Professional Documents

Culture Documents

Lab Direct Shear Test - New

Uploaded by

LaBuHiTamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lab Direct Shear Test - New

Uploaded by

LaBuHiTamCopyright:

Available Formats

G5 - DIRECT SHEAR TEST GENERAL In a direct shear test a square prism of soil is laterally restrained and sheared along

a predetermined horizontal plane while being subjected to a pressure applied normal to that plane. The shearing resistance offered by the soil, as one portion is made to slide on the other, is measured at regular intervals of displacement. Failure occurs when the shearing resistance reaches the maximum value which the soil can sustain. By carrying out set of tests on asset of (usually three sets) some soil sample under different normal pressures, the relationship between measured shear stress at failure and normal applied stress can be obtained. The shear box apparatus is only suitable for carrying out drained tests for the determination of effective shear strength parameters. There is no control of drainage and the procedure cannot be used for undrained tests. OBJECTIVE The shear strength is one of the most important engineering properties of a soil, because it is required whenever a structure is dependent on the soils shearing resistance. The shear strength is needed for engineering situations such as determining the stability of slopes or cuts, finding the bearing capacity for foundations, and calculating the pressure exerted by a soil on a retaining wall. The purpose of the test is to determine the parameters of shear strength of soil (i.e. cohesion, c and angle of shearing resistance, ) by direct shear. APPARATUS 1. specimen cutter

2. shear box apparatus 3. hanger weights 4. weighing balance

EXPERIMENTAL PROCEDURES First step for this experiment is the specimen cutter is weighed nearest to 0.1 g. After that the specimen is obtained and trimmed from soil sample using cutter and trimmer. The specimen then is weighed in cutter nearest to 0.1 g, and the initial mass (M o) of the specimen is calculated. Then the cutter is rested on the top surface of the assembled shear box with its inside faces in exact alignment with the inside faces of the shear box.

And then the specimen is pushed out of the cutter and into the shear box, keeping its upper face horizontal, until it is bedded on to the lower porous plate. The upper porous plate is placed firmly on the specimen. An equal clearance all around the edges of the plate is then ensured. Then the carriage had been position on its bearings on the machine bed, and the drive unit then been adjusted to the correct starting point of the shear test. The horizontal displacement gauge is secured in position. The loading system is assembled so that the loading yoke is supported by ball seating on top of the load cap and plus with hanger weight 2.5 kg. Then specimen is sheared to failure using the rate of shear displacement of 40mm/hr The test then is started at the same instant start the timer. The readings of the force measuring device, the horizontal displacement gauge, the vertical deformation gauge and elapsed time are recorded. At regular intervals of horizontal displacement (every 1 minute) such that at least 20 readings are taken up to the maximum load (peak shear strength). Must be take a note that intervals of horizontal displacement of 0.1 mm meet this requirement. For brittle specimens such as dense sand, sets of data should be recorded at frequent intervals of force, instead of displacement, to ensure that enough readings are taken. For plastic materials the intervals may be greater than normal. Then additional readings are taken as the maximum horizontal force is approached, so that if the peak occurs it can be clearly defined. Shearing and taking readings are continued beyond the maximum force, or until the full travel of the apparatus has been reached if there is no defined peak, then the test is stopped. The direction of travel of the carriage is then reversed and the two halves of the shear box are returned to their original alignment. The vertical force and loading yoke is removed from the specimen.

Finally the process from is repeated for one more specimen using hanger weight 1.25 kg, 2.5 kg and 3.75 kg respectively. NOTES If shear strength of a soil can be described by the Mohr- Coulomb equation:

Where;

= c + n tan

= shear strength

c = cohesion n = normal stress THEORY Shear strength of a soil can be described by the Mohr-Column equation: = c + n tan where: = shear strength c = cohesion n= normal stress = angle of shear resistance Shear strength, = F/A Where: F = shear force A = area of sample/shear box Normal stress, Where:

n n

= angle of shear resistance

= N/A

= normal shear stress

N = normal vertical force acting on the specimen Shear stress, = c + n tan

c Normal stress,

n

You might also like

- G5 Direct ShearDocument5 pagesG5 Direct ShearFairiey Izwan AzaziNo ratings yet

- Direct Shear TestDocument4 pagesDirect Shear TestanasNo ratings yet

- Geotechnical Engineering Shear Strength TestsDocument29 pagesGeotechnical Engineering Shear Strength Testsmannie edet100% (1)

