Professional Documents

Culture Documents

Antony Some Pros and Cons of Six Sigma

Uploaded by

harisrazaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Antony Some Pros and Cons of Six Sigma

Uploaded by

harisrazaCopyright:

Available Formats

Some Pros and Cons of Six Sigma

Dr Jiju Antony Division of Management Caledonian Business School Glasgow Caledonian University Glasgow, G4 0BA E-mail: j.antony@gcal.ac.uk

Six Sigma is a business strategy that seeks to identify and eliminate causes of errors or defects or failures in business processes by focusing on outputs that are critical to customers. It is a measure of quality that strives for near elimination of defects using the application of statistical methods. A defect is defined as anything which could lead to customer dissatisfaction. The fundamental objective of the Six Sigma methodology is the implementation of a measurement-based strategy that focuses on process improvement and variation reduction.

When Six Sigma was introduced to many organisations, the initial reactions varied from a lot of enthusiasm to an absolute scepticism, with the latter mood reflected in comments such as: It is another quality improvement initiative or flavour of the month There is nothing really new in Six Sigma compared to other quality initiatives such as TQM we have witnessed in the past. This too shall pass like others It is an old wine in a new bottle This wont work in our business We are doing Six Sigma already It is nothing more than a hype It is not for us as Six Sigma requires complicated statistical methods 1

I often ask a simple question to people in organisations who practise TQM, what do you understand by the term TQM?. I often get many varying answers to this question. However if I ask a bunch of Six Sigma practitioners, what do you know of the term Six Sigma?, I often get an answer which means more or less the same thing that I would have expected.

The following aspects of the Six Sigma strategy are not accentuated in previous quality improvement initiatives.

&

Six Sigma strategy places a clear focus on achieving measurable and

quantifiable financial returns to the bottom-line of an organisation . No Six Sigma project is approved unless the bottom-line impact has been clearly identified and defined. & Six Sigma strategy places an unprecedented importance on strong and

passionate leadership and the support required for its successful deployment & Six Sigma methodology of problem solving integrates the human elements

(culture change, customer focus, belt system infrastructure, etc.) and process elements (process management, statistical analysis of process data, measurement system analysis, etc.) of improvement. & Six Sigma methodology utilises the tools and techniques for fixing problems in

business processes in a sequential and disciplined fashion. Each tool and technique within the Six Sigma methodology has a role to play and when, where, why and how these tools or techniques should be applied is the difference between success and failure of a Six Sigma project.

&

Six Sigma creates an infrastructure of Champions, Master Black Belts

(MBBs), Black Belts (BBs) and Green Belts (GBs) that lead, deploy and implement the approach. & Six Sigma emphasises the importance of data and decision making based on

facts and data rather than assumptions and hunches ! Six Sigma forces people to put measurements in place. Measurement must be considered as a part of the culture change. & Six Sigma utilises the concept of statistical thinking and encourages the

application of well-proven statistical tools and techniques for defect reduction through process variability reduction methods (e.g.: statistical process control and design of experiments)

Just like any other quality improvement initiatives we have seen in the past, Six Sigma has its own limitations. The following are some of the limitations of Six Sigma which creates opportunities for future research. L The challenge of having quality data available, especially in processes where no data is available to begin with (sometimes this task could take the largest proportion of the project time) L The right selection and prioritisation of projects is one of the critical success factors of a Six Sigma program. The priorit isation of projects in many organisations is still based on pure subjective judgement. Very few powerful tools are available for prioritising projects and this should be the major thrust for research in the future. L The statistical definition of Six Sigma is 3.4 defects or failures per million opportunities. In service processes, a defect may be defined

as anything which does not meet customer needs or expectations. It would be illogical to assume that all defects are equally bad when we calculate the Sigma Capability level of a process. For instance, a defect in a hospital could be a wrong admission procedure, misdiagnosis, lack of training required by a staff member, misbehaviour of staff members, unwillingness to help patients when they have specific queries, etc. L Assumption of 1.5 sigma shift for all business processes does not make much sense. This particular issue should be dealt with extra caution as a small shift in sigma could lead to erroneous defect calculations. L Non-standardisation procedures in the certification process of Black belts, Green belts, etc. Research has shown that the skills and expertise developed by Black belts/Green belts are inconsistent across companies and are dependent a great deal on the certification body. Black belts believe they know all the practical aspects of advanced quality improvement methods such as Design of Experiments, Robust Design, Response Surface Methodology, Statistical Process Control and Reliability, when in fact they have barely scratched the surface. L Six Sigma can easily digress into a bureaucratic exercise if the focus is on such things as the number of trained Black Belts and Green Belts, number of projects completed, etc. instead of bottomline savings.

There is an overselling of Six Sigma by too many consulting firms. Many of them claim expertise in Six Sigma when they barely understand the tools and techniques and the Six Sigma roadmap.

The relationship between Cost of Poor Quality (COPQ) and Process Sigma Quality Level requires more justification.

