Professional Documents

Culture Documents

Process of Coal Quality Control

Uploaded by

Hamza WahidOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process of Coal Quality Control

Uploaded by

Hamza WahidCopyright:

Available Formats

Study on Whole Process Quality Control in Coal Production Based on Industry Engineering

LI Yingde1, WU Yanzhong2 1. College of Mechanical Engineering, Zhejiang University of Technology, Hangzhou , P.R.China,310014 2. Shandong University of Science and Technology , taian , P.R.China,271000 Liyingde2008@sina.com Abstract: This paper constitutes the entire process quality control method starting with the analysis to the quality control key indexes in mine production, analysis the main contents of the entire process quality control method which includes coal cutting coal loading coal transportation moving conveyer support goaf management , the quality control method reaches to the working procedure level, achieving the entire process quality control to the mining production. The method provides the positive meaning to the practice of mines and promotes the utilization of industry engineering in tradition excavate industries. Keywords: Industry Engineering; Mining Production; Whole Process Quality Control

1 Introduction

In last few years, the industry engineering has made considerable progress in manufacturing enterprises, but the application of IE in the manufacture of coal is still at an initial stage. So it is urgent to optimize the coal production system with the theory and the methods of IE, combining the coal production system factures and the objective of high quality, high production, high efficiency, low cost on the basis of safe production. Now, the study on the application of industry engineering in coal production mainly focus on the popularization, methods, studying on time quota and standardization of mining process with fundamental industry engineering, the application of information technology in production and so on. Fang Wenjie [1] pointed out that the popularization of industry engineering in coal production system should be carried out in the fields which include capital construction, mining, coal washing and deep processing, electricity equipment manufacturing and maintenance and so on. The guiding ideology and basic methods of each fields were given based on the industry engineering theory and methods. Song Linfa[2] studied the standard formulation in coal production scene management with the methods of industry engineering. Duan Yuling[3] studied the produce process and key steps to mining from the perspective of the fundamental industry engineering. Chen Liangpeng[4] explained that industry engineering can promote mines to improve staff quality and improve technology, taking the improvement of the tunneling method with industry engineering methods as an example. Lu Houjun[5] analyses the problems in information construction in mines and pointed out the application and developmental direction of industry engineering in future. Now, the insufficient research to how to control the coal quality with industry engineering ideas and methods is a limitation. The coal produce process concludes exploit, transportation, wash and selected. It has great practical meanings to enhance coal quality, save resources and add benefit by strengthen control of coal quality in process of production, and we should pay more attention to it.

2 Analysis of coal quality control indexes

The coal quality is the characteristics which could satisfy the different requirements in the course of own process of formation and development, mining, deep processing. According to statistics[7], the average utilization ratio of the coal is about 30% in china, one of the important reasons is the poor quality of the coal. The worse the coal quality is, the more heat loss is, the lower the thermal efficiency

