Professional Documents

Culture Documents

8735GB

Uploaded by

Hebert Dacorrégio HeidenreichOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8735GB

Uploaded by

Hebert Dacorrégio HeidenreichCopyright:

Available Formats

Explosion-proof Solenoids

II 2 G / II 2 D EEx dm IIC T4, T5, T6

Catalogue 8735/GB

Maximum photo

ATEX

Explosion-proof Solenoids

8735/GB

"d" flameproof enclosure. The cable gland assembly M20x1.5 makes part of the "d" certificated enclosure. The solenoids are provided with an embedded non-resetting thermal fuse to prevent excessive heating, i.e. assuring the maximum allowed surface temperatures T4/T5. A varistor for peak voltages suppression is potted-in, in Epoxy resin Class H. Additional safety assures a built in replaceable fuse easily accessible in the connection box. (see table 2: fuses/ varistors). Low power version available.

Explosionproof solenoids with flameproof enclosure/encapsulation "dm"

According to ATEX directive 94/9/EC and Standards EN 50014, EN 50018, EN 50028 and EN 50281-1-1

Application:

Control of solenoid valves intended for installations in hazardous areas in which explosive gas- vapour- or dust atmospheres are present, i. e. zones 1, 21 or zones 2, 22 (ATEX: Group II, apparatus categories 2G/D or 3G/D). The enclosure of these explosion proofs solenoids "dm" is made entirely in synthetic material. All external metallic components in contact with the atmosphere are made in stainless steel. The integrated sealing and O-rings assure the degree of protection IP67. Therefore, these products took into account not only the suitability with hazardous areas but also extremely corrosive environment, e. g. Chemical, Petrochemical and Refineries industries (CPR). Due to the compact size and easy cable connection by screw terminals, these solenoids may be mounted in confined spaces.

Benefits:

Thanks to the innovative design of Parker Lucifer engineers, it has been possible to create a full plastic flameproof enclosure "d" with a very high safety level. The volume in the connection box (ignition volume) could be reduced to less than 10 cm3 only. In case of a spark, an explosion is much less probable and if it takes place, the explosion will generate a very low pressure only. The flame will extinguish immediately. Nevertheless, the design of the flameway / safe gap (between enclosure/cover) meets to an ignition volume of 100 cm3,. Therefore, the housing would resist even against the pressure generated by an internal explosion of an explosive mixture of 100 cm3; this gives an extra safety.

Features:

The coil winding (copper wires of insulation Class H) and magnetic iron path are encapsulated in synthetic material Class H and meet "m" protection. The connection box and cover of selected high quality synthetic material (Class H) in order to meet the standard EN 50018 for type of protection 495900 Low power 2W-2.5W (compatible with all Lucifer valves ending 97 , see table 1) 495905 Standard 8W (suitable with all Lucifer valves compatible with coil 481865 -9W)

Reference Approval Type of protection Gas Dust

495900 VDC

495900 VAC LCIE 02 ATEX 6451 X

495905

II 2 G - EEx dm IIC T5 / T6 II 2 D +95 C / +80C

II 2 G - EEx dm IIC T4 / T5 / T6 II 2 D +130 / +95 / +80C IP67

II 2 G EEx dm IIC T4 II 2 D +130 C

Degree of protection -40 to +65C / +55C Ambiant temperature Insulation Class Electrical connection Pn (hot) P (cold) 20C AC Pn (holding) Attraction cold

-40 to +65 / +55 / +40C

-40 to +65 C

The application is limited also by the temperature range of the valve H ( 180 ) Electric connection is done in the connection box on an easily accessible connector terminals. The introduction of the cable ( min 7 mm, max. 9 mm, section max. 2.5 mm) in the connection box passes by the built in M20x1.5 cable gland 2W 2.5 W 6 to 110 VDC 2.5 W 3W 12 to 240 VAC 10 % of the nominal voltage Continuous duty solenoid (ED 100%) 8W 9W 8W 9W 6 to 110 VDC 12 to 240 VAC

Nominal voltage Voltage tolerance Solenoid duty

Elec. Power

DC

Parker Lucifer SA Fluid Control Division Europe Carouge/Geneva - Switzerland

Explosion-proof Solenoids

8735/GB

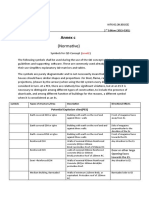

List of compatible valves with solenoid type 495900 (table 1)

Port size G Orifice size mm Operating pressure Bar Min. Max. Fluid temperature C Min. Max. Ambiant temperature C Valve only Min. Max.

