Professional Documents

Culture Documents

Blain Service Manual Low

Uploaded by

Sylvester SullivanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blain Service Manual Low

Uploaded by

Sylvester SullivanCopyright:

Available Formats

EV 100 Service Manual

EN ISO 9001

Service Manual

Page

Elevator Valve EV 100

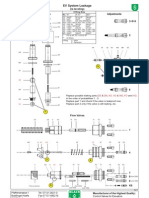

3/4 Cross Section Diagrams of Valve 1 1/2 - 2 Section Diagrams of Valve Quick Adjustment Procedure EV Parts List EV Trouble Shooting, Up Travel EV Trouble Shooting, Down Travel KS Slack Rope Valve Purpose and Adjustment Down Leveling Adj. 9, Replacement Overheating of Power Unit. System Leakage

1 2 3+4 5 6 7 8 9 10

11 Switches, Slow Down Distances 12 Flow-Pressure-Tables (metric), EV 100 Size Selection 13 Flow-Pressure-Tables (USA)

Blain Hydraulics GmbH Pfaffenstr. 1 Boellinger Hoefe D-74078 Heilbronn Germany Tel. +49 7131 2821-0 Fax +49 7131 48 52 16 www.blain.de info@blain.de Manufacturer of the Highest Quality: Control Valves for Elevators Tank Heaters - Hand Pumps - Pipe Rupture Valves - Ball Valves

Oct 02 Printed in Germany

BLAIN HYDRAULICS GmbH Boellinger Hoefe D-74078 Heilbronn Tel. +49 7131 28 21-0 Fax +49 7131 485216 www.blain.de info@blain.de

EV 100 Service Manual

EN ISO 9001

Caution

Only qualified elevator mechanics are permitted to install and adjust elevator control valves and controllers. Every Blain control valve is subjected to strong quality standards, from production, adjustment and testing, to final shipment. This manual will provide assistance whenever servicing is required. If necessary, please contact our technical department, stating the valve number, which is engraved into the EV casting above the nameplate, as well as other related technical data.

Technical Servicing

(from USA) 01149 7131 282139 01149 7131 282132

Dr. F. Celic: Frank Pausder:

Tel. +49 7131 282139 Tel. Tel. +49 7131 282132 Tel.

Fax: +49 7131 485216 Fax 01149 7131 485216

E-Mail: info@blain.de URL: http://www.blain.de

Oct 02 Printed in Germany

BLAIN HYDRAULICS GmbH Boellinger Hoefe D-74078 Heilbronn Tel. +49 7131 28 21-0 Fax +49 7131 485216 www.blain.de info@blain.de

EV 100 Service Manual

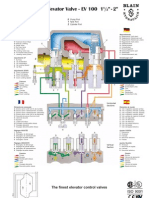

Elevator Valve - EV 100 for Home Lifts

EN ISO 9001

Control Elements A Solenoid (UP Stop) B Solenoid (UP Deceleration) C Solenoid (Down Deceleration) D Solenoid (Down Stop) H Manual Lowering S Relief Valve U By Pass Valve V Check Valve W Leveling Valve (Up) X Full Speed Valve (Down) Y Leveling Valve (Down) Adjustments UP 1 By Pass 2 Up Acceleration 3 Up Deceleration 4 Up Leveling Speed 5 Up Stop Adjustments DOWN 6 Down Acceleration 7 Down Full Speed 8 Down Deceleration 9 Down Leveling Speed Pressure Pumpe Bypass Valve Up Leveling Tank Cylinder Down Valve Down Leveling

P Pump Port T Tank Port Z Cylinder Port X V T P Z W Y U

Steuerelemente A Magnetventil (Halt oben) B Magnetventil (Abbremsen auf) C Magnetventil (Abbremsen unten) D Magnetventil (Halt unten) H Notablassventil S berdruckventil U Umlaufkolben V Rckschlagventil W Schleichfahrtventil (auf) X Senkkolben Y Schleichfahrtventil (ab) Einstellungen AUF 1 Umlaufeinstellung 2 Anfahrdrossel 3 Abbremsdrossel 4 Schleichfahrteinstellung 5 Haltedrossel Einstellungen AB 6 Anfahrtdrossel 7 Senkfahrteinstellung 8 Abbremsdrossel 9 Schleichfahrteinstellung Druck Pumpe Umlaufkolben Schleichfahrt (Auf) Tank Zylinder Senkkolben Schleichfahrt (Ab)

8 9 7 4 1

2 Horizontal Sections

Elments de commande A Electro-vanne arrt (en fin de monte) B Electro-vanne ralentissement (monte) C Electro-vanne ralentissement (descente) D Electro-vanne arrt (en fin de descente) H Descente de secour (homme mort) S Valve de scurit U By-pass V Clapet anti-retour W Soupape monte petite vitesse X Soupape descente Y Soupape descente petite vitesse Rglages MONTE 1 By-pass 2 Etrangleur de dmarrage 3 Etrangleur de ralentissement 4 Rglage de petite vitesse 5 Etrangleur darrt Rglages DESCENTE 6 Etrangleur de dmarrage 7 Rglage de grande vitesse 8 Etrangleur de ralentissement 9 Rglage de petite vitesse Pression Pompe By-pass Monte petit vitesse Cuve Vrin Soupape descente Descente petite vitesse

C 6 H D B C 3

B 5 A

Elementos de mando A Vlv. magntica parada (arriba) B Vlv. magntica frenado (subida) C Vlv. magntica frenado (bajada) D Vlv. magntica parada (abajo) H Vlv. parada de urgencia (manual) S Vlv. de seguridad U Vlv. de desviacin V Vlv. de retencin W Vlv. de subida lentsima X Vlv. de bajada Y Vlv. de bajada lentsima Ajustes SUBIDA 1 Desviacin 2 Arranque 3 Frenado 4 Recorrido lentsimo 5 Parada Ajustes BAJADA 6 Arranque 7 Recorrido en bajada 8 Frenado 9 Recorrido lentsimo Presin Bomba Vlvula de desviacin Subida lentsima Tanque Cylindro Vlvula de bajada Bajada lentsima

H 3 8

5 Vertical Section

D C

A B

Oct 02 Printed in Germany

BLAIN HYDRAULICS GmbH Boellinger Hoefe D-74078 Heilbronn Tel. +49 7131 28 21-0 Fax +49 7131 485216 www.blain.de info@blain.de

EV 100 Service Manual

Elevator Valve EV 100 1 ,2, 2

P Pump Port T Tank Port Z Cylinder Port

EN ISO 9001

Control Elements A Solenoid (UP Stop) B Solenoid (UP Deceleration) C Solenoid (Down Deceleration) D Solenoid (Down Stop) H Manual Lowering S Relief Valve U By Pass Valve V Check Valve W Leveling Valve (Up) X Full Speed Valve (Down) Y Leveling Valve (Down) Adjustments UP 1 By Pass 2 Up Acceleration 3 Up Deceleration 4 Up Leveling Speed 5 Up Stop Adjustments DOWN 6 Down Acceleration 7 Down Full Speed 8 Down Deceleration 9 Down Leveling Speed Pressure Pumpe Bypass Valve Up Leveling Tank Cylinder Down Valve Down Leveling

V U

X P

Steuerelemente A Magnetventil (Halt oben) B Magnetventil (Abbremsen auf) C Magnetventil (Abbremsen unten) D Magnetventil (Halt unten) H Notablassventil S berdruckventil U Umlaufkolben V Rckschlagventil W Schleichfahrtventil (auf) X Senkkolben Y Schleichfahrtventil (ab) Einstellungen AUF 1 Umlaufeinstellung 2 Anfahrdrossel 3 Abbremsdrossel 4 Schleichfahrteinstellung 5 Haltedrossel Einstellungen AB 6 Anfahrtdrossel 7 Senkfahrteinstellung 8 Abbremsdrossel 9 Schleichfahrteinstellung Druck Pumpe Umlaufkolben Schleichfahrt (Auf) Tank Zylinder Senkkolben Schleichfahrt (Ab)

