Professional Documents

Culture Documents

C Tpat

Uploaded by

Trivesh SOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C Tpat

Uploaded by

Trivesh SCopyright:

Available Formats

Combining ISO 9001 with C-TPAT requirements: A simple approach to building an integrated Quality Management System.

Apr16 Written by:Miriam Boudreaux 4/16/2010 1:09 PM Sweet Challenge I was called to a prospective client to help them implement ISO 9001. They seemed very interested at improving their processes in order to increase their quality and revenues. After contract negotiations, we were given the green light and quickly began process mapping the companys main functions. As we moved from process mapping to procedure development, we have been hearing that the organization had also been trying to get C-TPAT certification for several months. With our experience in information security we knew we could help out, but decided to wait. Soon we were officially told the company really wants to get C-TPAT certified, could you take a look at the C-TPAT requirements? At this point we had already developed the Quality Manual, the required ISO procedures and also the company procedures to serve their core processes. Surprise! A new variable was given to us and we loved it. What we really loved is the idea that we would be able to help the organization implement a single quality management system that would help them comply with both the ISO 9001 requirements as well as the C-TPAT requirements. Integrated Quality Management System, great! One of our best consulting traits!. Back To the Process Map Board As we got acquainted with the C-TPAT requirements, we found more similarities to the ISO 27001 standard, which of course is founded on the ISO 9001 standard. C-TPAT requirements however are not structured the way ISO 9001 is and also they are not as well organized. CTPAT requirements are newer than ISO 9001 and obviously ISO 9001 counts with constant reviews by its international committees and subcommittees. We decided to go back to our original process map to identify where each of the C-TPAT requirements could be addressed. The objective was to use existing processes indentified during the process mapping stage at all possible and wherever we could not find a process already established then we would create a new one.

Here is a sample picture of an organizations Process Map.

Each of the blocks above represented a procedure in itself. Each of these procedures was reviewed to assess if it needed additional measures to satisfy C-TPAT requirements. Basically we made the following decisions: 1. If the C-TPAT requirements were same or less than that of ISO 9001:2008, then we would set the ISO 9001 standard as the requirements and make no change to the procedure. 2. If the C-TPAT requirements were above the ISO 9001:2008 requirements, then we would address those requirements in the procedure by using italic font, to show that it is a C-TPAT requirement. 3. If the C-TPAT requirement did not have a relationship to ISO 9001:2008 then we would create a new procedure. The following table shows 2 C-TPAT requirements in parallel with ISO 9001:2008 requirements: # 1 C-TPAT Requirement For business partners eligible for C-TPAT certification, the Customs Broker must have documentation (e.g., C-TPAT certificate, SVI number, etc.) indicating whether these business partners are, or are not C-TPAT certified. Current or prospective business partners who have obtained a certification in a supply chain security program being administered by foreign Customs Administration should be required to indicate their status of participation to the broker. To the extent such information can be obtained, brokers will maintain secure provider lists of C-TPAT certified (or equivalent) service providers in all relevant categories. Access controls prevent unauthorized entry to facilities, maintain control of employees and visitors, and protect company assets. Access controls must include the positive identification ISO 9001 Requirement 7.4.1. The organization shall evaluate and select suppliers based on their ability to supply product in accordance with the organizations requirements. Criteria for selection, evaluation and re-evaluation shall be established. Records of the results of evaluation and any necessary actions arising from the evaluation shall be maintained.

of all employees and visitors at all points of entry.

