Professional Documents

Culture Documents

Fuchs Offshore Brochure

Uploaded by

Miko RokkoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fuchs Offshore Brochure

Uploaded by

Miko RokkoCopyright:

Available Formats

FUCHS Offshore Oil & Gas Division

FUCHS Offshore Oil & Gas Division

Innovative lubricants need experienced application engineers

Every lubricant change should be preceded by expert consultation on the application in question. Only then can the best lubricant system be selected. Experienced FUCHS engineers will be glad to advise on products for the application in question and also on our full range of lubricants.

Lubricant Specialists

Contact:

Product Guide

FUCHS LUBRICANTS (UK) PLC New Century Street, Hanley, Stoke-on-Trent, ST1 5HU Phone: +44 01782 203 700 Fax: +44 01782 202 072 E-mail: contact-uk@fuchs-oil.com www.fuchslubricants.com

Graphix 08/2009

FUCHS Offshore Oil & Gas Division

FUCHS Offshore Oil & Gas Division

The FUCHS Group

FUCHS is a multi-national lubricant company, manufacturing and marketing a wide range of lubricants and derived specialities. Founded in 1931 as RUDOLF FUCHS, and still operating from a Head Office in Mannheim, Germany, FUCHS PETROLUB AG has grown to become the worlds largest independent manufacturer of lubricants. We are committed to improving product quality To achieve such growth, the group has maintained a strategy of technical excellence in the field of lubrication, and as a result, our companys degree of specialisation and innovation is far in excess of the average in our market. and we are at the cutting edge of synthetic and biodegradable lubricant technology. Project teams, of engineers and chemists, develop new grades every day, offering our customers bespoke lubricant solutions, increased asset performance and improved value for money. FUCHS believes in the philosophy that our customers success is our success. FUCHS is a full line supplier of lubricants, utilising the resources of the individual companies worldwide, to deliver a complete lubricant package on both a local and global level.

FUCHS UK

With such large scale investment in offshore equipment, you need a production partner that you can rely on to derive maximum efficiency and return. FUCHS can guide you through to ensure correct lubricant selection. Formed from the amalgamation of two of the UK's most respected lubricant companies, Silkolene Lubricants and Century Oils, FUCHS has a history in the UK that stretches back over 100 years. We also have over 25 years of experience supplying lubricants and associated services to offshore and land-based installations. We are a true lubricant specialist, This benchmark for product performance is supplemented by a commitment to production quality and reliability. ISO 9001, ISO 14001, TS 16949 and AS 9100 are just some accreditations that FUCHS maintains, as well as FPAL (First Point Assessment Limited) especially for the Offshore Oil & Gas Industry. All this is supplemented by a commitment to service. World class logistical support, development of successful service concepts and qualified consulting are just some of the extra benefits of working with FUCHS. concentrating only on developing optimum products and unique customer solutions. Our accomplishments have been built on a continuing programme of innovation and first class customer service, and our state-ofthe-art production facility manufactures a significant proportion of the UK's total lubricant requirement. n Provides a complete customer service package n Has a wide range of products to suit most applications n Can help you achieve peak performance and reduce costs n Has an unparalleled understanding of lubrication requirements

n Is a leading supplier of quality mineral

As well as an extensive product portfolio, we offer unrivalled expertise and unparalleled experience in research and development. Customers are fully supported by qualified teams of technical advisors, who will recommend the right lubricant for your requirements. With the right products, commitment and knowledge, FUCHS can successfully serve all of the offshore industrys needs. FUCHS

and synthetic lubricants

...Your perfect partner

AS 9100

FUCHS Offshore Oil & Gas Division

Compressor Oils

Lubrication has a significant influence on the operational efficiency of all compressors. Modern compressors are not only smaller, but offer higher performance, therefore placing greater demands on the technical characteristics of the lubricating oil. To achieve maximum efficiency and lowest operating costs, reduced service times and increased maintenance intervals are demanded by users, meaning that the oil works harder for longer. FUCHS is at the forefront of compressor oil technology, working with OEMs to provide innovative solutions and market leading technology.

Lubricants for the Offshore Oil & Gas Industry

DESCRIPTION Compressed air has become a major form of energy and the reliable generation of compressed air is vital. Operators require compressors to function perfectly over and beyond entire service intervals. The RENOLIN UNISYN OL series was developed to meet the increased requirements of compressor manufacturers on the service life of compressor oils. Due to the function of compressors. At high compression temperatures, the oils are subjected to a strong oxidative attack that accelerates ageing.

