Professional Documents

Culture Documents

Ficha Tecnica 1006 GT

Uploaded by

Jonhatan Duque RamirezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ficha Tecnica 1006 GT

Uploaded by

Jonhatan Duque RamirezCopyright:

Available Formats

@Perkins

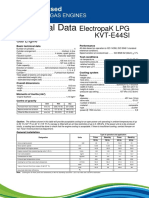

Technical Data

1006TG2A

1000 Series

kW @ 1800 rev/min

ElectropaK

Basic technical data

Performance

Number of cylinders . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 6

Cylinder arrangement .. ... ... ... ... ... ... ... ... ... ... ...Vertical, in-line

Cycle ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..4 stroke

Induction system .. ... ... ... ... ... ... ... ... ... ... ... ... ... . turbocharged

Compression ratio ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 160 : 1

Bore . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 100 mm (3.94 in)

Stroke .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 127 mm (5 in)

Cubic capacity . ... ... ... ... ... ... ... ... ... ... ... ... 5,99 litres (365 in)

Direction of rotation.. ... ... ... ... ... ... ... ... clockwise, from the front

Firing order .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1, 5, 3, 6, 2, 4

Estimated total weight (dry) . ... ... ... ... ... ... ... ... 586 kg (1291 lb)

Estimated total weight (wet). ... ... ... ... ... ... ... ... 623 kg (1373 lb)

Overall dimensions

-height.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1124 mm (44.25 in)

-length.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1559 mm (61.4 in)

-width (including mounting brackets) ... ... ... ... ... 709 mm (27.9 in)

Moments of inertia (mk)

-engine . ... ... ... ... ... ... ... ... ... ... ... ... . 0,2996 kg m (1024 lb in)

-flywheel .. ... ... ... ... ... ... ... ... ... ... ... ... ... ..See option drawings

Complete ElectropaK (wet engine)

-forward from rear of block... ... ... ... ... ... ... ... ... 402 mm (15.8 in)

-above block centre line ... ... ... ... ... ... ... ... ... ... . 187 mm (7.3 in)

-offset to RHS .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... 41 mm (1.6 in)

Note: All data based on operation to BS5514 1987; ISO3046/1

1982; DIN6271

Cyclic irregularity for engine and flywheel (D8001 or D8005)

-at 110% stand-by power .. ... ... ... ... ... ... ... ... ... ... ... ... .. 0,0023

Maximum overspeed limit . ... ... ... ... ... ... ... ... ... ... 2860 rev/min

Speed variation at constant load... ... ... ... ... ... ... ... ... ... .. 0.8%

Test conditions

-air temperature ... ... ... ... ... ... ... ... ... ... ... ... ... . 25 C (80.6 F)

-relative humidity ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 30%

-barometric pressure. ... ... ... ... ... ... ... ... ... 100 kPa (29.5 in Hg)

Average sound pressure level for bare engine (without inlet and

exhaust) at 1 metre ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 95,2 dBA

-all ratings certified to within . ... ... ... ... ... ... ... ... ... ... ... ... . 5%

If the engine is to operate in ambient conditions other than those of

the test conditions, suitable adjustments must be made for any

change in inlet air temperature, barometric pressure or humidity.

For full details, contact Perkins Technical Service Department.

90% of the prime power rating can be applied 10 seconds after the

starter motor is energised. The remaining 10% can be applied 15

seconds after start if the ambient temperature is not less than 15 C

(59 F). If it is less than 15 C (59 F), an immersion heater is

recommended. For additional information, contact Perkins

Technical Service Department.

