Professional Documents

Culture Documents

Motor GE CJ610-1

Uploaded by

César Pérez PerrusquíaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Motor GE CJ610-1

Uploaded by

César Pérez PerrusquíaCopyright:

Available Formats

U.S.

DEPARTMENT OF TRANSPORTATION FEDERAL AVIATION ADMINISTRATION TYPE CERTIFICATE DATA SHEET 1E16

TCDS NUMBER: REVISION: 15

1E16

DATE: August 21, 2008 MODELS: CJ610-1, CJ610-4, CJ610-5, CJ610-6, CJ610-8,

CJ610-8A, CJ610-9

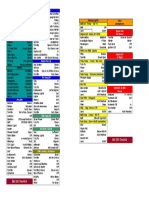

Engines of models described herein conforming with this data sheet (which is a part of Type Certificate No. 1E16) and other approved data on file with the Federal Aviation Administration, meet the minimum standards for use in certificated aircraft in accordance with pertinent aircraft data sheets and applicable portions of the Civil Air Regulations/Federal Aviation Regulations provided they are installed, operated, and maintained as prescribed by the approved manufacturer's manuals and other approved instructions. Type Certificate (TC) Holder: General Electric Company GE Aviation 1000 Western Ave Lynn, Massachusetts 01910 CJ610-1 CJ610-4 CJ610-5 CJ610-6 Turbojet: 8 stage axial flow compressor, 2 stage turbine, annular type combustion chamber 2700 2850 General Electric Model MFC-2 Chandler-Evans Model 9234 with integral boost. Kerosene, JP-4 & JP-5 type fuels conforming to G.E. Jet Fuel Spec. D50TF2, current revision. Oil conforming to G.E. Spec. D50TF1, current revision. -----2780 2950 ---------

Model Type Ratings (See NOTE 5) Maximum continuous at sea level, static thrust, lb. Takeoff (5 min.) at sea level, static thrust, lb. Fuel control (See NOTE 14) Fuel pump Fuel (See NOTES 7, 8, and 11)

Oil (See NOTE 11)

--

--

--

Principal dimensions Length, in. (flange to flange) 40.50 Max. dia., in. (max. flange) 17.56 Center of gravity (dry weight) with standard equipment: Aft of front frame flange fwd. face, in. 14.1 Below engine horizontal centerline, in. 1.8 To right of engine vertical centerline, in. 0.6 403 Weight (dry) lb. (includes as standard equipment basic engine accessories and speed control, oil tank, fuel-oil cooler, ignition system less power source, inlet antiicing system and exhaust thermocouples, Compressor Spool Rotor on CJ610-6 (SB 72-148) and CJ610-8A (SB 72-154)). Usable oil tank capacity (integral), qts. 3 Ignition (24 - 30 volts D.C.) Capacitor discharge exciter P/Ns 37D401588, 4006T58, 4016T54, 4920T03, or 4026T03 and two igniter plugs P/Ns 37B201652, 37C311124 or 4013T35. NOTES 1 thru 11, 13, 14, & 15

--16.1 1.7 0.5 393

--14.1 1.8 0.6 406

--15.55 1.7 0.5 418

---

---

---

--

--

--

PAGE REV.

1 15

2 15

3 14

4 15

LEGEND: "- -" INDICATES "SAME AS PRECEDING MODEL" "---" NOT APPLICABLE NOTICE: ALL PAGES ARE REFORMATTED. SIGNIFICANT CHANGES, IF ANY ARE BLACK.LINED IN THE LEFT MARGIN

TCDS 1E16

Page 2 of 4

Model Type Ratings (See NOTE 5) Maximum continuous at sea level, static thrust, lb. Takeoff (5 min.) at sea level, static thrust, lb. Fuel control (See NOTE 14) Fuel pump Fuel (See NOTES 7, 8, and 11)

CJ610-8 CJ610-8A CJ610-9 Turbojet: 8 stage axial flow compressor, 2 stage turbine, annular type combustion chamber 2925 3100 General Electric Model MFC-2 Chandler-Evans Model 9234 with integral boost. Kerosene, JP-4 & JP-5 type fuels conforming to G.E. Jet Fuel Spec. D50TF2, current revision. Oil conforming to G.E. Spec. D50TF1, current revision. 2850 2950 ---2925 3100 ----

Oil (See NOTE 11)

