Professional Documents

Culture Documents

Electrical Canle Trench Specification

Uploaded by

Sumit Kumar DattaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrical Canle Trench Specification

Uploaded by

Sumit Kumar DattaCopyright:

Available Formats

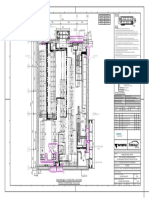

CABLE TRENCH INSTALLATION GUIDE

1.0 INDEX

1.0 INDEX 2.0 PURPOSE 3.0 GENERAL INFORMATION 4.0 PLANNING INFORMATION 5.0 CREW INFORMATION 6.0 CONTRACTOR INFORMATION 7.0 PRECASTED/ POURED-IN-PLACE TRENCH DRAWINGS

2.0

PURPOSE

This standard provides information for construction of Cable Trench. This installation is for underground services from 2001 amps to 4000 amps.

3.0

GENERAL INFORMATION

3.1 Cable Trench is suitable for the following conditions: 2001 Amp to 4000 amp services. Trench length should be limited to 20 feet, with the service cable length limited to less than 50' from transformer to customer panel.

4.0

PLANNING INFORMATION

ENGINEERING & CONSTRUCTION STANDARD

SHEET 36 OF 8 8 VOLUME 17

DRAWN JVV

DESIGN MB

SUPR MB

DATE 7/05

REV 8

CABLE TRENCH INSTALLATION GUIDE

DRAWING NUMBER

GI0011U

4.1 4.2

Location And Orientation Of Service Pad placement and switch board pull section should maximize trench window space. Service Entrances

The trench length must be determined, (see Section 6.8 for details). If the entrance is inside the building, then the wall must be cut or designed to allow the trough entry. The customer must meet NEC, Article 300-21 requirements. A. PREFERRED #1

ENGINEERING & CONSTRUCTION STANDARD

SHEET 37 OF 8 8 VOLUME 17

DRAWN JVV

DESIGN MB

SUPR DA

DATE 7/05

REV 8

CABLE TRENCH INSTALLATION GUIDE

DRAWING NUMBER

GI0011U

B.

PREFERRED #2

C.

PREFERRED #3

D.

NOT APPROVED CONSTRUCTION

ENGINEERING & CONSTRUCTION STANDARD

SHEET 38 OF 8 8 VOLUME 17

DRAWN JVV

DESIGN MB

SUPR MB

DATE 7/05

REV 8

CABLE TRENCH INSTALLATION GUIDE

DRAWING NUMBER

GI0011U

NOTES: 1. SPPC cable trench is not approved for installation inside a building to serve an internal / isolated Electrical Room. 2. If an internal / isolated Electrical Room is required, the customer must install a secondary splice can at the outer wall nearest the transformer. Refer to drawing below. 3. Outside splice can, and all facilities inside the building, will be customer owned and installed. Facilities must meet NEC requirements. D1. ACCEPTABLE CONSTRUCTION

4.3

Trench Covers There are two types of trench covers available: H-20 Full Traffic Rated Non-Traffic / Pedestrian Only Cable Selection Multiple runs of cable will be required to serve the load. The number of runs depends upon the main panel rating. Number of cables per phase is based on 80% rated panels. Add extra set(s) if 100% panel, noted by ( ) in table.

M AIN PAN EL R ATIN G 2001- 2500 Amps 3000 Amps 3500 Amps 4000 Amps N UM BER OF CABLES PER PHASE 5 (6) 6 (7) 6 (8) 7 (9)

4.4

See Table 8 of CB0003U, Vol. 17, Section 4, for cable ratings.

ENGINEERING & CONSTRUCTION STANDARD

SHEET 39 OF 8 8 VOLUME 17

DRAWN JVV

DESIGN MB

SUPR DA

DATE 7/05

REV 8

CABLE TRENCH INSTALLATION GUIDE

DRAWING NUMBER

GI0011U

4.5

Required Service Materials (to be supplied by SPPC)

ITEM STOCK NUM BER QUANITY

750 kcmil 1/C 600 Volt Cable (Phase) 350 kcmil 1/C 600 Volt Cable (Neutral) 750 kcmil Flat- to- Crimp Connectors (bolt set). Stackable lug: 25- 1315. 350 kcmil Flat- to- Crimp Connectors (bolt set). Stackable lug: 25- 1313 Cable Ties

23- 0895 23- 0781 25- 1356 (25- 2693) 25- 1351 (25- 2697) 95- 8084

See Section 4.4 See Section 4.4 6 connectors per cable run * 2 connectors per cable run * 1 pkg. per 10' trench length

* Customer to furnish cable connectors at panel. SPPC to furnish bolts.

