Professional Documents

Culture Documents

HAZMAT Articles - Dust Explosions

Uploaded by

manoj kumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HAZMAT Articles - Dust Explosions

Uploaded by

manoj kumarCopyright:

Available Formats

HAZMAT Articles

Dust Explosions

Introduction Some of the most destructive explosions have been caused by dust. There is more explosive energy in the dust from grains such as wheat, barley and corn, than 1 in an equal amount of TNT. While fires are far more common, explosions are far more costly in terms of loss of life, injury and property damage. Dust explosions have been quite common in the past. For example, there were 645 explosions in the coal mines of England from 1835 to 1850, in which coal dust was the major contributing factor. There were 1,085 dust explosions resulting in 351 fatalities, in the US from 1900 to 1956. Also in the US, among the 15,000 grain handling facilities from 1958 to 1977, there were 220 dust explosions resulting in 48 deaths and 500 injuries. The potential for a dust explosion has now become a well recognised hazard. Which dusts Any combustible solid material which can be dispersed in air as a dust cloud, is capable of causing a dust explosion. Explosions on record have originated from dusts from the following sources: Agriculture - grain dust, flour, sugar, milk powder, wool, paper, and wood. Metals - aluminium, magnesium, zinc. Mining - coal, combustible sulphide ores. Chemical industry - sulphur, most plastics, pesticides, pharmaceutical's including aspirin and vitamin C. The Bureau of Mines of the US Department of the Interior developed an arbitrary scale, (Table 1) based on tests using small amounts of dusts, as a guide to 2 the degree of hazard of each type of dust.

Explosion Weak Moderate Strong Severe Ignition Sensitivity <0.2 0.2 - 1.0 1.0 - 5.0 >5.0 Explosion Severity <0.5 0.5 - 1.0 1.0 -2.0 >2.0 Type of Dust Aluminium Aspirin Coal Coffee bean Cotton Egg wite Flour Grain dust Magnesium Milk, powdered Polyethylene Polystyrene Rubber Sugar Sulfur Vitamin C Ignition Sensitivity 7.3 2.4 2.2 0.1 <0.1 <0.1 2.1 2.8 3.0 1.6 24.0 6.0 4.6 4.0 20.2 1.0 Explosion Severity >10.2 >4.3 1.8 0.1 <0.1 0.2 1.8 3.3 7.4 0.9 2.2 2.0 1.6 2.4 1.9 2.2

TABLE 2. Explosion Potential of Some Dusts

What is a dust explosion? A dust explosion is the very rapid combustion of a dust cloud, to produce a flame and a pressure front. The flame front frequently causes loss of life, while the pressure front will often cause extensive damage to buildings. With some dusts, there is sometimes only a flame front and the pressure front is only minimal; with others, the flame spreads with the effect of an explosion. An explosion occurs as the flame generates heat and combustion products, and expansion from both these sources causes an immediate pressure rise which must then move out as a pressure wave and impact on the surroundings. Pressures of up to 700 to 800 kPa can be generated, and if it occurs in a confined space such as a building, the effects can be devastating, since most buildings can only withstand 2 kPa at most. Contributing factors Dust clouds may be ignited by the effects of mechanical friction such as overheated bearings, motors overheating from air cooling vents being clogged with dust, particles of steel or stone caught up in grinding machinery producing sparks, overheated dust coated light bulbs, static electricity, electrical arcing, welding sparks and naked flames. As a general rule, dusts require 20 to 50 times more energy from an ignition source compared with a flammable vapour, or they need direct contact with surface temperatures ranging from 300 to 600 deg C.

Page 1

TABLE 1. Explosion Hazard Scale for Dusts

There are two terms used on the scale, the ignition sensitivity (how easy to ignite), and explosion severity (how big a bang). The higher the number on each scale the greater the hazard that each dust represents (Table 2).