Qn NL/min

Kv L/min

Body material

Valve reference no.

Electrical part reference no.

2-way normally closed Direct operated

1/4" 1/4" 1/4" 1/4" 1,5 3 1,5 3 80 250 80 220 1,5 3,5 1,5 3,5 0 0 0 0 10 4,5 10 4,5 -25 -25 -25 -25 +75 +75 +75 +75 Brass Brass St. steel St. steel 121K0497 121K0397 121V5497 121V5397 495900 495900 495900 495900 -20 -20 -20 -20 +65 +65 +65 +65

3-way normally closed Direct operated

1/4" 1/4" SB SB 1/4" 1/4" 1,5 2,5 1,5 2,5 1,5 2,5 80 180 80 180 80 180 1,5 3 1,5 3 1,5 3 0 0 0 0 0 0 7 2 7 2 7 2 -25 -25 -25 -25 -25 -25 +75 +75 +75 +75 +75 +75 Brass Brass Brass Brass St. steel St. steel 131K0497 131K0397 131F4497 131F4397 131V5497 131V5397 495900 495900 495900 495900 495900 495900 -20 -20 -20 -20 -20 -20 +65 +65 +65 +65 +65 +65

3-way universal Direct operated

1/4" 1,5 80 1,5 0 3 -25 +75 Brass 133K0497 495900 -20 +65

4-way Pilot operated

1/8" 1/8" CETOP 1/8" 1/4" 1/4" - 1/8" 1/4" - 1/8 4 4 6 8 4 4 600 400 800 1400 355 600 1400 2 2 1 2 1 2 2 10 10 10 10 10 10 10 -25 -25 -10 -25 -10 -25 -25 +75 +75 +75 +75 +75 +75 +75 Aluminum Aluminum Delrin Aluminum Aluminum Aluminum Aluminum 341P2197 347P2197 341L0197 341P2297 341L9597 * 341N3197 * 341N3297 * 495900 495900 495900 495900 495900 495900 495900 -25 -25 -20 -25 -10 -25 -25 +65 +65 +65 +65 +65 +65 +65

1/4" 8 * NAMUR interface

Parameters of replaceables fuses and built-in varistors (table 2)

Nominal Current In [mA] Nominal Current In [mA] Fuse according to IEC 60127-3/4 EN 60127-3/4 Example Current Schurter Type [mA] MST 250 800 400 250 100 250 100 800 400 250 100 0034.6714 0034.6711 0034.6709 0034.6705 0034.6709 0034.6705 0034.6714 0034.6711 0034.6709 0034.6705 Fuse according to IEC 60127-3/4 EN 60127-3/4 Example Current Schurter Type [mA] MST 250 2000 1600 400 250 630 250 0034.6718 0034.6717 0034.6711 0034.6709 0034.6713 0034.6709

Shut-off Voltage [V]

Electrical Part

Electrical Part

495900A2 (24/50) 495900A4 (48/50) 495900E5 (115/50) 495900F4 (230/50) 495900K8 (110/60) 495900B8 (240/60) 495900C1 (12VDC) 495900C2 (24VDC) 495900C4 (48VDC) 495900C5 (110VDC)

190 95 40 20 40 19 200 100 49 21

35 95 385 385 385 385 35 35 95 385

495905A2 (24/50) 495905A4 (48/50) 495905E5 (115/50) 495905F4 (230/50) 495905K8 (110/60) 495905B8 (240/60)

550 275 115 57 136 65

495905C2 (24VDC) 495905C4 (48VDC) 495905C5 (110VDC)

360 180 75

1600 800 400

0034.6717 0034.6714 0034.6711

Parker Lucifer SA Fluid Control Division Europe Carouge/Geneva - Switzerland

Shut-off Voltage [V] 35 95 385 385 385 385 35 95 385

Explosion-proof Solenoids

8735/GB

How to order?