--

--

Principal dimensions Length, in. (flange to flange) 40.50 Max. dia., in. (max. flange) 17.56 Center of gravity (dry weight) with standard equipment: Aft of front frame flange fwd. face, in. 16.0 Below engine horizontal centerline, in. 1.7 To right of engine vertical centerline, in. 0.5 411 Weight (dry) lb. (includes as standard equipment basic engine accessories and speed control, oil tank, fuel-oil cooler, ignition system less power source, inlet antiicing system and exhaust thermocouples, Compressor Spool Rotor on CJ610-6 (SB 72-148) and CJ610-8A (SB 72-154)). Usable oil tank capacity (integral), qts. 3 Ignition (24 - 30 volts D.C.) Capacitor discharge exciter P/Ns 37D401588, 4006T58, 4016T54, 4920T03, or 4026T03 and two igniter plugs P/Ns 37B201652, 37C311124 or 4013T35. NOTES 1 thru 11, 13, 14, & 15

--15.65 --433

--14.2 1.8 0.6 421

---

---

--

--

Certification basis: Regulations & Amendments CAR 13 effective June 15, 1956 as amended by 13-1, 13-2, 13-3, 13-4 and 13-5 FAR 33 effective February 1, 1965 as amended by 33-1, 33-2, and 33-3

Model CJ610-1 CJ610-2B CJ610-4 CJ610-5 CJ610-6 CJ610-8 CJ610-9 J85-GE-17B CJ610-2B J85-GE-17B CJ610-8A

Date of Application September 14, 1960 September 13, 1961 November 6, 1963 February 15, 1966 February 15, 1966 June 27, 1967 June 27, 1967 November 30, 1967 November 23, 1976

Date Type Certificate No. 1E16 Issued/Revised December 6, 1961 December 6, 1961 May 11, 1964 June 30, 1966 June 30, 1966 January 31, 1968 January 31, 1968 January 15, 1968 Inactive - May 11, 1964 Inactive - November 15, 1976 April 13, 1977

Production basis:

Production Certificate No. 108

TCDS 1E16

Page 3 of 4

NOTE 1.

Maximum permissible engine rotor speeds are:

Takeoff Maximum continuous

16,700 r.p.m. 16,500 r.p.m.

NOTE 2.

Maximum permissible temperatures (F). Takeoff (5 min.) T5 Maximum continuous Maximum transient (10 seconds) Maximum transient for starting (5 seconds) Maximum transient for starting (2 seconds) Oil reservoir (steady state) (transient 3 minutes) No. 2 and No. 3 bearing scavenge oil CJ610-1 & -4 1300 1250 1440 1570 1670 365 380 380 CJ610-5 & -6 1321 1295 ------CJ610-8 & -9 1375 1345 ------CJ610-8A 1355 1335 -------

Refer to Operating Instructions SEI-188 for time-temperature envelope. The exhaust gas temperature is measured by 8 thermocouples mounted in a radial plane in the exhaust cone. NOTE 3. Fuel and oil pressure limits: Fuel: Minimum at engine pump inlet: 5 p.s.i. above true fuel vapor pressure; or a pressure equal to fuel supply tank pressure, whichever is greater with a maximum of 50 p.s.i.g. Minimum Maximum 5 p.s.i.g. 60 p.s.i.g.

Oil pressure at oil filter inlet or oil cooler discharge:

Refer to Operating Instructions SEI-188 for operating range limits. NOTE 4. Accessory drive provisions: Torque Rating H.P. Accessory Speed in. lb. Extraction Pad Drive Pads AND Type r.p.m. Cont. Static Maximum P2 Starter 20002 XII-D 7088 500 2200 56 Front Generator P3 Fluid 20002 XII-D 7088 500 2200 56 Rear Pump P4 Fluid 20001 XI-B 7811 250 1650 31 Rear Pump P1* Tachometer 20005 XV-B 4190 7 50 0.50 Total customer power extraction in any combination from Pads 2, 3, and 4 shall not exceed 65 hp. * Tachometer mounted on lube pump. ** "C" - Clockwise, "CC" - Counter-clockwise facing engine pad.

