENCES

this end, the layout on which the simulation is based

should have already addressed the issue of minimizing Bozer, Y. A., R. D. Meller, and S. J. Erlebacher. 1994.

parts travel distance and cost between departments. No An Improvement-type Layout Algorithm for Single

amount of simulating can directly point out that a and Multiple-floor Facilities. Management Science

particular department should not be located where it is 40:918-932.

now. For instance, a simulation model might recommend Tumay, Ken. 1992. Integrating Simulations with CAD

six instead of seven forklifts to service the plant but it Tools for Effective Facility Layout Evaluation. In

cannot directly show that by simply moving one Proceedings of the 1992 Winter Simulation

department to another location, only two forklifts will be Conference, eds. James J. Swain, David Goldsman,

needed. By doing a layout optimization study before any Robert C. Crain, and James R. Wilson, 995-999.

discrete event simulation, it may even show that forklifts Winston, Wayne L. 1994. Operations Research:

are not the most cost-effective way to transport the Applications and algorithms, 3rd edition. Belmont,

materials. California: Wadsworth, Incorporated.

What the simulation model can provide, though, is an Sly David P., Eric Grajo, and Benoit Montrenil. 1996.

effective scheme for allocating work among available Layout Design and Analysis Software. Industrial

forklifts. Operational issues such as work scheduling, Engineering Solutions 28(7): 18-25.

traffic flow control, break scheduling, and manpower Vollman, Thomas E., Christopher E. Nugent, and Robert

allocation are best addressed by a discrete event model L. Zarter. 1968. A Computerized Model for Office

that considers both system capacity constraints and time Layout. The Journal of Industrial Engineering,

or resource requirements. In this regard, it is important X1X(7): 312-327.

to emphasize the significance of layout planning in the

macro-level, strategic phase (department location and

space allocation) and that of simulation in the micro-

level, operational phase (resource scheduling and AUTHOR BIOGRAPHY

utilization). With LayOPT, developing an optimal layout

ensures that the overall cost of moving parts and finished RAMU NARAYANASWAMY holds bachelor degree

goods between departments is the lowest feasible. It then in mechanical engineering (Bangalore University, India

allows simulation to address the operational issues more 1982), masters degree in industrial engineering and

effectively, assured that the layout is already the most management (Asian Institute of technology, Bangkok,

cost-efficient it can be. Thailand 1984), and Ph.D in industrial engineering

The goal of lean manufacturing is the shortest, most (Clemson University 1996). From 1985 to 1989 he was

cost-effective product-to-customer time possible. By one teaching in Bangalore University in the department of

measure, that means the smallest, if not zero, non-value industrial and production engineering. During his Ph.D

added portion in the product manufacturing cycle time. he has taught several classes at Clemson University.

With that common goal, layout optimization and From 1994 he is working as a consultant. At present he

simulation are two complementary tools indispensable to is working at production modeling corporation as

any plant layout and productivity improvement task. simulation and material flow consultant. He is a member

of the Institute of Industrial Engineers and Society of

4 SUMMARY Manufacturing Engineers.

This tutorial presented LayOPT as a Windows-based

facilities layout analysis and optimization software

package. It was developed to assist layout planners and

engineers in solving single and multiple floor facility

layout problems and contains extensive features and

capabilities to that assistance (Sly, Grajo, and Montremil

1996). LayOPT overcomes the limitations of current

algorithms and generates solutions that are generally

50% to 80% more efficient. With its unique and state-of-

the-art, as well as state-of-the-practice optimization

engine, LayOPT empowers you to explore many quality

alternatives to your facilities layout design challenges.