736

is and the more the consumption of coal is. The research shows that when the ash of coking coal decreases by 1%, the iron-smelting coke consumption decreases by 2.66%, the iron-smelting coke ratio must decreases by 3%, smelts iron blast furnace's utilization ratio can be possibly increase to by 3.99%, the washed anthracite coal which can be used to produce the synthetic ammonia may save coal by 20%. When the ash of the coal which is used to generate electricity increases by 1%, the energy utilization ratio decreases by 1%, the calorific value decreases by 200~360J/g, the standard coal consumption increases 2~5g when generate one degree electricity. The ash decreases by 1% each time, the replacement ratio will increases by 1.5~2%, when the blast furnace injection powdered coal, and the thermal efficiency of the washed coal which is used in the industry boiler and the kiln stove may increase by 3%~8%.The waste which is leaded by poor coal quality is recessive, but the quantity of the waste is large; we should pay more attention on it. The improvement of coal quality can not only save the resource but also improve the environment. The ash content and sulfur may decrease by 50%~80% and 30%~40% respectively. As a result of the coal quality's improvement, the emission harmful gas will be reduced enormously which include the mist and dust, sulfur dioxide, the nitride and so on, It is estimated that when the sulfur content increases by 0.1%, the estimate loss of the environment caused by burning 1t coal would increase 4.1 to 10.73 Yuan [7]. There are many coal quality indexes, but the controllable indexes in production include mainly the ash content, the refuse rate and the moisture. This paper mainly chose these controllable indexes as the quality control key index [6]. (1) Ash content and refuse rate indexes In order to analyze the variation of coal quality in production, the mining quality index is defined The symbol means the mining quality index, the signal of g means the ash content of raw coal, and the symbol e means the refuse rate. The would affect the coal recovery rate and the clean coal washout rate. The smaller the s value is, the better the row coal quality is. The poor quality of raw coal in mining process would influence the clean coal quality obviously. The main performance is that the mining process cant provide qualified raw coal for the washing process, and the high ash content and refuse rate would affect the cleaned coal output rate. The indexes of refuse rate and ash content have big impact on the output rate of clean coal, but it is difficult to define the influence degree by quantity accurately. According to statistical data[7],if the number of g increases by 1%, the output rate of clean coal would decrease by about 0.5%, and the number of e would increase by 1%, the output ratio of clean coal would decrease by about 0.8~0.9%. If the number of g increases or reduces by 1%, the calorific value would reduce or increase by 0.35 0.5MJ/kg relevantly. If the steam coal ash content increases or reduce by 1%, the shadow price would reduce or increase by 2.26 3.23%. There is a reverse relationship between the coal recovery rate and the mining quality index[8]. For example, with caving coal or thin seam method, when to improve the coal recovery rate, the ash content and the refuse rate would increase and the coal quality would decrease. At the same time, the washing cost would increase and the clean coal profit rate would decrease because of the increasing of the raw coal consumption. So the mining quality index would be high in order to increase the coal recovery rate, and the coal recovery rate would decrease when the mining quality index decrease. (2) Moisture index The moisture in the raw coal divides into three types which are the intrinsic moisture content, the external moisture, the crystal water and the water of decomposition. When the moisture is oversized, it will go against the mining, deep processing ,the thermal stability and the heat conductivity will be influenced ,the thermal efficiency will decrease. It also will reduce the coke output, extend the coking cycle and cause the resources losses. The comprehensive clean coal is composed of the block, the fine and the flotation clean coal. The height of its moisture is based on each constituent's proportion and the average moisture which show as the table 1[7]. as a total sum of the ash content and refuse rate. The formula is show as

= g +e .

737

Table 1 The composition of moisture content in comprehensive clean coal block clean coal moisture /% proportion /% 5 8 35 fine clean coal 9 flotation coal 34 36 30 comprehensive clean coal 10 18 100

10 35

At present the moisture of comprehensive clean coal is about 10% and even to 18%in china which is higher than the US, Australia and other advanced countries where the moisture of comprehensive clean coal is about 8%. The main reason which cause the moisture high is that the raw slime in raw coal is high which related to the mechanized degree in mining directly, washing process and equipment are backward.

3 The whole process quality control method in coal production

The coal production is continues, long and complex, there are many processes and factors which affect each other in production. So the difficulty to manage the quality is higher in production. Based on the practices, the quality control should be done to build the harmonious quality control system which includes mining, transportation, ventilation, production scheduling, washing and so on, to strengthen the whole process dynamic control. There are mainly two methods to improve the coal quality with the ideas and methods of industry engineering. The first is to optimize the process of mining and decrease the ash content and refuse rate. The second is to optimize every process of washing to improve the clean coal quality. The whole process quality control should be done from optimizing each process in production, and expend the quality control to the process in order to find and get rid of the main factors which affect the coal quality. Now the mine did not achieve to the process level truly and dont combine the result with quality control the process management. So it is difficult to resolve the problem of quality control fundamentally. The whole process quality control method which extends the quality control to each process and emphases the human role in the quality control, combine the result of the quality control with the process management fully and solve the quality problems in production. The steps of whole process quality control which based on the industry engineering is as follows: (1)To Choose out the reasonable quality control index based on practice and experience in production, define the index control range scientifically. (2)To determine the most important control process in production. It is the most important part to control the quality in process. Because the different process has different affect on the forming of coal quality, it needs to pay more attention to the most important process. The first step is to decide the important process in quality control to be the key control process. And the whole process control also should be considered when we determine the control key process to assure that the quality problem do not arise in other process. (3)To assure the key factors which affect coal quality. With the staring to analysis factors include the man, equipment, material, method and environment which affect quality in every process, it needs to analyze the reasons which cause the coal quality seriously. Control quality from beginning is to control the factors which affect quality in order to improve the quality. The product quality can be assure if we control the key factors, which means that the control transfer from the under process to the upper process and from the produce result to the affective factors. (4)To define the control standard according to the key factors in every process and to set up the standard papers of quality control. (5)To give some corresponding countermeasures according to the key control factors. (6)To carry out the countermeasures and examine the effects, and respond the result to the process control to improve the countermeasures. The whole process quality control has five important factors which include man, machine, material, method and environment, and the man is the main body and is the key of quality control. So we should

738

constraint human behavior by drafting corresponding countermeasures according to human psychology and behavior to control product quality.

