Professional Documents

Culture Documents

Makmal Loji

Uploaded by

Mohammad ZapriOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Makmal Loji

Uploaded by

Mohammad ZapriCopyright:

Available Formats

4.

THEORY BACKGROUND

4.1

Boiler Mountings:

4.1.1

Boiler mountings are devices connected to the boiler which aid in its safe and efficient operation.

4.1.2

Types of mounting:

4.1.2.1

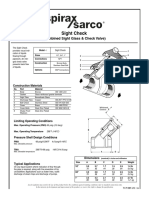

Water Gauge:

The function of water gauge is to show boiler water level for maintenance. According about specification B.S 759:1967 , each steam boiler shall have at least two independent means of indicating level can be observed, except that:

4.1.2.1.1

For boilers with all the drum safety valves set at or above 62 bar, two independent compensated manometer remote water level indicators be used in place of one of the water gauges.

4.1.2.1.2

For boilers of less than 300 lb per hour evaporative capacity one water gauge is sufficient.

4.1.2.1.3

For once-through boilers no water gauge are required.

4.1.2.2

Water Column

The column is a hollow casting or forging connected by pipes at top and bottom water spaces. The steam pipe connection to top of water column must not be lower than top of gauge glass and the water pipe connection to the column must not be higher than bottom of glass. Minimum size of these connecting pipes must not be less than 1 in. Plugged tees or crosses are used wherever practicable at right-angle turns so that all parts of piping may be easily examined and cleaned by removal of plugs. Cast iron water columns may be used for pressures not exceeding 250 psig (15 bar) , and malleable-iron columns for pressures not exceeding 350 psig (25 bar). Above that, steel columns must be used. Water column and water gauge must be test to prove that all passages are clear while the boiler is in operation.

4.1.2.3

Pressure Gauge The most common form is the Bourdon gauge. The

gauge is connected to the boiler drum through a siphon. The main feature is the Bourdon Tube, segment gear, pinion gear and calibrated scale.

4.1.2.3.1

Principle Work:

The main feature is the elliptical section Bourdon spring tube. The siphon contains water of condensed steam which enters the Bourdon tube. The pressure of the water makes the section more nearly circular and flattens the curve. The movement of the tips is practically between the internal and external pressure on the tube. Since the tube is surrounded by atmosphere, absolute pressure is the gauge pressure plus atmospheric pressure. The movement of the tip is magnified by the mechanism consisting of the adjustable link, the segment lever, pivoted, hairspring and calibrated scale. The gauge is generally made to indicate up to twice the maximum working pressure so that the pointer is vertical when the safety valve is about to blow off. B.S 759 states the graduation shall be from zero to not less than one and one-half times and not more than twice the operating pressure. Each dial shall have marked upon it the boiler operating pressure in red and the maximum permissible working pressure in purple.

4.1.2.4

Safety Valve All except small boiler should have at least two safety

valves which will open when the boiler pressure exceeds the safe working pressure. These valves are almost all of the

disc type with narrow flat or cornical seats. They should be large enough to discharge the whole of the steam as rapidly as it is generated when the boiler is working at full power. B.S 759 state: it is recommended that at least two safety valves, one of which may be of the high steam and low water type, be fitted to each boiler but in no case shall a boiler with more than 50m2. Heating surface be fitted with less than two safety valves. Every super heater shall have at least one safety valves on the outlet side.

4.1.2.5

Blow-off Valve: Periodically it is necessary to empty the boiler in order that it

may be cleaned and inspected internally. It also a common practice periodically to discharge a portion of the water from the bottom of the boiler in order that any sediment which may be deposited may be carries away. Soft scale, or sludge, may form as a result of water treatment and has to be got rid of. For these purpose a blowoff valve or cock is fitted to the lowest part of the boiler.