You might also like

- ElectricianDocument127 pagesElectricianAsokaNiranjanNo ratings yet

- Low-Current Systems Engineer’S Technical Handbook: A Guide to Design and SupervisionFrom EverandLow-Current Systems Engineer’S Technical Handbook: A Guide to Design and SupervisionRating: 5 out of 5 stars5/5 (1)

- A2 Poster Presentation TemplateDocument1 pageA2 Poster Presentation Templateranger1021994100% (1)

- Case Study In OOAD and UML: Case Studies in Software Architecture & Design, #1From EverandCase Study In OOAD and UML: Case Studies in Software Architecture & Design, #1No ratings yet

- Powerpoint Lecture in Grade 9Document265 pagesPowerpoint Lecture in Grade 9Gladys InventoNo ratings yet

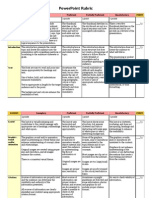

- PowerPoint RubricDocument2 pagesPowerPoint RubricfmacoolNo ratings yet

- UI Design Principles: Learn To Create Beautiful and Usable Interfaces From ScratchDocument323 pagesUI Design Principles: Learn To Create Beautiful and Usable Interfaces From Scratchdvcvc100% (1)

- 4 - Aldep Corelap and CraftDocument7 pages4 - Aldep Corelap and CraftBalamurugan P100% (1)

- Functional Analysis Module V1.0Document21 pagesFunctional Analysis Module V1.0Wardiman AlexsandroNo ratings yet

- Finite Element Analysis for Design Engineers, Second EditionFrom EverandFinite Element Analysis for Design Engineers, Second EditionNo ratings yet

- EWM15Document82 pagesEWM15dilip kumarNo ratings yet

- 03 Nesnas Challenges IrosDocument8 pages03 Nesnas Challenges IrosPedro LeonNo ratings yet

- Swe 7Document23 pagesSwe 7DevNo ratings yet

- Visual Modeling of Object-Oriented Distributed Systems: H G G WDocument20 pagesVisual Modeling of Object-Oriented Distributed Systems: H G G WRakeshNo ratings yet

- OOSE Chapter 5 LeactureDocument38 pagesOOSE Chapter 5 LeactureHiziki TareNo ratings yet

- Extended Model Driven Architecture To B Method: Ammar AljerDocument9 pagesExtended Model Driven Architecture To B Method: Ammar AljerUbiquitous Computing and Communication JournalNo ratings yet

- 9-Layout Planning ModelsDocument19 pages9-Layout Planning ModelsHello WorldNo ratings yet

- 4+1 Vista KruchtenDocument15 pages4+1 Vista KruchtenmarvandNo ratings yet

- Reverse Engineering Of: Object Oriented CodeDocument2 pagesReverse Engineering Of: Object Oriented Codekhurme1No ratings yet

- Dokumen - Tips - 5ed Solutions 10Document11 pagesDokumen - Tips - 5ed Solutions 10JESUS EMIRO GOMEZ JIMENEZNo ratings yet

- Analyzing Manufacturing Facility LayoutsDocument16 pagesAnalyzing Manufacturing Facility LayoutsSulficker Ali100% (1)

- Object Oriented DesignDocument37 pagesObject Oriented DesignGanesh ThapaNo ratings yet

- Structure of Automated CappDocument5 pagesStructure of Automated CappmaddyvarmaNo ratings yet

- Facility Layout IDocument54 pagesFacility Layout IsmartwebsNo ratings yet

- Programming For Problem Solving Unit 1Document10 pagesProgramming For Problem Solving Unit 1Womba LukamaNo ratings yet

- Section1: Identify Design Elements (17%)Document8 pagesSection1: Identify Design Elements (17%)vidhya_dharmarajNo ratings yet

- Automation System BoundaryDocument11 pagesAutomation System BoundaryJosh MahinayNo ratings yet

- FT Assignment 2Document11 pagesFT Assignment 2Josh MahinayNo ratings yet

- Tools in Structured Analysis: Data Flow DiagramDocument11 pagesTools in Structured Analysis: Data Flow DiagramMike AyanNo ratings yet

- Introduction of Rational Rose and UMLDocument27 pagesIntroduction of Rational Rose and UMLchetan1710198286% (7)

- 4e4b PDFDocument13 pages4e4b PDFmamaNo ratings yet

- Tutorial On High-Level Synthesis: and WeDocument7 pagesTutorial On High-Level Synthesis: and WeislamsamirNo ratings yet

- Modeling Componnet Level Design (2) - STUDENTDocument25 pagesModeling Componnet Level Design (2) - STUDENTBuncy MaddalaNo ratings yet