The solenoid valve is composed of two elements, the mechanical part that is the valve and the electrical part which means the solenoid including the fixing elements and nameplate. Both elements together (assembly) are ATEX certified. Therefore please specify: Valve type + solenoid type with voltage code. Example: 121K0397 / 495900C2

Dimensions / Electrical diagram

Parker Lucifer SA Fluid Control Division Europe 16, ch. du Faubourg de Cruseilles 1227 Carouge/Geneva Switzerland Tel. +41 22 307 71 11 Fax. +41 22 307 71 10 www.parker.com/lucifer

8735/GB Nov. 04

You might also like

- ASCO 327 Solenoid Valves ATEX IECEx Certified For Hazardous Areas2Document4 pagesASCO 327 Solenoid Valves ATEX IECEx Certified For Hazardous Areas2harishNo ratings yet

- Description Function Application: SolenoidsDocument2 pagesDescription Function Application: SolenoidsJuned VhoraNo ratings yet

- Solenoid Valves 3 - 2 General Service 327 CAT 80402GBDocument6 pagesSolenoid Valves 3 - 2 General Service 327 CAT 80402GBsaifulNo ratings yet

- Earthing Clamps: Installation: Hazardous Areas - Zone 1 / 2 (Gases) Classification: Group II - Category 2GDocument10 pagesEarthing Clamps: Installation: Hazardous Areas - Zone 1 / 2 (Gases) Classification: Group II - Category 2GthanhlangdaiNo ratings yet

- Asco Direct Acting Solenoid Valve - 320Document6 pagesAsco Direct Acting Solenoid Valve - 320SatyamEng100% (1)

- Bulgin Fuseholders Guide - Specs and Details for Panel, PCB, Inline ModelsDocument18 pagesBulgin Fuseholders Guide - Specs and Details for Panel, PCB, Inline ModelsVirginiaLaudaniNo ratings yet

- DRIESCHER - High-voltage high breaking capacity fuses up to 36 kVDocument12 pagesDRIESCHER - High-voltage high breaking capacity fuses up to 36 kVDuron WalkerNo ratings yet

- MS 02 316Document12 pagesMS 02 316gazwang478No ratings yet

- En PyrotenaxSystem2000 DS H57049 Tcm432 26219Document5 pagesEn PyrotenaxSystem2000 DS H57049 Tcm432 26219thanna9783No ratings yet

- Ode - 21a2kv25Document2 pagesOde - 21a2kv25meomimi9457No ratings yet

- NEBVO VoltmeterDocument3 pagesNEBVO Voltmetermanimaran75No ratings yet

- 14-000-R1 Pipeline Accessories Summary PDFDocument12 pages14-000-R1 Pipeline Accessories Summary PDFBoussaid SouheilNo ratings yet

- Self-Limiting Heat Tracing Cable Type PSB / HSB : 1 ApplicationDocument2 pagesSelf-Limiting Heat Tracing Cable Type PSB / HSB : 1 ApplicationNicolas150956No ratings yet

- Ds0780 Eexed Eu enDocument4 pagesDs0780 Eexed Eu enosto72No ratings yet

- Schneider GV3 Motor Circuit BreakerDocument16 pagesSchneider GV3 Motor Circuit BreakerMykola TitovNo ratings yet

- Dokumentation FES.123060 en PDFDocument10 pagesDokumentation FES.123060 en PDFbehnamatgNo ratings yet

- Nor GrenDocument5 pagesNor GrenSarlo11No ratings yet

- Fuses1 11Document19 pagesFuses1 11Joshi DhvanitNo ratings yet

- Robust IP65 Installation Switch for LightingDocument3 pagesRobust IP65 Installation Switch for LightingandreaNo ratings yet

- MK25 2 2S En-Instr 1390296721Document20 pagesMK25 2 2S En-Instr 1390296721Erik RochaNo ratings yet

- EVF Technical Data SheetDocument94 pagesEVF Technical Data SheetthanhlangdaiNo ratings yet

- 10 Ex-Safety and Main Current Switches PDFDocument91 pages10 Ex-Safety and Main Current Switches PDFrocket-vtNo ratings yet

- User Manual RK 01 REV 0 Engl CESIDocument3 pagesUser Manual RK 01 REV 0 Engl CESIJuned VhoraNo ratings yet

- OFFSHORE CABLES NEK 606 TITLEDocument32 pagesOFFSHORE CABLES NEK 606 TITLEBob JohnsonNo ratings yet

- Spark Gaps: Dehn (Uk) LTDDocument8 pagesSpark Gaps: Dehn (Uk) LTDElectromacnetist ElectrodNo ratings yet