4 Contents of whole process quality control in production

4.1 The coal quality control method The row coal quality depends on the natural conditions and mining process and being effected by production directly. There is different raw coal quality with different mining process at the same natural condition. In the last few years, with the improving of mechanization level and the increasing of the mining depth, the index of mining quality appeared to be an increase trend. In all factors which include the raw coal quality, the factors in mining process account for more 70%. So, the mining process is the main process to control and improve the coal quality. In mining process, gangues mix into the raw coal easily when roofs broken, rock parting, thin seam mining, top coal caving, cutting coal machine cutting roofs or floors, that is the main factors which effect the raw coal quality. The mining method includes blasting mining, ordinary mining, high-grade ordinary mining, fully mechanized mining, fully mechanized caving and so on. Each method has different processes and has five common processes which include coal cutting, coal loading, coal transportation, moving chute, support, goaf management. The fully mechanized caving include some processes such as coal cutting, extending the extendible beam, support, coal loading, pushing front chute, coal caving, coal transportation, pulling back chute, coal second-cutting, second-support, coal caving, coal transportation, clearing float coal, pulling back chute, working face end support, advanced support, goaf management, pushing and moving the transfer machine, cutting coal machine feeding and so on. The different mode of each process would effect the ash content and refused rate, so it is very important to analysis the mining processes, find and sure the key process to control with the method of expertise in practice. The key process and important point of quality control could be sure based on the influence degree to product quality, engineering quality and safety production, such as pulling chute, moving supports and advanced support and so on. The whole processes should be pay enough attention when controlling the key processes mainly, it is very necessary and important to sure the all processes to achieve the quality requirement for the raw coal quality in mining. The common processes which includes coal cutting, coal loading, coal transportation, moving chute, support and goaf management will be analysis to find the effect factors as follows: (1)Coal cutting process. The coal cutting method includes blasting and cutting machines mainly. It is very important to set the parameters such as the number of blast holes, charge weight and angle of blast holes and so on. The roof and floor gangues will fall with the raw coal and increase the refuse rate if the parameters are improper. The height and angle of spill plate should be designed rationally to reduce the coal loss. The mining height should be controlled strictly to avoid the cutting roofs and floors for the machined mining face. The ash content is different when the cutting mode is different: when one-way coal cutting and only one coal cutting and the great variation of coal thickness, floor fluctuation, the cutting machines will cut the floor; when two-way coal cutting and only one cutting, the roof would not be support in time and increase the ash content and refuse rate; when two-way coal cutting and two cuttings, the roof would be support in time, the gauges is less which would improve the coal quality. Some special measures should be adopted to avoid the gangue mixing into the raw coal when working face cross fault and broken areas. (2)Coal loading process. The main factor which effects the coal quality in this process include that the soft floor and mud and sand would mix into the raw coal to increase the ash content. So it should to load the coal and gangues respectively. (3)Coal transportation process. Transportation with scraper conveyor will reduce the gangue and content, and some mud and sand in floor will mix into the raw coal when using one-self back fall mode in some steeply inclined coal faces, so the chutes should be paved along the floors. Coal and gangue dividing load and carry under the shaft will reduce the refuse rate and improve clean coal output ratio.