- Direct Shear TestDocument4 pagesDirect Shear TestNajihaharifNo ratings yet

- Report-Direct Shear Test 1Document20 pagesReport-Direct Shear Test 1Ash BlackForest50% (2)

- Mohr-Coulomb Shear Strength TheoryDocument12 pagesMohr-Coulomb Shear Strength TheoryJoseph JboyNo ratings yet

- Determine Shear Strength Parameters Using Triaxial TestDocument4 pagesDetermine Shear Strength Parameters Using Triaxial TestRazakMaidenNo ratings yet

- Experiment No 1: Direct Shear TestDocument10 pagesExperiment No 1: Direct Shear TestAmir SultanNo ratings yet

- Direct Shear TestDocument11 pagesDirect Shear Testshahrolhazrien91% (34)

- Direct Shear Test Mohr Coulomb Failure EnvelopeDocument16 pagesDirect Shear Test Mohr Coulomb Failure EnvelopeNishanth Nanthakumar25% (4)

- Direct Shear TestDocument14 pagesDirect Shear TestAmin SaufiNo ratings yet

- Shear Strength of SoilsDocument10 pagesShear Strength of Soilstitukutty6032No ratings yet

- Direct Shear TestDocument23 pagesDirect Shear TestRajesh KhadkaNo ratings yet

- Direct ShearDocument4 pagesDirect ShearMUHAMMAD RIAZ AHMAD 2009-CIV-140No ratings yet

- Direct Shear TestDocument19 pagesDirect Shear Testshahrolhazrien75% (4)

- Unconfined Compression Lab Rapor 2Document12 pagesUnconfined Compression Lab Rapor 2Abdulsamed GözeNo ratings yet

- Shear Strength (Direct Shear Test)Document29 pagesShear Strength (Direct Shear Test)VidyaSagarSinghNo ratings yet

- Report Full Direct Shear Test Edit (Repaired)Document15 pagesReport Full Direct Shear Test Edit (Repaired)Asyraf Malik100% (15)

- See Direct Shear TestingDocument49 pagesSee Direct Shear TestingRajesh KhadkaNo ratings yet

- Shear Strength of SoilsDocument13 pagesShear Strength of Soilspankaj100% (1)

- Direct Shear Box TestDocument9 pagesDirect Shear Box TestMuhammad Yusoff Zakaria100% (1)

- CE 240 Soil Mechanics & Foundations Lecture 11Document40 pagesCE 240 Soil Mechanics & Foundations Lecture 11Anoop RajNo ratings yet

- Lab 1 Direct Shear Lab 1 Direct Shear TestTestDocument9 pagesLab 1 Direct Shear Lab 1 Direct Shear TestTest7e1a8821100% (1)

- ASTM D2850 Triaxial Test Cohesive SoilsDocument15 pagesASTM D2850 Triaxial Test Cohesive SoilsMin MiynNo ratings yet

- GEOTECHNICAL LAB REPORTDocument26 pagesGEOTECHNICAL LAB REPORTJawad AliNo ratings yet

- CE362 Geotechnical Engineering-II UNIT-1 B Soil ExplorationDocument32 pagesCE362 Geotechnical Engineering-II UNIT-1 B Soil Explorationjohn haokipNo ratings yet

- Direct Shear TestingDocument14 pagesDirect Shear TestingIlhamNo ratings yet

- Lab#09 Direct Shear StrengthDocument4 pagesLab#09 Direct Shear StrengthMuhammad UsmanNo ratings yet

- Shear Strength Calculations: Mohr-Coulomb EquationDocument23 pagesShear Strength Calculations: Mohr-Coulomb EquationNouman AmjadNo ratings yet

- Shear Strength and Testing of SoilsDocument2 pagesShear Strength and Testing of SoilsShamRock CasasNo ratings yet

- Laboratory Exercise: Direct Shear Test: References and SourcesDocument7 pagesLaboratory Exercise: Direct Shear Test: References and SourcesFarid MarufNo ratings yet

- Shear Strength of SoilsDocument14 pagesShear Strength of SoilsAnkit NagpalNo ratings yet

- Shear Strength of SoilsDocument21 pagesShear Strength of SoilsAslam KhanNo ratings yet