Rotation ** CC C C CC

The customer power extraction limits vs. engine speed are presented in General Electric CJ610 Installation Manual No. SEI-126A. Location and details of the accessory drive pads are presented on the Installation Drawing, Section 1. NOTE 5. Engine ratings are based on calibrated stand performance under the following conditions: Operation at rated engine speeds. Static sea level standard conditions of 59F and 29.92 in. Hg. General Electric bellmouth on air inlet and bullet nose. No external air bleed or accessory drive power for aircraft accessories Exhaust configuration as defined by General Electric Drawing 1076722-457P23 or 1076774-216. No anti-icing airflow. Turbine exhaust gas temperature limits not exceeded. At sea level static conditions below 59F, rated thrust will increase to maximum physical thrust limits as indicated: CJ610-1 & -4 3050 lb. @ 13F 2960 lb. @ 13F CJ610-5 & -6 3180 lb. @ 23F 3135 lb. @ 11F CJ610-8 & -9 -3100 lb. @ 37F CJ610-8A -3135 lb. @ 11F

Takeoff Maximum continuous

TCDS 1E16

Page 4 of 4

These limits may be authorized for use at any ambient temperature for engines whose individual characteristics permit higher than rated thrust to be developed without exceeding approved temperature or r.p.m. limits. For detailed performance data refer to the following General Electric publications: CJ610-1 & -4 SEI-167 TM64SE2103 CJ610-5 & -6 SEI-213 SEI-213 CJ610-8 & -9 SEI-252 SEI-252 CJ610-8A SEI-494 SEI-494 77002

Performance Bulletin Power Setting Manual Performance Deck NOTE 6.

Maximum permissible bleed air extraction for aircraft purposes is 6% of compressor inlet air flow. Refer to the currently approved CJ610 Installation Manual No. SEI-126A for additional data. Commercial kerosene, JP-4 and JP-5 type fuels are acceptable, but whenever a change is made or a mixture is used, a readjustment of the fuel control specific gravity setting must be made for optimum acceleration performance. The use of aviation gasoline as an emergency fuel is permitted provided that its use is limited to no more than 25 hours during any one overhaul period. Refer to Maintenance Manual SEI-186. Optional additives which may be used in approved fuels are: (1) Phillips PFA-55MB or anti-icing additives to Specifications MIL-I-27686E at a concentration not in excess of 0.15% by volume. (2) Shell ASA-3 anti-static additive at a concentration that will provide not in excess of 300 conductivity units which is approximately equivalent to one (1) RPM. (3) Sohio Biobor JF biocide additive at a concentration not in excess of 20 PPM elemental boron (270 PPM total additive). The above additives may be used in combination.

NOTE 7.

NOTE 8.

NOTE 9.

These engines meet FAA requirements for operation in icing conditions, for adequate turbine disk integrity and rotor blade containment and do not require airframe mounted armoring. Refer to Operating Instructions SEI-188 for operating procedure under icing conditions.

NOTE 10. The maximum permissible steady overspeed is 17,160 r.p.m. for 2 minutes and 17,820 r.p.m. on a transient basis. When either of these limits is exceeded, the engine must be inspected as defined in Operating Instructions SEI-188. NOTE 11. Refer to General Electric Operating Instructions SEI-188 (Operating Engineering Bulletins Nos. 1 and 2) for list of approved fuels and oils. NOTE 12. Deleted NOTE 13. The CJ610-4, CJ610-6, CJ610-8, and CJ610-8A are similar to the CJ610-1, CJ610-5, and CJ610-9 except for location of the accessory gearbox. The CJ610-8 and -9, CJ610-5 and -6, and the CJ610-1 and -4 models are similar except for increased performance with improved parts. The CJ610-8A is similar to the CJ610-8 except for derated performance and increased operating envelope. NOTE 14. An altitude idle speed reset unit (AIR) P/N 6002T64 is available and may be incorporated in the fuel control to automatically establish a special flight idle speed schedule within the limits of the minimum flight idle speeds defined in SEI-126A - CJ610 Installation Manual. For engines not equipped with AIR, either the aircraft system must be capable of maintaining the referenced minimum idle speed schedule or the pilot must monitor and manually reset idle speed to maintain the minimum speed schedule as defined in SEI-126A unless a modified schedule is coordinated with and approved by the General Electric Company. Engines equipped with AIR unit are identified by the letter "A" following the engine serial number. NOTE 15. Certain engine parts are life limited. These limits are listed in the FAA approved General Electric CJ610 Engine Overhaul Manual, SEI-136, Section 72-00, Inspection.

.....END.....