Z W Y

8 9 7 4 1

Elments de commande A Electro-vanne arrt (en fin de monte) B Electro-vanne ralentissement (monte) C Electro-vanne ralentissement (descente) D Electro-vanne arrt (en fin de descente) H Descente de secour (homme mort) S Valve de scurit U By-pass V Clapet anti-retour W Soupape monte petite vitesse X Soupape descente Y Soupape descente petite vitesse Rglages MONTE 1 By-pass 2 Etrangleur de dmarrage 3 Etrangleur de ralentissement 4 Rglage de petite vitesse 5 Etrangleur darrt Rglages DESCENTE 6 Etrangleur de dmarrage 7 Rglage de grande vitesse 8 Etrangleur de ralentissement 9 Rglage de petite vitesse Pression Pompe By-pass Monte petit vitesse Cuve Vrin Soupape descente Descente petite vitesse

Horizontal Sections

D 6 H D

C 3

A 5 A

S B

Elementos de mando A Vlv. magntica parada (arriba) B Vlv. magntica frenado (subida) C Vlv. magntica frenado (bajada) D Vlv. magntica parada (abajo) H Vlv. parada de urgencia (manual) S Vlv. de seguridad U Vlv. de desviacin V Vlv. de retencin W Vlv. de subida lentsima X Vlv. de bajada Y Vlv. de bajada lentsima Ajustes SUBIDA 1 Desviacin 2 Arranque 3 Frenado 4 Recorrido lentsimo 5 Parada Ajustes BAJADA 6 Arranque 7 Recorrido en bajada 8 Frenado 9 Recorrido lentsimo Presin Bomba Vlvula de desviacin Subida lentsima Tanque Cylindro Vlvula de bajada Bajada lentsima

Vertical Section 6 8 H 3 S 5 2

Oct 02 Printed in Germany

BLAIN HYDRAULICS GmbH Boellinger Hoefe D-74078 Heilbronn Tel. +49 7131 28 21-0 Fax +49 7131 485216 www.blain.de info@blain.de

EV 100 Service Manual

Quick adjustment procedure

EN ISO 9001

Solenoid Coils

During adjustment of the EV 100 valve, instead of making a full floor to floor travel to check operation, much time can be saved by removing the securing nuts of the coil and switching to deceleration or to acceleration by lifting or replacing the appropriate coil by hand, allowing several adjustment corrections during one car travel between floors. Caution: Once removed from the solenoid tube, the energised coil will begin to overheat after about 20 secs. If necessary, to slow the rate of heating, place an 8 or 10 mm socket key or similar steel rod as core thru the coil. Do not lay an energised coil to one side, otherwise it may overheat unnoticed. If the coil becomes too hot to hold, it must be replaced, back over the solenoid tube and any further adjustment carried out with the elevator making normal floor to floor runs.

Car not visible from Machineroom

If the car cannot be seen during adjustment of the valve, the acceleration and deceleration times can be heard from the change of the turbulent noise within the valve as the speed of the car changes. With no load in the car, the duration of the speed changes should be about 2,5 seconds. This applies to adjustments 2, 3, 6 and 8.

D C A B D C B A

S Z1 S 5 2 1 Z1 6 6 8 7 8 7 5 2

Up Travel (empty car)

PRE-SETTINGS Adjustment No. 1 Adjustment No. 2 Adjustment No. 3 Adjustment No. 4 Adjustment No. 5 Adjustment No. S level with flange face. all the way in then 2 turns out. 4 . level with flange face. all the way in then 4 turns out. 2 . 5 mm Socket key 3 mm 3 mm 5 mm 3 mm 3 mm

1. Pilot Pressure Setting Disconnect coil A. Energise Motor (pump). If the car does not move, turn No. 1 in until the car begins to move, turn No. 1 out until the car stops, then back out again 1/2 turn. The car remains standing still. DO NOT UP-LEVEL WITH THIS ADJUSTMENT! Between full and empty car, leveling speed differences would be extreme. 2. Up Acceleration Reconnect coil A. Start Motor and energise coil A and B (normal up call). Observe the up acceleration. If it is too quick, turn No. 2 in turn. If it is too long, turn No. 2 out turn. Repeat until acceleration is satisfactory. Acceleration time should be about 2,5 secs. 4. Up Leveling Disconnect coil B. Energise Motor and coil A (normal up-level call). With adjustment No. 4 level with the face of the flange the car will up level. If the leveling speed is too fast, turn No. 4 in until the speed is as required. If the speed is too slow, turn No. 4 out. Recommended speed 6 cm/sec.

Oct 02 Printed in Germany

BLAIN HYDRAULICS GmbH Boellinger Hoefe D-74078 Heilbronn Tel. +49 7131 28 21-0 Fax +49 7131 485216 www.blain.de info@blain.de

EV 100 Service Manual

EN ISO 9001 3. Up Deceleration With coil B still disconnected. Energise motor and coil A (normal up-level call). The car will travel upwards at leveling speed. Turn No. 3 in until the car starts to up level faster, then turn No. 3 out until the original leveling speed is observed. Reconnect coil B and place a normal up call. Observe the deceleration of the car. If it is too long, turn No. 3 out turn; if it is too short, turn No. 3 in turn. Repeat until deceleration is satisfactory. Deceleration time should be about 2,5 secs.

Quick adjustment procedure

5. Up Soft Stop Disconnect coil A. Energise Motor. The car should not move. Turn No. 5 in until the car starts upwards then turn No. 5 out until the car stops. Reconnect coil A. Energise Pump-Motor and A. The car will travel upwards at leveling speed. Lift A coil by hand briefly and observe the stopping of the car. If the stop is too hard turn No. 5 in turn. If the stop is too soft, turn No. 5 out, turn. Repeat until the stop is satisfactory. S Pressure Relief Valve Turn S screw out until about 2 mm of the screw head is showing. Close the ball valve in the cylinder line and open the manual lowering H to lower valve pressure down to zero. Place an up call, energising motor and coils A and B. The relief pressure will show on the pressure gauge. To increase the relief valve setting, turn S in. To decrease the relief valve setting, turn S out, then open the manual lowering for second with the pump still running to release locked-in pressure, before observing the pressure gauge reading.

Down Travel (empty car)

PRE-SETTINGS Adjustment No. 6 Adjustment No. 7 Adjustment No. 8 Adjustment No. 9 all the way in then 4 turns out. 3 mm under the flange face. all the way in then 2 turns out. level with flange face. 3 mm Socket key 5 mm 3 mm 5 mm

8. Down Deceleration Place down call (coils C and D energised). As the car approaches full speed, remove coil D by hand briefly from the solenoid and observe the deceleration of the car. If the deceleration is too long, turn No. 8 out turn; if it is too short, turn No. 8 in turn. Repeat until deceleration is satisfactory. Deceleration time should be about 2,5 secs. 6. Down Acceleration Turn No. 6 all the way in. Place down call (coils C and D energised). The car will not move. Turn No. 6 out slowly until the car accelerates downwards. If the acceleration is too long, turn No. 6 out turn. If it is too short, turn No. 6 in turn. Acceleration time should be about 2,5 secs. 7. Down Full Speed Place down call (coils C and D energised). Observe full down speed. Turn No. 7 in for slower, out for faster speed. 9. Down Leveling Speed Disconnect coil C. Place down call (D energised). Observe down leveling speed. Turn No. 9 in for slower, out for a fast down leveling speed. Recommended speed 6 cm/sec. H Emergency Lowering The manually operated emergency down speed and the D coil operated down leveling speed are the same. Down Stop When solenoid D is de-energised with solenoid C remaining de-energised, the car will stop according to the setting of adjustment 8 and no further adjustment will be required. KS Slack Rope Valve The KS is adjusted with a 3 mm Socket Key by turning the screw K in for higher pressure and out for lower pressure. With K turned all the way in, then half a turn back out, the unloaded car should descend when the D solenoid alone is energised. Should the car not descend, K must be backed off until the car just begins to descend, then backed off a further half turn to ensure that with cold oil, the car can be lowered as required.