- Module 3 Shear Strength of SoilDocument7 pagesModule 3 Shear Strength of SoilJeth LawNo ratings yet

- O.E.Lab - Docx For Direct Shear TestDocument14 pagesO.E.Lab - Docx For Direct Shear TestAmirah SyakiraNo ratings yet

- DiscussionDocument5 pagesDiscussionmtrego9441No ratings yet

- Shear Strength of Soil: Key Concepts & Laboratory TestsDocument94 pagesShear Strength of Soil: Key Concepts & Laboratory TestsRowdy BoyNo ratings yet

- Unit 5 - Shear Strength of SoilDocument66 pagesUnit 5 - Shear Strength of SoilMr.Bhaskar Wabhitkar100% (1)

- Shear Strength of SoilDocument43 pagesShear Strength of SoilChristian Jude LegaspiNo ratings yet

- Slope Stability and Soil/rock StrengthDocument11 pagesSlope Stability and Soil/rock StrengthEmran Banat95No ratings yet

- Consolidation Test: 1. ObjectiveDocument6 pagesConsolidation Test: 1. ObjectiveSwapan PaulNo ratings yet

- Test 12 ConsolidationDocument6 pagesTest 12 ConsolidationMuhammad Azeem Ashraf 139-FET/BSCE/F17No ratings yet

- Test 08Document6 pagesTest 08Kauther KautherNo ratings yet

- Lab Report #01 The Direct Shear Test (ASTM D-3080)Document18 pagesLab Report #01 The Direct Shear Test (ASTM D-3080)AHMED SOHELNo ratings yet

- Beng-Soil Mechanics IB-Slides 16-56Document43 pagesBeng-Soil Mechanics IB-Slides 16-56Tom WhanNo ratings yet

- KjhgilfljfljDocument3 pagesKjhgilfljfljGaming with SambhavNo ratings yet

- BS5930-2015 192Document1 pageBS5930-2015 192Ford cellNo ratings yet

- Geomechanics - Lab Session No 8 - Direct Shear Test SheetDocument2 pagesGeomechanics - Lab Session No 8 - Direct Shear Test SheetharinderNo ratings yet

- Unconfined Compression TestDocument3 pagesUnconfined Compression TestThrisha SoquitosoNo ratings yet

- Triaxial Test Report - Group 2Document20 pagesTriaxial Test Report - Group 2Khalidah RosmanNo ratings yet

- KNE373 Prac 1 - Direct Shear Strength TestDocument4 pagesKNE373 Prac 1 - Direct Shear Strength TestSebin GeorgeNo ratings yet

- BST MethodologyDocument6 pagesBST MethodologyMehedi HasanNo ratings yet

- Geo TechnicalDocument16 pagesGeo TechnicalAyush GorasiyaNo ratings yet

- The Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingFrom EverandThe Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingNo ratings yet

- Pressure, Resistance, and Stability of Earth American Society of Civil Engineers: Transactions, Paper No. 1174, Volume LXX, December 1910From EverandPressure, Resistance, and Stability of Earth American Society of Civil Engineers: Transactions, Paper No. 1174, Volume LXX, December 1910No ratings yet

- 136 ADMU V Capulong (Roxas)Document2 pages136 ADMU V Capulong (Roxas)Trisha Dela RosaNo ratings yet

- How To Use Oracle Account Generator For Project Related TransactionsDocument40 pagesHow To Use Oracle Account Generator For Project Related Transactionsapnambiar88No ratings yet

- Lfa Sop 00067Document6 pagesLfa Sop 00067Ahmed IsmaillNo ratings yet

- Green Ecobuses Run On This Route.: BusesDocument6 pagesGreen Ecobuses Run On This Route.: BusesLuis DíazNo ratings yet

- Lecture 2 Leader-Centred PerspectivesDocument24 pagesLecture 2 Leader-Centred PerspectivesLIVINGSTONE CAESARNo ratings yet

- NURKSE's Balanced GrowthDocument7 pagesNURKSE's Balanced GrowthArnab MutsuddyNo ratings yet

- Smart Card PresentationDocument4 pagesSmart Card PresentationNitika MithalNo ratings yet

- TESA Doorclosers and Door Operators PDFDocument46 pagesTESA Doorclosers and Door Operators PDFDawood Shaik Abdul CadarNo ratings yet