5.0

CREW INFORMATION

5.1 Cable Orientation Cable Ties are to be set at +/- 15" intervals along the cable run. Each cable run contains 3 different phases and a neutral.

ENGINEERING & CONSTRUCTION STANDARD

SHEET 40 OF 8 8 VOLUME 17

DRAWN JVV

DESIGN MB

SUPR MB

DATE 7/05

REV 8

CABLE TRENCH INSTALLATION GUIDE

DRAWING NUMBER

GI0011U

5.2

Support Arm and Tie-Down Spacing Support arms are to be set at 30 inch spacings. The cable is fastened to each arm.

5.3

Cable Lengths All X1 phase cables must be the same length, all X2 phase cables must be the same length, etc. However the length of the X1cables does not have to equal the X2 lengths or the X3 lengths. Example:

6.0

CONTRACTOR INFORMATION

6.1 Contractor Responsibility The contractor will provide trench, furnish and install materials as listed in section 6.7. Contractor will be responsible to submit to Jensen Precast (precasted trench ) and/or SPPC (poured in place trench) a preliminary drawing with the following items: Information as shown in 6.8 with pad size. Submit a preliminary design worksheet to Jensen Precast and/or SPPC Inspection group for verification of measurements and final approval. Jensen will fax final design to SPPC Inspection Group Reno or District Planner for final acceptance. Trench Construction The cable trench may be precast (Preferred) or poured in place (Non Preferrred). Poured-in-place trench walls to be formed, do not cast against existing soil. Exposed edges to be finished with edging tool. No customer conductor, including bare ground/bonding conductors, is to be installed in the trench.

6.2

ENGINEERING & CONSTRUCTION STANDARD

SHEET 41 OF 8 8 VOLUME 17

DRAWN JVV

DESIGN MB

SUPR DA

DATE 7/05

REV 8

CABLE TRENCH INSTALLATION GUIDE

DRAWING NUMBER

GI0011U

Unistrut or equivalent to be cast in wall. See details, Section 7.1. Unistrut shall be hot dip galvanized and have an "A" corrosion rating. 6.3 Backfill Composition Backfill material shall meet requirements of SPPC Standard SUB01X, Trench Bedding and Backfill (see Volume 17, Section 3). Service Entrance The contractor must check with local codes before running a service entrance. Service entrance into buildings must have 'fire proofing' per NEC #300.21 requirements. Firestopping - Building codes and standards provide strict requirements for sealing, or firestopping, penetrations through fire-rated walls, floors, and ceilings. Approved methods and materials must be used to reduce the chance of spreading fire, smoke, and toxic gases thoughout the building(s). See Section 7.0, note 11. Firestop materials are available as: Blankets, Caulking compounds, Cementitious compounds, Collar devices and chokes, Composite sheets, Pillows, Putty, Wrap strips, Sprays, and Mechanical systems. All firestopping solutions are generally a combination of firestop materials, holding devices, packing materials, and othe devices that make up a listed (approved) system. Aways use an approved and engineered system to firestop a penetratrion. Contact an appropriate firestop manufacturer with any questions.

6.4

6.5

Trench Covers To be stamped as shown in Sections 7.0. Will be coated with red oxide primer and finished with epoxy sand paint. All covers will be constructed in 24" lengths. If additional length is needed at the start or end up to 6" may be added to the 24" section. Cover needing additional width above 6" will be made to fit.