BLAIN HYDRAULICS GmbH Boellinger Hoefe D-74078 Heilbronn Tel. +49 7131 28 21-0 Fax +49 7131 485216 www.blain.de info@blain.de

Oct 02 Printed in Germany

EV 100 Service Manual

Pos. No. Item

EV Parts List

EN ISO 9001

FS Lock Screw - Flange FO 0-Ring - Flange 1F Flange - By Pass EO 0-Ring - Adjustment 1 1E Adjustment - By Pass UO 0-Ring - By Pass Valve U By Pass Valve UD Noise Suppressor UF Spring - By Pass 2 2 Adjustment - Up Acceleration 3 3 Adjustment - Up Deceleration EO 0-Ring - Adjustment 4E Adjustment - Up Leveling 4F Flange - Check Valve FO 0-Ring - Flange Spring - Check Valve 4 VF Up-Leveling Valve W WO 0-Ring - Up Leveling Valve VO Seal - Check Valve V Check Valve W6 Screw - Check Valve 5 3 Adjustment - Up Stop 6 3 Adjustment - Down Acceleration 7F Flange - Down Valve FO 0-Ring - Flange 7O 0-Ring - Adjustment 7E Adjustment - Down Valve 7 UO 0-Ring - Down Valve XO Seal - Down Valve X Down Valve XD Noise Suppressor F Main Filter 8 8 Adjustment - Down Deceleration EO 0-Ring - Adjustment 9 9E Adjustment - Down Leveling 9F Spring - Down Valve Y Down Leveling Valve Manual Lowering - Self Closing H H Seal - Manual Lowering HO SE Adjustment - Screw SM Hexagonal S MS Grub Screw SO 0-Ring - Nipple SZ Nipple SF Spring SK Piston MM Nut - Solenoid AD Collar - Solenoid M Coil - Solenoid (indicate voltage) A+B AR Tube - Solenoid 'Up' MO 0-Ring - Solenoid AN Needle - 'Up' AF Spring - Solenoid 'Up' AH Seat Housing - 'Up' AS Seat - Solenoid Up' MM Nut - Solenoid M Coil - Solenoid (indicate voltage) DR Tube - Solenoid 'Down' 0-Ring Solenoid C+D MO Spring -- Solenoid 'Down' DF DN Needle - 'Down' DK Core - Solenoid DG Seat Housing with Screen-'Down' FD Filter Solenoid DS Seat - Solenoid 'Down' Some parts occur more than once in different positions of the valve.

No. "

0-Ring-Size 1 " 2"

58x3P * 9x2P 58x3V 5.28x1.78V 60x3V ** 9x2P 47x3V 5.28x1.78V 5.28x1.78P 26x2P

MM

Solenoid Valves C+D A+B

MM AD M

Adjustments 3+5+6 2

SK SF SZ SO MS SM SE

FO 26x2P 47x2.5P EO 9x2P 9x2P UO 26x2V 39.34x2.62V WO 5.28x1.78V 5.28x1.78V VO 23x2,5V 42x3V 7O 5.28x1.78P 9x2P XO 13x2V 30x3V HO 5.28x1.78V 5.28x1.78V SO 5.28x1.78P 5.28x1.78P MO 26x2P 26x2P * FO by 4F 2" is 67x2.5P ** 90 Shore 0-Ring: V - Viton P - Perbunan

DR MO DF DN DK DG FD DS

AR MO AN

S

HO

AF AH AS

H 8

Flow Valves

UF UD U UO 1E EO 1F FO FS

1

V W6 V VO WO W VF FO 4F FS 4E EO

XD

XO

UO

7E 7O

FO 7F

FS

9E EO

7 9

F Do not remove! Y 9F

KS

Down Leakage (Releveling)

In case of down leakage, replace and test in the following order: DS & DN, XO, VO, WO, FO and HO.

EV 100 1", 2", 2"

D C B A V X

Z1

Z Y Vertical Section

9 7

4 1 Horizontal Sections

KS Option

Oct 02 Printed in Germany

5 5

BLAIN HYDRAULICS GmbH Boellinger Hoefe D-74078 Heilbronn Tel. +49 7131 28 21-0 Fax +49 7131 485216 www.blain.de info@blain.de

EV 100 Service Manual

Trouble Shooting

UP Travel

EN ISO 9001

For checking the operation of the solenoids, remove the top nuts. By lifting the solenoids a few millimeters, the magnetic pull of the solenoid can be felt. For testing, the operation of the elevator car, can also be controlled by lifting and replacing the coil.

Valves are fully adjusted and tested in the factory. Check electrical operation before changing valve setting.

Problem

Possible cause

Solenoid A not energised or voltage too low. Solenoid A tube not screwed down tight.

Recommended

Lift coil to check magnetic pull (see above). Tighten Solenoid A tube. Clean or change needle and seat. Turn out adjustment 2. Turn in adjustment 1 with the pump running. Set relief valve higher. Turn out adjustment 8. Insert smaller bypass flow guide (see flow guide charts at EV catalogue). Install the pump correct. Seal the pump connection. Select bigger pump or replace pump.

Test: Turn adjustment 5 all the way in. If the elevator now starts upwards the problem is at solenoid A.

No Up-Start (Elevator remains at floor)

Solenoid valve A - dirt or damage between needle AN and seat AS. Adjustment 2 not far enough open. Adjustment 1 too far back (open). Not enough pilot pressure. Relief valve is set too low. Adjustment 8 turned in too far (car sits on the buffer). Bypass flow guide is too large. Pump running in the wrong direction. The pump connection flange is leaking excessively. The pump is undersize or worn.

Test: If by turning adjustment 1 with the pump running the pressure does not rise above 5 bar, even with a smaller bypass valve inserted, the problem should be sought at the pump. Test: Turn adjustment 3 all the way in. If the elevator now travels upwards at full speed the problem is at solenoid B. Solenoid B not energised or voltage too low. Up-Start, but no Full Speed Solenoid B tube not screwed down tight. Solenoid valve B - dirt or damage between needle AN and seat AS. The pump connection flange is leaking excessively. The pump is undersize or worn. Lift coil to check magnetic pull (see above). Tighten Solenoid B tube. Clean or change needle and seat. Seal the pump connection. Select bigger pump or replace pump.

Test: If by turning adjustment 1 with the pump running the pressure does not rise above 5 bar, even with a smaller bypass valve inserted, the problem should be sought at the pump. Adjustment 1 turned in too far. Up-Start too hard Adjustment 2 turned out too far. O-Ring UO on Bypass Valve U is leaking. Star to Delta motor switch period is too long. Excessive friction on the guide rails or in the cylinder head. No deceleration into leveling speed Aufzug bremst ab, fhrt jedoch ber die Haltestelle Solenoid B does not de-energise. Adjustment 3 turned in too far. O-Ring UO on Bypass Valve U is leaking. Magnetventil A (Halt oben) zu spt stromlos. Drossel 5 (Weich-Halt) nicht weit genug geffent. Einstellung 1 nicht weit genug geffnet. Schleichfahrt aufwrts zu schnell (zu weit geffnet). Turn out adjustment 1. Turn in adjustment 2. Change O-Ring

see EV Spare Parts List.

0.2-0.3 sec. is sufficient. Can not be eliminated thru valve adjustment. Lift coil to check magnetic pull (see above). Slow down switch possibly set to high (late). Turn out adjustment 3. Turn in adjustment 2. Change O-Ring see EV Spare Parts List. Magnetspule anheben (siehe Vermerk ). Drossel 5 weiter aufdrehen. Einstellung 1 zwei Umdrehungen weiter ffnen. Einstellung 4 auf 6 - 10 cm/sek. hineindrehen Lift coil to check magnetic pull (see above). Turn out adjustment 4. Change O-Ring see EV Spare Parts List. Set relief valve higher. Replace one seal point and test before proceeding to the next point of possible leakage, if still necessary.

Solenoid A and B reversed. Aufzug bleibt vor der Haltstelle Up leveling speed too slow. stehen (keine Middle O-Ring FO of flange 4F is leaking. Schleichfahrt) Relief valve is set too low. Down Leak Releveling

Oct 02 Printed in Germany

For possible down leakage points, see EV Parts List, page 5. Releveling may also occur as hot oil cools down and contracts.

BLAIN HYDRAULICS GmbH Boellinger Hoefe D-74078 Heilbronn Tel. +49 7131 28 21-0 Fax +49 7131 485216 www.blain.de info@blain.de

EV 100 Service Manual

Trouble Shooting

DOWN Travel

EN ISO 9001

For checking the operation of the solenoids, remove the top nuts. By lifting the solenoids a few millimeters, the magnetic pull of the solenoid can be felt. For testing, the operation of the elevator car, can also be controlled by lifting and replacing the coil.

Valves are fully adjusted and tested in the factory. Check electrical operation before changing valve setting.

Problem

Possible cause

Solenoid D not energised or voltage too low. Adjustment 6 turned in too far. Adjustment 8 turned out too far. O-Ring UO on Down Valve X is leaking. Solenoid C not energised or voltage too low.