General installation

Type of operation and application

Designation

Gross engine power

Units

Prime

Stand-by

60Hz

60Hz

kW (bhp)

112,4 (150.7)

123,6 (165.7)

kPa (lbf/in)

1253 (181)

1393 (202)

Piston speed

m/s (ft/s)

7,62 (25)

7,62 (25)

ElectropaK net engine power

kW (bhp)

108,4 (145.4)

119,2 (159.8)

168 (44.4)

Brake mean effective pressure

Engine coolant flow

l/min (UK gal/min)

168 (44.4)

Combustion air flow

m/min (ft/min)

7,38 (260)

7,79 (275)

Exhaust gas flow

m/min (ft/min)

19,96 (704)

22,49 (794)

C (F)

540 (1004)

580 (1076)

Exhaust gas temperature

Cooling fan air flow

m/min (ft/min)

140 (4954)

140 (4954)

Total heat from fuel

kW (Btu/min)

293 (16663)

326 (18539)

Gross heat to power

kW (Btu/min)

112,5 (6398)

125 (7108)

Net heat to power

kW (Btu/min)

117,9 (6704)

120,4 (6847)

Heat to water and lubricating oil

kW (Btu/min)

72,0 (4094)

80,0 (4549)

Heat to exhaust

kW (Btu/min)

84,7 (4816)

89,4 (5084)

Heat to radiation

kW (Btu/min)

23,8 (1353)

31,6 (1797)

Caution: The airflows shown in this table will provide acceptable cooling for an open power unit operating in ambient temperatures of up

to 53 C (46 C if a canopy fitted). If the power unit is to be enclosed totally, a cooling test should be done to check that the engine cooling

is acceptable. If there is insufficient cooling, contact Perkins Technical Service Department.

1006TG2A ElectropaK, right side view

X

806,9

798,9

689,3 rear of alternator

552

189

14 removal

16,4

375 series blade

connector

- 14 NPSI

(plugged)

2 - M10 x 1,5 x 20

153,1

431

393

52 137,8

516,8

533,8

Y

Y

217,7

both sides

260

12

16 A/F

28,6

2 - 20,5

both sides

50

30,3

- 18 NPSI

(plugged water drain)

127,7

210

X

A1537

1006TG2A ElectropaK, left side view

- 14 NPSI

(plugged)

854

786,9

772,5

Cap - 10 PSI

(69 KPA)

200

40

30

Nut and olive to

suit 6,4 pipe

744,2

692,3

611,8

231,9 pipe end

(leak off to fuel tank)

100

78,3

79,2

79,2

388,8

165,1

152,4

131,8

76,2

200

100

308,8

354

441

480,9

515,9

527,8

Centre line

core

338,2

241,3

Y

4 - M12 x 1,75

both sides

234

14 holes

M6 x 1,0

(4 each side and

3 top and bottom)

94

M16 x 1,5

(plugged)

2 - 21

both sides

330

492,3

573,6

594,3

631

701,7

- 18 NPSI

(plugged

water drain)

41,3

41,3

110

84,2

55,6

114,6 103,2

250 series blade

connector

M16 x 1,5 (plugged)

156,4

1150,7

1211

X

A1538

1000 Series

1006TG2A

Cooling system

Radiator

-face area... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 0,39 m (3.36 ft)

-rows and materials ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 4 brass

-gills/inch and material ... ... ... ... ... ... ... ... ... ... ... ... ... 12 copper

-width of matrix... ... ... ... ... ... ... ... ... ... ... ... ... ... 559 mm (22 in)

-height of matrix . ... ... ... ... ... ... ... ... ... ... ... ... . 698 mm (27.5 in)

-pressure cap setting . ... ... ... ... ... ... ... ... ... .75 kPa (10.8 lbf/in)

-maximum top tank temperature ... ... ... ... ... ... ... 103 C (207 F)

Estimated cooling air flow reserve (see caution on

the bottom of the front page).. ... ... ... ... ... .. 0,2 kPa (0.79 in HO)

Fan

-diameter ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 559 mm (22 in)

-drive ratio .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 125 : 1

-number of blades .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 7

-material . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. plastic

Coolant

Maximum pressure head at pump . ... ... ... ... ... ... ... . 8 m (26.2 ft)

Total system capacity ... ... ... ... ... ... ... 27,7 litres (48.7 UK pints)

-draindown capacity .. ... ... ... ... ... ... ... 27,6 litres (48.5 UK pints)

Minimum temperature to engine ... ... ... ... ... ... ... . 70 C (158 F)

Temperature rise across engine ... ... ... ... ... ... .. 7,7 C (13.8 F)