You might also like

- Engines Tpe331 14Document2 pagesEngines Tpe331 14Munkhbileg UlNo ratings yet

- Modify Turbojet To TurbofanDocument11 pagesModify Turbojet To TurbofanMohammad ChessterNo ratings yet

- Tipe Certificate CF700Document4 pagesTipe Certificate CF700Steph Amezquita Benhumea100% (1)

- Model 250 C40BDocument2 pagesModel 250 C40Bsnappish1No ratings yet

- Dornier 328jet EnginesDocument19 pagesDornier 328jet EnginesBuzz100% (1)

- Tpe331 Handout For AmelDocument45 pagesTpe331 Handout For AmelThanawat Rodtum100% (1)

- Unit 3.hot Section 16112019Document65 pagesUnit 3.hot Section 16112019motores4297No ratings yet

- Q400 - 12. PropellersDocument14 pagesQ400 - 12. PropellersDavid Owen100% (1)

- 002 Turbine Engine Starting System1Document30 pages002 Turbine Engine Starting System1Aishah HanisNo ratings yet

- Learjet ManualDocument35 pagesLearjet Manualalbix5850% (2)

- Fuel SystemDocument39 pagesFuel SystemDadang100% (2)

- MM Capítulo 09 - Fuel SystemDocument44 pagesMM Capítulo 09 - Fuel Systemoscar100% (1)

- G3 Self CheckDocument94 pagesG3 Self CheckSantiago Hidalgo100% (1)

- The Williams FJ44 Is A Family of SmallDocument44 pagesThe Williams FJ44 Is A Family of SmallXavier Diaz75% (4)

- Twin-Engine Helicopter Operations: AV8 Helicopters LTD 1Document17 pagesTwin-Engine Helicopter Operations: AV8 Helicopters LTD 1Pravin TambeNo ratings yet

- Bell 212 - Technical Ground PDFDocument75 pagesBell 212 - Technical Ground PDFemdcad3790100% (1)

- GE T700 Gas Turbine Engine (Updated 7 - 22 - 2014)Document4 pagesGE T700 Gas Turbine Engine (Updated 7 - 22 - 2014)Habib ur RehmanNo ratings yet

- Ata 22 I-Aea1Document9 pagesAta 22 I-Aea1Antonio CorteNo ratings yet

- TFE731-40 Turbofan Engine Publication Collection PDFDocument17 pagesTFE731-40 Turbofan Engine Publication Collection PDFYousefh Pineda100% (1)

- Pt6t Gearbox PDFDocument117 pagesPt6t Gearbox PDF13421301508No ratings yet

- 直升机打平衡相关知识与设备资料 PDFDocument132 pages直升机打平衡相关知识与设备资料 PDFrobinyNo ratings yet

- Bell 412 Technical DescriptionDocument13 pagesBell 412 Technical Descriptionfatkhur rahmanNo ratings yet

- EASA MMEL Bell Helicopter 429-00-14032011Document41 pagesEASA MMEL Bell Helicopter 429-00-14032011Matei CiprianNo ratings yet

- PC-7 TC DocumentationDocument6 pagesPC-7 TC Documentationadijorio100% (2)

- AS350B3-tech Data 2009Document70 pagesAS350B3-tech Data 2009trunNo ratings yet

- Dgca Exam Questions of Beech Craft g58Document1 pageDgca Exam Questions of Beech Craft g58xcd more0% (1)

- Pdf7164163971639616-Beechcraftpressurized Baron 58pa.p7cDocument663 pagesPdf7164163971639616-Beechcraftpressurized Baron 58pa.p7cjohn smithNo ratings yet

- Mmel Be1900dDocument79 pagesMmel Be1900dHonorio Perez M100% (1)

- AeroshellDocument1 pageAeroshellJerome Cardenas TablacNo ratings yet

- Motor JT9DDocument7 pagesMotor JT9Dfelipe murciaNo ratings yet

- Turboprops TNG Manual PDFDocument21 pagesTurboprops TNG Manual PDFIvan Bastiani100% (1)

- AW109SP - CockpitDocument1 pageAW109SP - Cockpitadwad100% (1)

- Engine DatasheetDocument5 pagesEngine DatasheetAlejandro EspinosaNo ratings yet

- Propeller Performance: Professor Von Kliptip's Twelve All-Time Favorite Questions and Answers AboutDocument16 pagesPropeller Performance: Professor Von Kliptip's Twelve All-Time Favorite Questions and Answers AboutaviationMYNo ratings yet

- HP3-BM FcuDocument13 pagesHP3-BM FcuMaung Oo100% (2)

- Aid Smith Bell 206 ChecklistDocument1 pageAid Smith Bell 206 Checklistchris josephsNo ratings yet

