Professional Documents

Culture Documents

Fly Ash Techdata

Uploaded by

Namrata SapkalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fly Ash Techdata

Uploaded by

Namrata SapkalCopyright:

Available Formats

CI/SfB I

I (90.4) I s I

ASH SOLUTIONS LTD

Fly Ash BSEN 450 1 Class N Category B LOI FLY ASH product information

EN 450 N is a Quality Assured processed Fly Ash (also known as Pulverised Fuel Ash, or abbreviated to PFA). Fly Ash is supplied to the readymixed concrete and concrete product markets as a cement replacement.

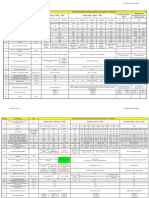

Using Fly Ash as a cement replacement reduces the overall CO2 footprint of the concrete. When PFA is used in concrete environmental savings can equate to 20% reduction in overall CO2 emissions for 30% Fly Ash content (based on mixes designed with equal 28 day strengths). Improved surface finish of the completed structure. Fly Ash contributes to producing a more cohesive concrete which has a reduced rate of bleeding making it easier to compact and giving the concrete better pumping properties. Reduces permeability, which reduces shrinkage, creep and gives greater resistance to chloride ingress and sulphate attack. Pozzolans such as PFA react with lime (alkali calcium hydroxide produced by cement hydrating) to form stable calcium silicates and calcium aluminate hydrates. These fill the voids in the concrete and remove some of the lime which reduces the permeability of the concrete. Improves long term strength, performance and durability. The Fly Ash reaction with lime also improves the strength, durability, chloride and sulfate resistance of the concrete. Using Fly Ash reduces the temperature rise in thick sections with the addition of less cement in a concrete mix the heat that is produced through hydration is greatly reduced. Minimises risk of Alkali Silica reaction Alkali Silica reaction is significantly reduced, if not completely eliminated, with the use of more than 25% of PFA. This is due to the fact that PFA readily reacts with sodium and potassium alkalis within the concrete. Admixtures can be used to extend the properties of Fly Ash in concrete, mortars and grouts. Applications Ash Solutions Limited Fly Ash can be combined with Type CEM I cement to produce material conforming to BSEN 1971. Basic oxide composition Component SiO2 AI2O3 Fe2O3 CaO MgO K2O Na2O TiO2 SO3* Cl Average % by weight 45 to 51 27 to 32 7 to 11 1 to 5 1 to 4 1 to 5 0.8 to 1.7 0.8 to 1.1 0.3 to 1.3 0.05 to 0.15

* Water soluble. The figures for SiO2 do not refer to free silica but to silicon present as silicates of varying compositions.

Fly Ash BSEN 450 1 Class N Category B LOI FLY ASH

product information

Specification BSEN450 1 CLASS N CATEGORY B LOI FLY ASH is classed as a TYPE II ADDITION, defined in BSEN 2061 CONCRETE as a finely divided inorganic pozzolanic or latent hydraulic material used in cements in order to improve certain properties or to achieve special properties. Complies with the requirements of BSEN 450 1 FLY ASH FOR CONCRETE, DEFINITIONS, REQUIREMENTS AND QUALITY CONTROL. Can be combined with CEM 1 Cement to BSEN 1971 Type CEM I at the concrete mixer or the cement factory to produce CEM 1 Fly Ash cements conforming to BSEN 1971:2000. Ash Solutions Limited Fly Ash is permitted to be used in concrete according to BS8500:2006 COMPLIMENTARY BRITISH STANDARD TO BSEN2061. Fly Ash can also be used to produce a wide range of cementitious products and is suitable as a filler or additive in concrete products. Production of Fly Ash at UK power stations When pulverised coal is burnt the Fly Ash has to be removed from the flue gases before they are released into the

atmosphere. The Fly Ash is therefore precipitated from the gas, first, by mechanical separation and then by a series of two or three electrostatic precipitators which progressively remove fine particles, so the last stage of precipitation collects the finest material of all. As a base raw material Fly Ash is variable for several reasons, including the sources of the coal, the efficiency of its pulverisation, and above all the furnace in which the pulverised coal is burnt and then the method of precipitating the ash from the combustion gases. In principle the furnace acts as a particle separator. About 20% of the ash particles either form together or combine into a form of clinker, which falls to the bottom of the furnace and is known as furnace bottom ash. The remaining 80% is known as Fly Ash and it is this material that is normally considered as an artificial pozzolan. Pozzolans Pozzolans are either naturally or artificially produced materials that, when mixed in finely divided form in concrete, chemically react at normal temperatures with the Calcium Hydroxide (LIME) that it is produced during the hydration of the CEM 1 Cement.