COMPRESSOR OIL

NAME DENSITY AT 15C KINEMATIC KINEMATIC VISCOSITY VISCOSITY AT 40C AT 100C VISCOSITY INDEX VI POUR POINT C FLASHPOINT CLEVELAND

RENOLIN UNISYN OL 32 RENOLIN UNISYN OL 46 RENOLIN UNISYN OL 68 RENOLIN UNISYN OL 100 RENOLIN UNISYN OL 150

838 843 845 845 849

32 46 68 100 150

6.1 7.9 10.6 14.4 19.4

142 146 144 148 148

<-60 <-60 <-60 -60 <-57

240 260 265 250 250

Turbine Oils

Increasing efficiency and performance of gas turbines is placing greater demands on the performance of lubricants used in these applications. Significantly lower oil volumes for higher performance turbines; along with the use of oil circuits in combined cycle gas turbines require long life turbine oils which display outstanding thermal oxidation stability and excellent water and air release properties. FUCHS developed the RENOLIN ETERNA range to meet the demands of such machinery as well as highly stressed gearboxes.

MAIN APPLICATION AREA RENOLIN UNISYN OL products are recommended for use in flooded or oil injection screw-type air compressors (ISO VG 32, 46, 68) and for piston and rotary vane compressors (ISO VG 100, 150) Used if mineral oil-based products are found to display insufficient thermal stability (resistance to ageing) or poor viscosity-temperature behaviours.

DESCRIPTION RENOLIN ETERNA turbine oils were developed for gas, steam, and expansion turbines as well as for turbo compressors with and without gearboxes based on the latest lubrication technology. The excellent properties of the base oils produced in a special process are enhanced using a carefully selected additive system. RENOLIN ETERNA oils contain no metalorganic compounds and are therefore ashless. They provide a zinc-free wear protection. Approved by: Siemens Power Generation. MAIN APPLICATION AREA RENOLIN ETERNA is especially suited for use in turbine systems with a common control and lubricating oil circuit. It can also be used as a bearing and sealing oil in hydrogencooled generators.

RENOLIN ETERNA - High quality turbine oils - new generation

NAME KINEMATIC VISCOSITY AT 40C KINEMATIC VISCOSITY AT 100C AIR RELEASE AT 50C DIN ISO 9120 TOST LIFETIME (H) FZG A/8, 3/90 LOAD STAGE RPVOT 150C (MIN)

RENOLIN ETERNA 32 RENOLIN ETERNA 46 RENOLIN ETERNA 68

32 46 68

5.8 7.6 9.9

4 4 6

10,000 10,000 10,000

10 10 10

1,000 1,000 1,000

DESCRIPTION RENOLIN GC 460 UCL contains synthetic fluid for the lubrication of cylinders and packing glands in gas compressors. It forms a tenacious film on surfaces and is extremely shear stable. RENOLIN GC 460 UCL protects against wear in high pressure compressors and is impermeable to water vapour and hydrocarbon gases. RENOLIN GC 460 UCL protects against corrosion in the compressor and maintains its viscosity to reduce the oil carry-over often experienced with other oils. RENOLIN GC 460 UCL has been formulated to offer a high degree of lubrication even where gases are wet, thus affording excellent anti-wear properties for cylinders and piston rings. Its low carbon forming properties also provide cleaner operation at high temperatures, thus preventing carbon build-up on valves, piston rings and downstream pipes and equipment.

RENOLIN GC 460 UCL - Semi-Synthetic Upper Cylinder Lubricant For Gas Compressors

NAME SPECIFIC GRAVITY AT 15.6C FLASHPOINT PMCC KINEMATIC VISCOSITY AT 40C KINEMATIC VISCOSITY VISCOSITY INDEX AT 100C VI POUR POINT C

RENOLIN GC 460 UCL

0.885

180

433.61

30.45

100

-15

RENOLIN ETERNA range also meets and exceeds requirement of: DIN 51 515-1 (RD) with and without gearbox DIN 51 515-2 (T9) with and without gearbox GE GEK 28568 A GE GEK 32568 F GE GEK 101941 A GE GEK 107395 A SIEMENS TLV 901304 SOLAR ES-9-224 (CLASS 1/CLASS 2) MIL-PRF-M331J

MAIN APPLICATION AREA RENOLIN GC 460 UCL is recommended for use in reciprocating compressors working with gases such as:natural gas, methane, hydrogen ethane, propane helium, nitrogen butane, ethylene, carbon dioxide, propylene LPG, etc. RENOLIN GC 460 UCL is commonly used in gas reinjection compressors.