8th Dec 2008

The finer the dust the greater the hazard. Not only can it be more easily blown into the air, it will stay suspended in air much longer. It has a greater surface area per unit volume so that it can burn all the more rapidly, increasing the intensity of the flame front and the violence of the explosion. Dusts like flammable vapours, have lower and upper explosive limits. The lower limit is the concentration of dust in air to just sustain the flame front. The lower flammability limit ranges from about 10 to 40 gm/m3 depending on the type of dust. At these concentration it will be quite visible to the naked eye as a fog or cloud. The upper limit is usually difficult to measure since there appears to be no clear cut-off point. Instead it may, or may not, ignite at a given concentration. If it does ignite, it tends to leave behind increasing amounts of charred residue. Concentrations of dust which are potentially explosive are intolerable for people to remain in and are not likely to be found in the open, however they can be found around machinery used for crushing, grinding, sanding, milling, filtering, blending, shredding, spray drying, or conveying bulk quantities of solid materials.

Why so dangerous? Dust explosions are dangerous, because they can set off a chain reaction. The initial explosion is usually small and localised, however it is often sufficient to disturb surrounding dust deposited on floors, roofs, beams, and machinery to form a second much larger cloud, which in turn can lead to a far more devastating explosion. Further explosions can follow in other parts of the building or even neighbouring buildings. These explosions may occur seconds or even minutes apart, and have been described by those who have survived a dust explosion, as sounding like 'rolling thunder'.3 A fire can then follow from scattered burning particles, or from other small dust accumulations that have been ignited.

On the 15th March, 1987, in Harbin, China, an explosion of flax dust triggered a chain of explosions that destroyed the whole 13,000 m2 linen plant, causing 58 deaths and 177 injuries. The strength and time of each explosion was detected at the nearby earthquake monitoring station. On the 2nd March, 1982, in the UK, an articulated lorry carrying 19 tonnes of powdered resin crashed into a roadside cottage spilling part of its load. A dust cloud was thrown up, which ignited and exploded, setting fire to the entire load. Noxious fumes from the fire affected the driver, occupants of the cottage, workmen at the nearby building site and some fishermen in a boat about 1.5 kilometres out to sea. In the US on 23rd December, 1977, at Westwego, Louisiana, a series of explosions destroyed 37 grain silos completely and damaged many others, causing 35 deaths and $100,000,000 worth of damage. The facility consisted of 73 silos with a capacity of 150,000 m3. It was one of 5 grain storage explosions that occurred over an 8 day period, and was attributed to unusually dry weather conditions. On the 6th February, 1979, in Bremen, Germany, the greater part of the 40,000 square metre Roland Mill complex was destroyed by a series of explosions. The complex included a seven story flour store, six story mill, other silos and administration building. A pressure wave struck a loaded truck, throwing it against a wall spreading its load into the air and believed to have caused an open air explosion. No traces were found of seven of the fourteen killed in the fire, believed to be cremated in parts of the fire where all traces of combustibles were consumed; an estimated 1,000 degrees C for several hours.

1

Bowen JE, "An Overview: Grain Dust Explosions." Fire Engineering, 136(1983):22,23,25,27 2 Fire Protection Handbook, Ed., McKinnon GP, 14th ed., 1976, NFPA, Boston, Mass 3 Nelson P, "Dust Explosions: The Forgotten Killer." Australian Safety News, 65(1994):51-55

Incidents involving dust The initial explosion need not necessarily be caused by dust. It may only be a small gas/vapour explosion, or even a mechanical or man-made disturbance sufficient to create a dust cloud. One incident on record involved an explosion of an air compressor in a wool combers store. It did not hurt anybody, however it triggered a dust cloud, which ignited and the resultant flame shot right across the room with 18 workers being burned, one fatally. In another, a fitter died after being enveloped in flame after walking across a 6 metre grating platform. The vibrations from his footsteps created a cloud of polymethylmethacrylate (a plastic!) dust, which dropped onto a shrink wrapping machine fuelled by an open propane gas flame.

Prepared by Leith Higgins, Principal Scientific Officer, FESA Any comments 08 93239311 or Leith.Higgins@fesa.wa.gov.au Dec, 2008 by the Fire & Emergency Services Authority of Western Australia (FESA) This material is copyright and provided courtesy of FESA and published in the members only area of the AFAC Knowledge Web. The material is subject to the operation of the Copyright Act 1968 and its subsequent amendments. Material may be downloaded, displayed, printed and reproduced in unaltered form only for the sole use of AFAC members or partner organisations. This material may not be used for commercial purposes. Distribution of material from the members only area of the Knowledge Website to personnel outside of AFAC members and partner agencies is not permitted unless written authorisation is obtained from the content owner.

