Professional Documents

Culture Documents

Geotextiles Con Works UK 0110

Uploaded by

Subhajit MazumderOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Geotextiles Con Works UK 0110

Uploaded by

Subhajit MazumderCopyright:

Available Formats

Fibertex Geotextiles

- makes your work easier

During construction works, you meet many different needs from your customers. We recommend having a Fibertex handy roll at hand at anytime - in the car, at work, at the construction site etc. You will then be ready to solve your customers needs in an easy and effective way.

- in temporary roads, permanent roads, parking areas and paths

- as membrane protection

Fibertex Geotextiles placed below the top gravel layer separate the different layers, stabilise the construction and increase the bearing capacity to withstand traffic loads.

Fibertex Geotextiles protect the membrane in garden ponds. When placed below the membrane the geotextile protects against perforation from stones and sharp objects and placed above the membrane against mechanical impact.

- as impact sound suppression

Fibertex Geotextiles are ideal as impact sound suppression in e.g. bathrooms in storey partition. Place the geotextile between the concrete floor and the bathroom floor.

- as separation/protection

Place the Fibertex Geotextile next to the excavation and avoid cleaning the lawn or patio when removing the soil. In the house Fibertex Geotextiles can be used as protection of floor and furniture during renovation. Placed in door openings the geotextile will prevent dust from spreading to other rooms.

- for driveways or terraces with slabs

For stabilisation of the foundation place a Fibertex Geotextile layer under the compressed graded aggregate to separate it from the sand layer. After levelling the sand place a layer of geotextile and lay out the slabs directly on the geotextile - minimising weeds from below and preventing sand from being pushed up.

- as drainage geotextile

Fibertex Geotextiles separate the drainage materials from the soil in drainage trenches while allowing water to pass through. In circumferential drains Fibertex Geotextiles ensure clean and effective drains along foundations and basement walls.

Other applications

Also use Fibertex Geotextiles as interlayer to avoid surface scratches in your sand box to separate sand from the soil as wind shielding in your flower box in the trunk of your car

- as separator

Fibertex Geotextiles placed on the capillarybreaking layer act as an effective separation from the concrete.

- for covering

Fibertex Geotextiles protect materials and machinery effectively against dust and sunlight. Being permeable to air and water the geotextile ensures a sound environment.

The only limit is your imagination

Roll size

Standard roll sizes are 4.0 m and 5.0 m x 100 m. Other roll sizes are available.

Fibertex Geotextiles

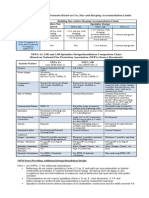

Weight, EN 965 Thickness, at 2 kPa, EN 964-1 CBR test (class value), EN/ISO 12236 Classification according to CBR Deformation, EN/ISO 12236 Water flow at 100 mm, EN/ISO 11058 Width Length % l/sec/m2 m m g/m2 mm N

F-20

100 0,6 1100 2 50 120 2 25

F-22

120 0,7 1500 2 50 120 2 25

F-25

130 0,8 1600 2 50 120 2 100

F-300M

300 3,0 3890 4 60 70 2 25

Application/project

F-20

F-22

F-25

F-300M

Fibertex Geotextiles

Protection Drainage Covering Separator (concrete floor) Under paving Temporary roads, roads, paths - on clay soil - on soft/peat soil Membrane protection Impact sound suppression

Fibertex manufactures nonwoven geotextiles using the drylaid needlepunch technology. Virgin polypropy-lene fibres are extruded, carded and finally needlepunched. All Fibertex Geotextiles are UV-stabilised, resistant to acids and alkalis, and cannot be attacked by fungi or rot. No chemical binders are used in the product or in the production process. Polypropylene is a polymer material which turns into carbon dioxide and water vapour when incinerated - both completely harmless substances.

()

()

Working with Fibertex Geotextiles

Quality Assurance

Fibertex Geotextiles are CE marked under the EU Construction Products Directive. CE marking certifies that Fibertexs quality management system (DS/EN ISO 9001:2000) complies with the EN standards (level 2+).

Advantages of using Fibertex Geotextiles

When using geotextiles between different construction layers, mixing of the layers is avoided, resulting in an increase of bearing capacity as well as time and material savings. High water flow and good filter properties combined with the necessary mechanical properties of the geotextile ensure that finegrained particles are retained, while free movement of water is maintained. Consequently, stability is improved and the lifetime of the entire construction is prolonged.