Recommended

Lift coil to check magnetic pull (see above). Turn out adjustment 6. Turn in adjustment 8 cautiously. Attention: Danger of traveling through Change O-Ring see EV Spare Parts List. Lift coil to check magnetic pull (see above). Turn out adjustment 6. Check insert size (see flow guide charts page 12) Lift coil to check magnetic pull (see above). Lift coil to check magnetic pull (see above). Turn out adjustment 9 to about 10 ft/min. leveling speed. Replace adjustment 9 complete. Turn out adjustment 8 about turn. Turn in adjustment 9 to about 10 ft/min. leveling speed. Clean or change needle and seat. Change O-Ring see EV Spare Parts List. Tighten Solenoid D tube. Turn out adjustment 8 about turn. Clean or change needle and seat. Change O-Ring see EV Spare Parts List. When Down Valve is compensated, replace Down Valve. Change Check Valve see EV Spare Parts List. Change O-Ring see EV Spare Parts List. Change O-Ring see EV Spare Parts List. Replace Manual Lowering. Remove suction tube and observe if handpump leaks. Replace complete handpump. Turn out adjustment 8. Clean or change needle and seat. Change O-Ring see EV Spare Parts List. Replace Manual Lowering.

No Down Start

No full speed

Adjustment 7 turned in too far. Down Valve flow guide too small. Solenoid C and D reversed.

No down leveling. Elevator stops before floor level

Solenoid D not energised or voltage too low. Adjustment 9 turned in too far. Spring 9F in adjustment 9 broken. Adjustment 8 turned in too far.

No down leveling. Adjustment 9 turned out too far. Elevator travels Solenoid valve C dirt or damage between needle DN and thru floor level seat DS. Inner O-Ring FO on flange 7F is leaking. Elevator sinks quickly Solenoid D tube not screwed down tight. Adjustment 8 turned in too far. Solenoid valve D - dirt or damage between needle DN and seat DS. Elevator sinks slowly due to inner leakage O-Ring XO of Down Valve X is leaking. O-Ring VO of Check Valve V is leaking. O-Ring WO of Leveling Valve W is leaking. Inner O-Ring FO on flange 4F is leaking. O-Ring HO of Manual Lowering H is leaking. Handpump leaking. Adjustment 8M turned in too far. Down valve HX/MX leaking. At MX - dirt or damage between needle DN and seat DS. O-Ring XO of Down Valve YM is leaking. Manual Lowering is leaking.

Contraction of oil during cooling especially from above 35C. Consider oil cooler if hot oil is a problem.

Oct 02 Printed in Germany

BLAIN HYDRAULICS GmbH Boellinger Hoefe D-74078 Heilbronn Tel. +49 7131 28 21-0 Fax +49 7131 485216 www.blain.de info@blain.de

EV 100 Service Manual Purpose

Slack Rope Valve `K

EN ISO 9001

In the case of the operation of the safeties in a 1:2 hydraulic lift system when the weight of the car is no longer carried by the ropes, the electrical supply to the elevator must automatically be switched off. The K Slack Rope Valve avoids the ram being lowered by the opening of the manual lowering valve which could otherwise cause a tangled rope condition. The K Slack Rope Valve prevents the pressure holding up the ram from being evacuated through the manual lowering valve.

Function

The K valve is adjusted to a pressure just above the pressure produced by the weight of the ram. When under normal operating conditions, the weight of the car acts upon the ram through the 1:2 roping, the resulting pressure is sufficient to open the poppet of the K valve when the manual lowering H is opened, allowing the car to descend as required. When however the `safeties have operated and only the weight of the ram and sheave block are acting upon the hydraulic system, the resulting pressure is too low to open the K valve. The ram and sheave block can not be lowered.

Adjustment

The K is adjusted with a 3 mm Socket Key by turning the screw K `in for higher pressure and `out for lower pressure. With K turned all the way `in, then half a turn back out, the unloaded car should descend when the D solenoid alone is energised. Should the car not descend, K must be backed off until the car just begins to descend, then backed off a further half turn to ensure that with cold oil, the car can be lowered as required.

Manual lowering H

Adjustment Screw K Down Flange 7 - 9

Plug Screw K 6 6 mm Ball K 5 Spring K 4 0-Ring K 3 Lock Screw K 2 Adjustment Screw K K Adjustment 9

Oct 02 Printed in Germany

BLAIN HYDRAULICS GmbH Boellinger Hoefe D-74078 Heilbronn Tel. +49 7131 28 21-0 Fax +49 7131 485216 www.blain.de info@blain.de

EV 100 Service Manual

Down Leveling Adjustment 9 Replacement

EN ISO 9001

Old Type

1971 - 1999 Replacement not necessary if operation is normal

New Type

from Jan. 2000

Identification 2x

Identification 4x

Old Y

New Y

Old 9F New 9F

Old 9

New 9

Identification

Advantages of new type

Smoother deceleration Higher mechanical closing force Longer spring life Easier assembly

In the past, a small number of the original springs No. 9F have broken. Beginning January 2000, the design of the down leveling adjustment was modified to take a stronger spring. The complete new adjustment is interchangeable with the original adjustment 9. A broken spring 9 would cause the down leveling speed to be slower. No danger to passengers would arise as a consequence.

Oct 02 Printed in Germany

BLAIN HYDRAULICS GmbH Boellinger Hoefe D-74078 Heilbronn Tel. +49 7131 28 21-0 Fax +49 7131 485216 www.blain.de info@blain.de

EV 100 Service Manual

Overheating of Power Units - System Leakage

EN ISO 9001

Oil temperatures above 55 C (130 F) should be avoided, otherwise the efficiency of the pump drops considerably and its life is reduced. Aging of the oil is also accelerated.

Possible causes of overheating:

1. Up leveling too long due to the leveling speed being too slow or the slow down switch being set too low. 2. Machine room ventilation inadequate. 3. The frequency of operation is too high for the normal rate of heat dissipation.

Temporary solution:

As a temporary measure to avoid overheating of the oil resulting in the shut down of the elevator, the down speed can be slowed to reduce frequency of operation until a permanent solution is installed.

Cooling systems

a. If the degree of overheating is not excessive and it takes for example two to three hours for the oil temperature to rise from 20 to 55C (70 to 130 F), it may be sufficient to improve air circulation around the power unit, for example through the installation of a 0.05 to 0.10 kW ventilator extracting air out of the machine room or through a fan of similar power, blowing air over the power unit. b. Should the above be inadequate, depending on the size of the elevator, it will be necessary to install a 10-50 l/min (3 - 13 gpm) pump to circulate the hot oil through an air cooled radiator of about 0.1 to 0.2 fan kW. It is also essential that there is sufficient extraction of warm air out of the machine room or that the cooler is out side of the machine room, for example in the elevator shaft. The effective cooling power of an air cooled radiator should not to be confused with the power of the fan drive which normally need only be 0.1 or 0.2 kW. Normally, the effective cooling power of a cooler need only be approximately of the main hydraulic elevator motor, in the case of submersible drives. Cooling systems for the above purpose should be switched into operation when the oil reaches 30 - 35C (85 95 F).

System leakage (re-leveling)

The aim of manufacturers of hydraulic elevator control valves is to produce valves with zero leakage. Due to fine contamination in the oil perfect sealing between valve parts may not always be achieved, leading to a slow down leak of the elevator car. It would become unnecessarily expensive to strive for perfect sealing in every valve in operation. Therefore, because code requirements assure a safe releveling system whether descent of the car is caused by valve leakage or through the cooling of the oil in the cylinder pressure system, a minor leakage of the control valve can be tolerated. 1. The European Code EN 81-2 require: that the loaded elevator does not leak downwards by more than 10 mm (3/8) in 10 minutes. This is the standard used to determine if a valve should be serviced for leakage. 2. For practical reasons, a quicker method for judging valve leakage is to close the ball valve in the cylinder line and observe the gauge showing pressure in the cylinder chamber of the valve. If this pressure falls to zero in less than 20 secs, it may be necessary to service the valve, depending on the diameter of the main ram and sensitivity of the customer. 3. Down sinking giving the impression of leakage can be due to cooling of the oil. When the elevator is at rest and the temperature of the oil falls, contraction of the oil in the cylinder and piping causes the car to sink. This sinking is very slow but overnight without releveling could amount to as much as half a meter, depending on the temperature drop of the oil and the volume of oil in the cylinder system. The elevator releveling system, operating normally however, keeps the car at floor level. 4. In the case of Blain EV valves, see page 6 indicating where valve down leakage can occur.

