Professional Documents

Culture Documents

Beam Engine

Uploaded by

Ahmed GamalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Beam Engine

Uploaded by

Ahmed GamalCopyright:

Available Formats

Proceedings of the 3rd Annual GRASP Symposium, Wichita State University, 2007

Beam Engine powered circular sawing machine

Khan Habeeb Ur Rahman*

Department of Mechanical Engineering, College of Engineering

Abstract. In this project, the output of a Beam Engine is used to drive a circular saw to cut timber. Here, instead of the rotating fly wheel, it is intended to have a rotating circular saw. This rotating circular saw is used to cut timber. Circular saws driven with electric power are a common feature. But in places where electricity is scarce, or absent, it is difficult to operate these equipments. But since the Beam Engine powered saw runs on fuel, it can be operated even in places where electricity is totally absent. A beam engine is a design of stationary steam engine [1]. A stationary engine is an engine whose framework does not move [2]. Usually, a stationary engine is used not to propel a vehicle but to drive a piece of immobile equipment such as a pump or power tools [4]. In a beam engine, the piston is mounted vertically, and the piston rod does not connect directly to the connecting rod, but instead to a rocker or beam above both the piston and flywheel. The beam is pivoted in the middle, with the cylinder on one side and the flywheel, which incorporates the crank, on the other. The connecting rod connects to the opposite end of the beam to the piston rod, and then to the flywheel [1].

1. Introduction

The motivation for this project comes from the ME 637 course that I had taken during the spring 2006 semester at Wichita State. A beam engine is a design of stationary steam engine [1]. A stationary engine is an engine that does not move [2]. Usually, a stationary engine is used not to propel a vehicle but to drive a piece of immobile equipment such as a pump or power tools [4]. The idea evolved at this point, using the beam engine to drive a circular saw to cut timber.

2. Development of idea, discussion and significance

As mentioned earlier the motivation for this project being the course ME 637, the course required each student to submit a project using the Pro-E modeling tool and the instructor emphasized that the project should be creative and something new. This made me think about something new and finally I arrived at the Beam Engine idea. The word power tools caught my attention and I just started to think why not I use a beam engine to drive a circular saw to cut timber. While electric powered saws are a common feature as also diesel and gasoline powered saws, a saw that works on the principle of a beam engine is something that I thought of. This saw, which can run either on diesel or gasoline, can be used in places where electricity is sparse or absent. Working principle When the piston in the cylinder reciprocates, it imparts an oscillating motion to the rocker arms, as shown in figure 1 on page 2. This oscillating motion of the rocker arm is converted into rotary motion by the crankshaft. The crankshaft, which is connected to the circular saw, makes the circular saw rotate. This rotary action of the circular wood saw is used to saw timber or wood blocks. There is a small table attachment for supporting the wooden block. The wooden block is placed on the table and pushed towards the rotating wood saw, which results in the sawing action. The main advantage of this machine is that it can be used in places where electricity is not economical or in places where electricity is absent

213

Proceedings of the 3rd Annual GRASP Symposium, Wichita State University, 2007

Fig 1. A schematic of a beam engine powered circular sawing machine [3]

3. Conclusions

This being a creative project, there are no particular instances of this type of machine being available in the commercial market. But the aim of this project is to show that this type of machine too is an option for wood working industry in remote places in the absence of electricity. Further improvements include using reduction gears, to vary the speed of the circular saw, having an adjustable bed with slots for adjusting the table length, so that even large sizes of timber can be sawed by varying the distance of the table and the size of the circular saw.

4. Acknowledgements

The credit for this project also goes to the ME 637 course co-coordinator, Dr. Behnam Bahr, Professor and Chair, Department of Mechanical Engineering and course instructor Moontasir Hanief. I am thankful to them for being helpful and supportive throughout the duration of this course.

5. References

[1] http://en.wikipedia.org/wiki/Beam_engine [2] http://www.answers.com/topic/stationary-engine [3] http://www.keveney.com/unkbeam.html [4] http://en.wikipedia.org/wiki/Stationary_engine

214

You might also like

- Analysis of Disc Brake by Modifying in Design and Material CompositionDocument9 pagesAnalysis of Disc Brake by Modifying in Design and Material CompositionInternational Research Journal in Engineering and Emerging Technology100% (1)

- Exp 4 - Simple Indexing Using Milling MachineDocument4 pagesExp 4 - Simple Indexing Using Milling MachineRaj PratyushNo ratings yet

- Pnumatic Ramming and Punching Machine ReportDocument28 pagesPnumatic Ramming and Punching Machine ReportSun SriNo ratings yet