- Arquitectura Basada en CapasDocument4 pagesArquitectura Basada en CapasJesus David PinoNo ratings yet

- Unit I Uml Diagrams Introduction To Ooad Object-Oriented Analysis and Design (OOAD) Is A Software Engineering Approach ThatDocument45 pagesUnit I Uml Diagrams Introduction To Ooad Object-Oriented Analysis and Design (OOAD) Is A Software Engineering Approach ThatGopinath NNo ratings yet

- Alovera Joven Joshua C. BSIT 3B Formative Test Module 5Document5 pagesAlovera Joven Joshua C. BSIT 3B Formative Test Module 5Valerie MelendresNo ratings yet

- Alovera Joven Joshua C. BSIT 3B Formative Test Module 5Document5 pagesAlovera Joven Joshua C. BSIT 3B Formative Test Module 5Valerie MelendresNo ratings yet

- P P P P PDocument10 pagesP P P P PAlpesh PanchalNo ratings yet

- Kvarnstrom Domain AnalysisDocument10 pagesKvarnstrom Domain AnalysisgoldengateNo ratings yet

- IE-484 Ch6Document25 pagesIE-484 Ch6ecelara02No ratings yet

- UNIT 2 - Elaboration Elaboration PhaseDocument26 pagesUNIT 2 - Elaboration Elaboration PhaseAbi LashNo ratings yet

- A Framework For Capacity Planning and Machine Configuration in Flexible Assembly SystemsDocument30 pagesA Framework For Capacity Planning and Machine Configuration in Flexible Assembly SystemsYan1203100% (1)

- 00 Paper 24 - Melkamzer AsefaDocument23 pages00 Paper 24 - Melkamzer AsefamelkamzerNo ratings yet

- Task Space Ap: Planning For Robotic Manipulation in Icat IonsDocument11 pagesTask Space Ap: Planning For Robotic Manipulation in Icat IonsVamsidhar Reddy RNo ratings yet

- Physical Design For Block Level Implementation: Project ReportDocument20 pagesPhysical Design For Block Level Implementation: Project ReportMahesh JagabattuniNo ratings yet

- Branch - Variant ManagementDocument25 pagesBranch - Variant ManagementAhmad Syu'a'ulNo ratings yet

- 4.1 Overview: Chapter-Four DesignDocument15 pages4.1 Overview: Chapter-Four DesignAyush SharmaNo ratings yet

- 1-Suppose You Design An Architecture For An Application For College Registration. What Is A Good Style To Use? Give Your Justification. (Answer)Document4 pages1-Suppose You Design An Architecture For An Application For College Registration. What Is A Good Style To Use? Give Your Justification. (Answer)Jayanth JaidevNo ratings yet

- Dranreb AlmojeraDocument33 pagesDranreb AlmojeraDranreb AlmojeraNo ratings yet

- Application (Level Support For Dynamic Extension and Flexible CompositionDocument14 pagesApplication (Level Support For Dynamic Extension and Flexible CompositionmosssnerNo ratings yet

- Menurut Chase, Aquilano Dan Jacobs (1998, 380) Metode Layout Terbagi Menjadi 3 (Tiga) Yaitu: 1. Computerized Layout Techniques (CRAFT)Document3 pagesMenurut Chase, Aquilano Dan Jacobs (1998, 380) Metode Layout Terbagi Menjadi 3 (Tiga) Yaitu: 1. Computerized Layout Techniques (CRAFT)Jomantara Putra DaudNo ratings yet

- CH 11Document12 pagesCH 11Ramesh KumarNo ratings yet

- SE Experiment 5Document9 pagesSE Experiment 5Anurag ChorgheNo ratings yet

- Object Bridge PatternDocument17 pagesObject Bridge PatternVishy AnandNo ratings yet

- Complex-Systems Design Methodology For Systems-Engineering Collaborative EnvironmentDocument33 pagesComplex-Systems Design Methodology For Systems-Engineering Collaborative EnvironmentwaseheNo ratings yet

- Software Architecture DesignDocument9 pagesSoftware Architecture DesignAli RajaNo ratings yet