Oct 02 Printed in Germany

BLAIN HYDRAULICS GmbH Boellinger Hoefe D-74078 Heilbronn Tel. +49 7131 28 21-0 Fax +49 7131 485216 www.blain.de info@blain.de

10

EV 100 Service Manual

Switch Distances

EN ISO 9001

Recommended distances between leveling and stop switches

Elevator Speed mtrs/sec.

0,10 0,15 0,20 0,25 0,30 0,35 0,40 0,45 0,50 0,55 0,60 0,70 0,80 0,90 1,00

Switch Distance approx. cm

5 10 15 18 25 30 40 46 50 58 70 80 95 105 120

Elevator Speed ft/min.

20 30 40 50 60 70 80 90 100 110 120 140 160 180 200

Switch Distance approx. inches

2 4 6 7 9 12 16 18 20 23 28 31 36 41 48

With no load in the car, the deceleration time should be 2 to 2,5 secs. from full speed to leveling speed. The leveling time should be 1 to 2 secs. Accurate landing can be affected by different factors as follows: a. If the leveling speed is fast i.e. 0,1 m/sec (20 ft/min), landing will not be as accurate as when the leveling speed is slower i.e. 0,05 m/sec (10 ft/min). b. If the soft stop adjustment 5 is set too soft, stopping will be less accurate as when 5 is set for a quicker stop. c. Particularly when the mechanic can not see the operation of the elevator car, it is possible that the elevator has not finished decelerating from fast speed before reaching the floor. In other words, the elevator has not slowed down to its correct leveling speed before the stop switch is actuated. Usually, the leveling operation can be observed through the crack in the car doors. Alternatively, in the machine room, the turbulant noise within the valve during leveling can be heard and should last 1 to 2 secs. following 2 to 2,5 secs. deceleration time with no load in the car. d. A difference in landing accuracy between the elevator being loaded and unloaded, can be due to the car under load, leaning to one side by several millimeters causing an alteration in the operating position of the stop switch by some centimetres.

Oct 02 Printed in Germany

BLAIN HYDRAULICS GmbH Boellinger Hoefe D-74078 Heilbronn Tel. +49 7131 28 21-0 Fax +49 7131 485216 www.blain.de info@blain.de

11

EV 100 Service Manual

Speed-Flow

Geschwindigkeit-Durchfluss

Flow-Pressure-Tables (metric)

Vitesse -Dbit

Velocidad-Caudal

EN ISO 9001

Ram Area Speed Flow

Load-Pressure

Gewicht-Druck

Cargaision-Pression

Carga-Presin

Ram Area Load Pressure

cm = in 6,45

m/sec x 197 = ft/min.

mm = inches 25,4

l/min x 0,26 = US. gpm

kg x 2,2 = lbs

bar x 14,7 = psi

Flow Guide Selection Charts

"

50

US gpm.

Druck bei unbeladener Kabine

5 10 15 20 25 30 35 700 01 02 03 04 05 600 500

1 " & 2"

20 40 50 40 30 20 10 0 1

US gpm.

60

80

100 120 140 160

180 200 700

2 "

50

US gpm.

100 150 200 250 300 350 400

Pression avec cabine vide

40 30 20 10 0

600 500 400

40 30 20 10 0

600 500 400

400 06 300 200

300 200

10

300 200

bar

20 40 60

psi

100

bar

0 100 200 300

psi

100

bar

200 400 600

psi

100

Oct 02 Printed in Germany

l/min.

80

100

120

140

l/min.

400

500

600

700

l/min.

800

1000

1200

1400

1600

BLAIN HYDRAULICS GmbH Boellinger Hoefe D-74078 Heilbronn Tel. +49 7131 28 21-0 Fax +49 7131 485216 www.blain.de info@blain.de

12

Presin con cabina vaca

50

700

Empty car pressure

EV 100 Service Manual

Flow - Pressure-Tables (USA)

Ram Area Speed Flow

EN ISO 9001

ft/min inch in 1,4 1,6 1,8 2,0 2,2 21/2 2,6 23/4 3,0 3,2 31/2 3,6 3,8 4,0 4,2 43/8 41/2 4,8 1,5 2,0 2,5 3,1 3,8 4,9 5,3 5,9 7,1 8,0 9,6 10,2 11,3 12,6 13,9 15,0 15,9 18,1

10 0,8 1,0 1,3 1,6 2,0 2,6 2,8 3,1 3,7 4,2 5,0 5,3 5,9 6,5 7,2 7,8 8,3 9,4 10,2 12,1 12,4 14,7 17,3 18,9 20,0 23,0 26,1 29,5 31,6 36,8 46,1 51,2 58,8

20 1,6 2,1 2,6 3,3 4,0 5,1 5,5 6,2 7,3 8,4 10,0 10,6 11,8 13,1 14,4 15,6 16,5 18,8 20,4 24,1 24,7 29,4 34,5 37,8 40,0 45,9 52,3 59,0 63,2 73,7 92,2 102,4 117,6

30 2,4 3,1 4,0 4,9 5,9 7,7 8,3 9,3 11,0 12,5 15,0 15,9 17,7 19,6 21,6 23,4 24,8 28,2 30,6 36,2 37,1 44,1 51,8 56,6 60,0 68,9 78,4 88,5 94,9 110,5 138,3 153,6 176,4

40 3,2 4,2 5,3 6,5 7,9 10,2 11,0 12,4 14,7 16,7 20,0 21,2 23,6 26,1 28,8 31,3 33,1 37,6 40,8 48,3 49,4 58,8 69,0 75,5 80,0 91,9 104,5 118,0 126,5 147,4 184,4 204,9 235,2

50 4,0 5,2 6,6 8,2 9,9 12,8 13,8 15,4 18,4 20,9 25,0 26,5 29,5 32,7 36,0 39,1 41,3 47,0 51,0 60,4 61,8 73,5 86,3 94,4 100,0 114,8 130,7 147,5 158,1 184,2 230,5 256,1 294,0

60 4,8 6,3 7,9 9,8 11,9 15,3 16,6 18,5 22,0 25,1 30,0 31,7 35,4 39,2 43,2 46,9 49,6 56,4 61,2 72,4 74,1 88,2 103,5 113,3 120,0 137,8 156,8 177,0 189,7 221,1 276,6 307,3 352,8

70 5,6 7,3 9,3 11,4 13,8 17,9 19,3 21,6 25,7 29,3 35,0 37,0 41,3 45,7 50,4 54,7 57,9 65,8 71,5 84,5 86,5 102,9 120,8 132,2 140,0 160,8 182,9 206,5 221,3 257,9 322,6 358,5 411,6

80 US gpm 6,4 8,4 10,6 13,1 15,8 20,4 22,1 24,7 29,4 33,4 40,0 42,3 47,2 52,3 57,6 62,5 66,1 75,3 81,7 96,6 98,8 117,6 138,0 151,0 160,1 183,7 209,0 236,0 252,9 294,8 368,7 409,7 470,4

90 7,2 9,4 11,9 14,7 17,8 23,0 24,8 27,8 33,1 37,6 45,0 47,6 53,1 58,8 64,8 70,3 74,4 84,7 91,9 108,6 111,2 132,3 155,3 169,9 180,1 206,7 235,2 265,5 284,6 331,6 414,8 460,9 529,1

100 8,0 10,5 13,2 16,3 19,8 25,5 27,6 30,9 36,7 41,8 50,0 52,9 59,0 65,3 72,0 78,1 82,7 94,1 102,1 120,7 123,5 147,0 172,5 188,8 200,1 229,7 261,3 295,0 316,2 368,5 460,9 512,2 587,9

110 8,8 11,5 14,6 18,0 21,7 28,1 30,4 34,0 40,4 46,0 55,0 58,2 64,9 71,9 79,2 86,0 90,9 103,5 112,3 132,8 135,9 161,7 189,8 207,7 220,1 252,6 287,4 324,5 347,8 405,3 507,0 563,4 646,7

120 9,6 12,5 15,9 19,6 23,7 30,6 33,1 37,1 44,1 50,2 60,0 63,5 70,7 78,4 86,4 93,8 99,2 112,9 122,5 144,9 148,2 176,4 207,0 226,6 240,1 275,6 313,6 354,0 379,4 442,2 553,1 614,6 705,5