DESCRIPTION RENOLIN HC 100 is a specially formulated polyalkylene glycol product for use in compressors handling hydrocarbon gases. The ability to withstand dilution by hydrocarbon and other compressed gases is particularly advantageous in flooded screw compressors. Other advantages include stability, low ash content, high viscosity index, shear stability, low solubility with many hydrocarbons and excellent lubricity. RENOLIN HC 100 is insoluble in water at temperatures above 70C. The decomposition products of RENOLIN HC 100 do not form carbon build-up on valves and elbows, thus reducing the risks of explosion. MAIN APPLICATION AREA For use in hydrocarbon gas compressors.

RENOLIN HC 100 - Polyalkylene glycol for use in hydrocarbon gas compressors

NAME SPECIFIC GRAVITY AT 20C FLASHPOINT PMCC KINEMATIC VISCOSITY AT 40C KINEMATIC VISCOSITY VISCOSITY INDEX AT 100C VI POUR POINT C

RENOLIN HC 100

1.047

>230

101.7

20

221

-45

FUCHS Offshore Oil & Gas Division

Lubricants for the Offshore Oil & Gas Industry

Hydraulic Oils

The performance of a hydraulic fluid has a major influence on the reliability and performance of hydraulic system components. FUCHS is a major supplier of hydraulic fluids and through the use of our technology, product life can be extended, grades rationalised, operating costs lowered and operational reliability improved.

DESCRIPTION The RENOLIN B RANGE is based on selected mineral base oils. High quality additives improve the ageing and oxidation stability. They also guarantee excellent corrosion protection properties (steel and iron materials). Synergistically acting copper deactivators protect copper / yellow metal materials. The selected anti-wear / mild EP additives based on zincdialkyldithiophosphates protect hydraulic pumps, motors, components and machine elements from wear (at low and high temperatures and at high loads). The RENOLIN B RANGE are mineral oil based hydraulic fluids according to DIN 51 524-2 (demulsifying, zinc containing) and lubricating oils according to DIN 51 517. Synergistically acting additives guarantee a long lifetime and the highest hydraulic performance. Even at high temperatires and high loads the base oils together with the additives ensure that the system will be operated reliably during a long lifetime. The RENOLIN B RANGE fulfills the high requirements of the DENISON HF 0 specification (hybrid pump test, a combination of a vane and a piston pump T6H20C combination). DESCRIPTION In the past few years, zinc-free hydraulic oils have become more and more important. The oils of the RENOLIN ZAF B RANGE are zinc-free and ash-free hydraulic oils HLP according to DIN 51 524, Part 2 with very good wear protection and load carrying capacity. MAIN APPLICATION AREA The oils of the RENOLIN ZAF B RANGE are high quality products that can be used both as hydraulic oils and also as lubricating oils for various applications, e.g. in bearings and recirculation systems.

HYDRAULIC OILS

NAME DENSITY KINEMATIC KINEMATIC AT VISCOSITY VISCOSITY AT 40C AT 100C 15C VISCOSITY INDEX VI POUR POINT C FLASHPOINT CLEVELAND

HYDRAULIC OILS

NAME DENSITY AT 15C KINEMATIC KINEMATIC VISCOSITY VISCOSITY VISCOSITY INDEX AT 40C AT 100C VI POUR POINT C FLASHPOINT CLEVELAND

RENOLIN B 1 VG 5 RENOLIN B 3 VG 10 RENOLIN B 4 VG 15 RENOLIN B 5 VG 22 RENOLIN B VG 32 RENOLIN B 11 VG 37 RENOLIN B 15 VG 46 RENOLIN B 20 VG 68 RENOLIN B 30 VG 100 RENOLIN B 40 VG 150 RENOLIN B 50 VG 220

837 852 865 863 876 875 875 882 881 887 894

5 10 15 22 32 37 46 68 100 150.0 220

1.7 2.6 3.2 4.3 5.5 6.2 6.9 8.7 11.1 14.5 19.2

96 90 107 109 103 105 100 96 94 97

-20 -30 -42 -27 -24 -31 -24 -24 -18 -15 -15

130 178 150 180 205 208 210 224 232 224 230

RENOLIN ZAF B 10 B RENOLIN ZAF B 22 B RENOLIN ZAF B 32 B RENOLIN ZAF B 46 B RENOLIN ZAF B 68 B RENOLIN ZAF B 10O B RENOLIN ZAF B 150 B