All concretes made with CEM 1 Cement alone produce an excess of lime which weakens the concrete because it is porous and chemically vulnerable to acids, carbon dioxide and soluble sulphates. If a material such as a pozzolan that combines with and fixates the lime, is added under controlled conditions, the result is a stabilized hydrate that is not only stronger but also less permeable to chemical attack. Manufacturing Standard All Ash Solutions Limiteds products are supplied in accordance with BS ISO 9001:2008, BS ISO 14001:2004 & BS OHSAS 18001:2007. Logistics Ash Solutions Limited supplies PFA to its national customer base in pressurised road tankers. COSHH data COSHH data on Ash Solutions Limited products is available on request. Technical support For technical support please call our Technical Services on: 01469 585806. Reports of tests providing data on chemistry and fineness are available.

Ash Solutions Limited,

Unit 2 & 3 Yarborough Court,

Front Street, Ulceby. Nr Grimsby,

North Lincolnshire DN39 6RZ

Tel: +44 (0) 1469 585806

Fax: +44 (0) 1469 588912

Aggregate Industries UK Limited. December 2009

The information contained within this publication was accurate at time of production. However, Aggregate Industries reserves the right to introduce modifications or changes to detail at any time without notice. No charge is levied for this publication or advice therein, and accordingly the company, its employees and authorised agents can accept no liability whatsoever, either indirectly or directly arising from the use of its products in connection with any information or advice contained in this guide.

You might also like

- Fly Ash Cement Replacement Tds PDFDocument2 pagesFly Ash Cement Replacement Tds PDFabualamalNo ratings yet

- Fly Ash: Boral CementDocument1 pageFly Ash: Boral CementBhuidhar VermaNo ratings yet

- Hanson Bs en 450 Fly Ash Technical Data Sheet 1Document2 pagesHanson Bs en 450 Fly Ash Technical Data Sheet 1Amina MujkanovicNo ratings yet

- Chapter 4 - Additive and Chemical AdmixturesDocument42 pagesChapter 4 - Additive and Chemical Admixtureseyob yohannesNo ratings yet

- Introduce About CementDocument3 pagesIntroduce About CementSinu DonNo ratings yet

- AdditivesDocument42 pagesAdditivesJo FlashNo ratings yet

- Manufacturing of Flyash BricksDocument14 pagesManufacturing of Flyash BricksSHASHANKDUBEY52No ratings yet

- Concrete Lec 7Document10 pagesConcrete Lec 7Owais Khan100% (1)

- MB SCMS Feb24Document4 pagesMB SCMS Feb24Gnansabesan JathurschanNo ratings yet

- Fly AshDocument11 pagesFly AshVineet KediaNo ratings yet

- Advances in Concrete TechnologyDocument53 pagesAdvances in Concrete TechnologySimranjit Singh MarwahNo ratings yet

- (Effects of Fly Ash in Cement Properties)Document9 pages(Effects of Fly Ash in Cement Properties)ShowvikNo ratings yet

- Uses Fly AshDocument13 pagesUses Fly AshMardav PanwarNo ratings yet

- Customer Manual PDFDocument110 pagesCustomer Manual PDFvivekm8850% (2)

- Ycet Jammu: Seminar OnDocument19 pagesYcet Jammu: Seminar OnSherry SherNo ratings yet

- Lecture 8 9 10Document39 pagesLecture 8 9 10ewaqasak2013No ratings yet

- IntroductionDocument9 pagesIntroductionAsaruChampNo ratings yet

- IntroductionDocument9 pagesIntroductionAsaruChampNo ratings yet

- IntroductionDocument9 pagesIntroductionAsaruChampNo ratings yet

- IntroductionDocument9 pagesIntroductionAsaruChampNo ratings yet

- Seminar Presentation: Fly Ash: Utilization and DisposalDocument29 pagesSeminar Presentation: Fly Ash: Utilization and DisposalCivil 2No ratings yet

- Construction Materials Guide: Cement, Concrete, TestingDocument49 pagesConstruction Materials Guide: Cement, Concrete, TestingAliñabo RoqueNo ratings yet

- Background of Recovered Mineral Components in ConcreteDocument24 pagesBackground of Recovered Mineral Components in ConcreteTgemunuNo ratings yet

- Types of Admixtures and Their Effects on Concrete PropertiesDocument9 pagesTypes of Admixtures and Their Effects on Concrete PropertiesAsaruChampNo ratings yet

- Types of Mineral AdmixturesDocument3 pagesTypes of Mineral Admixturesash_chhatbarNo ratings yet

- Presenter: Rafeeq Kamel Ali Muhaisen Laboratory Supervisor / Chemist Qatar National Cement CoDocument58 pagesPresenter: Rafeeq Kamel Ali Muhaisen Laboratory Supervisor / Chemist Qatar National Cement CoNael100% (2)

- Construction Materials & TestingDocument65 pagesConstruction Materials & TestingNicholas Bonn SingNo ratings yet