140 11,2 14,6 18,5 22,9 27,7 35,7 38,6 43,2 51,4 58,5 70,0 74,1 82,5 91,5 100,8 109,4 115,8 131,7 142,9 169,0 172,9 205,8 241,5 264,3 280,1 331,5 365,8 413,0 442,7 515,9 645,3 717,0 823,1

160 12,8 16,7 21,2 26,1 31,6 40,8 44,2 49,4 58,8 66,9 80,0 84,7 94,3 104,5 115,2 125,0 132,3 150,5 163,3 193,1 197,6 235,2 276,0 302,1 320,1 367,5 418,1 472,0 505,9 589,6 737,5 819,5

180 14,4 18,8 23,8 29,4 35,6 45,9 49,7 55,6 66,1 75,3 90,0 95,2 106,1 117,6 129,6 140,7 148,8 169,3 183,7 217,3 222,3 264,6 310,5 339,8 360,1 413,4 470,4 531,0 569,1 663,3

200 16,0 20,9 26,5 32,7 39,5 51,0 55,2 61,8 73,5 83,6 100,0 105,8 117,9 130,7 144,0 156,3 165,4 188,1 204,1 241,4 247,0 294,0 345,0 377,6 400,1 459,3 522,6 590,0 632,4 737,0

5,0 19,6 57/16 23,2 51/2 6,0 61/2 6,8 7,0 71/2 8,0 81/2 8,8 91/2 105/8 11,2 23,8 28,3 33,2 36,3 38,5 44,2 50,3 56,7 60,8 70,9 88,7 98,5

829,7 921,9 921,9 1024,3 1175,9

12,0 113,1

940,7 1058,3

Ram Area Load Pressure

lbs inch in 1,4 1,6 1,8 2,0 2,2 21/2 2,6 23/4 3,0 3,2 31/2 3,6 3,8 4,0 4,2 43/8 41/2 4,8 1,5 2,0 2,5 3,1 3,8 4,9 5,3 5,9 7,1 8,0 9,6 10,2 11,3 12,6 13,9 15,0 15,9 18,1 1100 1650 2200 3300 4400 5500 6600 7700 psi 8800 10000 11000 13200 15400 17600 19800 22000

714,6 1071,9 1429,1 2143,7 2858,3 3572,9 4287,4 5002,0 5716,6 6496,1 7145,7 8574,9 10004,0 11433,2 12862,3 14291,5 547,1 820,6 1094,2 1641,3 2188,4 2735,5 3282,6 3829,7 4376,8 4973,6 5471,0 6565,1 7659,3 8753,5 9847,7 10941,9 432,3 350,1 289,4 224,1 207,2 185,2 155,6 136,8 114,3 108,1 97,0 87,5 79,4 73,2 69,2 60,8 56,0 47,4 46,3 38,9 33,1 30,3 28,6 24,9 21,9 19,4 18,1 15,5 12,4 11,2 648,4 525,2 434,1 336,1 310,8 277,8 233,4 205,2 171,5 162,1 145,5 131,3 119,1 109,8 103,7 91,2 84,0 71,1 69,4 58,4 49,7 45,4 42,9 37,3 32,8 29,1 27,1 23,3 18,6 16,7 864,5 1296,8 1729,1 2161,4 2593,6 3025,9 3458,2 3929,8 4322,7 5187,3 6051,8 6916,4 7780,9 8645,5 700,3 1050,4 1400,6 1750,7 2100,8 2451,0 2801,1 3183,1 3501,4 4201,7 4902,0 5602,3 6302,5 7002,8 578,7 448,2 414,4 370,4 311,2 273,5 228,7 216,1 194,0 175,1 158,8 146,3 138,3 121,6 112,0 94,7 92,6 77,8 66,3 60,6 57,2 49,8 43,8 38,8 36,2 31,0 24,8 22,3 868,1 672,3 621,6 555,6 466,9 410,3 343,0 324,2 291,0 262,6 238,2 219,5 207,5 182,4 168,1 142,1 138,9 116,7 99,4 90,9 85,7 74,7 65,7 58,2 54,3 46,6 37,2 33,5 1157,5 1446,9 1736,2 2025,6 2315,0 2630,7 2893,7 3472,5 4051,2 4630,0 5208,7 5787,5 896,4 1020,5 1344,5 1568,6 1792,7 2037,2 2240,9 2689,1 3137,3 3585,4 4033,6 4481,8 828,7 1035,9 1243,1 1450,3 1657,5 1883,5 2071,8 2486,2 2900,6 3314,9 3729,3 4143,7 740,8 926,0 1111,2 1296,4 1481,6 1683,6 1852,0 2222,4 2592,8 2963,2 3333,6 3704,0 622,5 547,1 457,3 432,3 388,0 350,1 317,6 292,7 276,7 243,2 224,1 189,5 185,2 155,6 132,6 121,2 114,3 99,6 87,5 77,5 72,3 62,1 49,6 44,7 778,1 683,9 571,7 540,3 485,0 437,7 397,0 365,9 345,8 303,9 280,1 236,9 231,5 194,5 165,7 151,4 142,9 124,5 109,4 96,9 90,4 77,6 62,0 55,8 933,7 1089,3 1244,9 1414,7 1556,2 1867,4 2178,7 2489,9 2801,1 3112,4 820,6 957,4 1094,2 1243,4 1367,7 1641,3 1914,8 2188,4 2461,9 2735,5 686,0 648,4 582,0 525,2 476,4 439,0 415,0 364,7 336,1 284,2 277,8 233,4 198,9 181,7 171,5 149,4 131,3 116,3 108,5 93,1 74,4 67,0 800,3 756,5 678,9 612,7 555,8 512,2 484,1 425,5 392,2 331,6 324,1 272,3 232,0 212,0 200,1 174,3 153,2 135,7 126,6 108,6 86,8 78,2 914,7 1039,4 1143,3 1372,0 1600,6 1829,3 2058,0 2286,6 864,5 982,4 1080,7 1296,8 1513,0 1729,1 1945,2 2161,4 775,9 700,3 635,2 585,4 553,3 486,3 448,2 379,0 370,4 311,2 265,2 242,3 228,7 199,2 175,1 155,1 144,7 124,1 99,3 89,3 881,7 795,8 721,8 665,2 628,8 552,6 509,3 430,6 420,9 353,7 301,4 275,4 259,8 226,4 198,9 176,2 164,4 141,1 112,8 101,5 969,9 1163,9 1357,9 1551,9 1745,9 1939,8 875,4 1050,4 1225,5 1400,6 1575,6 1750,7 794,0 731,7 691,6 607,9 560,2 473,7 463,0 389,0 331,5 302,9 285,8 249,0 218,8 193,8 180,9 155,2 124,1 111,7 952,8 1111,6 1270,4 1429,1 1587,9 878,1 1024,4 1170,8 1317,1 1463,4 830,0 729,5 672,3 568,4 555,6 466,9 397,8 363,5 343,0 298,8 262,6 232,6 217,0 186,2 148,9 134,0 968,3 851,0 784,3 663,2 648,2 544,7 464,1 424,0 400,2 348,6 306,4 271,4 253,2 217,3 173,7 156,3 1106,6 1244,9 1383,3 972,6 1094,2 1215,8 896,4 1008,4 757,9 852,7 740,8 622,5 530,4 484,6 457,3 398,4 350,1 310,2 289,4 248,3 198,5 178,6 833,4 700,3 596,7 545,2 514,5 448,2 393,9 348,9 325,5 279,3 223,3 201,0 1120,5 947,4 926,0 778,1 663,0 605,8 571,7 498,0 437,7 387,7 361,7 310,4 248,1 223,3

5,0 19,6 57/16 23,2 51/2 6,0 61/2 6,8 7,0 71/2 8,0 81/2 8,8 91/2 105/8 11,2 23,8 28,3 33,2 36,3 38,5 44,2 50,3 56,7 60,8 70,9 88,7 98,5

Oct 02 Printed in Germany

BLAIN HYDRAULICS GmbH Boellinger Hoefe D-74078 Heilbronn Tel. +49 7131 28 21-0 Fax +49 7131 485216 www.blain.de info@blain.de

13

You might also like

- Blain Service Manual GBDocument40 pagesBlain Service Manual GBsmsobhanNo ratings yet