852 865 872 875 879 882 890

9.8 22.0 32.0 46.0 67.2 99.7 150.0

2.6 4.3 5.4 8.8 8.7 11.2 14.7

100 102 102 101 100 97 97

-30 -30 -30 -27 -21 -18 -20

170 212 215 234 230 240 206

MAIN APPLICATION AREA Universally applicable demulsifying hydraulic fluids and lubricating oils. They can be used in all trypes of mobile and stationary hydraulic units where the use of a demulsifying hydraulic oil (type HLP) is recommended. DESCRIPTION Proper function and operating safety of hydraulic systems is largely influenced by the quality of the hydraulic medium. In addition to the task of transferring forces, the operating fluid must seal, cool and lubricate. Since hydraulic oils are exposed to high stress due to the operating conditions, they have to fulfill a large number of requirements. Formulated using highly ageing resistant mineral oils and additives. Zinc containing HVLP hydraulic and general lubricating oils according to DIN 51 524-3. Mineral oil based, demulsifying.

DESCRIPTION The RENOLIN ZAF HV RANGE of hydraulic fluids has been developed to meet the challenge posed by hydraulic systems which are sensitive to viscosity variations, by the inclusion of shear stable viscosity stabilisers. The range is also ideal for powering hydraulic systems working in refrigerated plant, mobile equipment, or where the system demands a fluid capable of working over a wide temperature range. Based on high quality mineral oil, the RENOLIN ZAF HV RANGE offer excellent product characteristics including better viscosity / temperature relationship than convential type hydraulic fluids, enhanced anti-wear, anti-oxidation, demulsification and air release properties, along with decreased sludge formation and improved wet and dry filterability. Another major factor is their compatibility with silver plated components in hydraulic circuits.

NAME

DENSITY KINEMATIC KINEMATIC VISCOSITY AT VISCOSITY VISCOSITY INDEX AT 40C AT 100C VI 15C

POUR POINT C

FLASHPOINT CLEVELAND

RENOLIN ZAF HV 15 HV RENOLIN ZAF HV 32 HV RENOLIN ZAF HV 46 HV RENOLIN ZAF HV 68 HV

15.5 32.0 46.0 68.0

3.8 6.5 8.2 10.7

140 170 160 148

-45 -3 -35 -30

150 193 200 196

NAME

DENSITY AT 15C

KINEMATIC KINEMATIC VISCOSITY VISCOSITY AT 40C AT 100C

VISCOSITY INDEX VI

POUR POINT C

FLASHPOINT CLEVELAND

RENOLIN B 15 HVI RENOLIN B 32 HVI RENOLIN B 46 HVI RENOLIN B 68 HVI

859 870 875 882

15 32 46 68

3.8 6.3 8.1 11.0

150 150 150 154

-45 -42 -42 -42

180 178 186 210

MAIN APPLICATION AREA RENOLIN B HVI RANGE are high quality products used as hydraulic oil and as lubricating oil for various applications such as bearings and gear boxes, where high viscosity index and good load carrying capacity are required. Especially recommended for applications where a low start-up viscosity at higher temperatures is required. Particularly suited to all applications in mobile and industrial hydraulic systems that require the use of an HVLP oil according to DIN 51 524-3 with a wide service temperature range. DESCRIPTION The products of the RENOLIN MR MC series are universally applicable, zinccontaining lubricating and hydraulic fluids based on special semi-synthetic base oils with a high, shear-stable viscosity index (VI > 150). They have detergent / dispersant properties. The base oils which are used for the RENOLIN MR MC series are special, hydrotreated fluids, so-called MC base oils which are generated in a special hydrocracking process. These special base oils offer a higher performance compared to conventional lubricating and hydraulic fluids.

MAIN APPLICATION AREA Formulated for use in hydraulic systems which are sensitive to viscosity variations or operate in extremes of temperature.