- Control station-ENDocument79 pagesControl station-ENFlorin MNo ratings yet

- Energy Cable Accessories Epp1984 EngDocument156 pagesEnergy Cable Accessories Epp1984 EngSathiyanathan ManiNo ratings yet

- ENG DS OMI 2 Pole Series Relay Data Sheet E 0411Document3 pagesENG DS OMI 2 Pole Series Relay Data Sheet E 0411letterniNo ratings yet

- Trfricate Kit For 3C Cold Shrink TerminationDocument4 pagesTrfricate Kit For 3C Cold Shrink Terminationdes1982No ratings yet

- LEGRAND Industrial Plugs & SocketsDocument33 pagesLEGRAND Industrial Plugs & Sockets2zeceNo ratings yet

- Pulse Valves - Turbocontrols - It PDFDocument40 pagesPulse Valves - Turbocontrols - It PDFRicardo Ferrari TrevisanNo ratings yet

- Heatshrink Cable Terminations for Power UtilitiesDocument63 pagesHeatshrink Cable Terminations for Power UtilitiesBasman GeorgeNo ratings yet

- Multiconductor TechnicalDocument24 pagesMulticonductor TechnicalJuan Felipe Vieira GaviriaNo ratings yet

- Pic 05 0033 GBDocument14 pagesPic 05 0033 GBLis LisNo ratings yet

- LV16 3VL Ul489Document108 pagesLV16 3VL Ul489kiderilkeNo ratings yet

- Valvula Mariposa 705 VictaulicDocument7 pagesValvula Mariposa 705 Victaulicrvalentino2012No ratings yet

- 0 8 enDocument34 pages0 8 enrocket-vtNo ratings yet

- Addison: Fire Resistant M17/155-RG 58 (RG 58 C/U) Coaxial CablesDocument3 pagesAddison: Fire Resistant M17/155-RG 58 (RG 58 C/U) Coaxial Cablesrose chenNo ratings yet

- Surge Voltage ProtectionDocument22 pagesSurge Voltage Protectionrajpre1213No ratings yet

- U 1015 OedatasheetDocument4 pagesU 1015 OedatasheetGabriel GarciaNo ratings yet

- ABB RCCB F 804Document12 pagesABB RCCB F 804catalinccNo ratings yet

- Insulation Joints for PipelinesDocument5 pagesInsulation Joints for PipelinesHoria BancilaNo ratings yet

- Iiw 1693 05Document19 pagesIiw 1693 05Pradip Goswami100% (1)

- 5 1 Calpak Products Mark5 ManualDocument55 pages5 1 Calpak Products Mark5 ManualΑΝΑΣΤΑΣΙΟΣ ΣΑΦΡΙΔΗΣNo ratings yet

- Features: 44 Series - Miniature PCB Relays 6 - 10 ADocument12 pagesFeatures: 44 Series - Miniature PCB Relays 6 - 10 AKim RamirezNo ratings yet

- Weidmuller Indicating Fuse Terminal BlocksscrewDocument2 pagesWeidmuller Indicating Fuse Terminal BlocksscrewKanna RsNo ratings yet

- Cata GB 2013 Dxn3Document2 pagesCata GB 2013 Dxn3Vincenzo GiaconiaNo ratings yet

- 3ek7 Iec Ansi enDocument12 pages3ek7 Iec Ansi enReynaldo Flores AncietaNo ratings yet

- Amisco Pilot ValveDocument8 pagesAmisco Pilot ValveRaul CostiniucNo ratings yet

- Brochure TG enDocument8 pagesBrochure TG enpascal_chinNo ratings yet

- Fisa Tehnica Volet Rectangular SystemAirDocument17 pagesFisa Tehnica Volet Rectangular SystemAiroelbergluisNo ratings yet

- 511 Pressure TransmitterDocument5 pages511 Pressure TransmitterDhp CiaNo ratings yet

- Introduction InsulatorsDocument14 pagesIntroduction InsulatorsEyad A. Feilat100% (1)

- Vahle Enclosed Conductor System - KBHDocument24 pagesVahle Enclosed Conductor System - KBHKS Chee0% (1)

- The Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingFrom EverandThe Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Monash University: Department of Materials and Science EngineeringDocument4 pagesMonash University: Department of Materials and Science EngineeringRazana RazakNo ratings yet