- PK ASY Evolution BC61F 2022 04 enDocument233 pagesPK ASY Evolution BC61F 2022 04 enYousef ShishaniNo ratings yet

- Elevator spare parts SchindlerDocument132 pagesElevator spare parts Schindlerhunt hunt0% (1)

- Orden de PedidoDocument20 pagesOrden de PedidoRonald NietoNo ratings yet

- 7.2 Safety Brake - Q 409 710: 1 Description and Mode of OperationDocument7 pages7.2 Safety Brake - Q 409 710: 1 Description and Mode of OperationDobra Alexandru RomeoNo ratings yet

- 3.4.4 Installation Car Door 4010PM (07.2014) NEWDocument24 pages3.4.4 Installation Car Door 4010PM (07.2014) NEWdjidjelli nassirNo ratings yet

- Maintenance and service manual for elevator control valve EV 100 blainDocument13 pagesMaintenance and service manual for elevator control valve EV 100 blaindragishabl100% (1)

- 004 - 1set Up Winch and Install Pit Equipment - MRDocument9 pages004 - 1set Up Winch and Install Pit Equipment - MRAli DiabNo ratings yet

- Installation Manual - Tervis Bidirecioanal Lift 2000.Document8 pagesInstallation Manual - Tervis Bidirecioanal Lift 2000.Albano FerreiraNo ratings yet

- PDF Translator 1678819931985 PDFDocument76 pagesPDF Translator 1678819931985 PDFMuMoMaNo ratings yet

- Fermator Vvvf 5 Manual Pdf DownloadDocument3 pagesFermator Vvvf 5 Manual Pdf DownloadMauricio LustigNo ratings yet

- лифт арбат 2Document25 pagesлифт арбат 2Anton LyakhovNo ratings yet

- Encoder WDG 100H PDFDocument12 pagesEncoder WDG 100H PDFAlex GonzalezNo ratings yet

- DrakaTechTipNo.1 CompensatingChain PDFDocument2 pagesDrakaTechTipNo.1 CompensatingChain PDFKar Keong LewNo ratings yet

- Analogue Speed Sensor Q264127 EngDocument5 pagesAnalogue Speed Sensor Q264127 EngPio RodolfoNo ratings yet

- Troubleshooting Schindler Miconic TX and TX-GCDocument31 pagesTroubleshooting Schindler Miconic TX and TX-GCDon LuongNo ratings yet

- DO2000 Programação DCSSDocument1 pageDO2000 Programação DCSSAlan LimachiNo ratings yet

- Schindler R300: High Performance Roller Guide ShoeDocument2 pagesSchindler R300: High Performance Roller Guide ShoeWashington MazziniNo ratings yet

- صينى 300P-Miconic TX5Document40 pagesصينى 300P-Miconic TX5yahia MahmoudNo ratings yet

- ايتينورDocument48 pagesايتينورمحمد حسينNo ratings yet

- Spare Parts Catalogue: IndexDocument28 pagesSpare Parts Catalogue: IndexZoran Tesla BorojevicNo ratings yet

- 04 OtisDocument37 pages04 OtisNirun IngrodNo ratings yet

- OMARLIFT General Catalogue en Rev. 01Document183 pagesOMARLIFT General Catalogue en Rev. 01Marcelo SantibañezNo ratings yet

- PKR SCH Price ListDocument5 pagesPKR SCH Price ListRavi MagroriyaNo ratings yet

- Gen2 Flex 26l PDFDocument16 pagesGen2 Flex 26l PDFGustavo CastilloNo ratings yet

- Ovf20 Startup RoutineDocument14 pagesOvf20 Startup RoutineRaja DuraiNo ratings yet

- Instruction Manual: Car DoorDocument58 pagesInstruction Manual: Car Doorekrem kayaNo ratings yet

- Lift Control SLC4 Information For The Expert I Subranges of The Main Card of Central Unit - AZE0Document6 pagesLift Control SLC4 Information For The Expert I Subranges of The Main Card of Central Unit - AZE0raymon janszenNo ratings yet

- Schindler Escalator 9700AE - Handrail MaintenanceDocument9 pagesSchindler Escalator 9700AE - Handrail MaintenanceHùng VĩNo ratings yet

- Manuales OtisDocument4 pagesManuales Otisghosthacker98No ratings yet

- Schindler Actionboard User Manual v5Document30 pagesSchindler Actionboard User Manual v5Josue GomezNo ratings yet

- Door Drive Operating Instructions ID Unique PM.2.000186ENDocument15 pagesDoor Drive Operating Instructions ID Unique PM.2.000186ENHugo SoaresNo ratings yet

- Innovative SIGMA MRL ElevatorDocument16 pagesInnovative SIGMA MRL ElevatorAaron BermontNo ratings yet

- Micelect Technical Manual LM3D STD Din Ver 01.2004Document1 pageMicelect Technical Manual LM3D STD Din Ver 01.2004Armando100% (1)

- ML65X Kullanim KilavuzuDocument16 pagesML65X Kullanim KilavuzuRefaat RaslanNo ratings yet

- Intelligent Lift Control Valve With Electronic CardDocument13 pagesIntelligent Lift Control Valve With Electronic CardAlex MakarovNo ratings yet

- Guide Specifications For NCE Escalator by Otis Elevator CoDocument7 pagesGuide Specifications For NCE Escalator by Otis Elevator Comulai119No ratings yet

- 100 - 1. Lift Controller ManualDocument41 pages100 - 1. Lift Controller ManualDjordje GavrilovicNo ratings yet

- Schindler Westinghouse Elevator Parts GuideDocument58 pagesSchindler Westinghouse Elevator Parts GuideSergio MasinNo ratings yet

- SCM Go Flex: Product Technical SheetDocument8 pagesSCM Go Flex: Product Technical SheetKen LeeNo ratings yet

- Folding Door Assembly and Maintenance Manual: Automatic Doors For LiftsDocument12 pagesFolding Door Assembly and Maintenance Manual: Automatic Doors For LiftsDmitry PlatovNo ratings yet

- Augusta Evo: Car DoorsDocument21 pagesAugusta Evo: Car DoorsCoil98No ratings yet

- Titan Full CatalogDocument57 pagesTitan Full CatalogTomas Hubner NeumannNo ratings yet

- Saturn DriveDocument21 pagesSaturn DrivefreddyjoertyNo ratings yet

- Schéma Électrique WitturDocument19 pagesSchéma Électrique WitturMoh DaraNo ratings yet

- Tlsv3 Autodialler Basic Functioning: Document Code: Last RevisionDocument6 pagesTlsv3 Autodialler Basic Functioning: Document Code: Last RevisionEmadNo ratings yet

- Schindler Escalator 9700AE - Brake MaintenanceDocument4 pagesSchindler Escalator 9700AE - Brake MaintenanceHùng VĩNo ratings yet

- KONE Maintenance Manual OTISDocument99 pagesKONE Maintenance Manual OTISFelipe GonzalezNo ratings yet

- Variador de Frecuencia Yask.616G5Document114 pagesVariador de Frecuencia Yask.616G5yoyo50100% (1)

- TKE-GEC-24 - Códigos de Falhas e Alertas-PortuguêsDocument6 pagesTKE-GEC-24 - Códigos de Falhas e Alertas-PortuguêsValdo100% (1)

- лифт арбат 3Document42 pagesлифт арбат 3Anton LyakhovNo ratings yet

- DELTA User Manual GuideDocument35 pagesDELTA User Manual GuideMiroslav Ožeg100% (1)

- 05-1. Standard IO MapDocument5 pages05-1. Standard IO MapБахтияр ЮмачиковNo ratings yet

- Thang Máy Gia Đình CIBES S300 - Cibeslift - Com.vnDocument4 pagesThang Máy Gia Đình CIBES S300 - Cibeslift - Com.vnThang máy gia đình Cibes Thụy ĐiểnNo ratings yet

- 思迈特 零件Document78 pages思迈特 零件Jeremy LinNo ratings yet

- Traccion EscalerasDocument16 pagesTraccion EscalerasRafael BrunoNo ratings yet

- Hydraulic Elevator Installation Checklist: Schindler 330ADocument4 pagesHydraulic Elevator Installation Checklist: Schindler 330AMMMOH200No ratings yet