ENGINEERING & CONSTRUCTION STANDARD

SHEET 42 OF 8 8 VOLUME 17

DRAWN JVV

DESIGN MB

SUPR MB

DATE 7/05

REV 8

CABLE TRENCH INSTALLATION GUIDE

DRAWING NUMBER

GI0011U

6.6

Drains/Sump hole Precast and Poured in place: Locate knockout for the drain hole and the sump hole as shown in sections 7.0 and 7.1. List of Materials The materials listed below are for reference only, a detailed list of quantities should be generated by referenceing the final drawing and the specifications shown in this standard.

6.7

M ate rials to be Supplie d by Contractor/Je ns e n Pre cas t Poure d-In-Place (N on-Traffic) Concrete, 3000 psi strength @ 28 days PVC, 6" Dia. N elson Studs, 2" Rebar, #4 @ 11" O C. Rebar #3 @ 12" O C. Unistrut P4000 or Equivalent Angle Iron, 3" x 4" x 1/4" Diamond Plate Cover 1/4" Thickness Structural Angle Iron 3- 1/2" x 3- 1/2" x 1/4" 4" Long Unistruts For Holding Covers In Place Drain Rock, 3/4", 1 Cu. Ft. 12" Sump Penta Head Bolts 1/2" x 3- 1/2" . Cable Suport Racks, Arms, & Hardware Poure d-In-Place (Traffic) Concrete, 3000 psi strength @ 28 days PVC, 6" Dia. N elson Studs, 2" Rebar, #4 @ 11" O C. Rebar, #3 @12" O C. Unistrut P4000 or Equivalent Angle Iron, 3" x 4" x 1/4" Diamond Plate Cover 1/2" Thickness Structural Tubing 3" x 3" x 1/4" 4" Long Unistruts For Holding Covers In Place Drain Rock, 3/4", 1 Cu. Ft. 12" Sump Penta Head Bolts 1/2" x 3- 1/2" . Cable Suport Racks, Arms, & Hardware

ENGINEERING & CONSTRUCTION STANDARD

SHEET 43 OF 8 8 VOLUME 17

DRAWN JVV

DESIGN MB

SUPR DA

DATE 7/05

REV 8

CABLE TRENCH INSTALLATION GUIDE

DRAWING NUMBER

GI0011U

6.8

Determine Bus Trench Length

ENGINEERING & CONSTRUCTION STANDARD

SHEET 44 OF 8 8 VOLUME 17

DRAWN JVV

DESIGN MB

SUPR MB

DATE 7/05

REV 8

CABLE TRENCH INSTALLATION GUIDE

DRAWING NUMBER

GI0011U

7.0 PRECASTED/POURED IN PLACE TRENCH DRAWINGS

1. 2. 3. Contractor is to furnish and install concrete trench (Precasted is Preferred Installation). Contractor to furnish and install unistruts as shown on plan view. Contractor to provide SPPC and/or Jensen Precast with a preliminary layout to confirm transformer and trench layout. See section 6.8. 4. Trench walls to be formed, not cast against existing soil. 5. Concrete strength to be 3000 PSI at 28 days. Rebar yield strength shall be 60KSI. 6. Non traffic 1/4" diamond plate steel cover to be stamped "NON-TRAFFIC", "SPPCO ELECTRIC" and painted with red oxide primer and sand epoxy painted. 7. H20 traffic rated 1/2" diamond plate steel cover to be stamped "H20 TRAFFIC", "SPPCO ELECTRIC" and painted with red oxide primer and sand epoxy painted. 8. Finish exposed concrete trench edges with edging tool. 9. Backfill material shall be adjusted to 2% of optimum moisture content, placed and compacted in 8" lifts to 95% of maximum dry density per ASTM-0-1557. 10. Unistrut or equivalent (1-5/8"X 13/16"shall be cast into wall sections with spacing locations (vertical/horizontal) and a length to fit wall sections as specified on SPPC standard drawings. Unistrut shall be HDG unistrut P400 or equal and shall be "A" rated corrosion resistant. 11. The trench may not be extended into the building unless approved by local Inspection authority and adequate seal against water/fire is provided. (SEE NEC 300.21)