NAME

DENSITY AT 15C

KINEMATIC KINEMATIC VISCOSITY VISCOSITY AT 40C AT 100C

VISCOSITY INDEX VI

POUR POINT C

FLASHPOINT CLEVELAND

RENOLIN MR 22 MC RENOLIN MR 32 MC RENOLIN MR 46 MC RENOLIN MR 68 MC

855 858 865 870

22 32 46 68

4.9 6.4 8.3 11.3

153 152 154 157

-54 -48 -48 -42

200 220 234 253

DESCRIPTION The products of the PLANTOHYD S RANGE are environmentally aware, highperformance lubricating and hydraulic oils based on special synthetic esters. They can be used universally in the temperature range from -35C to +90C and are rapidly biodegradable. The German Blue Angel environmental seal has been issued for ISO VG 15, 22 and 46. MAIN APPLICATION AREA The products of the PLANTOHYD S RANGE are synthetic, rapidly biodegradable oils based on sustainable raw materials. They are exceptionally suitable for applications in mobile and stationary hydraulic systems, for which a rapidly biodegradable hydraulic oil according to ISO 15380, HEES is recommended, especially if there is an environmental hazard to the ground, ground water or the surface waters due to leakage.

BIO-DEGRADABLE HYDRAULIC OILS

NAME DENSITY KINEMATIC KINEMATIC AT VISCOSITY VISCOSITY 15C AT 40C AT 100C VISCOSITY INDEX VI POUR POINT C FLASHPOINT CLEVELAND

PLANTOHYD S 10 PLANTOHYD S 15 PLANTOHYD S 22 PLANTOHYD S 32 PLANTOHYD S 46 PLANTOHYD S 68

929 927 926 921 921 927

10.5 15.5 22.7 32.4 48.8 69

3.0 4.0 5.4 7.1 9.6 12.2

150 161 191 188 186 177

<-51 <-51 -36 -51 -42 -48

214 225 240 246 304 >280

MAIN APPLICATION AREA Mobile and stationery hydraulic units. The RENOLIN MR MC products can also be used as spindle, running-in, test and corrosion protection oils. RENOLIN MR MC oils are recommended for machinery operating in unfavourable atmospheric conditions such as high humidity. The RENOLIN MR MC products have excellent viscosity-temperature behaviour. They can be used even if great changes of the ambient temperature are encountered. The high, shear-stable viscosity index generates multigrade characteristics, a reduction of different ISO viscosity classes can be possible.

FUCHS Offshore Oil & Gas Division

FUCHS Offshore Oil & Gas Division

Lubricants for the Offshore Oil & Gas industry

Wire line lubricants

DESCRIPTION RENOLIT WIRELINE BOP HTHP is a semi synthetic product resistant to oil well gases, including Hydrogen Sulphide (H2S) and Carbon Dioxide (CO2). RENOLIT WIRELINE BOP HTHP is an inhibited grease for wireline use all year round, thus avoiding the need for different grades of grease at different temperatures. This product contains a corrosion inhibitor that is effective against corrosion caused by Hydrogen Sulphide and Carbon Dioxide.

Specialities for the Offshore Oil & Gas industry

Environmentally acceptable chemicals for rig wash cleaning

The ecotoxicity of chemicals used on rigs for cleaning and maintenance purposes is of primary importance, especially as failure to comply with legislation can result in hefty financial penalties. FUCHS has for many years been at the forefront of supplying ecological sound chemicals for offshore rig washing practices. Our product portfolio is maintained to ensure CEFAS compliance, providing reliability and security for users. Our extensive research and development department ensures that FUCHS products offer ecology, economy and excellent technical performance. FUCHS products are designed to be non-toxic, odourless, free from harmful solvents, rapidly biodegradable and non corrosive and designed to offer users versatility in a number of operations.

RENOLIT WIRELINE BOP HTHP - Wire Rope Grease designed for oil and gas well wirelines

NAME DENSITY AT 15C FLASHPOINT CLEVELAND KINEMATIC VISCOSITY AT 40C KINEMATIC VISCOSITY AT 0C VISCOSITY INDEX VI POUR POINT C

RENOLIT WIRELINE BOP HTHP

>200

3000

25000

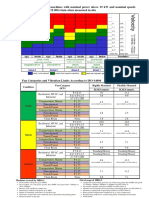

CONE AND PLATE VISCOMETRICS FOR RENOLIT WIRELINE BOP HTHP

MAIN APPLICATION AREA Braided cable oil well wirelines. Wire Ropes. RENOLIT WIRELINE BOP HTHP is designed for use in well conditions with pressure and temperatures greater than 10,000psi and 300F respectively. RENOLIT WIRELINE BOP HTHP injection rate is subject to system conditions.