Fibertex Geotextile rolls can be cut with a chain saw (cool blade to prevent fabric from melting). Unrolled, the fabric can be cut with a knife or scissors. Overlaps can be seamed by sewing, stapled or glued together.

Storage of rolls

Fibertex Geotextiles are delivered in 0799-CPD rolls with a protective wrapping. During storage the rolls must be elevated Fibertex is certified according to from the ground and protected from DS/EN ISO9001:2000 (Quality) and exposure to direct sunlight. DS/EN ISO14001 (Environment).

Distributor:

Manufacturer:

Fibertex A/S Box 8029

Svendborgvej 2

9220 Aalborg

Denmark

Tel. +45 96 35 35 35

Fax +45 98 15 85 55

e-mail fibertex@fibertex.com

web www.fibertex.com

B10/KOE/0110

You might also like

- Nonwoven Polypropylene Geotextile: GeosyntheticsDocument6 pagesNonwoven Polypropylene Geotextile: Geosyntheticsyara100% (1)

- Dreno Tex PDFDocument10 pagesDreno Tex PDFvranceanu.ovidiu-1No ratings yet

- Fosroc GeotexDocument3 pagesFosroc GeotexBalasubramanian AnanthNo ratings yet

- Geocomposite 22Document48 pagesGeocomposite 22Sumit GuptaNo ratings yet

- BPD Master Catalogue-2Document18 pagesBPD Master Catalogue-2Dr. Manamohan R KalgalNo ratings yet

- DualProof E 2016Document8 pagesDualProof E 2016Tung Doan ThanhNo ratings yet

- Automotive TextilesDocument20 pagesAutomotive TextilesABHISHEKNo ratings yet

- Cement Fibre BoardDocument3 pagesCement Fibre Boardgouri hooliNo ratings yet

- Fiberglass Systems Glass-Fiber Reinforced Epoxy Pipes: The Piping System of The FutureDocument16 pagesFiberglass Systems Glass-Fiber Reinforced Epoxy Pipes: The Piping System of The FutureCong Trinh NGuyenNo ratings yet

- TDS Nitoproof Damp Protect India2Document2 pagesTDS Nitoproof Damp Protect India2hitesh315No ratings yet

- Precast Glass Block FlooringDocument6 pagesPrecast Glass Block FlooringLevenția LauraNo ratings yet

- Jinbiao Full Brochure PDFDocument24 pagesJinbiao Full Brochure PDFDarren ChungNo ratings yet

- Fairfix UnderlaymentDocument4 pagesFairfix UnderlaymentfairmatechemicalNo ratings yet

- SealantTraining InstallationDocument31 pagesSealantTraining Installationkeroppifrog647No ratings yet

- Rockwool Thermalrock S (Slab) : General Product InformationDocument2 pagesRockwool Thermalrock S (Slab) : General Product InformationMohsin RazaNo ratings yet

- 003 FAIRMATE - Construction ChemicalsDocument8 pages003 FAIRMATE - Construction Chemicalsfairmatechemical100% (1)

- Data Sheet - Gabion Box - English R0 10feb2013Document1 pageData Sheet - Gabion Box - English R0 10feb2013Željko GrisNo ratings yet

- Roofing & Walling Installation Manual: For Design and Installation Professionals 2014-2015 EditionDocument68 pagesRoofing & Walling Installation Manual: For Design and Installation Professionals 2014-2015 EditionDenise2512No ratings yet

- Submat Mattress PDFDocument5 pagesSubmat Mattress PDFtanjungulieNo ratings yet

- Slopes & Channels: Installation GuideDocument11 pagesSlopes & Channels: Installation GuideAlejandra GomezNo ratings yet

- Kimmco InsulationDocument7 pagesKimmco InsulationMujjo SahbNo ratings yet

- RegDocument73 pagesRegArun KumarNo ratings yet

- POLYFOAM Brochure - Qatar InsulationDocument16 pagesPOLYFOAM Brochure - Qatar InsulationAbdullah Ahmed FarazNo ratings yet

- Design Guide For MassBloc Retaining WallDocument17 pagesDesign Guide For MassBloc Retaining WallKen LiewNo ratings yet

- PU SealantDocument6 pagesPU Sealantudupiganesh3069100% (1)

- Questions: On EveryDocument24 pagesQuestions: On EveryAshish KumarNo ratings yet

- Types of Sealants Used For Joints in Buildings - Properties, Uses, WorkingDocument6 pagesTypes of Sealants Used For Joints in Buildings - Properties, Uses, WorkingJustin MusopoleNo ratings yet