Max permissible external system resistance . ... .. 35 kPa (5 lbf/in)

Thermostat operation range... ... ... ... ... ... .82-93 C (180-199 F)

Electrical System

-type ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. Negative ground

-alternator... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 12/24V options

-starter motor . ... ... ... ... ... ... ... ... ... ... ... ... ... ... 12/24V options

Cold start recommendations

Battery specifications

Minimum

Grade of

starting

SAEJ537 Number

BS3911

engine

Perkins

of

Cold

Cold

temperature lubricating

cranking

amps

batteries

needed

Type

oil

start

amps

-7

19

20W

520

800

-15

10W

520

800

-18

10W

315

535

-20

-4

5W

315

535

kW @ 1800 rev/min

Diesel Fuel to conform to BS2869 1983 Class A2 or ASTM D975

66T Number 2D.

Governor type ... ... ..Mechanical integral with fuel injection pump

-speed control to.. ... ... ... ... ... ... ... ... ... ... ... ...BS5514 Class A1

Induction system

Maximum air intake restriction at engine

-clean filter... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 3 kPa (12 in HO)

-dirty filter. ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 5 kPa (20 in HO)

-air filter type ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... dry element

-minimum dirt capacity ... ... ... ... ... ... ... ... ... ... ... ...353g/m3/min

-turbocharger... ... ... ... ... ... ... ... Garret Airesearch TO4B/L3/0.8F

Lubrication system

Lubricating oil capacity

-total system ... ... ... ... ... ... ... ... ... ... .. 16,1 litres (28.3 UK pints)

-sump only ... ... ... ... ... ... ... ... ... ... ... ... . 13,1 litres (23 UK pints)

Maximum engine operating angles

-front up, front down, right side or left side .. ... ... ... ... ... ... ... . 25

Lubricating oil pressure

-relief valve opens ... ... ... ... ... ... ... 345 - 414 kPa (50 - 59 lbf/in)

-at maximum no-load speed ... ... ... 300 - 340 kPa (43 - 49 lbf/in)

-idle speed... ... ... ... ... ... ... ... ... ... ... .. 62 - 90 kPa (9 - 13 lbf/in)

Lubricating oil temperature

-normal oil temperature ... ... ... ... ... ... ... ... ... ... ... 95 C (203 F)

-maximum ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 125 C (257 F)

Oil consumption as a % of fuel consumption .. ... ... ... ... 0.5% max

Recommended SAE viscosity

A Single of multigrade oil which conforms to API CD/SE or CCMC

D4 must be used.

0W

5W20

10W30

15W40

20W50

20

30

40

-30

-22

Exhaust system

Maximum back pressure for total system .. ... ... 6 kPa (1.77 in Hg)

Inside diameter of outlet at maximum rating .. ... ... 78 mm (3.07 in)

Note: Changes to induction restriction, exhaust back pressure and

fuel viscosity/remperature/specific gravity, can affect power output.

For further details contact Perkins Technical Service Department.

-20

-4

-10

14

0

32

10

50

20

68

30

86

40

50 oC

104 122oF

Ambient temperarture

W1355

Mountings

Maximum bending moment at

rear face of block ... ... ... ... ... ... ... ... ... ... ... 1130 Nm (835 lbf ft)

Type of injection . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...Direct

Fuel injection pump ... ... ... ... ... ... ... ... ... ... ... ... ... .. Rotary type

Fuel atomiser . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .Multi-hole

Nozzle opening pressure ... ... ... ... ... ... ... ... 23,3 MPa (230 atm)

Fuel lift pump

-delivery/hour . ... ... ... ... ... ... ... ... ... ...133,7 litres (235 UK pints)

-pressure ... ... ... ... ... ... ... ... ... ... ... ... ... ... .30 kPa (4.35 lbf/in)

Maximum suction head .. ... ... ... ... ... ... ... ... ... ... ... ...1,8 m (6 ft)

Maximum static pressure head .. ... ... ... ... ... ... ... ... ...3 m (9.8 ft)

@Perkins

Perkins Engines Company Limited

Peterborough PE1 5NA United Kingdom

Telephone +44 (0) 1733 583000

Fax +44 (0) 1733 582240

www.perkins.com

All information in the document is substantially correct at the time

of printing but may be subsequently altered by the company.