ENGINEERING & CONSTRUCTION STANDARD

SHEET 45 OF 8 8 VOLUME 17

DRAWN JVV

DESIGN MB

SUPR DA

DATE 7/05

REV 8

CABLE TRENCH INSTALLATION GUIDE

DRAWING NUMBER

GI0011U

7.1

Trench Section Details (Pedestrian / H20 Traffic Rated)

ENGINEERING & CONSTRUCTION STANDARD

SHEET 46 OF 8 8 VOLUME 17

DRAWN JVV

DESIGN MB

SUPR MB

DATE 7/05

REV 8

CABLE TRENCH INSTALLATION GUIDE

DRAWING NUMBER

GI0011U

7.2

Trench Section Details

ENGINEERING & CONSTRUCTION STANDARD

SHEET 47 OF 8 8 VOLUME 17

DRAWN JVV

DESIGN MB

SUPR DA

DATE 7/05

REV 8

CABLE TRENCH INSTALLATION GUIDE

DRAWING NUMBER

GI0011U

You might also like

- 8F/-Electrical Installation: Block - D Superstructure 08Document46 pages8F/-Electrical Installation: Block - D Superstructure 08Sajeewa Lakmal90% (10)

- Saudi Arabian Oil Company: Table 1 Minimum Cover RequirementsDocument1 pageSaudi Arabian Oil Company: Table 1 Minimum Cover RequirementsAswin KurupNo ratings yet

- Column Interaction Diagram Lecture21Document58 pagesColumn Interaction Diagram Lecture21kzlondon50% (2)

- Electrical SOQ EVDocument16 pagesElectrical SOQ EVjaiNo ratings yet

- Key Plan: Vertical Vertical VerticalDocument1 pageKey Plan: Vertical Vertical VerticalBumiLangitNo ratings yet

- Design Criteria (Based On BS)Document23 pagesDesign Criteria (Based On BS)Sebastian Eron DavidNo ratings yet

- Primary Metering DesignDocument14 pagesPrimary Metering DesignCj Nicole TanNo ratings yet

- General notes and details for substation constructionDocument1 pageGeneral notes and details for substation constructionA.K.M Shafiq MondolNo ratings yet

- 12kV Air Insulated Metal Clad Switchgear PanelDocument2 pages12kV Air Insulated Metal Clad Switchgear PanelHarmanPreetNo ratings yet

- Method Statement IPBsDocument7 pagesMethod Statement IPBskamil100% (1)

- Part10 13.8 & 33 KV Metered Ring Main Unit SF6 Room SubstationsDocument10 pagesPart10 13.8 & 33 KV Metered Ring Main Unit SF6 Room SubstationsashrafNo ratings yet

- 220 3PS Akbp 00001 000Document14 pages220 3PS Akbp 00001 000faradioNo ratings yet

- J910-YL16-P0AB-145714 500kV Cable List & Connection For Diameter 4, Rev. 1 (ARWC)Document176 pagesJ910-YL16-P0AB-145714 500kV Cable List & Connection For Diameter 4, Rev. 1 (ARWC)Devy MangimbaNo ratings yet

- CSWIP Question Answers PDFDocument32 pagesCSWIP Question Answers PDFAnonymous SA40GK6100% (2)

- LPG-1102-E-EL-ELS-001 - Electrical Load Schedule - Rev. ADocument11 pagesLPG-1102-E-EL-ELS-001 - Electrical Load Schedule - Rev. ARadhaNo ratings yet

- Safelink CB: Gas Insulated Ring Main UnitDocument2 pagesSafelink CB: Gas Insulated Ring Main UnitABCDNo ratings yet

- Volume 3 - Scope of Works, Technical SpecificationsDocument79 pagesVolume 3 - Scope of Works, Technical Specificationsmudassir mNo ratings yet

- Column & Footing Details Block-1 & Block-2Document1 pageColumn & Footing Details Block-1 & Block-2Sandeep VarmaNo ratings yet

- MetalClad Outdoor VCBEnglish PDFDocument2 pagesMetalClad Outdoor VCBEnglish PDFdip461No ratings yet

- E474content PDFDocument64 pagesE474content PDFbhavikNo ratings yet

- The Switchboard That Your Installation Deserves: BloksetDocument12 pagesThe Switchboard That Your Installation Deserves: Bloksetmumi87No ratings yet

