Professional Documents

Culture Documents

(Issued 1 Mar. 1974) C R D - C 6 - 7 4 Method of Test For Remolding Effort of Freshly Mixed Concrete C6

Uploaded by

kmsiddheshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Issued 1 Mar. 1974) C R D - C 6 - 7 4 Method of Test For Remolding Effort of Freshly Mixed Concrete C6

Uploaded by

kmsiddheshCopyright:

Available Formats

(Issued 1 Mar. 1974) CRD-C 6-74 METHOD OF TEST FOR REMOLDING EFFORT OF FRESHLY MIXED CONCRETE 1. Scope 1.

1 This method of test covers a procedure to be used in the laboratory for determining the mechanical effort required to remold samples of freshly mixed concrete from the molded form of a frustum of a cone to a cylindrical disk. The apparatus described is for use with concrete samples containing coarse aggregate of not over 1-1/2 in. (37.5 mm) nominal maximum size, or from which larger aggregate has been removed by wet-screening. 2. Apparatus 2.1 Remolding Apparatus. - The remolding apparatus shall consist of a cylindrical met al container 12 in. (305 mm) in diameter and 8 in. (203 mm) high, and an inner ring with a three-arm assembly. The assembled apparatus is shown in Fig. 1. The apparatus shall be made of the materials and to the dimensions shown in Fig. 2.

C 6

2.2 Flow Table. - The flow table shall conform to the design shown in Fig. 3 and shall be mounted on and bolted to a concrete base having a height of 15 to 20 in. (or 380 to 510 mm) and weighing not less than 300 lb (136 kg). 3. Sample 3.1 The sample shall be taken in accordance with the requirements of CRD-C 4. When more than 10 percent of the coarse aggregate is retained on a 1-1/2-in. (37.5-mm) sieve, the sample shall be wet-screened through a 1-1/2-in. (37.5-mm) sieve and the concrete passing through the sieve shall be used to mold the test specimen. 4. Procedure 4.1 The container shall be clean and damp and shall be clamped firmly to the center of the flow table. The inner ring shall be adjusted to give the appropriate clearance based on

Fig. 1.

Remolding apparatus assembled and mounted on flow table 1

(Issued 1 Mar. 1974) 2 METHOD OF TEST FOR REMOLDING OF CONCRETE (C 6-74)

(Issued 1 Mar. 1974) METHOD OF TEST FOR REMOLDING OF CONCRETE (C 6-74)

C 6

Plunger

Cam

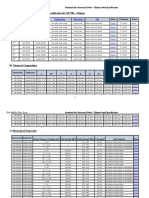

Metric Equivalents in. mm in. mm in. mm in. mm 1/32 0.8 5/16 7.9 1 25.4 3-5/8 92.1 1/16 1.6 25/64 9.9 1-7/16 36.5 7-1/4 184.2

Fig. 3.

5/64 1.9 15/32 11.9 1-9/16 39.7 12 305

1/8 3.2 1/2 12.7 2 50.8 17 432

5/32 3.9 35/64 13.9 2-3/8 60.3 30 762

15/64 5.9 5/8 15.9 3-3/8 85.7

1/4 6.4 3/4 19.1 3-1/2 88.9

Flow table apparatus

(Issued 1 Mar. 1974) 4 METHOD OF TEST FOR REMOLDING OF CONCRETE (C 6-74) 4.3 The slump mold shall be filled and rodded as required by CRD-C 5. The 10-in. (254-mm) outer ring shall be removed, the clamp released, and the slump cone shall be removedusing the procedure described in CRD-C 5, with a minimum of disturbance to the The slump shall then be concrete. measured. 4.4 The rider guide shall then be placed in position and the rider lowered gently on the concrete. The table shall then be raised and dropped 1/2 in. (12.7 mm) at the rate of one drop per seconduntil the concrete has been remolded from a truncated cone into a cylindrical disk which will be the case when the 0 reading of the rider rod descends to the upper surface of the rider guide. 5. Remolding Effort 5.1 The remolding effort (R.E.) shall be reported in terms of the number of drops required to remold.

the nominal maximum size of coarse aggregate in the sample as indicated in the following tabulation: Inner Ring Clearance in. (mm) 2-1/2 (63.5) 2-3/4 (69.8) 3 (76.2) Nominal Maximum Size of Coarse Aggregate in. (mm) 3/8 (9.5) 3/4 (19.0) 1-1/2 (38.1)

4.2 The slump cone shall then be placed wit hi n the inner ring and clamped tightly. It is-helpful if a funnel is used to prevent spilling of the concrete while the mold is being filled; and a 10-in. (254-mm) circular, flat, galvanized iron disk with a 4-1/2-in. (114-mm) diameter hole in the center is placed around the slump cone and over the ring clamp to prevent spilling of concrete into the remolding container outside of the cone during the strike off.