4.1.2.6

Fusible Plug: The crown of the furnace or combustion chamber should be

fitted with a plug held in position by a fusible metal or alloy. This plug under normal conditions is covered with the water in the boiler which keeps the temperature of the fusible metal below its melting point. But should the water in the boiler fall below the low-water level, the fusible metal is melted by the heat of the fires or gives warning to the stoker that the furnace or combustion chamber crown is in danger of being overheated.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Series 93/193 and Series 94/194 Low Water Cut-Off/Pump ControllersDocument12 pagesSeries 93/193 and Series 94/194 Low Water Cut-Off/Pump ControllersHenry Diaz CristanchoNo ratings yet

- Manual Usuario Selectra Pro S 5 PDF FreeDocument260 pagesManual Usuario Selectra Pro S 5 PDF FreeAkbar SetiawanNo ratings yet

- SSC Cat - Steam Relief ValvesDocument15 pagesSSC Cat - Steam Relief ValvesArief sitompulNo ratings yet

- Commissioning Manual DH-6155: Descon Engineering LTDDocument102 pagesCommissioning Manual DH-6155: Descon Engineering LTDHammad AhmedNo ratings yet

- CMS Tanque AguaDocument31 pagesCMS Tanque AguaMarcel BaqueNo ratings yet

- Supra 550 1501 PDFDocument78 pagesSupra 550 1501 PDFAndryNo ratings yet

- Technical Spec - Final PDFDocument13 pagesTechnical Spec - Final PDFLuisSilvaNo ratings yet

- Hanla Vol1Document40 pagesHanla Vol1CvitaCvitićNo ratings yet

- 3755 176 00 USL06 EngDocument2 pages3755 176 00 USL06 EngpsnmyNo ratings yet

- Sight Glass InstallationDocument20 pagesSight Glass InstallationRendy MulyadiNo ratings yet

- DocumentDocument2 pagesDocumentAung Pyae TheinNo ratings yet

- #656 DAC-Polaris HOT PresentationDocument15 pages#656 DAC-Polaris HOT PresentationDerrick HensonNo ratings yet

- Comprehensive Guide to Oil Sight GlassesDocument10 pagesComprehensive Guide to Oil Sight Glasseskamal arabNo ratings yet

- Burnham Boiler v8h - ManualDocument100 pagesBurnham Boiler v8h - ManualEdwin GeeqNo ratings yet

- Round Sight Red GlassesDocument1 pageRound Sight Red GlassesjegadishNo ratings yet

- Autoclave PM Inspection Sheet: Plumbing - PressuresDocument2 pagesAutoclave PM Inspection Sheet: Plumbing - PressuresAd MinNo ratings yet

- Flexiflo TankTruckEquipmentsDocument20 pagesFlexiflo TankTruckEquipmentstdecebalus100% (2)

- Combined Sight Glass & Check ValveDocument2 pagesCombined Sight Glass & Check ValveLINA MARIA GARCIA CRUZNo ratings yet

- Fuel Gard VF 21 Coalescer SeparatorDocument2 pagesFuel Gard VF 21 Coalescer SeparatorEdisonCorderoNo ratings yet

- Manual Caldera FultonDocument69 pagesManual Caldera FultonMaria Gabriela Sosa100% (1)

- VMP Manual PDFDocument106 pagesVMP Manual PDFkikiNo ratings yet

- Air Compressor On A ShipDocument2 pagesAir Compressor On A ShipBhalchandra ChandakkarNo ratings yet

- PCMSRMDocument3 pagesPCMSRMErickNo ratings yet

- DIN 7060 Curcular Sight Glass PDFDocument14 pagesDIN 7060 Curcular Sight Glass PDFalathekoala100% (2)

- Boiler Operating ProcedureDocument3 pagesBoiler Operating ProcedureSathish KumarNo ratings yet

- V500 - 800le - HD Parts Manual SN 13658 - 13696 PDFDocument157 pagesV500 - 800le - HD Parts Manual SN 13658 - 13696 PDFLeon VaiciusNo ratings yet

- Heat Exchangers PDFDocument11 pagesHeat Exchangers PDFMaxi452No ratings yet

- Bladder Tank Proportioning System - 1298-9944-5 (A) - Angus Fire EngDocument62 pagesBladder Tank Proportioning System - 1298-9944-5 (A) - Angus Fire EngNaveed Anjum100% (1)

- Vacuum Pump Tuthill KVAH40 CatologueDocument20 pagesVacuum Pump Tuthill KVAH40 CatologueSamir JadhavNo ratings yet

- #656 - Hands-On Operations Training SkidDocument2 pages#656 - Hands-On Operations Training SkidDerrick HensonNo ratings yet