8th Dec 2008

Page 2

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The World of Darkness - Martial ArtsDocument23 pagesThe World of Darkness - Martial Artscdparazo86% (7)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Lucifer Conspiracy PDFDocument28 pagesThe Lucifer Conspiracy PDFmanoj kumarNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Psionic PredatorDocument88 pagesThe Psionic PredatorJoinM50% (2)

- Microsoft Word - Emergency Management Plankpp0.Document20 pagesMicrosoft Word - Emergency Management Plankpp0.kirandevi1981No ratings yet

- Introduction To Burns, Types and Sources of BurnsDocument45 pagesIntroduction To Burns, Types and Sources of BurnsRita LakhaniNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Accident InvestigationsDocument21 pagesAccident InvestigationsChandan KumarNo ratings yet

- Enki Is SatanDocument2 pagesEnki Is Satanmanoj kumarNo ratings yet

- TATPDocument2 pagesTATPkimkiko100% (3)

- Parthiban Kanavu Part (1 & 2) - KalkiDocument85 pagesParthiban Kanavu Part (1 & 2) - KalkiBala SubramanianNo ratings yet

- GB 50016-2014Document120 pagesGB 50016-2014BUĞRANo ratings yet

- JK Short Stories TamilDocument95 pagesJK Short Stories Tamilselva1965No ratings yet

- Lesson 1 IMDG CodeDocument32 pagesLesson 1 IMDG CodeBernard Mamora100% (2)

- Experimental Record Joe CellDocument24 pagesExperimental Record Joe CellRuddyMartini100% (2)

- Charles Cosimano - The Unknown PlagueDocument186 pagesCharles Cosimano - The Unknown PlagueShara RobertsNo ratings yet

- Boiling Liquid Expanding Vapour Explosion - Industrial Safety ReviewDocument12 pagesBoiling Liquid Expanding Vapour Explosion - Industrial Safety ReviewRik De ClercqNo ratings yet

- CLP Regulation (EC) No. 1272-2008 On The Classification, Labelling and Packaging of Substances and Mixtures PDFDocument1 pageCLP Regulation (EC) No. 1272-2008 On The Classification, Labelling and Packaging of Substances and Mixtures PDFCan YıldırımNo ratings yet

- Manual Book Genset Denyo DCA-70, - 125, & - 180ESEIDocument65 pagesManual Book Genset Denyo DCA-70, - 125, & - 180ESEIDadung PrakosoNo ratings yet

- Medicine in Tamil 1986Document321 pagesMedicine in Tamil 1986arunram86100% (2)

- Analysis of Building Under BlastDocument6 pagesAnalysis of Building Under BlastsjsubinNo ratings yet

- ET 2 Using PendulumDocument24 pagesET 2 Using Pendulummanoj kumarNo ratings yet

- ET 2 Using PendulumDocument24 pagesET 2 Using Pendulummanoj kumarNo ratings yet

- Expelling Jinn From Your HomeDocument101 pagesExpelling Jinn From Your Homegirasol1234No ratings yet

- Pyrotechnics - Weingart 1947 PDFDocument247 pagesPyrotechnics - Weingart 1947 PDFtom2susanNo ratings yet

- Tamil Romance RagasiyangalDocument57 pagesTamil Romance Ragasiyangalshanmars50% (2)

- LCdSM-The Red BookDocument34 pagesLCdSM-The Red BookIniziazioneAnticaNo ratings yet

- Power Cardio PDFDocument32 pagesPower Cardio PDFmanoj kumar100% (1)

- Tamil PDFDocument64 pagesTamil PDFmanoj kumarNo ratings yet

- The Happines Tamil PDFDocument64 pagesThe Happines Tamil PDFmanoj kumarNo ratings yet

- Boxer PrimeDocument32 pagesBoxer Primemanoj kumarNo ratings yet

- The Quran Advocates Rape and Sex-Slavery of Non-Muslim Women Islam Also Encourages and Promotes PedophiliaDocument12 pagesThe Quran Advocates Rape and Sex-Slavery of Non-Muslim Women Islam Also Encourages and Promotes Pedophiliamanoj kumarNo ratings yet

- 200 Ways To Revive Hard DiskDocument74 pages200 Ways To Revive Hard Diskdanielle leighNo ratings yet