- Design and Fabrication of Multi-Spindle MachineDocument6 pagesDesign and Fabrication of Multi-Spindle MachineIJIRSTNo ratings yet

- Design of lightweight carbon fiber rear axle shaftDocument68 pagesDesign of lightweight carbon fiber rear axle shaftLợi Lê Đình100% (1)

- Agriculture Reciprocating Sprayer 2222Document4 pagesAgriculture Reciprocating Sprayer 2222Avneesh BabreNo ratings yet

- Design and Fabrication of Stair Climbing Trolley: Click To Edit Master Subtitle StyleDocument15 pagesDesign and Fabrication of Stair Climbing Trolley: Click To Edit Master Subtitle StyleBablu RoyNo ratings yet

- Centrifugal Clutch: Micro Project Presentation On TopicDocument12 pagesCentrifugal Clutch: Micro Project Presentation On TopicMONUNo ratings yet

- Hybrid Vehicles Syllabus B.E VI SemesterDocument1 pageHybrid Vehicles Syllabus B.E VI Semesterashoku24007No ratings yet

- Design and Fabrication of Low-Cost Groundnut Sheller MachineDocument31 pagesDesign and Fabrication of Low-Cost Groundnut Sheller MachineSaurabh Vaidya100% (1)

- Free PPT Templates: Insert The Title of Your Presentation HereDocument12 pagesFree PPT Templates: Insert The Title of Your Presentation HereK B AbhishekNo ratings yet

- Design and Analysis Mini CNC Plotter MachineDocument23 pagesDesign and Analysis Mini CNC Plotter MachineUsman BhattiNo ratings yet

- Beam Engine Mechanism Powered Circular Sawing Machine ReportDocument34 pagesBeam Engine Mechanism Powered Circular Sawing Machine ReportSanjay CrNo ratings yet

- Multi Spindle Drilling MachineDocument4 pagesMulti Spindle Drilling Machinejohn2292No ratings yet

- Go Kart SynopsisDocument9 pagesGo Kart SynopsisShubham PuriNo ratings yet

- 360 Degree Rotating Vehicle: Submitted byDocument39 pages360 Degree Rotating Vehicle: Submitted byShubham RawatNo ratings yet

- A Review On Multi Spindle Drilling Speci PDFDocument3 pagesA Review On Multi Spindle Drilling Speci PDFAdelina RomanNo ratings yet

- Project Report On: "Construction of Road Pavements Using Geotextile Sheet"Document53 pagesProject Report On: "Construction of Road Pavements Using Geotextile Sheet"Sanjay NgarNo ratings yet

- Hydraulicjack SynopsisDocument3 pagesHydraulicjack SynopsisUmesh KsNo ratings yet

- Reciprocating pump flow separation and air vesselsDocument7 pagesReciprocating pump flow separation and air vesselsAnkush JainNo ratings yet

- Be-Automobile Lab ManualDocument42 pagesBe-Automobile Lab ManualA.j. Jain100% (1)

- Design and Fabrication of Cycloidal Gear Box: A Project Report OnDocument25 pagesDesign and Fabrication of Cycloidal Gear Box: A Project Report OnAjay NishadNo ratings yet

- Fma3602 Asign1memoDocument15 pagesFma3602 Asign1memoKasturie Pillay100% (1)

- Vertical Axis Wind TurbineDocument18 pagesVertical Axis Wind TurbineKiran SaipolaNo ratings yet

- Machine Tools KesavanDocument95 pagesMachine Tools Kesavanvenkateshyadav2116100% (6)

- Lynx Vertical Axis Wind TurbineDocument46 pagesLynx Vertical Axis Wind TurbineEric MajaoNo ratings yet

- Haramaya UniversityDocument129 pagesHaramaya Universitybiruk wase100% (1)

- Design and Fabrication of Modern Three Way Dumping Trolley MechanismDocument8 pagesDesign and Fabrication of Modern Three Way Dumping Trolley MechanismvenkataNo ratings yet

- Multi Type ForkliftDocument46 pagesMulti Type ForkliftlokeshNo ratings yet

- Pulse Detonation Engine Full ReportDocument4 pagesPulse Detonation Engine Full ReportShahil ChatholilNo ratings yet

- Three Axis Pneumatic Modern TrailerDocument6 pagesThree Axis Pneumatic Modern TrailerUNITED CADDNo ratings yet

- Rajat Report On Folding TableDocument21 pagesRajat Report On Folding TableRajat Thakur0% (1)

- Everything You Need to Know About Lathe Machine ToolsDocument22 pagesEverything You Need to Know About Lathe Machine ToolsRaghavMaheshwariNo ratings yet