Distributed by

ublication No. TPD 1466E, Issue 1. Printed in England. Perkins Engines Company Limited.

Fuel system

1006TG2A ElectropaK, rear view

Z

Trim line

79

1

G

- 19 BSP drain

4

plugged

172,5

Z

Engine front mounting bracket with radiator

Z

381

704 element removal

327,8

277,8

328,2

323,2

170 fan cowling tapping

274 return to tank

258,4 timing case

255,4 water return

170

66,2

43,7 centre

filler cap

100

Removal

68

- 14 NPSI

(plugged)

651,8

259

864

223,3

488

20

158,4

Trim line

388,8

390,8

396,7

222,8

45

See option D0000 sht 5 for spigot

bore and flywheel fixing details

152

152

228 front mounting

228 front mounting

238,1

241,3 rear mounting

238,1

241,3 rear mounting

12 - M10 x 1,5 x 20

drill pattern

flange and spigot

to no. 3 S.A.E.

265

253

265

318,6

273,6

302

Z

A1539

1006TG2A ElectropaK, other details

Inlet connection

1,4

1,2 7

2

6,1

6,0 5

5

182,3

17

,

1 7 78

,2 7

3,3

3,0 0

5

6,

5

6,4 8

8

8,

1

8,0 8

8

Z

Eff. 82,6

11

,

10 4 3

,92

9,5

30

-2

0U

NF

355,5

30

241,6

329,3 max

1

/

2

1

1,

11 55

,30

9,

5

9 ,2 2

7

Section A-A

ALTERNATOR - BOSCH 55A - 97 BELT LINE

Trim line

PUMP - FUEL LIFT

48

Z

7,6

28,5

35,66

34,72

1,14

x 45

0,76

30

22,2

12 holes 1/2 - 20 UNF x 19

equispaced on 107,95 P.C.D.

133,32

133,27

76,2

51,991

51,966

46

12

Arrow position

cyl no 1 at TDC

250 series

blade

connector

Y

1

11,05 A/F

- 27 NPTF

1,02 max

15,8

LUB. OIL PRESSURE SWITCH

15,1

22,2

CRANKSHAFT PALM

55,6

8,1

6,6

Z

279,1

20

231,1

18,8

390,8

20 removal

89,7

8,5

11,2

30

R 56

77,98

77,47

Elbow flange detail 30

3 - M10 x 1,5

equispaced

on 104,8 P.C.D.

3,2

9,4

R 11

11,4

1

/2 - 20 UNF

EXHAUST OUTLET FLANGE

Section A - A

205,4

116

3 holes 11

equispaced

on 104,78 P.C.D.

158,2

128,2

R 56

81,28

80,01

PRE - FILTER - STANADYNE

10,67

8,89

90

Z

PLATES - LIFTING

62

Exhaust pipe flange

30

50

15

3 holes 11 dia

on 127 P.C.D.

X

677,6

Blade connector

644,4

6,4

187,5

Terminal M10 x 1,5

View on arrow A

88,880

88,793

7,5

226,2

129

Z

Y

STARTER MOTOR

X

Y

2 - 250 series blade

connectors for electric

shut off

Nominal gear

ring clearance 3

30,5

28,5

6,7 for

throttle control

80

108,8

e

Blad

s

conn

79

35

157,2

37,7

61,5

Trim line

R 44,5

H igh

idle

1,

12

Low

idle

23

264,5

FUEL PUMP - STANADYNE

23

View on arrow B

A1540

You might also like

- High-Security Mechanical Locks: An Encyclopedic ReferenceFrom EverandHigh-Security Mechanical Locks: An Encyclopedic ReferenceRating: 5 out of 5 stars5/5 (9)

- Power Electronics Design: A Practitioner's GuideFrom EverandPower Electronics Design: A Practitioner's GuideRating: 4.5 out of 5 stars4.5/5 (3)