- CS504 Short NotesDocument40 pagesCS504 Short NotesWaqar HassanNo ratings yet

- Transform Flow and Transaction Analysis Information Technology EssayDocument9 pagesTransform Flow and Transaction Analysis Information Technology EssayAkhil TripathiNo ratings yet

- The Performance of Bags-of-Tasks in Large-Scale Distributed SystemsDocument12 pagesThe Performance of Bags-of-Tasks in Large-Scale Distributed SystemsRafael BragaNo ratings yet

- Chapter 10 - Component-Level DesignDocument8 pagesChapter 10 - Component-Level DesignYugendra BabuNo ratings yet

- An Experiment in Design and Analysis of Real-Time ApplicationsDocument15 pagesAn Experiment in Design and Analysis of Real-Time ApplicationsRoberto Romero TerceroNo ratings yet

- Fae10068 2Document7 pagesFae10068 2dgdgdNo ratings yet

- Models and Analysis for Distributed SystemsFrom EverandModels and Analysis for Distributed SystemsSerge HaddadNo ratings yet

- Responsive WebDocument5,922 pagesResponsive WebNelton GemoNo ratings yet

- UTM Thesis TemplateDocument44 pagesUTM Thesis TemplateMp GopalNo ratings yet

- UET Taxila FYP TemplateDocument14 pagesUET Taxila FYP TemplateAleeza AnjumNo ratings yet

- Salesforce Agent Console CheatsheetDocument5 pagesSalesforce Agent Console Cheatsheetlionel24No ratings yet

- Empowerment TechnologiesDocument7 pagesEmpowerment TechnologiesAlliah ManilaNo ratings yet

- Process Selection and Facility LayoutDocument42 pagesProcess Selection and Facility LayoutJessica VasquezNo ratings yet

- PGDBP 2020-2021 AssignmentDocument10 pagesPGDBP 2020-2021 AssignmentDevesh RajNo ratings yet

- Fiery Training 1Document346 pagesFiery Training 1shamilbasayevNo ratings yet

- SSO Feature (Sap)Document8 pagesSSO Feature (Sap)Narendra TomarNo ratings yet

- Imperial College London PHD Thesis Latex TemplateDocument6 pagesImperial College London PHD Thesis Latex Templatedawnrobertsonarlington100% (1)

- Page LayoutDocument12 pagesPage LayoutNJ Dominica De GalaNo ratings yet

- English Sample Unit: Global Connections Stage 3Document12 pagesEnglish Sample Unit: Global Connections Stage 3S TANCREDNo ratings yet

- Instructions NP PPT19 CS1-2aDocument5 pagesInstructions NP PPT19 CS1-2arahulNo ratings yet

- LAS ICT For PrintingDocument18 pagesLAS ICT For PrintingGlenda AstodilloNo ratings yet

- Printing PressDocument4 pagesPrinting PressYakubu EnochNo ratings yet

- Prinergy Evo TIFF Downloader Overview and FAQDocument7 pagesPrinergy Evo TIFF Downloader Overview and FAQRogerio FerracinNo ratings yet

- Autocad Tutorial 4 PDFDocument7 pagesAutocad Tutorial 4 PDFMaarij AnjumNo ratings yet

- PagePlus X8Document177 pagesPagePlus X8Andros MafraNo ratings yet

- Advance Did Creator User GuideDocument63 pagesAdvance Did Creator User GuideAly Ryf'an100% (1)

- A Report of 6 Weeks Industrial Training at A2It, PVT LTDDocument24 pagesA Report of 6 Weeks Industrial Training at A2It, PVT LTDRohit RanaNo ratings yet

- CVs Merged 2Document136 pagesCVs Merged 2Ali AlharbiNo ratings yet

- Project Report Beng/Bsc/Msc: Delete As AppropriateDocument17 pagesProject Report Beng/Bsc/Msc: Delete As AppropriateIheb HamedNo ratings yet

- Creating A Gmail AccountDocument12 pagesCreating A Gmail AccountJamaica BorromeoNo ratings yet

- BMM Syllabus of University of MumbaiDocument30 pagesBMM Syllabus of University of MumbaiDhanyaa NairNo ratings yet