- 2011 2012 2013 Sermons Volume 2Document60 pages2011 2012 2013 Sermons Volume 2Tiler SmithNo ratings yet

- 2011 2012 2013 Sermons of Satan Vol 1Document58 pages2011 2012 2013 Sermons of Satan Vol 1Tiler SmithNo ratings yet

- Manojkumar KDocument2 pagesManojkumar Kmanoj kumar100% (1)

- Household ChemicalsDocument3 pagesHousehold Chemicalsmanoj kumarNo ratings yet

- ZenDocument18 pagesZeneiztaoNo ratings yet

- Bird Migration Is The Regular Seasonal Movement, Often North and South Along ADocument20 pagesBird Migration Is The Regular Seasonal Movement, Often North and South Along Amanoj kumarNo ratings yet

- Household ChemicalsDocument3 pagesHousehold Chemicalsmanoj kumarNo ratings yet

- SportsDocument5 pagesSportsmanoj kumarNo ratings yet

- Exposing of IslamDocument27 pagesExposing of Islammanoj kumarNo ratings yet

- Hunting Is The Practice of Pursuing Any Living Organism, UsuallyDocument25 pagesHunting Is The Practice of Pursuing Any Living Organism, Usuallymanoj kumarNo ratings yet

- VegetablesDocument11 pagesVegetablesmanoj kumarNo ratings yet

- Unit 5Document21 pagesUnit 51804 Anto JeoferNo ratings yet

- United States - Detonating - Cord - All - Types - SDS - US - 110718 - FINAL - 1 PDFDocument7 pagesUnited States - Detonating - Cord - All - Types - SDS - US - 110718 - FINAL - 1 PDFAmgalanbaatarJargalsaikhanNo ratings yet

- Metallic Epoxy: Safety Data SheetDocument13 pagesMetallic Epoxy: Safety Data Sheetmanager simrsNo ratings yet

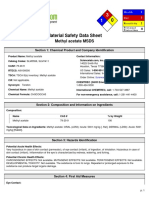

- Methyl Acetate MSDS: Section 1: Chemical Product and Company IdentificationDocument6 pagesMethyl Acetate MSDS: Section 1: Chemical Product and Company IdentificationTriyaldi MaulanaNo ratings yet

- Explosion Relief: General PrinciplesDocument11 pagesExplosion Relief: General Principlesdhineshbabu rNo ratings yet

- Nadopod 2004Document21 pagesNadopod 2004Jin Yi LimNo ratings yet

- MSDS Pupuk Haracoat PDFDocument4 pagesMSDS Pupuk Haracoat PDFAnonymous UQVygYg3lfNo ratings yet

- FMDS0785 Metals and AlloysDocument14 pagesFMDS0785 Metals and AlloysAlif GhazaliNo ratings yet

- 52 72 PDFDocument22 pages52 72 PDFchanchalkNo ratings yet

- Manual G7 SLHSJ MEZCLADORA PDFDocument63 pagesManual G7 SLHSJ MEZCLADORA PDFGeovany Silva ChingNo ratings yet

- Covered Car Parks Fire Safety Guidance For Electric VehiclesDocument96 pagesCovered Car Parks Fire Safety Guidance For Electric VehiclesDmitryNo ratings yet

- Nagpur District Offsite Emergency Plan PDFDocument235 pagesNagpur District Offsite Emergency Plan PDFshaileshgadbailNo ratings yet

- Chopper Glass CraftDocument36 pagesChopper Glass CraftA.Subin DasNo ratings yet

- Is 3786 1983Document33 pagesIs 3786 1983Swapnil SNo ratings yet

- Process Interruptions: A Threat To Process Safety: Did You ?Document1 pageProcess Interruptions: A Threat To Process Safety: Did You ?Abdullah AnarNo ratings yet

- Cosmic RaysDocument26 pagesCosmic RayskidseismicNo ratings yet

- Cedd TC 2020 - 06 - 200630Document16 pagesCedd TC 2020 - 06 - 200630LeoNo ratings yet

- Installation, Operation, and Maintenance Manual: 80 Series PumpDocument29 pagesInstallation, Operation, and Maintenance Manual: 80 Series PumpFelipe Ignacio PaillavilNo ratings yet