- Machine Shop GuideDocument6 pagesMachine Shop GuideZain MirzaNo ratings yet

- Mahabal Metals PVT LTDDocument14 pagesMahabal Metals PVT LTDanushaNo ratings yet

- Mini-Hacksaw ProjectDocument8 pagesMini-Hacksaw ProjectPrajwal NayakNo ratings yet

- Mahindra Gears Transmiision Training ReportDocument32 pagesMahindra Gears Transmiision Training Reportbestmadeeasy50% (2)

- SYNOPSIS Solar Powered Mechanical HacksawDocument10 pagesSYNOPSIS Solar Powered Mechanical HacksawEsteFan AjayNo ratings yet

- Bullock Cart Tilting MechanismDocument80 pagesBullock Cart Tilting MechanismrajasekarNo ratings yet

- Monorail ReportDocument40 pagesMonorail ReportErole Technologies Pvt ltd Homemade EngineerNo ratings yet

- Design and Fabrication of Pedal Powered Lawn Mower CycleDocument2 pagesDesign and Fabrication of Pedal Powered Lawn Mower CycleVinayaga ProjectinstituteNo ratings yet

- c5 - 3-Way Dropping DumperDocument32 pagesc5 - 3-Way Dropping DumperAshokNo ratings yet

- 360 Rotating Trolly Shubham Rawat ProjectDocument30 pages360 Rotating Trolly Shubham Rawat ProjectShubham RawatNo ratings yet

- Roller Conveyor Chain AttachmentsDocument19 pagesRoller Conveyor Chain AttachmentsRichard VachonNo ratings yet

- Unit 1 Power Transmission DevicesDocument69 pagesUnit 1 Power Transmission DevicesAbhijeet somawarNo ratings yet

- Mechanical Engineering Minor Project Report On Staircase Climber MAE IPUDocument26 pagesMechanical Engineering Minor Project Report On Staircase Climber MAE IPUAakash SachdevaNo ratings yet

- R.M.K Engineering College: Me8712-Technical SeminarDocument15 pagesR.M.K Engineering College: Me8712-Technical SeminarPraveenNo ratings yet

- Motorized Ramming MachineDocument53 pagesMotorized Ramming Machineilayaraja6100% (1)

- Group No. 2 Project Report Review 2Document35 pagesGroup No. 2 Project Report Review 2Devansh SharmaNo ratings yet

- Green Engine: Presented BY: Akshay Kumar 1203240019Document19 pagesGreen Engine: Presented BY: Akshay Kumar 1203240019Mukhil RajasekaranNo ratings yet

- Development of A Portable Motorized Car JackDocument8 pagesDevelopment of A Portable Motorized Car JackBerk DemirbasNo ratings yet

- Fabrication of portable hammer using crank and lever mechanismDocument14 pagesFabrication of portable hammer using crank and lever mechanismMassive Minds100% (1)

- Steam Turbines: Prepared by Venkat Chintala Asst. Prof. S.G. Mechanical Engg. Deptt., UPESDocument85 pagesSteam Turbines: Prepared by Venkat Chintala Asst. Prof. S.G. Mechanical Engg. Deptt., UPESRaj NarayanNo ratings yet

- Maulana Maududi Guidelines For WorkersDocument56 pagesMaulana Maududi Guidelines For WorkersThe Time Traveler (1989-....)No ratings yet

- Beam Engine Hack SawDocument20 pagesBeam Engine Hack SawRif Riz100% (2)

- Pedal Operated Hacksaw: Ayneendra B, Sachin HulageriDocument3 pagesPedal Operated Hacksaw: Ayneendra B, Sachin HulageriAmbikesh Mishra100% (1)

- Mini HackshawDocument43 pagesMini Hackshawshalini paulNo ratings yet

- Design of Composite Material FlywheelDocument7 pagesDesign of Composite Material FlywheelIJSTE100% (1)

- Project Report 2.0Document22 pagesProject Report 2.0Yassar YelurkarNo ratings yet

- Chapter 1Document8 pagesChapter 1Renato OrosaNo ratings yet

- Allouzi 2018Document36 pagesAllouzi 2018arti sahuNo ratings yet

- Axial Cylindrical Roller Bearings - Cages and WashersDocument14 pagesAxial Cylindrical Roller Bearings - Cages and WashersKamlesh DalavadiNo ratings yet

- Manual CBR 600fDocument446 pagesManual CBR 600fJavi erNo ratings yet

- Fahud Compressor Station Site Visit ReportDocument2 pagesFahud Compressor Station Site Visit ReportDeepak RajanNo ratings yet