- 4006-23TRS1&2 Gas EngineDocument16 pages4006-23TRS1&2 Gas Enginenanocycle100% (1)

- 4008-30TAG3 TPD2011E2 Nov2015Document5 pages4008-30TAG3 TPD2011E2 Nov2015tienlamNo ratings yet

- Incompressible Flow Turbomachines: Design, Selection, Applications, and TheoryFrom EverandIncompressible Flow Turbomachines: Design, Selection, Applications, and TheoryNo ratings yet

- Technical Data: @perkinsDocument6 pagesTechnical Data: @perkinsOGNo ratings yet

- Financial Market and Portfolio Management Assignment 2Document6 pagesFinancial Market and Portfolio Management Assignment 2leeroy mekiNo ratings yet

- 1104C 44taDocument8 pages1104C 44taWilmerNo ratings yet

- 404D 22Document8 pages404D 22aiulica20100% (2)

- Perkins 1100 Series HDDocument8 pagesPerkins 1100 Series HDSaadNo ratings yet

- Individual TaxpayersDocument3 pagesIndividual TaxpayersJoy Orena100% (2)

- 404D-22T Iopu (Tpd1717e2)Document10 pages404D-22T Iopu (Tpd1717e2)hecazorlaNo ratings yet

- Unit 3: The Catering Service Industry Topic: Catering Service Concept Digest (Discussion)Document5 pagesUnit 3: The Catering Service Industry Topic: Catering Service Concept Digest (Discussion)Justin MagnanaoNo ratings yet

- Technical Data: @perkinsDocument8 pagesTechnical Data: @perkinsHoang Minh HungNo ratings yet

- Technical Data: @perkinsDocument6 pagesTechnical Data: @perkinsHendra SyalalaNo ratings yet

- Microprocessor Programming and Applications for Scientists and EngineersFrom EverandMicroprocessor Programming and Applications for Scientists and EngineersNo ratings yet

- Electricity BillDocument1 pageElectricity BillSushila SinghNo ratings yet

- 1104a 44tg2perkinsDocument8 pages1104a 44tg2perkinsEdilson Matias CastroNo ratings yet

- Manual Motor Perkins PDFDocument8 pagesManual Motor Perkins PDFRobertoSoares0% (1)

- Technical Data: 1100 SeriesDocument8 pagesTechnical Data: 1100 SeriesWillianNo ratings yet

- 1104C-44T IOPU Technical Data Sheet PDFDocument8 pages1104C-44T IOPU Technical Data Sheet PDFBob100% (2)

- 1104A-44TG1 PerkinsDocument8 pages1104A-44TG1 PerkinsMario Eduardo Santos MartinsNo ratings yet

- 1104 C44 TAG2 TPD1637 Technical Data SheetDocument8 pages1104 C44 TAG2 TPD1637 Technical Data SheetFarhan JuttNo ratings yet

- SSTMCV Retail PowerDocument5 pagesSSTMCV Retail Powervipin.yadavNo ratings yet

- Dau Terminal AnalysisDocument49 pagesDau Terminal AnalysisMila Zulueta100% (2)

- 3 1524 (1500)Document6 pages3 1524 (1500)mkNo ratings yet

- 1006tag2 PDFDocument6 pages1006tag2 PDFMuhammad Ahmad100% (4)

- Ficha Tecnica C 40Document1 pageFicha Tecnica C 40Abrar HussainNo ratings yet

- Technical Data: 400 Series 403C-11GDocument6 pagesTechnical Data: 400 Series 403C-11Gmuhammad arifNo ratings yet

- 1006TG2A - Especificaciones MLS-100Document7 pages1006TG2A - Especificaciones MLS-100Lucia TorresNo ratings yet

- 4006-23tag2a 3a (Tpd1512e-4)Document14 pages4006-23tag2a 3a (Tpd1512e-4)Soubhik MishraNo ratings yet

- Technical Data Sheet - Kvt-E44si - LPG - Elektropak - V1.2Document2 pagesTechnical Data Sheet - Kvt-E44si - LPG - Elektropak - V1.2mebarki aberraoufNo ratings yet