You might also like

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- ASTM D 560-96 Standard Test Methods For Freezing and Thawing Compacted Soil-Cement MixturesDocument6 pagesASTM D 560-96 Standard Test Methods For Freezing and Thawing Compacted Soil-Cement MixturesPablo Antonio Valcárcel Vargas100% (1)

- C 1610 - C1610M-06 STM For Static Segregation of Self-Consolidating Concrete Using Column Technique PDFDocument4 pagesC 1610 - C1610M-06 STM For Static Segregation of Self-Consolidating Concrete Using Column Technique PDFpatriciovernal67% (3)

- Astm C87Document3 pagesAstm C87avrajan100% (2)

- Astm C 348Document6 pagesAstm C 348husse_15_700884849100% (1)

- Astm C143Document4 pagesAstm C143Audrey Schwartz100% (2)

- Master Drawing List For GE - All Ge DrawingsDocument7 pagesMaster Drawing List For GE - All Ge DrawingsSulaiman JafferyNo ratings yet

- Method of Testing Remolding Effort of Fresh ConcreteDocument4 pagesMethod of Testing Remolding Effort of Fresh ConcreteSiddhesh Kamat MhamaiNo ratings yet

- ASTM D 2844 - 01 Resistance R-Value and Expansion Pressure of Compacted SoilsDocument8 pagesASTM D 2844 - 01 Resistance R-Value and Expansion Pressure of Compacted Soilsalin2005No ratings yet

- Portland (W/C 0.485) 242: (Air-Entraining Portland (W/C 0.460) 230 Non-Portland (As Required For Flow of 110) )Document3 pagesPortland (W/C 0.485) 242: (Air-Entraining Portland (W/C 0.460) 230 Non-Portland (As Required For Flow of 110) )Anuradha RumeshNo ratings yet

- T 99-18 Standard Method of Test For Moisture-Density Relations of Soils Using A 2.5-kg (5.5-lb) Rammer and A 305-mm (12-In.) DropDocument14 pagesT 99-18 Standard Method of Test For Moisture-Density Relations of Soils Using A 2.5-kg (5.5-lb) Rammer and A 305-mm (12-In.) DropMelissa SammyNo ratings yet

- Asphalt Sampling and Testing MethodsDocument125 pagesAsphalt Sampling and Testing MethodsWaqas SadiqNo ratings yet

- 04 MillingDocument21 pages04 MillingMKPashaPasha100% (1)

- To Determine Compressive Strength of CementDocument5 pagesTo Determine Compressive Strength of CementAnish OhriNo ratings yet

- ASTM D 559-96 Standard Test Method For Wetting and Drying Compacted Soil-Cement MixturesDocument6 pagesASTM D 559-96 Standard Test Method For Wetting and Drying Compacted Soil-Cement MixturesPablo Antonio Valcárcel Vargas50% (2)

- D 1632 - 96Document6 pagesD 1632 - 96realchicNo ratings yet

- Making and Curing Concrete BeamsDocument5 pagesMaking and Curing Concrete BeamsjjaavenidoNo ratings yet

- C943Document4 pagesC943Jorge Luis Arevalo Lopez100% (1)

- Crushed Aggregate Base Course SpecificationsDocument6 pagesCrushed Aggregate Base Course SpecificationsAlejandro VelandiaNo ratings yet

- ASTM D 1632-96 Standard Practice For Making and Curing Soil-Cement Compression and Flexure Test Specimens in The LaboratoryDocument6 pagesASTM D 1632-96 Standard Practice For Making and Curing Soil-Cement Compression and Flexure Test Specimens in The LaboratoryPablo Antonio Valcárcel Vargas100% (1)

- Abrasion Resistance C944Document4 pagesAbrasion Resistance C944takiasNo ratings yet

- D558Document6 pagesD558jimmy AndresNo ratings yet

- 31) Marshal Mix DesignDocument6 pages31) Marshal Mix DesignPn EkanayakaNo ratings yet