In the case of item #1, the C-TPAT requirements were in essence merged with the organizations Supply Chain procedure to ensure that suppliers evaluation includes review of the C-TPAT certificate, SVI number, etc. These requirements were made in italic on the same procedure. In the case of item #2, an ISO requirement regarding security does not exist in ISO 9001, with the closest being perhaps 6.3 Infrastructure. In this case, we decided to go ahead and create a new procedure to address how access and security controls would be implemented and maintained. Overall we only had to add 2 procedures, one to address physical security and another to address information security. In most procedures also, the requirements section was modified to ensure that it explicitly show that the procedure satisfies the requirements of ISO 9001 as well as C-TPAT. We also made sure that the Quality Policy was modified to be a Quality and Security Policy to show their commitment to cargo and information security. Implementation Once all processes and procedures were established, they were rolled out as part of the Web QMS implementation. Employees were trained in their quality management system, which as we explained above satisfied both the requirements of C-TPAT and ISO 9001:2008. Most employees felt comfortable with the system, as they had been involved during the development process. After a few months of implementation, the Internal Audit was conducted. As ISO 9001 requires any company to include legislative, statutory requirements, C-TPAT requirements were also audited. There were several nonconformities but all were closed prior to the External Audit. A Management Review was also conducted and review of the organizations C-TPAT profile was included in the presentation and made part of the agenda so that it will be reviewed periodically once a year. Both the C-TPAT audit and ISO 9001:2008 were conducted with successful outcomes. The organization was made a C-TPAT partner and received its ISO 9001:2008 certification within a month of each other. Integrated QMS is always a Winner Whenever an organization wants its employees to follow procedures, it is best to have a single system of procedures than 2 or more set of directives. That is what an Integrated QMS means, a single set of directives that your employees can follow and identify with. An Integrated QMS can satisfy multiple requirements, is simple to maintain and best of all easy to follow! That is what Mireaux Management Solutions and the Web QMS can do for you to help you become a world class quality organization. ******** About C-TPAT

C-TPAT stands for Customs-Trade Partnership Against Terrorism and is a voluntary supply chain security program led by U.S. Customs and Border Protection (CBP) and focused on improving the security of private companies' supply chains with respect to terrorism. The program was launched in November 2001 with seven initial participants, all large U.S. companies. As of April 2005, there were more than 9000 companies participating.

You might also like

- IATF 16949:2016 Audit Guide and Checklist 2nd EditionFrom EverandIATF 16949:2016 Audit Guide and Checklist 2nd EditionRating: 4.5 out of 5 stars4.5/5 (10)

- ISO 9001:2015 Quality Manual (Preview)Document9 pagesISO 9001:2015 Quality Manual (Preview)Centauri Business Group Inc.47% (51)

- Integrated Management System ManualQMS, EMS, OHSASDocument46 pagesIntegrated Management System ManualQMS, EMS, OHSASTrivesh S100% (7)

- 01 Alison 9001Document34 pages01 Alison 9001Thant AungNo ratings yet

- Benchmarking Best Practices for Maintenance, Reliability and Asset ManagementFrom EverandBenchmarking Best Practices for Maintenance, Reliability and Asset ManagementNo ratings yet

- Tranformer Oil Testing ProcedureDocument2 pagesTranformer Oil Testing ProcedureTrivesh S100% (2)

- ISO 9001 Gap Analysis ChecklistDocument4 pagesISO 9001 Gap Analysis ChecklistmukundisoNo ratings yet

- Project On Iso 9001:2015 Mgt-408Document7 pagesProject On Iso 9001:2015 Mgt-408Abubakar MughalNo ratings yet

- Iso 9001 - 2015 Quality Manual - Trace InternationalDocument37 pagesIso 9001 - 2015 Quality Manual - Trace Internationalchaminda nayanajithNo ratings yet

- Iso 9001 Audit Trail: A Practical Guide to Process Auditing Following an Audit TrailFrom EverandIso 9001 Audit Trail: A Practical Guide to Process Auditing Following an Audit TrailRating: 5 out of 5 stars5/5 (3)

- Quality Management Iso9001:2015 Changes: A Guide to ImplementationFrom EverandQuality Management Iso9001:2015 Changes: A Guide to ImplementationRating: 5 out of 5 stars5/5 (1)

- FSSAI Inspection Checklist and Other FormsDocument24 pagesFSSAI Inspection Checklist and Other FormsTrivesh SNo ratings yet

- Food Safety ChecklistDocument4 pagesFood Safety Checklistjalali007No ratings yet

- Iso 9001 ThesisDocument7 pagesIso 9001 ThesisPaperWritersOnlineCanada100% (2)

- What Is ISO 9001 - 9001academyDocument16 pagesWhat Is ISO 9001 - 9001academytaufik_ahmad_4100% (1)

- Iso 90012015 Faq WP FinalDocument3 pagesIso 90012015 Faq WP FinalGirish KumarNo ratings yet

- Checklist of Mandatory Documentation Required by ISO 9001-2015 PDFDocument12 pagesChecklist of Mandatory Documentation Required by ISO 9001-2015 PDFΠερικλής ΣδραβόπουλοςNo ratings yet

- Master Thesis Iso 9001Document8 pagesMaster Thesis Iso 9001GhostWriterForCollegePapersUK100% (2)

