Professional Documents

Culture Documents

TTI - Water Damaged Cables in Europe

Uploaded by

Jesudhason PrinceOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TTI - Water Damaged Cables in Europe

Uploaded by

Jesudhason PrinceCopyright:

Available Formats

Revitalizing

Water-Damaged Cables

from Within

By Ian Clarke

s we all know water and electricity are not known to mix well. So to have water in an electricity carrying cable of any sort, cannot be a good thing in the long run. Frequently, power cables manufactured in the 1970s and 1980s are mentioned in the failure statistics of utilities across the world because of their susceptibility to degradation from water trees.Water trees occur where the plastic insulation used for covering the power carrying metal cables allows percolation of water through from the surroundings through microscopic defects in the plastic into the inner core.The water permeates along the microscopic flaw lines in the plastic to form tree-like structures within the plastic. Due to degradation of this type in cables manufactured during this time, utilities must now invest significantly in terms of cost and time to maintain power quality and the safety of cables. CableCURE is a technology that eliminates the water tree problem by enhancing the dielectric strength of the insulation and represents an advanced and cost-saving alternative to cable replacement.

the affected cables. In the age of market liberalization, unsatisfied end-users can change supplier if the services does not perform. Consequently, the maintenance of the distribution grid must be a high priority. With the need for highly reliable power supplies and cost consciousness, CableCURE technology has come to offer both owners and customers a cost-saving and technically advanced alternative to cable replacement with its 20-year, money-back-guarantee.

The Technology

The CableCURE process is explained quite simply. Approximately 11 percent of a cable core is free space into which the silicone CableCURE fluid is injected. The fluid reinforces the primary insulation and combines with the water molecules present. The fluid is pumped into the cable under pressure from one end until it has completely filled the cable. If required a vacuum can be applied to the free end of the cable to increase the efficiency of the filling process. In slightly more detail, the CableCURE system comprisThe Problem es a restoration fluid that is injected into a cable and difIn the early 1970s, the first reports of increasing failures on A view of how water is ejected from the inner core of cable using the fuses into the insulation CableCURE system. immediately starting to PE-insulated, medium-voltage restore its dielectric strength. cables were noted in the In the insulation itself, the fluid reacts with water moleUnited States. At the beginning of the 1980s, similar cable cules, eliminates the negative effect of the water trees and faults were noted also in Europe. The cause of these faults retards future water tree growth. The process raises the was found to be the formation of water trees. It was found dielectric strength of the water tree and the insulation to that water trees grow with the correct combination of a uniform high strength. water, imperfections of the PE, XLPE or EPR insulation Additionally, in the reaction with water, the CableCURE around a cable and the operating voltage over the course of molecule grows to a larger size, which keeps the fluid in time. the insulation.This assures the restoration of the cable will When a water tree reaches a critical size, it can convert last many years. into an electrical tree accompanied by partial discharge to Some 200 utilities all over Europe and around the globe ground that inevitably leads to an electrical fault on the have utilized CableCURE technology with some 15,000 cable. All solid dielectric medium-voltage cables are suskm of water tree damaged medium voltage cables having ceptible to water treeing regardless of the existence of a been successfully treated over the past 17 years. jacket or strand filling. As with power cables, many of the troubles within airToday, cable failures are not only the owners problem in core telecommunications cables, such as noise on the line terms of time and cost intensive repairs or replacement of

www.trenchlessonline.com

July 2005

TRENCHLESS TECHNOLOGY INTERNATIONAL

and cross talk, and the resulting customer complaints, arise through problems resulting from water-damaged cables.Again solving these problems can get expensive not only because they often require repeated service calls, but also because they can eventually lead to abandoning so many lines that system capacity can become a problem. CableCURE/CB treatment can eliminate most of these problems, significantly reducing trouble calls and saving time and money. It can also recover 90 percent of abandoned lines, so increasing capacity. The CableCURE/CB fluid used for these circumstances is injected directly into the cable.This process pushes the water out of the cable and the fluid thickens to a re-enterable gel within 48 to 72 hours so engineers can get into the cable if needed but water cannot. CableCURE/CB treatment comes with a full money-back warranty for as long as owners choose to keep the cable in service. Not only is the system good for the cables but it also enables contractors to carry out repairs with minimal excavation. The contractor carrying out the work is also less dependent on the weather.