- Vebe ApparatusDocument4 pagesVebe Apparatusaduqueg284No ratings yet

- CBR Test Method for Soil StrengthDocument11 pagesCBR Test Method for Soil StrengthMuhammad Iqbal100% (4)

- ASTM D 558-96 Standard Method For Misture-Density Relations of Soil-Cement MixturesDocument5 pagesASTM D 558-96 Standard Method For Misture-Density Relations of Soil-Cement MixturesPablo Antonio Valcárcel Vargas50% (2)

- 3495 Part 1 Bricks PDFDocument10 pages3495 Part 1 Bricks PDFVb SeriesNo ratings yet

- Exp 9Document10 pagesExp 9sju65No ratings yet

- Astm C 185Document3 pagesAstm C 185cristian_agpNo ratings yet

- C1610C1610MDocument4 pagesC1610C1610MJorge Luis Arevalo LopezNo ratings yet

- CMU CE Program SIM Guide: Testing Materials Lab Activities 4-6Document10 pagesCMU CE Program SIM Guide: Testing Materials Lab Activities 4-6REX IAN BONGALESNo ratings yet

- 03 01 DOCU Concrete ManualDocument209 pages03 01 DOCU Concrete ManualJeronimo FatimaNo ratings yet

- Argillaceous Swellingxocks - Methods For Laboratory TestingDocument16 pagesArgillaceous Swellingxocks - Methods For Laboratory Testingvenkatraman20No ratings yet

- C 143 - C 143M - 03 Slump TestDocument4 pagesC 143 - C 143M - 03 Slump TestHaris Alam100% (1)

- Reconfirmation Notice: AS 1012.3.2-1998 (Reconfirmed) 2014-10-24Document9 pagesReconfirmation Notice: AS 1012.3.2-1998 (Reconfirmed) 2014-10-24heyh jdjNo ratings yet

- Astm D1558Document3 pagesAstm D1558johan lopez100% (1)

- T 106Document14 pagesT 106ploskonka84No ratings yet

- Astm C1688-08Document3 pagesAstm C1688-08Sergio Vidal ArcosNo ratings yet

- C882Document4 pagesC882Jorge Luis Arevalo LopezNo ratings yet

- BS 812-Part 113-90Document10 pagesBS 812-Part 113-90anish_am2005No ratings yet

- Standard Test Method For Slump Flow of SCCDocument6 pagesStandard Test Method For Slump Flow of SCCPris Twins TobingNo ratings yet

- Compressive Strength of Cylindrical Concrete Specimen Using Unbonded Caps ASTM C-1231Document3 pagesCompressive Strength of Cylindrical Concrete Specimen Using Unbonded Caps ASTM C-1231Ren Salazar100% (1)

- The Determination of In-Place Stiffness by The Dynamic Cone Penetrometer (DCP)Document7 pagesThe Determination of In-Place Stiffness by The Dynamic Cone Penetrometer (DCP)bluemoon1172No ratings yet

- Aashto T 87-1986 R2004Document4 pagesAashto T 87-1986 R2004Nikolay Drumev0% (1)

- D 427 - 98 - Rdqyny1sruqDocument5 pagesD 427 - 98 - Rdqyny1sruqgrats_singcoNo ratings yet

- Methods of Physical Tests FOR Hydrauliccement: Indian StandardDocument8 pagesMethods of Physical Tests FOR Hydrauliccement: Indian StandardAshish KumarNo ratings yet

- AST 05:2000 Sample PreparationDocument7 pagesAST 05:2000 Sample Preparationतिप्लोकाची तिरुनचिपल्ली केरकेट्टाNo ratings yet

- CRD c260 PDFDocument8 pagesCRD c260 PDFJersey Mae PerlasNo ratings yet

- CRD c260 PDFDocument8 pagesCRD c260 PDFJersey Mae PerlasNo ratings yet

- Prompting Science and Engineering Students in Practical TrigonometryFrom EverandPrompting Science and Engineering Students in Practical TrigonometryNo ratings yet

- Civil Engineering Structures According to the Eurocodes: Inspection and MaintenanceFrom EverandCivil Engineering Structures According to the Eurocodes: Inspection and MaintenanceNo ratings yet

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIFrom EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IITatsuki OhjiNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- The Fabrication of Materials: Materials TechnologyFrom EverandThe Fabrication of Materials: Materials TechnologyRating: 5 out of 5 stars5/5 (1)