DESCRIPTION RENOCLEAN S 08 RIG WASH is a water-based fluid designed for most general cleaning, degreasing and de-waxing operations. It is suitable for manual use or in steam cleaners or pressure washers. It is designed for the rapid release of emulsified oil. The most cost-effective approach for cleaning oil and grease contamination in industry is to use aqueous degreasing fluids. These fluids often, in the past, contained additives that were not biodegradable or ecologically safe. A further disadvantage was that traditional degreasers tended to be difficult to separate in down stream interceptors. FUCHS have overcome this problem by using high performance, water miscible degreasers meeting internationally accepted environmental standards and the requirements for down stream separators.

RIG WASHES

NAME APPEARANCE ODOUR CHARACTERISTICS SPECIFIC GRAVITY AT 15.6C PH VALUE TEMPERATURE STABILITY SHELF LIFE

RENOCLEAN S S08 RIG WASH

Clear pale yellow to water white fluid

Virtual non/soapy

1.03

8-9

Store below 40C Protect from frost

12 mths when stored in original container

Cefas Registration N 000000023122 OCNS Gold Band (The highest environmental band achievable).

MAIN APPLICATION AREA RENOCLEAN S 08 RIG WASH is a fast acting aqueous degreaser with no emulsion forming properties. It is suitable for light to medium oil contamination where immediate oil separation is required, the maximum dilution being 50:1.

DESCRIPTION RENOCLEAN SC 08 RIG WASH is a water miscible degreaser for the removal of heavy oil contamination. It is designed for the rapid release of emulsified oil when used at a 20:1 dilution. The most cost-effective approach for cleaning oil and grease contamination in industry is to use aqueous degreasing fluids. These fluids often, in the past, contained additives that were not biodegradable or ecologically safe. A further disadvantage as that traditional degreasers tended to be difficult to separate in down stream interceptors. FUCHS have overcome this problem by using high performance, water miscible degreasers meeting internationally accepted environmental standards and the requirements for down stream separators.

NAME

APPEARANCE

ODOUR CHARACTERISTICS

SPECIFIC GRAVITY AT 15.6C

PH VALUE

TEMPERATURE STABILITY

SHELF LIFE

RENOCLEAN SC 08 RIG WASH

Clear pale yellow fluid

Virtually none/soapy

1.07

8-9

Store below 40C

12 mths when stored in original container

Cefas Registration N 000000023123 OCNS Gold Band (The highest environmental band achievable).

MAIN APPLICATION AREA RENOCLEAN SC 08 RIG WASH is suitable for heavy oil contamination and is supplied as a concentrate that may be diluted with up to 200 parts water to 1 part concentrate, depending on the level of contamination.

FUCHS Offshore Oil & Gas Division

Technical support services

It has been said that the lubricant contained within a piece of machinery can be considered as a component of that machine. Its condition must therefore be maintained and monitored just like the machine itself. Because the life of machinery depends on the longevity of the lubricants used, routine and frequent analysis, to monitor their performance and quality, should be performed. In addition to a wide range of products, we also offer a variety of tailored support and management packages that take care of the maintenance of your plant and equipment and ensure the most effective use of your lubricants. Other technical support services include: n 24-Hour emergency telephone support line n Assistance with all lubricant queries and problems n OPITO certified engineers at your service n Full range of IMO certified bulk storage tanks available n Full range of lubricant dispensing equipment available n Advice on correct disposal of used lubricants and drums n Waste oil management services n Personnel training on all lubrication aspects n Advice on product change overs and clean outs n Complete laboratory facilities in the UK n Lubrication surveys and schedules n Advice on rationalisation and cost reduction initiatives n Plus more! Please just ask.

CENT condition monitoring service accurately analyses the condition of the fluid in use, generating easy-to-understand reports to establish wear trends and contamination sources. This helps to determine the anticipated life of the fluid, highlights potential problems before they occur and eliminates the possibility of machine failure, allowing maintenance work to be specifically targeted without affecting production (preventative maintenance).