- RR250 - C30 OmmDocument16 pagesRR250 - C30 OmmturboshaftNo ratings yet

- SMFD UH-1 OPERATORS MANUAL Nov 2012Document93 pagesSMFD UH-1 OPERATORS MANUAL Nov 2012Slendrei100% (1)

- LJ 55 - Pilot Training Manual - (Vol 1)Document84 pagesLJ 55 - Pilot Training Manual - (Vol 1)Cassiano Capellassi100% (3)

- Williams Fanjet FamilyDocument1 pageWilliams Fanjet FamilyIon PopescuNo ratings yet

- 29 Hydraulic SystemDocument10 pages29 Hydraulic SystemAlejandro FernandezNo ratings yet

- Cessna 550-551-560 (PWC JT15D) Initial Aircraft Type Rating CourseDocument27 pagesCessna 550-551-560 (PWC JT15D) Initial Aircraft Type Rating CourseNitsuga50% (2)

- JT3D (TF33) S2P4Document128 pagesJT3D (TF33) S2P4junmech-1No ratings yet

- Arriel 1 Cours Pilotes 2009 06Document46 pagesArriel 1 Cours Pilotes 2009 06883573No ratings yet

- Bell 429 Helicopter - High Resolution PanelDocument1 pageBell 429 Helicopter - High Resolution Panelguicordova0% (1)

- Axel Humpert, Clive Schley Eurocopter Deutschland GMBH Donauwoerth, GermanyDocument10 pagesAxel Humpert, Clive Schley Eurocopter Deutschland GMBH Donauwoerth, GermanyVishnu SankarNo ratings yet

- Engine Stands Catalogue BDDocument23 pagesEngine Stands Catalogue BDHasan RazaNo ratings yet

- TPE331-14 Turboprop EngineDocument2 pagesTPE331-14 Turboprop EnginemishanbgdNo ratings yet

- Gulf Stream G100 Type Certificate Data Sheet - A16NMDocument14 pagesGulf Stream G100 Type Certificate Data Sheet - A16NMsupermoix100% (1)

- R-11 Turbojet Engine Specification: ConstructionDocument2 pagesR-11 Turbojet Engine Specification: ConstructionmauryapiaeNo ratings yet

- Continental Fuel Injection Contamnimation SB08-4ADocument4 pagesContinental Fuel Injection Contamnimation SB08-4AAMSNo ratings yet

- Master Minimum Equipment List (MMEL) : U.S. Department of Transportation Federal Aviation AdministrationDocument116 pagesMaster Minimum Equipment List (MMEL) : U.S. Department of Transportation Federal Aviation AdministrationFidel Arellano100% (1)

- Faa Aircraft Maintenance PDFDocument2 pagesFaa Aircraft Maintenance PDFGary100% (1)

- Pilatus-Pc7 ManualDocument19 pagesPilatus-Pc7 ManualRoderick Diaz MoraNo ratings yet

- A320-Auxiliary Power UnitDocument11 pagesA320-Auxiliary Power UnitNabeel S. Al WazzanNo ratings yet

- Hartzell Owner's ManualDocument202 pagesHartzell Owner's ManualJesseNo ratings yet

- Student Manual Makila2A-2A1 Rev 0Document367 pagesStudent Manual Makila2A-2A1 Rev 0Henrique costa mello100% (2)

- Stabilization and Dynamic of Premixed Swirling Flames: Prevaporized, Stratified, Partially, and Fully Premixed RegimesFrom EverandStabilization and Dynamic of Premixed Swirling Flames: Prevaporized, Stratified, Partially, and Fully Premixed RegimesNo ratings yet

- Customer: HVN Type: A330 Rev. Date: Oct 01/11 Manual: AMM Selected Effectivity: ALL 71-00-00-860-817-A - Engine Operation Limits and GuidelinesDocument7 pagesCustomer: HVN Type: A330 Rev. Date: Oct 01/11 Manual: AMM Selected Effectivity: ALL 71-00-00-860-817-A - Engine Operation Limits and GuidelinesLê Viết DũngNo ratings yet

- I. Models CF34-10E5 CF34-10E5A1 CF34-10E6 CF34-10E6A1: Maximum ContinuousDocument6 pagesI. Models CF34-10E5 CF34-10E5A1 CF34-10E6 CF34-10E6A1: Maximum ContinuousEstevam Gomes de AzevedoNo ratings yet