- A-FLY Quotation For Schindler Parts-20170815-142636703Document2 pagesA-FLY Quotation For Schindler Parts-20170815-142636703habibullaNo ratings yet

- Mayr Roba Stop b.1110.1.GbDocument9 pagesMayr Roba Stop b.1110.1.GbsundewsNo ratings yet

- Ev Quick-GbDocument2 pagesEv Quick-GbGul Nawab KhanNo ratings yet

- Trouble Ev eDocument2 pagesTrouble Ev eSylvester SullivanNo ratings yet

- Blain Sys Leak EVDocument1 pageBlain Sys Leak EVSylvester SullivanNo ratings yet

- Troubleshooting GuideDocument8 pagesTroubleshooting GuideSylvester SullivanNo ratings yet

- Trouble KV eDocument2 pagesTrouble KV eSylvester SullivanNo ratings yet

- Blain Service Manual LowDocument15 pagesBlain Service Manual LowSylvester SullivanNo ratings yet

- Slack Rope Valve KS For BLAIN EV, KV Down Valve and L10Document1 pageSlack Rope Valve KS For BLAIN EV, KV Down Valve and L10Sylvester SullivanNo ratings yet

- Blain Spare Parts EV KVDocument2 pagesBlain Spare Parts EV KVSylvester SullivanNo ratings yet

- Blain Sys Leak KVDocument1 pageBlain Sys Leak KVSylvester SullivanNo ratings yet

- Sys Leak EVDocument1 pageSys Leak EVSylvester SullivanNo ratings yet

- Slack Rope Valve KS For BLAIN EV, KV Down Valve and L10Document1 pageSlack Rope Valve KS For BLAIN EV, KV Down Valve and L10Sylvester SullivanNo ratings yet

- Quick Adj Ev eDocument2 pagesQuick Adj Ev eSylvester SullivanNo ratings yet

- EV Spare Parts List: Down Leak Solenoid Valves AdjustmentsDocument1 pageEV Spare Parts List: Down Leak Solenoid Valves AdjustmentsSylvester SullivanNo ratings yet

- RL RL RL RL RL: R R R R R Amloc Amloc Amloc Amloc AmlocDocument5 pagesRL RL RL RL RL: R R R R R Amloc Amloc Amloc Amloc AmlocSylvester SullivanNo ratings yet

- MD eDocument4 pagesMD eSylvester SullivanNo ratings yet

- HPDocument2 pagesHPSylvester SullivanNo ratings yet

- Full KV Valves InfoDocument6 pagesFull KV Valves InfoSylvester Sullivan100% (1)

- Blain CX-EDocument1 pageBlain CX-ESylvester SullivanNo ratings yet

- Flow - Pressure Chart (US and Metric)Document4 pagesFlow - Pressure Chart (US and Metric)Sylvester SullivanNo ratings yet

- Blain Sys Leak KVDocument1 pageBlain Sys Leak KVSylvester SullivanNo ratings yet

- Blain BVDocument2 pagesBlain BVSylvester SullivanNo ratings yet

- EV Poster34Document1 pageEV Poster34Sylvester SullivanNo ratings yet

- Ev eDocument6 pagesEv eSylvester SullivanNo ratings yet

- EV Poster1-12Document1 pageEV Poster1-12Sylvester SullivanNo ratings yet

- Blain Spare Parts EV KVDocument2 pagesBlain Spare Parts EV KVSylvester SullivanNo ratings yet

- Blain Price List 300 Euro 2008Document1 pageBlain Price List 300 Euro 2008Sylvester SullivanNo ratings yet

- Blain RL-EDocument4 pagesBlain RL-ESylvester SullivanNo ratings yet

- Blain MD - GBDocument4 pagesBlain MD - GBSylvester SullivanNo ratings yet

- Blain KV Trouble-GbDocument2 pagesBlain KV Trouble-GbSylvester Sullivan100% (1)

- Blain KV-GBDocument6 pagesBlain KV-GBSylvester SullivanNo ratings yet

- Blain HP - 4spDocument2 pagesBlain HP - 4spSylvester SullivanNo ratings yet

- Ambient Air Quality Sampling and Analysis MethodsDocument36 pagesAmbient Air Quality Sampling and Analysis MethodsReymond IgayaNo ratings yet

- Air Pollution EssayDocument2 pagesAir Pollution EssayRaghunandan R'dyNo ratings yet

- Learning Competency: Describe The Characteristics of Earth That Are Necessary To Support LifeDocument11 pagesLearning Competency: Describe The Characteristics of Earth That Are Necessary To Support LifeJayjay RonielNo ratings yet

- Robert Frost poem talks isolation and lonelinessDocument17 pagesRobert Frost poem talks isolation and lonelinessLeah PerezNo ratings yet

- Air Pressure Is The Weight of The Atmosphere Pressing Down On TheDocument5 pagesAir Pressure Is The Weight of The Atmosphere Pressing Down On TheFred Michael L. GoNo ratings yet

- Kuning Pink Ilustrasi Lucu Brainstorm PresentasiDocument15 pagesKuning Pink Ilustrasi Lucu Brainstorm Presentasisucimildayuni96No ratings yet

- Evm MCQ TheoryDocument254 pagesEvm MCQ TheoryPooja Pillai100% (1)

- 1st Law of EcologyDocument5 pages1st Law of EcologyCatherine MOSQUITENo ratings yet

- Air Cannon PDFDocument8 pagesAir Cannon PDFNazar KhanNo ratings yet

- Global Warming - Simple English Wikipedia, The Free EncyclopediaDocument13 pagesGlobal Warming - Simple English Wikipedia, The Free EncyclopediaSai parkavi ParthasarathyNo ratings yet

- Sumative Test (4TH Quarter) Science 8Document4 pagesSumative Test (4TH Quarter) Science 8Jonel Rule100% (2)

- Lesson PlanDocument4 pagesLesson PlanJohnsaloma96% (28)

- Answer Key: PHYSICS 1050 Mid-Term Test 2Document8 pagesAnswer Key: PHYSICS 1050 Mid-Term Test 2hey_hopNo ratings yet

- Comfort in Any ClimateDocument73 pagesComfort in Any Climateiade2010e1100% (2)

- AQI levels in Lahore on 17.05.2022Document1 pageAQI levels in Lahore on 17.05.2022fahadNo ratings yet

- ASOS User GUIDE PDFDocument74 pagesASOS User GUIDE PDFDanu TriatmokoNo ratings yet

- S LB CombustifumeDocument20 pagesS LB CombustifumeThaiminh VoNo ratings yet

- Engineers Newsletter Air Distribution Cold Air Makes Good SenseDocument6 pagesEngineers Newsletter Air Distribution Cold Air Makes Good SensesamersibaniNo ratings yet

- TM 1-1500-204-23-1, Change 6Document450 pagesTM 1-1500-204-23-1, Change 6"Rufus"No ratings yet

- Planet Paper by AlexisDocument8 pagesPlanet Paper by AlexisAlexis LindsayNo ratings yet

- Oxygen Plant Process GuideDocument4 pagesOxygen Plant Process Guidebrad100% (1)

- Chapter 13Document12 pagesChapter 13Tdoc TonyNo ratings yet

- CRL 1790Document3 pagesCRL 1790nandhus2227No ratings yet

- Environmental Chemistry: Single Choice Questions (Type-I) 1Document7 pagesEnvironmental Chemistry: Single Choice Questions (Type-I) 1Himanshu YadavNo ratings yet

- Positive Corona Inception Voltages and Corona Currents For Air at Various Pressures and HumiditiesDocument8 pagesPositive Corona Inception Voltages and Corona Currents For Air at Various Pressures and HumiditiesRogelio RevettiNo ratings yet

- Direct-Current Glow Discharges in Atmospheric Pressure Air PlasmasDocument10 pagesDirect-Current Glow Discharges in Atmospheric Pressure Air Plasmaseze_firmatenseNo ratings yet

- Confined Space Ventilation MethodsDocument2 pagesConfined Space Ventilation Methodsreda mesbahNo ratings yet

- Understanding the Greenhouse EffectDocument19 pagesUnderstanding the Greenhouse EffectFitri RahmawatiNo ratings yet

- N2 Generation - Adsorption TypeDocument2 pagesN2 Generation - Adsorption Typeashim_ju983902No ratings yet

- Heat gain loads in air conditioning designDocument18 pagesHeat gain loads in air conditioning designNg Swee Loong Steven100% (2)