- ASTM - STP 425 - Stress Corrosion Testing 1967 PDFDocument390 pagesASTM - STP 425 - Stress Corrosion Testing 1967 PDFnarmathaNo ratings yet

- Erection BOQ - SaranDocument339 pagesErection BOQ - SaranPrasanna kumar subudhiNo ratings yet

- Fundamentals of Metal FormingDocument9 pagesFundamentals of Metal FormingGeorge CamachoNo ratings yet

- 4-Technical Specs - LVDocument29 pages4-Technical Specs - LVtauqeer544gmailcomNo ratings yet

- CBS Commissioning GuideDocument7 pagesCBS Commissioning Guidenawazeee2840No ratings yet

- User Manual Ecu Test Bench 2020Document24 pagesUser Manual Ecu Test Bench 2020jhoan maestreNo ratings yet

- Plumbing SpecialitiesDocument4 pagesPlumbing SpecialitiesphilipyapNo ratings yet

- Copeland Electrical Handbook PDFDocument543 pagesCopeland Electrical Handbook PDFjotalopecincoNo ratings yet

- VCB 06 (1) .07.07 PDFDocument56 pagesVCB 06 (1) .07.07 PDFrazvansasuNo ratings yet

- Catalog of Dpe-12ntf&24ntf (Dongwoo)Document2 pagesCatalog of Dpe-12ntf&24ntf (Dongwoo)Minh VienNo ratings yet

- ESC Steel Philippines Brochure - Oct 2019 PDFDocument12 pagesESC Steel Philippines Brochure - Oct 2019 PDFCarlos_CriticaNo ratings yet

- WEG Three Phase Induction Motors M Line 50019089 Brochure EnglishDocument12 pagesWEG Three Phase Induction Motors M Line 50019089 Brochure Englishhossein447No ratings yet

- Prime Electric Ltd's State-of-the-Art Transformer Manufacturing FacilityDocument29 pagesPrime Electric Ltd's State-of-the-Art Transformer Manufacturing FacilitynaveenchamarthyNo ratings yet

- MOS-CVL-11 Concrete Repair MOSDocument2 pagesMOS-CVL-11 Concrete Repair MOSWaqar Ahmad MalikNo ratings yet

- Concrete Hollow Block LayeringDocument7 pagesConcrete Hollow Block LayeringMichael Adrian Magbanua100% (1)

- Titanium and Titanium AlloysDocument24 pagesTitanium and Titanium AlloysGuilherme FranzoiNo ratings yet

- Pipeline Leak Detection SystemDocument9 pagesPipeline Leak Detection SystemMohamad PizulNo ratings yet

- ABB Modular eHouse Solutions CatalogueDocument12 pagesABB Modular eHouse Solutions CatalogueSuneelKumarNo ratings yet

- Vitreous China Plumbing Fixtures 75SMSS2Document25 pagesVitreous China Plumbing Fixtures 75SMSS2Pageduesca RouelNo ratings yet

- Firefighting Sprinkler and Standpipe System Testing and Commissioning Method Statement - Method Statement HQ PDFDocument5 pagesFirefighting Sprinkler and Standpipe System Testing and Commissioning Method Statement - Method Statement HQ PDFjajakaNo ratings yet

- Electra Sample Drawing 1Document17 pagesElectra Sample Drawing 1stelios_yuhas4576No ratings yet

- Managed Stations Manual - Temporary HoardingsDocument8 pagesManaged Stations Manual - Temporary HoardingsMichael BatleyNo ratings yet

- 66 KV Single Core XLPE Power Cable PDFDocument11 pages66 KV Single Core XLPE Power Cable PDFRani VjNo ratings yet

- Haryana Vidyut Prasaran Nigam Limited: SPECIFICATION No. HGD/S-67/DGMS-171 (APRIL-2017)Document37 pagesHaryana Vidyut Prasaran Nigam Limited: SPECIFICATION No. HGD/S-67/DGMS-171 (APRIL-2017)samkarmakar2002No ratings yet

- Sample Form Inspection ChecklistDocument5 pagesSample Form Inspection Checklistadolf001No ratings yet