- Operating Instruction PMD55Document218 pagesOperating Instruction PMD55Dilip ARNo ratings yet

- Mike She Printed v1Document370 pagesMike She Printed v1Grigoras MihaiNo ratings yet

- Unit 5 PythonDocument10 pagesUnit 5 PythonVikas PareekNo ratings yet

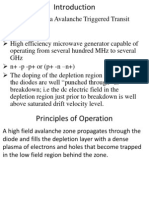

- Trapatt ModeDocument30 pagesTrapatt Modebchaitanya_555100% (1)

- Avimator Beginners GuideDocument13 pagesAvimator Beginners GuideluluzichaNo ratings yet

- 3 Filtration Lecture NotesDocument16 pages3 Filtration Lecture NotesRuben SIbayanNo ratings yet

- Making The Quantum LeapDocument22 pagesMaking The Quantum LeapRJ DeLongNo ratings yet

- Pass4sure 400-101Document16 pagesPass4sure 400-101Emmalee22No ratings yet

- Cima E1 2019 Notes Managing Finance in A Digital WorldDocument91 pagesCima E1 2019 Notes Managing Finance in A Digital Worldumarfarooque869No ratings yet

- Guillang Vs Bedania and SilvaDocument2 pagesGuillang Vs Bedania and Silvajdg jdgNo ratings yet

- UPDATED CV-Neeraj KR - Sharma-2021.Document5 pagesUPDATED CV-Neeraj KR - Sharma-2021.supriyaNo ratings yet

- Fax Cross ReferenceDocument32 pagesFax Cross ReferenceBranga CorneliuNo ratings yet

- Fault Tree AnalysisDocument23 pagesFault Tree Analysiskenoly123No ratings yet

- Due Friday, February 21, 2014 by 5:00 P.M. To The AE312 MailboxDocument3 pagesDue Friday, February 21, 2014 by 5:00 P.M. To The AE312 MailboxankstamanNo ratings yet

- Isuzu 4be1 Engine Manual KolesooreDocument5 pagesIsuzu 4be1 Engine Manual KolesooreRaymart Dealca75% (8)

- Royal Classic e BrochureDocument14 pagesRoyal Classic e Brochureidreesali8654No ratings yet

- Creating Website Banners With Photoshop PDFDocument18 pagesCreating Website Banners With Photoshop PDFLiza ZakhNo ratings yet

- Sweet Delight Co.,Ltd.Document159 pagesSweet Delight Co.,Ltd.Alice Kwon100% (1)

- Prime Time FeaturesDocument15 pagesPrime Time FeaturesPruthwish PatelNo ratings yet

- CH03 HKM Law Investigation and EthicsDocument32 pagesCH03 HKM Law Investigation and Ethicsmilkikoo shiferaNo ratings yet

- Activity 2.1 Test Your Food Safety IQDocument3 pagesActivity 2.1 Test Your Food Safety IQAustin PriceNo ratings yet

- 4-Sided Planer & Moulder Operation Manual: For Spares and Service ContactDocument48 pages4-Sided Planer & Moulder Operation Manual: For Spares and Service ContactAlfred TsuiNo ratings yet

- Maxiim Vehicle Diagnostic ReportDocument3 pagesMaxiim Vehicle Diagnostic ReportCarlos Cobaleda GarcíaNo ratings yet

- 2008 Almocera vs. OngDocument11 pages2008 Almocera vs. OngErika C. DizonNo ratings yet

- Nahid's p4 Solar Fan Final-1 EditedDocument3 pagesNahid's p4 Solar Fan Final-1 Editedrajkumar karjeeNo ratings yet

- Debugging With The PL/SQL Debugger: PhilippDocument51 pagesDebugging With The PL/SQL Debugger: PhilippBenjytox BenjytoxNo ratings yet

- 1.0 Design Andheri Khola Bridge, 1x25m 8.4m 3 GirderDocument18 pages1.0 Design Andheri Khola Bridge, 1x25m 8.4m 3 GirderManoj ChaudharyNo ratings yet

- Periodical Increment CertificateDocument1 pagePeriodical Increment CertificateMD.khalil100% (1)

- Soal Dan Jawaban Audit IIDocument22 pagesSoal Dan Jawaban Audit IIsantaulinasitorusNo ratings yet

- Advantages, Disadvantages and Applications of Regula Falsi MethodDocument12 pagesAdvantages, Disadvantages and Applications of Regula Falsi MethodMd Nahid HasanNo ratings yet