- Hanson Portland Limestone Cement Data SheetDocument2 pagesHanson Portland Limestone Cement Data Sheetyaser666No ratings yet

- Module 3 ADVANCED CONCRETE DESIGN NOTESDocument18 pagesModule 3 ADVANCED CONCRETE DESIGN NOTESshalu R FNo ratings yet

- Silica Fume and Fly Ash Effects on Fresh and Hardened ConcreteDocument14 pagesSilica Fume and Fly Ash Effects on Fresh and Hardened ConcreteSohail Anwar100% (1)

- ACC - Cement User GuideDocument51 pagesACC - Cement User Guideharun_inamdar100% (2)

- MINERAL ADMIXTURES: THE BENEFITS OF FLY ASH IN CONCRETEDocument53 pagesMINERAL ADMIXTURES: THE BENEFITS OF FLY ASH IN CONCRETENezar AlaqeeliNo ratings yet

- Pozzolanic MaterialsDocument14 pagesPozzolanic MaterialsBahy ElkolalyNo ratings yet

- Cement Materials: Geology and Benefication ofDocument37 pagesCement Materials: Geology and Benefication ofAMPamasengiNo ratings yet

- 2005 - Stabilization of Soil With Self Cementing Coal AshesDocument7 pages2005 - Stabilization of Soil With Self Cementing Coal AshesAlivia Nur AnindyNo ratings yet

- Portland Pozzolona CementDocument35 pagesPortland Pozzolona CementAustin RodriguesNo ratings yet

- V. Sulfate-Resisting Cement: Concrete Technology (I) Lecture 7Document9 pagesV. Sulfate-Resisting Cement: Concrete Technology (I) Lecture 7Mahmoud HosnyNo ratings yet

- Building Limes in Conservation - Building Lime StaDocument8 pagesBuilding Limes in Conservation - Building Lime StaHuyentrang NguyenNo ratings yet

- Assignment 21-09-2019Document6 pagesAssignment 21-09-2019Engr Nazeer AhmadNo ratings yet

- 01 Flyash Brick1Document142 pages01 Flyash Brick1Jigar M. Upadhyay100% (2)

- 4147ictte384 PDFDocument6 pages4147ictte384 PDFKandasamy AsohanNo ratings yet

- Cement and Concrete Presentation LafargeDocument131 pagesCement and Concrete Presentation LafargeJohnnie Strydom100% (1)

- Fly Ash Bricks-10lDocument16 pagesFly Ash Bricks-10lRENUSREE ENTERPRISESNo ratings yet

- Some Basics About-EV CSDocument9 pagesSome Basics About-EV CSபுருஷோத்தமன் சரவணன்No ratings yet

- Cement Replacement Materials LectureDocument36 pagesCement Replacement Materials LectureCyrus HongNo ratings yet

- INSEE EXTRA Product DescriptionDocument2 pagesINSEE EXTRA Product DescriptionYasndra AbeygunewardhaneNo ratings yet

- Fly Ash Stabilization: An Inexpensive Soil Improvement MethodDocument7 pagesFly Ash Stabilization: An Inexpensive Soil Improvement MethodMohamed AdnanNo ratings yet

- Admixtures For ConcreteDocument5 pagesAdmixtures For ConcreteShahril ZainulNo ratings yet

- MasterRheobuild 2000 Hyperplasticizing AdmixtureDocument2 pagesMasterRheobuild 2000 Hyperplasticizing AdmixtureKonax Lihysd MandeNo ratings yet

- Self-Consolidating Concrete or Self-Compacting Concrete: HycreteDocument4 pagesSelf-Consolidating Concrete or Self-Compacting Concrete: HycreteSami Mohammed FazilNo ratings yet

- Overview On Cement and Cement TypesDocument12 pagesOverview On Cement and Cement Typescollostero6No ratings yet

- Cement Chemistry Guide: Types, Properties & ApplicationsDocument9 pagesCement Chemistry Guide: Types, Properties & ApplicationsSyed Mohd MehdiNo ratings yet

- Sika Concrete HandbookDocument151 pagesSika Concrete Handbooksmartman35No ratings yet

- REPORT MaterialDocument14 pagesREPORT Material050 Syed EhsaanNo ratings yet

- Modern Cements: Industrial RevolutionDocument5 pagesModern Cements: Industrial RevolutionHareesh HariNo ratings yet

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringFrom EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringRating: 4 out of 5 stars4/5 (5)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Low Carbon Stabilization and Solidification of Hazardous WastesFrom EverandLow Carbon Stabilization and Solidification of Hazardous WastesDaniel C.W. TsangNo ratings yet

- Sandblasting Process ExplainedDocument19 pagesSandblasting Process ExplainedJeet GuptaNo ratings yet

- Spectrofotometru SpectroDirect (De La Lovibond)Document360 pagesSpectrofotometru SpectroDirect (De La Lovibond)FlaviusNo ratings yet