- CMMI n2 n3 Comparison Iso 9001 2000Document9 pagesCMMI n2 n3 Comparison Iso 9001 2000jgonzalezsanz8914No ratings yet

- ISO9001 2015 Frequently Asked QuestionsDocument5 pagesISO9001 2015 Frequently Asked QuestionsJyoti Jeevan SharmaNo ratings yet

- 815 CMII Enhancement of ISO 9001Document8 pages815 CMII Enhancement of ISO 9001dissymmetryNo ratings yet

- 5952 Frequently Asked Questions 9001 2015Document4 pages5952 Frequently Asked Questions 9001 2015ramanadkNo ratings yet

- Internship Proposal Nitol Motors ISODocument6 pagesInternship Proposal Nitol Motors ISOrokyom100% (1)

- ISO 9001-2008 ManagementDocument4 pagesISO 9001-2008 ManagementJason TehNo ratings yet

- Iso 9001 Thesis PDFDocument8 pagesIso 9001 Thesis PDFmeganmoorearlington100% (2)

- I So GuidebookDocument12 pagesI So GuidebookMuhammad Rizal Iqbal FalahNo ratings yet

- IsoDocument47 pagesIsofree2dreamsNo ratings yet

- ISO 9001-2015 TrainingDocument14 pagesISO 9001-2015 TrainingZain AliNo ratings yet

- CSA Group DivisionsdDocument4 pagesCSA Group Divisionsdsam1hi5No ratings yet

- Twelve-Step Transition Process Using ISO 9001:2015 Transition ToolkitDocument8 pagesTwelve-Step Transition Process Using ISO 9001:2015 Transition ToolkitMaría DesiderioNo ratings yet

- Quality Management Internal Auditing in Smalland Medium-Sized Companies An Exploratorystudy On Factors For Significantly Improving Qualityperformance PDFDocument22 pagesQuality Management Internal Auditing in Smalland Medium-Sized Companies An Exploratorystudy On Factors For Significantly Improving Qualityperformance PDFVjeran Furlan100% (1)

- Iso 9001 - 2015 ALISONDocument5 pagesIso 9001 - 2015 ALISONAymane LAKHALNo ratings yet

- ISO 9001 Application in Pizza CompanyDocument10 pagesISO 9001 Application in Pizza CompanyAndra100% (2)

- ISO 9001 Whitepaper The History and Future of ISO 9001Document4 pagesISO 9001 Whitepaper The History and Future of ISO 9001Sunit MishraNo ratings yet

- 5 Main Changes Expected in ISO 9001:2015 From The 2014 Draft International Standard (DIS)Document2 pages5 Main Changes Expected in ISO 9001:2015 From The 2014 Draft International Standard (DIS)Jeff DrewNo ratings yet

- Report On Total Quality ManagementDocument20 pagesReport On Total Quality Managementfaiza bhattiNo ratings yet

- Module - 5 TQM (Mgmcet) FinalDocument31 pagesModule - 5 TQM (Mgmcet) FinalSiddharth PatilNo ratings yet

- QualityPediaDocument2 pagesQualityPediasuparnaNo ratings yet

- BVC+ISO 9001+2008+interpretationDocument42 pagesBVC+ISO 9001+2008+interpretationmeinzul100% (1)

- Famina ME 2nd Sem Module 5Document18 pagesFamina ME 2nd Sem Module 5Abul KhayasNo ratings yet

- CQI IRCA ISO90012015 White PaperDocument6 pagesCQI IRCA ISO90012015 White PaperHina KhurshidNo ratings yet

- QMS-An Executive SummaryDocument10 pagesQMS-An Executive SummaryGary WhiteNo ratings yet

- Iso9001 PDFDocument6 pagesIso9001 PDFblitzkrigNo ratings yet

- Twelve-Step Transition Process From ISO 9001:2008 To 2015 RevisionDocument6 pagesTwelve-Step Transition Process From ISO 9001:2008 To 2015 RevisionIonut GabrielNo ratings yet

- Webinar, 20 June 2014 "ISO 9001 - The Story So Far"Document10 pagesWebinar, 20 June 2014 "ISO 9001 - The Story So Far"abdelmutalabNo ratings yet

- Standards and Management SystemsDocument4 pagesStandards and Management SystemsaaaviatorNo ratings yet

- History of ISO 9001 RevisionsDocument60 pagesHistory of ISO 9001 Revisionsromy sibugNo ratings yet