What does the future hold for Six Sigma? In my opinion, Six Sigma will be around as long as the projects yield measurable or quantifiable bottom-line results in monetary or financial terms. When Six Sigma projects stop yielding bottom-line results, it might disappear. One of the real dangers of Six Sigma is to do with the capability of Black Belts (the so called technical experts) who tackle challenging projects in organisations. We cannot simply assume that all Black Belts are equally good and their cap ability vary enormously across industries (manufacturing or service), depending a great deal on the certification body. Another danger is the attitude of many senior managers in organisations that Six Sigma is an instant pudding solving all their ever-lasting problems.

I would like to accentuate the point that Six Sigma does provide an effective means for deploying and implementing statistical thinking, which is based on the following three rudimentary principles: All work occurs in a system of interconnected processes Variation exists in all processes, and Understanding and analysing the data that explains variation in processes.

The above principles of statistical thinking within Six Sigma are robust and therefore it is fair to say that Six Sigma will continue to grow in the forthcoming years.

However the total package may change in the evolutionary process. It is important to remember that Six Sigma has a better record than Total Quality Management (TQM) and Business Process Re-Engineering (BPR), since its inception in the mid-late 1980s.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Sky Over DimasDocument5 pagesThe Sky Over DimasMiguel MartinezNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Leeka Kheifets PrincipleDocument6 pagesLeeka Kheifets PrincipleAlexandreau del FierroNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Bed Romance (SPG)Document556 pagesBed Romance (SPG)Dylen Mae Larican LoqueroNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 9 Zagala, Neil - ModelDocument57 pages9 Zagala, Neil - ModelNeil ZagalaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Student Will Revise Their Output From YesterdayDocument4 pagesThe Student Will Revise Their Output From Yesterdayjeson galgoNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Film Viewing Reaction Paper "Miracle in Cell No. 7"Document2 pagesFilm Viewing Reaction Paper "Miracle in Cell No. 7"Jenny Rose CornejoNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Kamustahan Balitaan Kamustahan Balitaan Kamustahan Balitaan Kamustahan Balitaan Kamustahan BalitaanDocument6 pagesKamustahan Balitaan Kamustahan Balitaan Kamustahan Balitaan Kamustahan Balitaan Kamustahan BalitaanPaulC.GonzalesNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Gnanacheri: Sathguru Sri Sadasiva BramendrarDocument5 pagesGnanacheri: Sathguru Sri Sadasiva BramendrarAnand G100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Power of HelloDocument2 pagesThe Power of HelloHailey CaffieNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- BorosoftDocument4 pagesBorosoftajgiganiNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Leadership Lessons From Great Past PresidentsDocument3 pagesLeadership Lessons From Great Past Presidentsakhtar140No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Literature 7 Explorations 4th Ed LpoDocument11 pagesLiterature 7 Explorations 4th Ed LpoTetzie Sumaylo0% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Do Now:: What Is Motion? Describe The Motion of An ObjectDocument18 pagesDo Now:: What Is Motion? Describe The Motion of An ObjectJO ANTHONY ALIGORANo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Early Career English Teacher Identity ReportDocument28 pagesEarly Career English Teacher Identity ReportNguyễn LinhNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- In Defense of Globalization: Jagdish BhagwatiDocument25 pagesIn Defense of Globalization: Jagdish BhagwatiSatyajit RanaNo ratings yet

- DMIT Sample ReportDocument33 pagesDMIT Sample ReportgkreddiNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Legal OpinionDocument2 pagesLegal OpinionJovz BumohyaNo ratings yet

- Language Techniques - Figurative DevicesDocument28 pagesLanguage Techniques - Figurative DevicesElizabeth BishopNo ratings yet

- Object Oriented ABAP GuideDocument40 pagesObject Oriented ABAP Guidenavabhatt100% (3)

- Handouts On DOMDocument10 pagesHandouts On DOMGitanj ShethNo ratings yet

- From The Complaints of PovertyDocument11 pagesFrom The Complaints of PovertyManuel Oro JaénNo ratings yet

- To The Philosophy Of: Senior High SchoolDocument25 pagesTo The Philosophy Of: Senior High SchoolGab Gonzaga100% (3)

- Biblical HermeneuticsDocument5 pagesBiblical HermeneuticsLem SuantakNo ratings yet

- The Tathagatagarbha Sutra: Siddhartha's Teaching On Buddha-NatureDocument6 pagesThe Tathagatagarbha Sutra: Siddhartha's Teaching On Buddha-NatureBalingkangNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

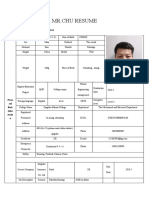

- Mr. Chu ResumeDocument3 pagesMr. Chu Resume楚亚东No ratings yet

- DLL Grade 6 Week-4Document12 pagesDLL Grade 6 Week-4Marianne BatapaNo ratings yet

- 33 Degrees in Free MasonryDocument6 pages33 Degrees in Free Masonrylvx6100% (1)

- Sample Essays - M AKRAM BHUTTODocument17 pagesSample Essays - M AKRAM BHUTTOAnsharah AhmedNo ratings yet

- Review of Related Literature: A. The Nature of ListeningDocument24 pagesReview of Related Literature: A. The Nature of ListeningJayanti Putri PermataNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- One - Act Play RefundDocument13 pagesOne - Act Play RefundSEHAJ SOFAT100% (3)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)