- Rhetorical Moves in The Literature Review Section of A Sample Research ArticleDocument1 pageRhetorical Moves in The Literature Review Section of A Sample Research ArticleKim Sydow Campbell100% (1)

- MATLAB code for Mann–Kendall test and Sen's slope estimationDocument7 pagesMATLAB code for Mann–Kendall test and Sen's slope estimationTubaiNandiNo ratings yet

- Marking SchemeDocument8 pagesMarking Schememohamed sajithNo ratings yet

- Line Sets in Oracle Order ManagementDocument9 pagesLine Sets in Oracle Order ManagementS S PatelNo ratings yet

- Office of The Controller of Examinations Anna University:: Chennai - 600 025Document4 pagesOffice of The Controller of Examinations Anna University:: Chennai - 600 025M.KARTHIKEYANNo ratings yet

- G.R. No. 175350 June 13, 2012 Equitable Banking Corporation, Inc. Petitioner, Special Steel Products, and Augusto L. Pardo, RespondentsDocument8 pagesG.R. No. 175350 June 13, 2012 Equitable Banking Corporation, Inc. Petitioner, Special Steel Products, and Augusto L. Pardo, RespondentsHp AmpsNo ratings yet

- Mr. Arshad Nazer: Bawshar, Sultanate of OmanDocument2 pagesMr. Arshad Nazer: Bawshar, Sultanate of OmanTop GNo ratings yet

- Employee Training and DevelopmentDocument33 pagesEmployee Training and DevelopmentMoogii50% (2)

- DESIGN AND FABRICATION TURBO WOOD STOVE TIET OriginalDocument71 pagesDESIGN AND FABRICATION TURBO WOOD STOVE TIET OriginalSHIELDNo ratings yet

- Norlys 2016Document124 pagesNorlys 2016elektrospecNo ratings yet

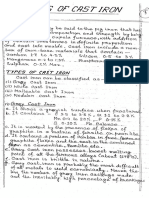

- Welding of Cast IronDocument10 pagesWelding of Cast IronKrishnendu RouthNo ratings yet

- D882 - Pruebas A Películas.Document11 pagesD882 - Pruebas A Películas.CamiloSilvaNo ratings yet

- Pg-586-591 - Annexure 13.1 - AllEmployeesDocument7 pagesPg-586-591 - Annexure 13.1 - AllEmployeesaxomprintNo ratings yet

- Guidelines Regarding The Handling of Cable Drums During Transport and StorageDocument5 pagesGuidelines Regarding The Handling of Cable Drums During Transport and StorageJegan SureshNo ratings yet

- Office of The Protected Area Superintendent: Mt. Matutum Protected LandscapeDocument3 pagesOffice of The Protected Area Superintendent: Mt. Matutum Protected LandscapeNurah LaNo ratings yet

- Caterpillar Cat 330L EXCAVATOR (Prefix 8FK) Service Repair Manual (8FK00001 and Up)Document27 pagesCaterpillar Cat 330L EXCAVATOR (Prefix 8FK) Service Repair Manual (8FK00001 and Up)kfm8seuuduNo ratings yet

- 244256-Exabeam Security Content in The Legacy Structure-Pdf-EnDocument142 pages244256-Exabeam Security Content in The Legacy Structure-Pdf-EnYoussef MohamedNo ratings yet

- Understanding Nominal Pipe Sizes (NPS) and Pipe DimensionsDocument39 pagesUnderstanding Nominal Pipe Sizes (NPS) and Pipe DimensionsprathikNo ratings yet

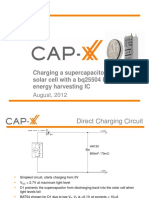

- 1208 CAP XX Charging A Supercapacitor From A Solar Cell PDFDocument12 pages1208 CAP XX Charging A Supercapacitor From A Solar Cell PDFmehralsmenschNo ratings yet

- Monopoly - Indian RailwaysDocument35 pagesMonopoly - Indian Railwaysvrj1091No ratings yet

- Regulations 2020: Mechanical Engineering CurriculumDocument162 pagesRegulations 2020: Mechanical Engineering CurriculumdsathiyaNo ratings yet

- Stock Futures Are Flat in Overnight Trading After A Losing WeekDocument2 pagesStock Futures Are Flat in Overnight Trading After A Losing WeekVina Rahma AuliyaNo ratings yet