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- P055azr 05P00 3059 01Document1 pageP055azr 05P00 3059 01Deshwa SaravananNo ratings yet

- King Saud University Mass Transfer ExamDocument7 pagesKing Saud University Mass Transfer ExamAnnisa RahmaditaNo ratings yet

- Atlas Copco LSV-LSF UsDocument4 pagesAtlas Copco LSV-LSF Usovi_julianNo ratings yet

- Standard Specification For GB 700Document12 pagesStandard Specification For GB 700Ma'arif Nuzul AddibNo ratings yet

- Method of Scaffolding WorksDocument25 pagesMethod of Scaffolding WorksFarrukh Javed100% (1)

- High Efficiency Compressed Air Filtration & Water SeparationDocument8 pagesHigh Efficiency Compressed Air Filtration & Water SeparationMelvic BinosNo ratings yet

- GLXXMobil Vacuoline 100 SeriesDocument3 pagesGLXXMobil Vacuoline 100 SeriesAdrian RoperoNo ratings yet

- Poly (Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent (DWV) Pipe and Fittings Having Post-Industrial Recycle ContentDocument7 pagesPoly (Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent (DWV) Pipe and Fittings Having Post-Industrial Recycle Contentastewayb_964354182No ratings yet

- Cost Estimate For 2 - Storey Residential 10.13.22Document17 pagesCost Estimate For 2 - Storey Residential 10.13.22Regie JoaquinNo ratings yet

- Experimental Investigation of Resistance Spot Welding of Duplex Stainless SteelDocument5 pagesExperimental Investigation of Resistance Spot Welding of Duplex Stainless SteelM.SoundarrajanNo ratings yet

- API RP505 Classfication SelectedDocument2 pagesAPI RP505 Classfication SelectedSing Yew LamNo ratings yet

- Cable Impedance Calculations - Open ElectricalDocument4 pagesCable Impedance Calculations - Open Electricaludayakumart100% (1)

- NETZSCH Progressing Cavity Pumps 04 16aDocument28 pagesNETZSCH Progressing Cavity Pumps 04 16aCarlos TomeyNo ratings yet

- Fabrication Failures and SolutionsDocument3 pagesFabrication Failures and SolutionsSyed Muhammad Shukri Al-IdrusNo ratings yet

- Module 3: Cutting Tool Materials and FluidsDocument88 pagesModule 3: Cutting Tool Materials and FluidssushilNo ratings yet

- Iron Cast Iron Wrought IronDocument18 pagesIron Cast Iron Wrought IronvelavansuNo ratings yet

- Introduction To Wastewater ManagementDocument18 pagesIntroduction To Wastewater ManagementMuhammad IqmalNo ratings yet

- Imsbc CodeDocument2 pagesImsbc CodeBBluningningNo ratings yet

- Comparison Between Vacuum and SF6 Circuit BreakerDocument12 pagesComparison Between Vacuum and SF6 Circuit BreakerecsanyiNo ratings yet

- Coutnry Wise All Commodities 2023 by IndiaDocument9 pagesCoutnry Wise All Commodities 2023 by IndiaindienkhanNo ratings yet

- Site Plan 02 Puerto Baru Rev.04Document1 pageSite Plan 02 Puerto Baru Rev.04TaihimyNo ratings yet

- Science Exam NewDocument3 pagesScience Exam NewShahani BarredoNo ratings yet

- Ingersoll Rand Dryer O&M Manual 80442833-EnDocument48 pagesIngersoll Rand Dryer O&M Manual 80442833-EnBill BrighamNo ratings yet

- Aqua Culture Brochure - Fusi TechDocument2 pagesAqua Culture Brochure - Fusi Techsaradhi sravan kumarNo ratings yet

- Modification of LV Panels at Dubai International AirportDocument14 pagesModification of LV Panels at Dubai International AirportPushpakumara KarunadasaNo ratings yet

- DC 163Document2 pagesDC 163manox007No ratings yet

- Harduaganj Thermal Power Plant by Geetesh SharmaDocument66 pagesHarduaganj Thermal Power Plant by Geetesh Sharmageeteshaccurate100% (1)

- Advantages and Disadvantages of Prestressed Concrete ConstructionDocument6 pagesAdvantages and Disadvantages of Prestressed Concrete Constructionpilipinas19No ratings yet

- Latching Assignment PLC Ladder LogicDocument4 pagesLatching Assignment PLC Ladder LogicsalonyNo ratings yet