- Technical Data: - HA?DIDocument6 pagesTechnical Data: - HA?DIOGNo ratings yet

- 4006-23tag2a - Tag3aDocument14 pages4006-23tag2a - Tag3aImran MazharNo ratings yet

- 1006TG2A 103 8kW@1500 (TPD1465E-2)Document8 pages1006TG2A 103 8kW@1500 (TPD1465E-2)Taher Al-TammamNo ratings yet

- Technical Data: - HA?DIDocument6 pagesTechnical Data: - HA?DIOGNo ratings yet

- Technical Data: @perkinsDocument2 pagesTechnical Data: @perkinsOGNo ratings yet

- General Engine SpecificationsDocument4 pagesGeneral Engine Specificationstruong nguyenNo ratings yet

- Technical Data: @perkinsDocument8 pagesTechnical Data: @perkinsdfheardNo ratings yet

- 1104C 44na - (TPD1532 E1)Document8 pages1104C 44na - (TPD1532 E1)朕宏國際技術頻道No ratings yet

- Technical Data: @perkinsDocument6 pagesTechnical Data: @perkinsOGNo ratings yet

- Technical Data: 400 Series 404C-22GDocument6 pagesTechnical Data: 400 Series 404C-22GmkNo ratings yet

- LEHM20671-00 - C4.4 Electronic Data SheetDocument3 pagesLEHM20671-00 - C4.4 Electronic Data Sheetkman548No ratings yet

- Technical Data: @perkinsDocument6 pagesTechnical Data: @perkinsHendra SyalalaNo ratings yet

- 1103A-33TG2 - (Sound Level)Document1 page1103A-33TG2 - (Sound Level)Md ShNo ratings yet

- EMI4050T18 WebDocument1 pageEMI4050T18 WebJuli B.No ratings yet

- Perkins 1104 44tg1 Spec SheetDocument8 pagesPerkins 1104 44tg1 Spec SheetRodrigoThuLokithoPkmzNo ratings yet

- TPD2127 1206D-E70TTAG1Document4 pagesTPD2127 1206D-E70TTAG1marwanqaisi85No ratings yet

- Cooling of 1103A-33GDocument2 pagesCooling of 1103A-33GMd ShNo ratings yet

- Buldozer - CASE 550H - Specs 1-18-2012 - ENDocument4 pagesBuldozer - CASE 550H - Specs 1-18-2012 - ENMaurizio De LucaNo ratings yet

- Articulated Dump TrucksDocument8 pagesArticulated Dump TrucksZouhair WahbiNo ratings yet

- John Deere DGset DatasheetDocument3 pagesJohn Deere DGset DatasheetChandru RangarajNo ratings yet

- KG 850,650 LB: Maximum GVWDocument4 pagesKG 850,650 LB: Maximum GVWVasquez EjvbNo ratings yet

- Electropak: 1206A-E70Ttag2Document4 pagesElectropak: 1206A-E70Ttag2Andres SorinNo ratings yet

- TPD2158E2Document4 pagesTPD2158E2MohamedJaberKutkutMjkNo ratings yet

- Komatsu Pala Pc4000Document8 pagesKomatsu Pala Pc4000Franco Rojas BozaNo ratings yet

- Case 570mxtspDocument4 pagesCase 570mxtspJesús PatiñoNo ratings yet

- Technical Data: 4000 Series 4008TAG 4008TAG1 4008TAG2Document8 pagesTechnical Data: 4000 Series 4008TAG 4008TAG1 4008TAG2Ulma HudinNo ratings yet

- TPD2076 1Document7 pagesTPD2076 1Alfonso RivasNo ratings yet

- 4016T 61TRG32250kVA For 50Hz PDFDocument13 pages4016T 61TRG32250kVA For 50Hz PDFParinya100% (1)

- AKSA 6.49L Inline 6 Turbo Diesel Engine SpecsDocument3 pagesAKSA 6.49L Inline 6 Turbo Diesel Engine SpecsChristian Rivera FloverNo ratings yet

- 300c Technical DataDocument18 pages300c Technical DataRobin HughesNo ratings yet