- Information Booklet Elements Compounds and MixturesDocument40 pagesInformation Booklet Elements Compounds and MixturesnowhinesonchemistryNo ratings yet

- UWO Chem 3300g Computer MethodsDocument2 pagesUWO Chem 3300g Computer MethodsmejiasclaudiaNo ratings yet

- PLAJEX SN Leaflet 2019Document2 pagesPLAJEX SN Leaflet 2019pushpanjali singhNo ratings yet

- Anti-Dandruff Shampoo With Zinc Pyrithione: INCI Name, Trade Name Weight % FunctionDocument2 pagesAnti-Dandruff Shampoo With Zinc Pyrithione: INCI Name, Trade Name Weight % FunctionandreeaNo ratings yet

- PV Module IonDocument4 pagesPV Module IonrmalewarNo ratings yet

- NRAC Publication No. 170 An Introduction To Water Chemistry in Freshwater AquacultureDocument4 pagesNRAC Publication No. 170 An Introduction To Water Chemistry in Freshwater AquacultureSk RajNo ratings yet

- What Are Magic RocksDocument2 pagesWhat Are Magic Rocksdatta sdNo ratings yet

- Statistical Mechanics: Alice PaganoDocument253 pagesStatistical Mechanics: Alice PaganoSharon Di SpenaNo ratings yet

- Innovative Use of Recycled Tyres in Civil Engineering ApplicDocument73 pagesInnovative Use of Recycled Tyres in Civil Engineering Applicparasgandhi187874100% (5)

- Epoxy resin free flow grout for heavy duty applicationsDocument4 pagesEpoxy resin free flow grout for heavy duty applicationsFeri Oktara IrawanNo ratings yet

- Deformation and Fracture Mechanics of Engineering MaterialsDocument44 pagesDeformation and Fracture Mechanics of Engineering MaterialsSyed Muhammad AliNo ratings yet

- Nuclear Medicine Inc.'s Iodine Value Chain AnalysisDocument6 pagesNuclear Medicine Inc.'s Iodine Value Chain AnalysisPrashant NagpureNo ratings yet

- 2017 Presentation03 HandaDocument21 pages2017 Presentation03 HandasatyaseerNo ratings yet

- 005-1-Vocabulary Qs 2PsgsDocument2 pages005-1-Vocabulary Qs 2PsgsAlondra RezaNo ratings yet

- HS Analysis of AminesDocument10 pagesHS Analysis of AminesВиталий ШариповNo ratings yet

- Overview of GRP PipesDocument14 pagesOverview of GRP PipesMD IBRARNo ratings yet

- 12.co Ordination CompoundsExerciseDocument34 pages12.co Ordination CompoundsExerciseMaster Of HakingNo ratings yet

- Group 11-Operations Management - Systems ViewDocument6 pagesGroup 11-Operations Management - Systems ViewRohit MenonNo ratings yet

- Brook CromptonDocument28 pagesBrook Cromptonsumitsharma2010100% (1)

- B42 - Midterm10w CH 15-16-17-1Document7 pagesB42 - Midterm10w CH 15-16-17-1Siao Ryan YangNo ratings yet

- 1974 - The Occurrence of Organohaiides in Chlorinated Drinking Waters Journal AWWA - 1974 - BellarDocument5 pages1974 - The Occurrence of Organohaiides in Chlorinated Drinking Waters Journal AWWA - 1974 - Bellaryuwang.waterNo ratings yet

- Aging of LiFePO4 Upon Exposure To H2O PDFDocument13 pagesAging of LiFePO4 Upon Exposure To H2O PDFadalid contrerasNo ratings yet

- SIS 2.0 Refill Capacities (M0124697-02)Document6 pagesSIS 2.0 Refill Capacities (M0124697-02)Carlos U. CallirgosNo ratings yet

- A 826 - A826m - 95 Qtgyni05nqDocument5 pagesA 826 - A826m - 95 Qtgyni05nqsachinguptachdNo ratings yet

- Bonga University: Engineering Material (Meng2091)Document40 pagesBonga University: Engineering Material (Meng2091)Mul'isaa JireenyaaNo ratings yet

- Edicto - Thermodynamics Lab - Heat FusionDocument2 pagesEdicto - Thermodynamics Lab - Heat FusionEdicto, Beatrice CarolineNo ratings yet

- Protons, Neutrons, and Electrons Practice WorksheetDocument2 pagesProtons, Neutrons, and Electrons Practice WorksheetRedHoeBeerNo ratings yet

- Refineria de Cartagena (Reficar) Refinery Expansion - Hydrocarbons TechnologyDocument3 pagesRefineria de Cartagena (Reficar) Refinery Expansion - Hydrocarbons TechnologyGjorgeluisNo ratings yet