- SikaSwell - Hydrophilic Profiles and SealantsDocument12 pagesSikaSwell - Hydrophilic Profiles and Sealantskhx2No ratings yet

- Biodegradable Mat: Coconut Coir (CC)Document2 pagesBiodegradable Mat: Coconut Coir (CC)Kamal LatifNo ratings yet

- Plugin Paints Coatings New Developments 2k Waterborne Epoxy CoatingsDocument14 pagesPlugin Paints Coatings New Developments 2k Waterborne Epoxy CoatingsjasminneeNo ratings yet

- 02 Bayset Sec2.WaterproofingmembrainsDocument39 pages02 Bayset Sec2.WaterproofingmembrainsKha PhucNo ratings yet

- Construction Materials Lab: Supervisor Name: Lawend Kamal AskerDocument7 pagesConstruction Materials Lab: Supervisor Name: Lawend Kamal AskerIbrahim walled IbrahimNo ratings yet

- Brochure DHP - PU 3000 R1Document17 pagesBrochure DHP - PU 3000 R1Zainudin Zuhri100% (1)

- Drfixit Torchshield PDFDocument4 pagesDrfixit Torchshield PDFshashiNo ratings yet

- Designing With Advance Material: Lab Report - Important Industrial Methods of FRP Composite FabricationDocument9 pagesDesigning With Advance Material: Lab Report - Important Industrial Methods of FRP Composite Fabricationprashant chouhanNo ratings yet

- Grass Crete BrochureDocument12 pagesGrass Crete BrochureAlexandra KropokNo ratings yet

- 1A - SealantsDocument20 pages1A - Sealantsyuyang1024100% (1)

- Techcell For Slope ProtectionDocument6 pagesTechcell For Slope ProtectionN GANESAMOORTHYNo ratings yet

- Expansion Joint Waterproofing Specs - SD Combiflex SG v2Document5 pagesExpansion Joint Waterproofing Specs - SD Combiflex SG v2VIJAYTECH CONSULTANTS PVT. LTD.No ratings yet

- 2018 Civilcast Brochure PDFDocument20 pages2018 Civilcast Brochure PDFariNo ratings yet

- Types of GeosyntheticsDocument8 pagesTypes of Geosyntheticsvadlamani7No ratings yet

- Stretch Ceiling System Newmat Uk Midlands LTDDocument24 pagesStretch Ceiling System Newmat Uk Midlands LTDNewmatUKNo ratings yet

- Supercast PVC WaterstopDocument4 pagesSupercast PVC WaterstopArun KumarNo ratings yet

- TerraFirmBrochureDocument8 pagesTerraFirmBrochureikhmalNo ratings yet

- Sheet Pile Capping System ManualDocument54 pagesSheet Pile Capping System Manual류태하No ratings yet

- PU Water Proofing in India - Poly Urethane Water Proofing in India - PuwaterproofingDocument8 pagesPU Water Proofing in India - Poly Urethane Water Proofing in India - Puwaterproofingmaris polymersNo ratings yet

- GeosyntheticsDocument162 pagesGeosyntheticsEslam Amr100% (1)

- Modern WaterproofingDocument17 pagesModern WaterproofingDileepa DissanayakeNo ratings yet

- 3m IATD CatalogueDocument25 pages3m IATD Catalogueapi-3725857100% (2)

- Cement Reinforced With Steel FibreDocument2 pagesCement Reinforced With Steel FibreMaheswara VarmaNo ratings yet

- Experimental Investigation On Mechanical Properties of Geosynthetic Cementitous Composite Mat (GCCM)Document10 pagesExperimental Investigation On Mechanical Properties of Geosynthetic Cementitous Composite Mat (GCCM)Phan Thanh HiếuNo ratings yet

- Protect PRODUCTS From NATURE So That, PRODUCT Protects You From NATUREDocument14 pagesProtect PRODUCTS From NATURE So That, PRODUCT Protects You From NATUREannayya.chandrashekar Civil EngineerNo ratings yet

- Gen Broc - Basal Reinforcements (100 300-gb-0412)Document8 pagesGen Broc - Basal Reinforcements (100 300-gb-0412)Jack VongmontyNo ratings yet

- Basement WaterproofingDocument2 pagesBasement WaterproofingKiran Kumar JhaNo ratings yet

- Tile Laying LeafletDocument1 pageTile Laying LeafletniroNo ratings yet

- VSL Buildings BrochureDocument12 pagesVSL Buildings BrochureDrPadipat ChaemmangkangNo ratings yet