Use in the Netherlands

Many first-generation, synthetic-insulated, medium-voltage cables (10,000-volt) were extensively used in the Netherlands over the period from 1975 to 1981. These cables were mainly laid in the Dutch provinces Noord Brabant, Drenthe and Groningen. For example, the Dutch utility Essent has successfully

used the renovation service of CableCUREs European Operation Center for cable works in cooperation with A.Hak Infranet, which provided the craftworks for splice and termination fitting as well as civil engineering. A recent project involved the CableCURE treatment, of some 160-system km of water tree damaged medium voltage cable in the Brabant region of the Netherlands for Essent (South). The longest single run made on the project was on a cable length of about 3.5 system km. For the treatment of the Essent cables, all old cable splices were replaced with modern equivalent, pressure resistant and injectable splices from specialist manufacturer,Tyco. It is also possible to treat single segments of a cable when necessary or preferable. The advantage of choosing CableCURE for this project instead of cable replacement was that it became possible to stretch the budget for asset management and maintenance. The regular cost-savings of CableCURE compared with cable replacement is between 60 to 80 percent. In the case of the Essent project, the client was happy to confirm that it benefited to about 80 percent compared to the replacement cost of the cables. In addition, cable treatment is easy to perform and the organizational requirements are low. To date, some 99.5 percent of all CableCURE-treated, medium-voltage cables are operating undisturbed in service subsequent to their treatment. Ian Clarke is a freelance writer with No-Dig Media, which is based in the United Kingdom.

USA: 1-800-252-0556 Europe: +49 5751 918 715 Outside:+1 (253) 395-0200 marketing@utilx.com www.utilx.com

TRENCHLESS TECHNOLOGY INTERNATIONAL

July 2005

www.trenchlessonline.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- V MeasuringDocument1 pageV MeasuringJesudhason PrinceNo ratings yet

- IG55 TesterDocument1 pageIG55 TesterJesudhason PrinceNo ratings yet

- How To Convert The Tamil PDF File To Tamil Word FileDocument4 pagesHow To Convert The Tamil PDF File To Tamil Word FileJesudhason PrinceNo ratings yet

- PDFlib Lite LicenseDocument2 pagesPDFlib Lite LicenseDedik KurniawanNo ratings yet

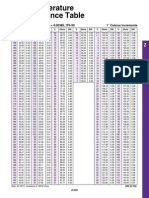

- For European Curve, Alpha 0.00385, ITS-90 1° Celsius IncrementsDocument3 pagesFor European Curve, Alpha 0.00385, ITS-90 1° Celsius IncrementsMary HarrisonNo ratings yet

- Types of SubstationDocument3 pagesTypes of SubstationJesudhason Prince100% (2)

- (PMP Exam Changes) How PMBOK Guide 6th Edition Affect PMP Aspirants in 2017Document39 pages(PMP Exam Changes) How PMBOK Guide 6th Edition Affect PMP Aspirants in 2017Jesudhason PrinceNo ratings yet

- VRLA Battery Lifetime Study - Factors Affecting Lead Acid Battery LifeDocument13 pagesVRLA Battery Lifetime Study - Factors Affecting Lead Acid Battery LifeRahul ShelkeNo ratings yet

- Bh6340h-Fb Bindllk Sim 1745Document2 pagesBh6340h-Fb Bindllk Sim 1745Jesudhason PrinceNo ratings yet

- Icici Claim FormDocument3 pagesIcici Claim FormjspinkuNo ratings yet

- Tests before terminating XLPE cablesDocument3 pagesTests before terminating XLPE cablesJesudhason PrinceNo ratings yet

- Advanced Outlook PDFDocument30 pagesAdvanced Outlook PDFOhiwei OsawemenNo ratings yet

- Moving Up The Ladder 10 Strategies For Getting PromotedDocument3 pagesMoving Up The Ladder 10 Strategies For Getting PromotedJesudhason PrinceNo ratings yet

- Power Plants Product Catalogue 2010Document92 pagesPower Plants Product Catalogue 2010Jesudhason PrinceNo ratings yet

- 3.5core Copper PVC ArmouredDocument1 page3.5core Copper PVC ArmouredJesudhason PrinceNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Landfill Capacity CalculationDocument3 pagesLandfill Capacity CalculationJhon Jairo Mazuera Guzman50% (2)