- Lubrex Product Catalog 2021Document73 pagesLubrex Product Catalog 2021Mohammed BabatinNo ratings yet

- RCC Is Provision NotesDocument4 pagesRCC Is Provision NotessameerNo ratings yet

- Physio Mechanical Properties-8Document2 pagesPhysio Mechanical Properties-8Umesh MishraNo ratings yet

- 87 s10Document12 pages87 s10carlosestayNo ratings yet

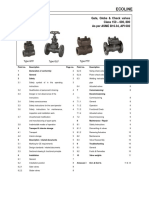

- Type GTF Type GLF Type PTF Type SCF: Gate, Globe & Check Valves Class 150 - 600, 800 As Per ASME B16.34, API 602Document12 pagesType GTF Type GLF Type PTF Type SCF: Gate, Globe & Check Valves Class 150 - 600, 800 As Per ASME B16.34, API 602Qaswa Imran KhanNo ratings yet

- A Study of Liquid Metal AtomizationDocument22 pagesA Study of Liquid Metal AtomizationAlisha Allison0% (1)

- Valve Vault Connection 2Document50 pagesValve Vault Connection 2Joel LacbayoNo ratings yet

- Knuckle Joints DesignDocument10 pagesKnuckle Joints DesignKvrd Prasad100% (1)

- Z22 DoubleSuctionAxiallysplitSingleStageCentrifugalPump60HzUS E10118 USDocument2 pagesZ22 DoubleSuctionAxiallysplitSingleStageCentrifugalPump60HzUS E10118 USediNo ratings yet

- Electro-Hydraulic Actuators For Valves SKB32.. SKB82.. SKB62.. SKB60Document16 pagesElectro-Hydraulic Actuators For Valves SKB32.. SKB82.. SKB62.. SKB60Avotech DubaiNo ratings yet

- Breakdown of The Schmid Law in BCC Molybdenum Related To The Effect of Shear Stress Perpendicular To The Slip Direction, V. VitekDocument4 pagesBreakdown of The Schmid Law in BCC Molybdenum Related To The Effect of Shear Stress Perpendicular To The Slip Direction, V. VitekErsin KeserNo ratings yet

- Din 6914-10.9 PDFDocument2 pagesDin 6914-10.9 PDFvpjagannaathNo ratings yet

- Lg956l&Lg958l&Lg959 Service ManualDocument367 pagesLg956l&Lg958l&Lg959 Service ManualAimHigh100% (1)

- 1 KESSEL Backwater ProtectionDocument18 pages1 KESSEL Backwater ProtectionAhmed HakamNo ratings yet

- 3 - 2017 - Superia X 5 StarDocument26 pages3 - 2017 - Superia X 5 Starsomnath serviceNo ratings yet

- ISO 9001 Certified U4.70-U4.250 Series Oil-Flooded Vacuum PumpsDocument4 pagesISO 9001 Certified U4.70-U4.250 Series Oil-Flooded Vacuum PumpsAndy MulyonoNo ratings yet

- Tabela TROUBLESHOOTING FT 2010Document14 pagesTabela TROUBLESHOOTING FT 2010Lucas TavaresNo ratings yet

- P&ID Symbols (Complete List & PDFDocument13 pagesP&ID Symbols (Complete List & PDFArjhay GironellaNo ratings yet

- A Natural Gas Fired Duplex Stirling For Domestic RefrigeratiDocument11 pagesA Natural Gas Fired Duplex Stirling For Domestic RefrigeratiditoNo ratings yet

- NEF Coupling Catalog English 20061201Document48 pagesNEF Coupling Catalog English 20061201Aryo WicaksonoNo ratings yet

- Propulsion, machinery, and safety questionsDocument10 pagesPropulsion, machinery, and safety questionsIlker KoksoyNo ratings yet

- Caseih Serie 20Document1,267 pagesCaseih Serie 20Fernando Sabino100% (2)

- Volvo XC70 L5-2.5T ManualDocument9,721 pagesVolvo XC70 L5-2.5T Manualwllopez75% (4)

- ENFLO 0110 Wind Turbine Data SheetDocument2 pagesENFLO 0110 Wind Turbine Data SheetCriss MereutaNo ratings yet

- Training System DS4Document164 pagesTraining System DS4Henrry Roberto Amaya BazánNo ratings yet

- Ground Floor Fire Fighting Layout: Legends & AbbreviationsDocument1 pageGround Floor Fire Fighting Layout: Legends & Abbreviationsahmad almasriNo ratings yet