- Airport Underground Electrical Duct Banks and ConduitsDocument8 pagesAirport Underground Electrical Duct Banks and ConduitsDevrim Gürsel0% (1)

- 500 KV Lattice Angle Tower Design and TestDocument8 pages500 KV Lattice Angle Tower Design and TestAnonymous SA1rs3KWNo ratings yet

- Specification For 33 KV PTDocument7 pagesSpecification For 33 KV PTPapun Scribd100% (1)

- Low Voltage Electrical Works SpecificationDocument35 pagesLow Voltage Electrical Works Specificationefmartin21100% (1)

- Surge CapacitorDocument2 pagesSurge CapacitorvyroreiNo ratings yet

- Al-Bader 13213.8KV SubstationDocument18 pagesAl-Bader 13213.8KV SubstationfarhanyazdaniNo ratings yet

- Services-Drawings 2Document33 pagesServices-Drawings 2Andrew EllisonNo ratings yet

- Introduction of Modular High-Current Switchgear for Gas Turbine Power PlantsDocument1 pageIntroduction of Modular High-Current Switchgear for Gas Turbine Power PlantsmicajecicNo ratings yet

- Solidworks Report of Light PoleDocument12 pagesSolidworks Report of Light PoleThahir ShahNo ratings yet

- Typical Details For Metering Skid FoundationDocument1 pageTypical Details For Metering Skid FoundationSaravanan SelvamaniNo ratings yet

- 20 MTR HIGH MAST TECHNICAL SPECIFICATIONSDocument2 pages20 MTR HIGH MAST TECHNICAL SPECIFICATIONSrohit1980No ratings yet

- Alion Storm Tracker Ballasted Single-Axis Tracker Data SheetDocument2 pagesAlion Storm Tracker Ballasted Single-Axis Tracker Data SheetAnderson Lincoln BechNo ratings yet

- Sheath REPAIR - Non MetallicDocument6 pagesSheath REPAIR - Non MetallicM Kumar MarimuthuNo ratings yet

- Temporary Power Supply Arrangement Work BOQDocument1 pageTemporary Power Supply Arrangement Work BOQDeepa Junnarkar DegwekarNo ratings yet

- Submittal Rev 2Document264 pagesSubmittal Rev 2Haythamberg AhmedNo ratings yet

- 500kV Aluminum-Sheathed XLPE Cable in A 96m Vertical ShaftDocument6 pages500kV Aluminum-Sheathed XLPE Cable in A 96m Vertical ShaftshahpinkalNo ratings yet

- SSE 2227 Archivo Ingecon Sun Catalogue 2016 v2 EnglishDocument160 pagesSSE 2227 Archivo Ingecon Sun Catalogue 2016 v2 EnglishVitor Olivetti0% (1)

- Elastimold CableDocument40 pagesElastimold CableArmin Fernández GerardoNo ratings yet

- Raychem Screened, Separable Connection System RSTI-68 800 A Up To 42 KVDocument4 pagesRaychem Screened, Separable Connection System RSTI-68 800 A Up To 42 KVgiovany_vq91No ratings yet

- QES PEVC-ENG256 - Checklist For 33kV DP Foundation Design & DrawingDocument2 pagesQES PEVC-ENG256 - Checklist For 33kV DP Foundation Design & Drawingrupesh417No ratings yet

- Lifeline Design Calculations and Energy Absorption AnalysisDocument12 pagesLifeline Design Calculations and Energy Absorption AnalysismbranchteinNo ratings yet

- Cable Tray Load Calculation PDFDocument10 pagesCable Tray Load Calculation PDFu5ur5zoro5luNo ratings yet

- BJLS Lokfom CatalogueDocument2 pagesBJLS Lokfom CatalogueYizhar Bechamel Mestoko100% (1)

- Neutral Grounding Resistors: Installation and Maintenance InstructionsDocument7 pagesNeutral Grounding Resistors: Installation and Maintenance Instructionsks_ramachandra7017No ratings yet

- Cable Trench Installation GuideDocument12 pagesCable Trench Installation GuideTimothy LeonardNo ratings yet