- 1103a 33GDocument8 pages1103a 33GahmedalgaloNo ratings yet

- Chapter 7 - Trade and Investment EnvironmentDocument7 pagesChapter 7 - Trade and Investment EnvironmentMa. Cristel Rovi RibucanNo ratings yet

- Basic Accounting Principles and Budgeting FundamentalsDocument24 pagesBasic Accounting Principles and Budgeting Fundamentalskebaman1986No ratings yet

- Payroll Activity SummaryDocument1 pagePayroll Activity SummaryChoo Li ZiNo ratings yet

- SOLUTIONS : Midterm Exam For Simulation (CAP 4800)Document14 pagesSOLUTIONS : Midterm Exam For Simulation (CAP 4800)Amit DostNo ratings yet

- Asset-V1 RICE+46 6 4010+2021 Q1+type@asset+block@MCQs For HO SDH New WBCS 2nd SM 2nd Class Constitution QDocument5 pagesAsset-V1 RICE+46 6 4010+2021 Q1+type@asset+block@MCQs For HO SDH New WBCS 2nd SM 2nd Class Constitution QSourin bisalNo ratings yet

- Brochures Volvo Engines d11 CanadaDocument4 pagesBrochures Volvo Engines d11 CanadaDIONYBLINK100% (2)

- Dimetra Tetra System White PaperDocument6 pagesDimetra Tetra System White PapermosaababbasNo ratings yet

- Mr. Arshad Nazer: Bawshar, Sultanate of OmanDocument2 pagesMr. Arshad Nazer: Bawshar, Sultanate of OmanTop GNo ratings yet

- bq76pl455 RegistersDocument132 pagesbq76pl455 RegistersAhmet KARANo ratings yet

- Human Computer InteractionDocument12 pagesHuman Computer Interactionabhi37No ratings yet

- EffectofObligations PDFDocument0 pagesEffectofObligations PDFÄnne Ü KimberlieNo ratings yet

- Elegant Tranquil Blue Agency by SlidesgoDocument41 pagesElegant Tranquil Blue Agency by SlidesgoJoana TavaresNo ratings yet

- Tds Uniqflow 372s enDocument1 pageTds Uniqflow 372s enm daneshpourNo ratings yet

- Optimization TheoryDocument18 pagesOptimization TheoryDivine Ada PicarNo ratings yet

- Green Ecobuses Run On This Route.: BusesDocument6 pagesGreen Ecobuses Run On This Route.: BusesLuis DíazNo ratings yet

- Priceliost Ecatalog 2021 Div. DiagnosticDocument2 pagesPriceliost Ecatalog 2021 Div. Diagnosticwawan1010No ratings yet

- Quiz UtpDocument7 pagesQuiz UtplesterNo ratings yet

- Lifetime Physical Fitness and Wellness A Personalized Program 14th Edition Hoeger Test BankDocument34 pagesLifetime Physical Fitness and Wellness A Personalized Program 14th Edition Hoeger Test Bankbefoolabraida9d6xm100% (27)

- Group 2 - Assignment 2 - A Case Study of Telecom SectorDocument13 pagesGroup 2 - Assignment 2 - A Case Study of Telecom Sectorfajarina ambarasariNo ratings yet

- Plastic Waste Powerpoint TemplateDocument39 pagesPlastic Waste Powerpoint TemplateVinh Lê KhảiNo ratings yet

- Tagum Doctors Hospital Inc.,: Republic of The Philippines Department of Health National Highway 54, Tagum CityDocument8 pagesTagum Doctors Hospital Inc.,: Republic of The Philippines Department of Health National Highway 54, Tagum CityRoel John Atamosa CasilacNo ratings yet

- FM Butterfly ValvesDocument3 pagesFM Butterfly ValvesahsanNo ratings yet

- TurboVap LV Users ManualDocument48 pagesTurboVap LV Users ManualAhmad HamdounNo ratings yet

- Block P2P Traffic with pfSense using Suricata IPSDocument6 pagesBlock P2P Traffic with pfSense using Suricata IPSEder Luiz Alves PintoNo ratings yet