- Design of Steel FobDocument16 pagesDesign of Steel Fobmahak0% (1)

- CH 06 - Corrosion & ErosionDocument22 pagesCH 06 - Corrosion & ErosionvegaronNo ratings yet

- Arl On ProductsDocument0 pagesArl On Productscasda73No ratings yet

- 1033 H000 A11000 019 XXXX XXXX (Construction Manual For Final) Rev 00Document107 pages1033 H000 A11000 019 XXXX XXXX (Construction Manual For Final) Rev 00vhpatel67No ratings yet

- IATG 02.20 symbolsDocument3 pagesIATG 02.20 symbolsturamyuwiteka samuelNo ratings yet

- The Nature of MaterialsDocument11 pagesThe Nature of MaterialscdymlkNo ratings yet

- Sm-Etabs GuideDocument5 pagesSm-Etabs GuidetaroNo ratings yet

- The Effects of Abrasives On Electrical Submersible Pumps: Brown L. WilsonDocument5 pagesThe Effects of Abrasives On Electrical Submersible Pumps: Brown L. WilsonAnonymous VNu3ODGavNo ratings yet

- Vikings-Halar Coated Deluge ValveDocument12 pagesVikings-Halar Coated Deluge ValveHenry WuNo ratings yet

- Stockists of in Vadodara, A537 CL. 1 Boiler Plate, ASME SA537 Class 1 Plate, ASTM A537 Class 1 Pressure Vessel Plates Suppliers in GujaratDocument5 pagesStockists of in Vadodara, A537 CL. 1 Boiler Plate, ASME SA537 Class 1 Plate, ASTM A537 Class 1 Pressure Vessel Plates Suppliers in GujaratRaymundo Maldonado AlvarezNo ratings yet

- Prestressed Concrete AdvantagesDocument18 pagesPrestressed Concrete AdvantagesLarete PaoloNo ratings yet

- Fabrication and Processing of CeramicsDocument14 pagesFabrication and Processing of CeramicsMinJing ParkNo ratings yet

- Numerical Simulation of A Deep Excavation Near A Shield TunnelDocument9 pagesNumerical Simulation of A Deep Excavation Near A Shield TunnelEfi GusfianaNo ratings yet

- Rupture DiscDocument2 pagesRupture Discbigs1303No ratings yet

- F7az Em12kDocument1 pageF7az Em12kKara WhiteNo ratings yet

- iRSVP 3100 Data Sheet.Document2 pagesiRSVP 3100 Data Sheet.Gỗ MộcNo ratings yet

- Thermomechanical Treatment CorrosionDocument8 pagesThermomechanical Treatment CorrosionbharatNo ratings yet

- (0000+) Comparison of Static Pushover and Dynamic Analyses Using RC BuildingDocument11 pages(0000+) Comparison of Static Pushover and Dynamic Analyses Using RC BuildingmgdarioNo ratings yet

- Chloorrubber HB Coating (EN)Document2 pagesChloorrubber HB Coating (EN)Tomislav BrezicNo ratings yet

- Heat and Thermodynamics: This Chapter CoversDocument10 pagesHeat and Thermodynamics: This Chapter CoversLaxankNo ratings yet

- Practice problems-STEELDocument14 pagesPractice problems-STEELreanNo ratings yet

- Fuselage DesignDocument4 pagesFuselage DesignIndra FurwitaNo ratings yet

- Reality Lighting 2022 灯饰目录Document277 pagesReality Lighting 2022 灯饰目录qq1691492197No ratings yet

- TDS Tubings and Fittings-GlandsDocument2 pagesTDS Tubings and Fittings-GlandstetioNo ratings yet

- Revised Malaysian Code of Timber StructuresDocument6 pagesRevised Malaysian Code of Timber Structuresmcwong_98No ratings yet

- Rolling ProcessDocument17 pagesRolling ProcessRavichandran GNo ratings yet

- X4029960-301 - Bus Riser+UTX - R01Document15 pagesX4029960-301 - Bus Riser+UTX - R01MUH ILHAM MARZUKINo ratings yet

- Table 5-4 Quantity of Lumber For Scaffolding and StagingDocument1 pageTable 5-4 Quantity of Lumber For Scaffolding and Stagingmark dominicNo ratings yet

- Zetkama Fig. 234 SpecsDocument8 pagesZetkama Fig. 234 SpecsAntonio VelardeNo ratings yet