10

11

You might also like

- Single Port KVM Over Ip Switch User'S ManualDocument73 pagesSingle Port KVM Over Ip Switch User'S ManualMiko RokkoNo ratings yet

- RLH 2012 Fiber Catalog-WebDocument20 pagesRLH 2012 Fiber Catalog-WebMiko RokkoNo ratings yet

- IntesisBox Modbus Server ESSER Datasheet EngDocument9 pagesIntesisBox Modbus Server ESSER Datasheet EngMiko RokkoNo ratings yet

- Fuji Kura SplicerDocument2 pagesFuji Kura SplicerMiko RokkoNo ratings yet

- BiffiDocument12 pagesBiffiMiko RokkoNo ratings yet

- 14Document550 pages14Raj Kumar AhmedNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Sistema RSW-CSWDocument8 pagesSistema RSW-CSWDiego Trinidad100% (1)

- GMSL CNG EquipmentDocument13 pagesGMSL CNG EquipmentBambang SatrioNo ratings yet

- 101723b02 Pco3 Chiller - UserDocument39 pages101723b02 Pco3 Chiller - UserMallinatha PN100% (1)

- Rotary CompressorDocument24 pagesRotary Compressorvijayns_250355172No ratings yet

- Paper IIDocument142 pagesPaper IIPritamjit RoutNo ratings yet

- Compresor CatalogoDocument1 pageCompresor CatalogoRedimido Gonzalez de LeonNo ratings yet

- Graphical Symbols For Piping Systems and Plant: BASED ON BS 1553: PART 1: 1977Document9 pagesGraphical Symbols For Piping Systems and Plant: BASED ON BS 1553: PART 1: 1977Bruce QuareNo ratings yet

- 1Document6 pages1Jose RattiaNo ratings yet

- Protecting A Centrifugal Compressor From SurgeDocument2 pagesProtecting A Centrifugal Compressor From SurgeDylanAdams100% (1)

- Eit BootcampDocument137 pagesEit BootcampAman 'kebe' Kebede100% (1)

- Coren Report - Bell MTDocument40 pagesCoren Report - Bell MTMaknun71% (7)

- Preparatory Section: A. WarpingDocument30 pagesPreparatory Section: A. WarpingHumaun KabirNo ratings yet

- KAESER SX6 Service ManualDocument100 pagesKAESER SX6 Service ManualYassin AlkadyNo ratings yet

- Acoustic Catalog 0109Document63 pagesAcoustic Catalog 0109Socaciu VioricaNo ratings yet

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 72-60-00Document62 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 72-60-00anony8103No ratings yet

- 39.0044 - Rev.2 - ENG - February 2013 - FMQ 2 User ManualDocument21 pages39.0044 - Rev.2 - ENG - February 2013 - FMQ 2 User ManualdlseymourNo ratings yet

- API Rec Comm Mend Ded P Pract Tice 1 1110 0Document2 pagesAPI Rec Comm Mend Ded P Pract Tice 1 1110 0Đào_hải_10No ratings yet

- B U L L E T I N: Application EngineeringDocument2 pagesB U L L E T I N: Application EngineeringMaria DazaNo ratings yet

- Brosur Yaep ChillerDocument44 pagesBrosur Yaep ChillerPratikno Saja100% (1)

- Limit Table According To ISO (10816-3 and 14694)Document1 pageLimit Table According To ISO (10816-3 and 14694)Muhammad Haroon67% (3)

- Hermetic CompressorsDocument102 pagesHermetic CompressorsMalau Arief100% (1)

- Operating Manual - C30-C76Document68 pagesOperating Manual - C30-C76radojko75% (4)

- Importance of Solenoid ValvesDocument16 pagesImportance of Solenoid ValvesRahul PatilNo ratings yet

- Us 7851663 - PETROLEUM JellyDocument21 pagesUs 7851663 - PETROLEUM JellyAbbas AliNo ratings yet

- #Design of Biogas ScrubbingDocument6 pages#Design of Biogas ScrubbingLai Mei EeNo ratings yet

- Refrigeration and Airconditioning by S K Mondal T&Q .0002Document130 pagesRefrigeration and Airconditioning by S K Mondal T&Q .0002saitejaNo ratings yet

- 1 GeneralDocument548 pages1 Generalclinthen100% (1)

- Gas PlantDocument44 pagesGas PlantabbutalibbNo ratings yet

- Abstract Industrial Air and Gas Compressors Report 2014 PDFDocument2 pagesAbstract Industrial Air and Gas Compressors Report 2014 PDFrob mayerNo ratings yet

- Design Manual-Piping Mechanical: The M. W. Kellogg Company 3400Document13 pagesDesign Manual-Piping Mechanical: The M. W. Kellogg Company 3400Seungmin Paek100% (2)