- Summary of Iso 9001:2015Document3 pagesSummary of Iso 9001:2015Anonymous fcqc0EsXHNo ratings yet

- The New Systematic Approach To The Risks: 22/23 December 2016Document14 pagesThe New Systematic Approach To The Risks: 22/23 December 2016chaouch.najehNo ratings yet

- ISO 9001:2000 Combined The Three Standards: Process ManagementDocument14 pagesISO 9001:2000 Combined The Three Standards: Process ManagementMayank ManiNo ratings yet

- Iso-Ts 16949 (2002)Document6 pagesIso-Ts 16949 (2002)Serggie TabanaoNo ratings yet

- Quality Management SystemsDocument4 pagesQuality Management SystemsArman Ul NasarNo ratings yet

- Quality Management With ISO 9001Document24 pagesQuality Management With ISO 9001Mardi Rahardjo100% (1)

- Sgs Iso 9001 2015 Update Dis Version A4 en 14Document3 pagesSgs Iso 9001 2015 Update Dis Version A4 en 14오동욱No ratings yet

- PROJECT .. SEMESTER FALL-2019 Submission Date (December 18, 2019) BY Sabahat RaniDocument16 pagesPROJECT .. SEMESTER FALL-2019 Submission Date (December 18, 2019) BY Sabahat RaniAbubakar MughalNo ratings yet

- Quality SystemsDocument31 pagesQuality SystemsfriendNo ratings yet

- What Are The ISO 9001 RequirementsDocument11 pagesWhat Are The ISO 9001 RequirementsMd. AnwarKabirNo ratings yet

- Developing An Asset Maintenance Quality Management System and Processes To ISO 9001 RequirementsDocument8 pagesDeveloping An Asset Maintenance Quality Management System and Processes To ISO 9001 RequirementsFemi ObiomahNo ratings yet

- Cqi Iso 9001 2015Document6 pagesCqi Iso 9001 2015andruta1978100% (1)

- 10 Tips For ISO Internal AuditDocument6 pages10 Tips For ISO Internal Auditharivs80No ratings yet

- 0 AuditComply IATF TraDocument3 pages0 AuditComply IATF TraPaulaMagalhãesNo ratings yet

- Process Management AuditingDocument98 pagesProcess Management AuditingMarlon R. FelicianoNo ratings yet

- CMMI ProcessDocument1 pageCMMI ProcessTrivesh SNo ratings yet

- Kwality Cable India: Manufacturer Quality PlanDocument3 pagesKwality Cable India: Manufacturer Quality PlanTrivesh SNo ratings yet

- PDIRDocument5 pagesPDIRTrivesh S100% (1)

- Quality ObjectivesDocument1 pageQuality ObjectivesTrivesh SNo ratings yet

- 04 AirAct&RulesDocument1 page04 AirAct&RulesTrivesh SNo ratings yet

- Brand Analysis India Private Limited Risk Assessment: Risk Risk Impact C I A Risk Value Threat Miltigation PlanDocument2 pagesBrand Analysis India Private Limited Risk Assessment: Risk Risk Impact C I A Risk Value Threat Miltigation PlanTrivesh SNo ratings yet

- Vendor Evaluation FarmDocument2 pagesVendor Evaluation FarmTrivesh SNo ratings yet

- Bhushan Steel Limited - SBDDocument6 pagesBhushan Steel Limited - SBDTrivesh SNo ratings yet

- QSP-7.1.4 Work EnvironmentDocument2 pagesQSP-7.1.4 Work EnvironmentTrivesh SNo ratings yet

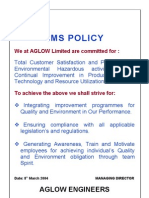

- Ims PolicyDocument1 pageIms PolicyTrivesh SNo ratings yet

- Integrated Procedure 10 May 2018Document36 pagesIntegrated Procedure 10 May 2018Trivesh S100% (1)

- C TpatDocument4 pagesC TpatTrivesh SNo ratings yet

- AttitudeDocument2 pagesAttitudeTrivesh SNo ratings yet

- STD SlideDocument8 pagesSTD SlideTrivesh SNo ratings yet

- Part Submission Warrant: Grom P473 B 71000540 M11961Document1 pagePart Submission Warrant: Grom P473 B 71000540 M11961Trivesh SNo ratings yet