- 3phase Blast WallDocument39 pages3phase Blast WallKaren-John Richard NelsonNo ratings yet

- Electricity Prices in IndiaDocument11 pagesElectricity Prices in IndiaSumit Kumar DattaNo ratings yet

- Transformer CalcDocument1 pageTransformer CalcSumit Kumar DattaNo ratings yet

- Recent Developments in Electrical MetrologyDocument25 pagesRecent Developments in Electrical MetrologySumit Kumar DattaNo ratings yet

- Trends in Electrical TransmissionDocument47 pagesTrends in Electrical TransmissionSumit Kumar DattaNo ratings yet

- Bee Star Rating For Existing Office BuildingsDocument8 pagesBee Star Rating For Existing Office BuildingsSumit Kumar DattaNo ratings yet

- Impact On Farmer Income in View of Current Trends in Agri - RetailingDocument8 pagesImpact On Farmer Income in View of Current Trends in Agri - RetailingSumit Kumar DattaNo ratings yet

- The West Bengal Groundwater Resources (Management, Control and Regulation) Act (2005)Document12 pagesThe West Bengal Groundwater Resources (Management, Control and Regulation) Act (2005)Sumit Kumar DattaNo ratings yet

- Lecture Note About Project Life CycleDocument4 pagesLecture Note About Project Life CycleSaid Abdi MohamudNo ratings yet

- CP 00342-2-1974 (2007) PDFDocument30 pagesCP 00342-2-1974 (2007) PDFStanislav PerevezentsevNo ratings yet

- MOS-002B Door Frame, Door Leaf & IronmongeriesDocument6 pagesMOS-002B Door Frame, Door Leaf & IronmongeriesChezy629No ratings yet

- ASME B18.2.6 2010 (1) - Fasteners For Use in Structural Applications-15-17Document3 pagesASME B18.2.6 2010 (1) - Fasteners For Use in Structural Applications-15-17Andres SilveyraNo ratings yet

- AC Plastiques 1,2,3 - General Catalog PDFDocument5 pagesAC Plastiques 1,2,3 - General Catalog PDFRicardo BustamanteNo ratings yet

- Gravity Based Structure FoundationDocument8 pagesGravity Based Structure FoundationHa NgNo ratings yet

- Boiler ManualDocument68 pagesBoiler ManualAnwar AliNo ratings yet

- ESB Construction SafetyDocument12 pagesESB Construction Safetytexas_peteNo ratings yet

- Tech Tips 16 - What Causes Gray Coloured Hot Dip Galvanized Coatings On SteelDocument2 pagesTech Tips 16 - What Causes Gray Coloured Hot Dip Galvanized Coatings On SteelLong TomahawkNo ratings yet

- (Janssen) The History of Ventilation and Temperature ControlDocument6 pages(Janssen) The History of Ventilation and Temperature ControlEtienne MagriNo ratings yet

- F.L. Vargas College Tuguegarao City, Cagayan Chapter I - IntroductionDocument29 pagesF.L. Vargas College Tuguegarao City, Cagayan Chapter I - IntroductionDexter BaretNo ratings yet

- Ministry Hospital Project Coordination IssuesDocument1 pageMinistry Hospital Project Coordination IssuescdnaveenNo ratings yet

- Japanese Garden Design ElementsDocument6 pagesJapanese Garden Design ElementsFARHANA SHAJINo ratings yet

- Engineering Instructions - FTTH House WiringDocument18 pagesEngineering Instructions - FTTH House WiringReena SharmaNo ratings yet

- 40N Draft 141205 PDFDocument58 pages40N Draft 141205 PDFPrabartak DasNo ratings yet

- CAE TestDocument3 pagesCAE TestDijana KrstevskaNo ratings yet

- C-1 Highway System-1Document18 pagesC-1 Highway System-1Nathan KebedeNo ratings yet

- GEZE Installation Instructions en 742566Document120 pagesGEZE Installation Instructions en 742566PiotrNo ratings yet

- Geotechnical Lab Preliminary Report on Stabilization of Residual SoilDocument20 pagesGeotechnical Lab Preliminary Report on Stabilization of Residual SoilJODIN MAKINDA -No ratings yet