- CAT992Document24 pagesCAT992Miriam Ruiz Cabellos100% (1)

- Honda Sales ProjectDocument72 pagesHonda Sales Projectsurendar100% (2)

- Building EstimateDocument16 pagesBuilding EstimateMrinal TalukdarNo ratings yet

- 4l80e Teardown Rebuild and InstallationDocument146 pages4l80e Teardown Rebuild and Installationobx4ever50% (2)

- Icmeas 2017: Local Advisory CommitteeDocument3 pagesIcmeas 2017: Local Advisory CommitteeZawad AbedinNo ratings yet

- List of BAPIsDocument35 pagesList of BAPIsthiago.alves.85No ratings yet

- Support Dept Cost Allocation - 3 Allocation MethodsDocument6 pagesSupport Dept Cost Allocation - 3 Allocation MethodsSophie PearsonNo ratings yet

- Mechanical Engineer Resume For FresherDocument5 pagesMechanical Engineer Resume For FresherIrfan Sayeem SultanNo ratings yet

- Bloomberg Businessweek USADocument84 pagesBloomberg Businessweek USAalexe012No ratings yet

- Company Introduction PDFDocument11 pagesCompany Introduction PDFVishwanath ShervegarNo ratings yet

- bb9df927-5af1-44e0-ae49-d3fd10a5eb4b (1)Document6 pagesbb9df927-5af1-44e0-ae49-d3fd10a5eb4b (1)anonymphantomNo ratings yet

- How To Upload PsDocument16 pagesHow To Upload Psrohan sharmaNo ratings yet

- International GTA220Document1 pageInternational GTA220Anwar MdNo ratings yet

- ISA RP60.3 Human Engineering For Control CentersDocument22 pagesISA RP60.3 Human Engineering For Control CentersDaniel Arrieta DarrásNo ratings yet

- CV Summary for Network EngineerDocument2 pagesCV Summary for Network EngineerManisha PatilNo ratings yet

- Tecnotion Torque Motor Brochure Ver 10120150120Document16 pagesTecnotion Torque Motor Brochure Ver 10120150120ElectromateNo ratings yet

- Presentation Consulting Change of Fiscal PeriodsDocument16 pagesPresentation Consulting Change of Fiscal PeriodsmnryanNo ratings yet

- Cookbook Measuring StrategiesDocument27 pagesCookbook Measuring StrategiesArzillo Salvatore50% (2)

- Rotex Poly-Norm: Torsionally Flexible CouplingsDocument27 pagesRotex Poly-Norm: Torsionally Flexible CouplingsAngelica Ochoa FlorezNo ratings yet

- CivicrmDocument361 pagesCivicrmmandohNo ratings yet

- Minimum Equipment List (MEL) - SKYbrary Aviation SafetyDocument1 pageMinimum Equipment List (MEL) - SKYbrary Aviation SafetyhmmnksyNo ratings yet

- Written Lockout/Tagout Program University of South Carolina (Enter Department Name Here)Document13 pagesWritten Lockout/Tagout Program University of South Carolina (Enter Department Name Here)SaidNo ratings yet

- Stockdale Method Roundabout PDFDocument50 pagesStockdale Method Roundabout PDFAnonymous O7BzqVvmINo ratings yet

- Creating The Lean Car DealerDocument52 pagesCreating The Lean Car DealerMahadiMohdDinNo ratings yet

- Ers EDocument16 pagesErs ERdy SimangunsongNo ratings yet

- Continuous Improvement SWOT AnalysisDocument2 pagesContinuous Improvement SWOT AnalysisichintanNo ratings yet

- Nokia: FDD and TDD LTE Radio Planning (FL15A/TL15A)Document6 pagesNokia: FDD and TDD LTE Radio Planning (FL15A/TL15A)tooma123No ratings yet

- A Study On Dyeing Machine & ETPDocument56 pagesA Study On Dyeing Machine & ETPDipayon SahaNo ratings yet

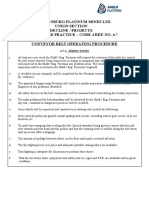

- 4.7 Conveyor Belt Operating ProcedureDocument3 pages4.7 Conveyor Belt Operating Procedurejohnson OlubiNo ratings yet