739

The high and poor quality coal bunkers should be built. (4)Moving chute (scraper conveyor) process. Before moving the scraper conveyor, the floor should be leveled near the coal wall and avoid moving chute by force and mix the mud and sand into raw coal. (5)Working face support process. After mining, the roof gangues mix the coal easily especially when the roofs are broken, so the rational support measures should be adopted as soon as possible. The arrangements of supports in working face effects the rate of coal containing waste rock, the hydraulic support in fully mechanized working face should close up to each other and the side guard plate should be open, It is important to deal with the leakage of gangues , the support and the repairing net timely under the false roofs. (6) Goaf management process. It is better to improve the coal quality for the filling method than falling method to manage the goaf. When prop drawing in the individual hydraulic prop working face which includes the Gun working face, ordinary mechanized working face and advanced mechanized working face, The order of first up second down should be adopted to stop the gangues and reduce the falling gangues from upper roofs. On the fully mechanized and fully-mechanized sublevel working face, it is should pay more attention to avoid the curetting to the roofs to reduce the ash content, the hydraulic shield support should be use under the broken roofs to reduce gangues. 4.2 Control to coal quality in washing process Washing is most important method to improve coal quality, it should pay special attention to quality control in washing. there are four main indexes which include granularity, ash content, total moisture and non-lint content should to control in total processes of washing. According to the experience of advanced countries such as American and Austria, there are some measures to adopt to control the total quality in washing generally: firstly, the raw coal would be screened and crushed to control the granularity after being classified. The granularity of raw coal and the upper limit of mix-coal should be controlled strictly, the cleaned coal should be crushed secondly before warehousing to assure the requirement to the granularity. Secondly, the control to ash content based on the separating screen equipment mainly. The online ash mater should used to control the ash content in the belt conveyor, the adjustment should be made content when ash content exceed the normal range. Thirdly, the clean coal production should to be dehydrated with the sieve bend and vibrating-dewatering screen, and the slack coal dehydrated with the centrifugal hydro-extractor lastly. Fourthly, to remove the impurities is necessary in some processes such as raw coal warehouse, washing, washed, product warehouse, loading and so on. It needs different facilities to remove different impurities, such as removing the iron-impurities with magnetic separator, removing mood-impurities with hydraulic shaker and so on.

5 Conclusion

It is a complex process to control the coal quality in production and needs the emphasis control in total programs and total processes. This paper sets up the total process quality control method based on the basic theory of industry engineering starting with detailed analysis to the important indexes of quality control in production, analysis the total process quality control contents to work with the six main processes which include mining coal loading coal transporting coal moving conveyer supporting goaf management. The thinking and methods of industry and engineering have application in the quality control of mining production successfully, and the control to quality extend to the process level really, achieve to the total process quality control primarily, there are active meaning for practice of mines.

References

[1]Fang Wenjie Zeng Xianlin. Study on Industry Engineering and Its Application in Mine System[J].Coal Economy Research,1994,(8):40-42.

740

[2]Song Linfa,Ding Weijie. Application of Industry Engineering in Sene Management Standardization of Coal Production[J].Neimenggu Coal Economy,1995,(z3):28-31 [3]Duan yuling. Study on Application of Based Industry Engineering in Coal Industry [J].Coal Engineering,2007,(7):113-116. [4]Chen Liangpeng. Efficiency Way to Intension Type Development with Industry Engineering[J].Coal, 2000,9(1):57-59. [5]Lu Houjun,Han Keqi .Study on Application of Industry Engineering in Information of Mines [J].Energy Technology and Mangement,2007, (3):116-118. [6]Chen Peng. Feature, Classification and Utilization of Mine in China[M],Beijing: Chemical Industry press,2007 [7]Cui Minxuan. Energy Reourece Blue Book of 2007 in China[M],Beijing: Society Scientific Literature Press,2007 [8]Guo Zhongping. Study of Optimization on the Dilution Ratio of Roof Coal in Sublevel Caving Mining[J],Joural of China Coal Cociety.,2000,25(4):137-140 [9]Yu Yue, Wang Zuoqiu. Research on the Control of Coal Quality[J],Coal Quality Control,2007,(6):4-7 [10]Li Wenhua, Management and Business of Coal Quality[M],Beijing:china standard press,2003

Introduction of the author

Li Ying-de (1978-) , male, shouguang city Shandong province, PHD, mayor in industry engineering and system simulation.

741

You might also like

- Coal in the 21st Century: Energy Needs, Chemicals and Environmental ControlsFrom EverandCoal in the 21st Century: Energy Needs, Chemicals and Environmental ControlsNo ratings yet

- Best Practice - Env MGT - PT Adaro PDFDocument22 pagesBest Practice - Env MGT - PT Adaro PDFchaikal alghifari100% (1)

- Coal SopDocument8 pagesCoal SopRizal TengkuNo ratings yet

- Coal Resources and Reserves SummaryDocument1 pageCoal Resources and Reserves Summaryalbab onyonNo ratings yet

- Basic Coal Exploration To Production in Coal Mining IndustryDocument34 pagesBasic Coal Exploration To Production in Coal Mining IndustryMuh. Dwiki Satrio WicaksonoNo ratings yet