- Geotextil TencateDocument2 pagesGeotextil TencateHugo HiddNo ratings yet

- Nonwoven Polypropylene Geotextile: GeosyntheticsDocument6 pagesNonwoven Polypropylene Geotextile: Geosyntheticseasytigeruk15No ratings yet

- Geotessili IngDocument15 pagesGeotessili IngSathiya SeelanNo ratings yet

- GeotextileDocument10 pagesGeotextileAnwar ParvesNo ratings yet

- Mudon Views Apartments by Dubai Properties +97145538725Document27 pagesMudon Views Apartments by Dubai Properties +97145538725SandeepNo ratings yet

- HeatTransfer2010Document54 pagesHeatTransfer2010Nurul Izzati Raihan RamziNo ratings yet

- Number and Spacing of Piles in A GroupDocument7 pagesNumber and Spacing of Piles in A GroupmadaraNo ratings yet

- Fire Fighting SpecificationDocument23 pagesFire Fighting SpecificationsurendramaharjanNo ratings yet

- Starken Lightweight Block PresentationDocument40 pagesStarken Lightweight Block Presentationhjlee91No ratings yet

- As3740-2004 Bsa GuideDocument5 pagesAs3740-2004 Bsa GuideOwen Perrin100% (1)

- Arch Prasan SukanDocument14 pagesArch Prasan SukanINTAN FARHANA MOHD ROSLANNo ratings yet

- Cabaret, Margueron, Saraiva Thebirthofthemoderncity CompressedDocument26 pagesCabaret, Margueron, Saraiva Thebirthofthemoderncity Compressedhugo.cabaretNo ratings yet

- Ceiling Framing Plan Roof Framing Plan: B C D ADocument1 pageCeiling Framing Plan Roof Framing Plan: B C D AMark Ruby OpawonNo ratings yet

- Cannington Court, SomersetDocument95 pagesCannington Court, SomersetWessex ArchaeologyNo ratings yet

- Planos para Gabinete Esquinero de MaderaDocument16 pagesPlanos para Gabinete Esquinero de MaderaIsmael Perez100% (2)

- Architecture of Materialism - A Study of Craft in Design CultureDocument148 pagesArchitecture of Materialism - A Study of Craft in Design CultureVictoria TozlovanuNo ratings yet

- 21th Floor Snag ListDocument1 page21th Floor Snag ListNedunuri.Madhav MurthyNo ratings yet

- Ec 164219Document2 pagesEc 164219Stooef IpulNo ratings yet

- Estimate 29 - 11Document19 pagesEstimate 29 - 11Ositha WarunaNo ratings yet

- Conmix Utg 2011Document2 pagesConmix Utg 2011Fredj Ben SalemNo ratings yet

- SatipDocument5 pagesSatipMuhammad Abdul Kadher100% (3)

- CCTV Case StudyDocument8 pagesCCTV Case StudySameer Ali100% (1)

- Malvern Property News 07/01/11Document15 pagesMalvern Property News 07/01/11NQDMSNo ratings yet

- Introduction of FrameDocument8 pagesIntroduction of FrameTricia GonzalesNo ratings yet

- Exxon Mobile Colour - Code For PaintingDocument1 pageExxon Mobile Colour - Code For PaintingellamellamNo ratings yet

- Shear Wall Analysis and DesignDocument7 pagesShear Wall Analysis and DesigndaniNo ratings yet

- Setting Up Standards For High-Rise ConstructionDocument4 pagesSetting Up Standards For High-Rise ConstructionsansarepNo ratings yet

- Apartment Buildings Today (Architecture Art Ebook)Document294 pagesApartment Buildings Today (Architecture Art Ebook)Ionut TesuNo ratings yet

- Stairs Ramps and Lifts - Australian StandardsDocument7 pagesStairs Ramps and Lifts - Australian StandardsdeleNo ratings yet

- Brickforce Engineers Guide and Load Tables PDFDocument28 pagesBrickforce Engineers Guide and Load Tables PDFrehabbedNo ratings yet

- The Rotating TowerDocument6 pagesThe Rotating TowerAreeba Imtiaz HUssainNo ratings yet

- Mike Holt's 2008 NEC IndexDocument18 pagesMike Holt's 2008 NEC IndexMora TMNo ratings yet

- Limited Asbestos Survey (8!19!13)Document22 pagesLimited Asbestos Survey (8!19!13)TOTA OWASSONo ratings yet

- Foam ChambersDocument4 pagesFoam ChambersIvo KovachevNo ratings yet