- Flow Chart Penambangan: Operation & Engineering DeptDocument6 pagesFlow Chart Penambangan: Operation & Engineering DeptMuhammad Riza AsyharNo ratings yet

- Spotted Dog PaperDocument9 pagesSpotted Dog PaperpaulogmelloNo ratings yet

- Resume-Simplified Chinese Translator-QiufangDocument1 pageResume-Simplified Chinese Translator-QiufangGermano Matias100% (1)

- 4 Exploration of Coal - IV Coal Resource EstimationDocument30 pages4 Exploration of Coal - IV Coal Resource EstimationRasmiranjan Jena RajaNo ratings yet

- Case Study MineSched at SebukuDocument27 pagesCase Study MineSched at SebukuDadanNo ratings yet

- Cost Reduction in Mining Operations - DiscussionDocument4 pagesCost Reduction in Mining Operations - DiscussionSebastiánHernandezAlbayayNo ratings yet

- 5021 Melak Coal Mine ProjectDocument1 page5021 Melak Coal Mine ProjectAchmad Bachtiar FirmanNo ratings yet

- Coal Quality Issues and Options: DR Andrew Minchener OBEDocument10 pagesCoal Quality Issues and Options: DR Andrew Minchener OBEKhan Ahmed MuradNo ratings yet

- Coking Coal IndexDocument12 pagesCoking Coal IndexZaidan EffendieNo ratings yet

- Quality of Coal ReservesDocument2 pagesQuality of Coal ReservesDiego Martínez FernándezNo ratings yet

- Coal Guidelines 2014 - Final Ratified DocumentDocument47 pagesCoal Guidelines 2014 - Final Ratified DocumentSundar RajNo ratings yet

- Presentation - Roles Geologist 210130Document57 pagesPresentation - Roles Geologist 210130gabrielNo ratings yet

- Mining Quality Planning AdaroDocument12 pagesMining Quality Planning AdaroFebriansyah NurdinNo ratings yet

- ANDAL Lampiran4 Coal Stockpile Management SelfCombustion Control ProcedureDocument4 pagesANDAL Lampiran4 Coal Stockpile Management SelfCombustion Control Procedurefranco_2010100% (1)

- Australian Coal Guidelines Exposure Draft March 18032014Document48 pagesAustralian Coal Guidelines Exposure Draft March 18032014Soumen BhadraNo ratings yet

- Asset Optimization Systems: 5 Lessons From 10 Years in MiningDocument12 pagesAsset Optimization Systems: 5 Lessons From 10 Years in MiningSACHIDHANANDHAM ANo ratings yet

- Coal ExplorationDocument6 pagesCoal ExplorationJennifer RiversNo ratings yet

- Underground Coal MineDocument17 pagesUnderground Coal MineFavorSea Industrial Channel Limited100% (1)

- Reliance Case StudyDocument38 pagesReliance Case Studyhihimanshu70100% (2)

- Open Pit Mining: Mine Planning & Design: Focus On Surface Mining Technology: Lecture 2Document34 pagesOpen Pit Mining: Mine Planning & Design: Focus On Surface Mining Technology: Lecture 2TinozivasheNo ratings yet

- Maptek Australia2012 Sean Dixon Using ROM in HARP ModellingDocument23 pagesMaptek Australia2012 Sean Dixon Using ROM in HARP ModellingKenny Casilla100% (2)

- Coal Exploration ReportDocument58 pagesCoal Exploration Reportpuput utomoNo ratings yet

- Bayan ReviewDocument20 pagesBayan Reviewakbar suhadaNo ratings yet

- NPV ProjectxDocument2 pagesNPV Projectxalfri121No ratings yet

- JP Morgan - Indonesia Coal Mining 2011Document39 pagesJP Morgan - Indonesia Coal Mining 2011KJPP ASRNo ratings yet

- Maputo Development CorridorDocument18 pagesMaputo Development CorridorRaimundo Paulo Langa100% (1)

- Summary of Progress Transhipment On Vessel Mv. Manalagi TisyaDocument1 pageSummary of Progress Transhipment On Vessel Mv. Manalagi TisyaMuhammad Rabbil AlbadriNo ratings yet

- Mine Operations Supervisory Skills Development v3Document103 pagesMine Operations Supervisory Skills Development v3Maddy Sirampe MeloNo ratings yet

- 02 - Geological Interpretation For Resource Modelling and Estimation - J H Duke and P J HannaDocument10 pages02 - Geological Interpretation For Resource Modelling and Estimation - J H Duke and P J HannaIron Huayhua Chávez100% (1)

- Analysis Coal FinalDocument21 pagesAnalysis Coal FinalAlok KumarNo ratings yet

- Bayan Investor Presentation PDFDocument16 pagesBayan Investor Presentation PDFRosikh Falah Adi CandraNo ratings yet

- Argumentation Manganese Ore Prices Export 2012Document38 pagesArgumentation Manganese Ore Prices Export 2012leniucvasileNo ratings yet

- MineScape 7.0 BrochureDocument2 pagesMineScape 7.0 Brochuretenri wijaNo ratings yet

- Coal MarketingDocument5 pagesCoal MarketingVenuNo ratings yet

- Coal Mine Field Trip ReportDocument14 pagesCoal Mine Field Trip Reportvictory shahbazNo ratings yet

- Petrography of CoalDocument24 pagesPetrography of CoalAhsanRazaNo ratings yet

- PMRC 131 - Mining Financial Analysis PDFDocument26 pagesPMRC 131 - Mining Financial Analysis PDFEmmanuel CaguimbalNo ratings yet

- Flyash ManagementDocument13 pagesFlyash ManagementShahinshaNo ratings yet

- Coal Geology Research ProgressDocument254 pagesCoal Geology Research ProgressIvica PavičićNo ratings yet

- Coal Handling OperationalDocument12 pagesCoal Handling Operationalmugiraharjo7No ratings yet

- Combustion in Coal StockpilesDocument12 pagesCombustion in Coal StockpilesMuksin SalehNo ratings yet

- Coal Quality Improvement Technology Brief-EngDocument10 pagesCoal Quality Improvement Technology Brief-EngRiko C PribadiNo ratings yet

- CourseOutline MINE4260 2014Document20 pagesCourseOutline MINE4260 2014Welsinsin Kevin SinNo ratings yet

- Allight Hl8whd A CatDocument2 pagesAllight Hl8whd A CatAlbert AloepchaNo ratings yet

- Application of Cycle Time Techniques For Estimation Dump Truck NeedsDocument13 pagesApplication of Cycle Time Techniques For Estimation Dump Truck NeedsNisrina Amalia Dyah UtamiNo ratings yet

- Toka Tindung Ore Reserve Estimate 30 June 2016Document46 pagesToka Tindung Ore Reserve Estimate 30 June 2016Zulkifly Rumba A SingkuNo ratings yet

- 10 Things To Know About Strategic Mine Planning For Open PitsDocument3 pages10 Things To Know About Strategic Mine Planning For Open PitsClider NiñoNo ratings yet

- 3DS 2017 GEO Surpac 5tips and Tricks Ebook Vol 1 PDFDocument13 pages3DS 2017 GEO Surpac 5tips and Tricks Ebook Vol 1 PDFAbush Desta100% (1)

- Mine ManagementDocument7 pagesMine ManagementBranden OxfordNo ratings yet

- Discover3D TutorialsDocument76 pagesDiscover3D TutorialsAlejandroNo ratings yet

- Longwall MiningDocument43 pagesLongwall MiningMeyyer Christopher LumembangNo ratings yet

- 2020-09-04 Basic Coal Exploration To Production ShareDocument35 pages2020-09-04 Basic Coal Exploration To Production ShareMuh. Dwiki Satrio WicaksonoNo ratings yet

- Study On Whole Process Quality Control in Coal Production Based On Industry EngineeringDocument5 pagesStudy On Whole Process Quality Control in Coal Production Based On Industry EngineeringSusanto AesNo ratings yet

- Study On Clean Coal Technology With Oil Agglomeration in Fujian ProvinceDocument7 pagesStudy On Clean Coal Technology With Oil Agglomeration in Fujian ProvinceJose VargasNo ratings yet

- CH1-P1 Coal BeneficiationDocument25 pagesCH1-P1 Coal BeneficiationKroya HunNo ratings yet

- Geoplast Slabs Solution English BrochureDocument52 pagesGeoplast Slabs Solution English BrochureMohamedNo ratings yet

- ST - Mother Theresa Engineering College Subject Wise Result AnalysisDocument36 pagesST - Mother Theresa Engineering College Subject Wise Result AnalysisSiva RamanNo ratings yet

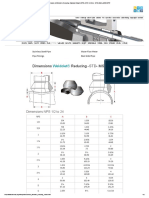

- Dimensions of Weldolets Reducing, Standard Weight (STD), NPS 1 - 2 (3 - 4) - NPS (20) 24, MSS-SP97Document2 pagesDimensions of Weldolets Reducing, Standard Weight (STD), NPS 1 - 2 (3 - 4) - NPS (20) 24, MSS-SP97Qiuniu100% (1)

- Paparan Kegiatan Alih Teknologi Pengujian Kereta ApiDocument9 pagesPaparan Kegiatan Alih Teknologi Pengujian Kereta ApiMuhammad Didit PrasodjoNo ratings yet

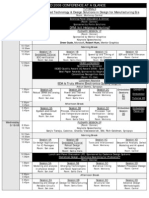

- ISQED08 Program v3Document48 pagesISQED08 Program v3Al MtdrsNo ratings yet

- Construction Estimate &value EngineeringDocument30 pagesConstruction Estimate &value EngineeringCharles Nacorda100% (1)

- PreviewpdfDocument67 pagesPreviewpdfAurélien Kinet100% (1)

- Cico No.3: Quick Setting and Rapid Hardening Admixture For Plain Cement Concrete and MortarDocument2 pagesCico No.3: Quick Setting and Rapid Hardening Admixture For Plain Cement Concrete and MortarankitraginiNo ratings yet

- Aero PDFDocument93 pagesAero PDFImranKabirNo ratings yet

- Welcome To ENG1060: Unit StaffDocument7 pagesWelcome To ENG1060: Unit StaffSasha WijesekeraNo ratings yet

- Concrete Centre How To Design Concrete Structures To EC 2Document116 pagesConcrete Centre How To Design Concrete Structures To EC 2mauNo ratings yet

- Cayan Tower InfoDocument2 pagesCayan Tower InfoAatifNo ratings yet

- Strengthening Existing SteelworkDocument4 pagesStrengthening Existing SteelworkFourHorsemen100% (1)

- National Institute of Technology Rourkela: End Semester Examination Programme (2020-21 / Autumn) 24 JUN 2021 21:26Document11 pagesNational Institute of Technology Rourkela: End Semester Examination Programme (2020-21 / Autumn) 24 JUN 2021 21:26Veda SherlaNo ratings yet

- 3D Scaning ER BWTS InstalDocument36 pages3D Scaning ER BWTS InstalToni ToniNo ratings yet

- Lecture 1 Part 1 Introduction To Tribology v1Document15 pagesLecture 1 Part 1 Introduction To Tribology v1Aziful AimanNo ratings yet

- Effect of Temperature Loads On Beam Design in Thermal AnalysisDocument4 pagesEffect of Temperature Loads On Beam Design in Thermal AnalysisMohammad AasimuddinNo ratings yet

- Engineering Council of South Africa: Background: The ECSA Education System DocumentsDocument14 pagesEngineering Council of South Africa: Background: The ECSA Education System Documentsprisca ncuncuNo ratings yet

- BSI Little Book of BIM 2018 UK enDocument32 pagesBSI Little Book of BIM 2018 UK enjasminetso100% (1)

- Ra 8495 ClarificationsDocument17 pagesRa 8495 Clarificationsqweqweqweq qweasdqwedqweqwNo ratings yet

- 2010 SEAOC Convention ProceedingsDocument9 pages2010 SEAOC Convention ProceedingsPE EngNo ratings yet

- INM8521Document43 pagesINM8521heka2006No ratings yet

- ECE521 Course Outline Sept2017-Jan2018 (Latest)Document4 pagesECE521 Course Outline Sept2017-Jan2018 (Latest)mdmahfudzNo ratings yet

- 12-L&T ESP Price List-06.08.12Document76 pages12-L&T ESP Price List-06.08.12Prashanth ChandrashekarNo ratings yet

- Tape and Paper Tower ProjectDocument2 pagesTape and Paper Tower Projectapi-308013553No ratings yet

- Architectural Working DrawingsDocument62 pagesArchitectural Working DrawingsDondie Porcil CorduwaNo ratings yet

- Software Guide Sept 2005Document5 pagesSoftware Guide Sept 2005pvrk_78100% (1)

- SAEP 1610 (Oct 2017)Document9 pagesSAEP 1610 (Oct 2017)nadeem shaikhNo ratings yet

- Nfpa 1142Document38 pagesNfpa 1142Sebastián Lagos100% (1)