Professional Documents

Culture Documents

Sspc-Pa9 1311669483

Uploaded by

mrreachOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sspc-Pa9 1311669483

Uploaded by

mrreachCopyright:

Available Formats

SSPC-PA 9 February 1, 2008

SSPC: The Society for Protective Coatings

Measurement of Dry Coating Thickness on Cementitious Substrates Using Ultrasonic Gages

PainT aPPLiCaTiOn SPECiFiCaTiOn nO. 9

1. Scope

1.1 This standard describes procedures to measure the thickness of dry, homogeneous coatings applied on cementitious surfaces using commercially available ultrasonic coating thickness gages. These procedures are intended to supplement manufacturers operating instructions for the manual operation of the gages and are not intended to replace them. 1.2 The procedures for calibration, adjustment, and general use of using ultrasonic coating thickness gages are described in ASTM D 6132 and the gage manufacturers instructions. This document focuses on the correct method for taking measurements. 1.3 Current ultrasound technology may not be capable of accurately measuring the DFT of some coatings (see Notes 8.1 and 8.2).

refers to a coating of uniform composition throughout that does not contain large, solid particles such as sand. 2.3.5 Calibration: The controlled and documented process of measuring traceable calibration standards and verifying that the results are within the stated accuracy of the gage. Calibrations are typically performed by the gage manufacturer or by a qualified laboratory in a controlled environment using a documented process. The standards used in the calibration are such that the combined uncertainties of the resultant measurement are less than the stated accuracy of the gage. 2.3.6 Verification: An accuracy check performed by the user using known reference standards. 2.3.7 adjustment: The act of aligning the gages thickness readings to match those of a known sample in order to improve the accuracy of the gage on a specific surface or in a specific portion of its measurement range.

2. Description

2.1 The procedures described in this standard include criteria for determining the number of measurements, location of measurements, and whether the dry film thickness (DFT) of the coating conforms to project specifications. 2.2 Description of Gages: Ultrasonic gages use a transducer in the probe to send pulses into the coating and measure the time taken by that pulse to return to the probe tip to calculate coating thickness (see Note 8.3). 2.3 DEFiniTiOnS 2.3.1 Gage Reading: A single reading at one point. 2.3.2 Spot Measurement: The average of at least three gage readings made within a 15 cm (6 inch) diameter circle. 2.3.3 Structure: A unit composed of one or more connected concrete members. It is possible for a single concrete shape (beam, pipe, channel, etc.) to be considered a structure if it is painted in a shop. 2.3.4 Homogeneous: of the same or similar in composition or structure. In this standard, the term homogeneous coating

3. References

3.1 The latest issue, revision, or amendment of the referenced standards in effect on the date of invitation to bid shall govern, unless otherwise specified. Standards marked with an asterisk (*) are referenced only in the Notes, which are not requirements of this standard. 3.2 If there is a conflict between the requirements of any of the cited referenced standards and this standard, the requirements of this standard shall prevail. 3.3 aSTM inTERnaTiOnaL STanDaRDS1 * D 4138 Standard Test Methods for Measurement of Dry Film Thickness of Protective Coating Systems by Destructive, Cross-Sectioning Means Standard Test Method for Nondestructive Measurement of Dry Film Thickness of Applied Organic Coatings Using an Ultrasonic Gage

D 6132

1 ASTM International, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959. Standards are available online from http:// www.astm.org.

SSPC-PA 9 February 1, 2008 5.3 nUMBER OF MEaSUREMEnTS: Make five (5) separate spot measurements (average of the gage readings, see Section 5.2) spaced arbitrarily over each 10 m2 (108 ft2) area to be measured unless otherwise specified. The five spot measurements shall be made for each 10 m2 (108 ft2) of area as follows: 5.3.1 For structures not exceeding 30 m2 (323 ft2) in area, each 10 m2 (108 ft2) (or increment thereof) area shall be measured. 5.3.2 For structures not exceeding 100 m2 (1,076 ft2) in area, three 10 m2 (108 ft2) (or increment thereof) areas shall be arbitrarily selected by the inspector and measured. 5.3.3 For structures exceeding 100 m2 (1,076 ft2) in area, the first 100 m2 (1,076 ft2) shall be measured as stated in Section 5.3.2 and for each additional 100 m2 (1,076 ft2) of area (or increment thereof), one 10 m2 (108 ft2) area shall be arbitrarily selected by the inspector and measured. 5.3.4 If the dry film thickness for any 10 m2 (108 ft2) area or increment thereof (see Sections 5.3.1, 5.3.2 and 5.3.3) is not in compliance with the requirements of Section 6, additional measurements shall be made to isolate the non-conforming area, and each 10 m2 (108 ft2) area painted during that work shift shall be measured. 5.4 SPECiFYinG THiCKnESS: Both a maximum and a minimum thickness are customarily specified for the coating. If a maximum thickness value is not specified, (as in Restriction Level 4 of Table 1) the specified thickness shall be the minimum and there shall be no maximum.

* D 7091

Standard Practice for Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied to Ferrous Metals and Nonmagnetic, Nonconductive Coatings Applied to Non-Ferrous Metals * SSPC-Pa 2 Measurement of Dry Coating Thickness with Magnetic Gages

4. Gage Requirements

The ultrasonic gage shall be capable of measuring the thickness of a coating over a cementitious substrate. To qualify under this standard, the gage shall have a minimum accuracy within 10%. All gages shall be calibrated and adjusted following the manufacturers instructions and be in accordance with ASTM D 6132.

5. Measurement Procedures

5.1 Verify that the gage will provide accurate readings over the coating to be measured, using the procedure in Note 8.2. 5.2 SPOT MEaSUREMEnT: Repeated gage readings, even at points close together, usually differ due to surface irregularities of the coating and the substrate (see Notes 8.4 and 8.5). Therefore, a minimum of three (3) gage readings shall be made for each spot measurement of the coating. For each new gage reading, move the probe to a new location within the 15 cm (6 inch) diameter circle defining the spot. Each gage reading shall be at least 5 cm (2 inches) from the other gage readings. Discard any single unusually high or low gage reading that cannot be repeated consistently. Take the average of the acceptable gage readings as the spot measurement (see Note 8.6).

Table 1 Restriction Levels Coating Thickness on Concrete Thickness Spot Reading As specified As specified As specified 125% of maximum 75% of minimum 125% of maximum 75% of minimum Unrestricted area Reading As specified As specified As specified As specified As specified As specified As specified Unrestricted

Level 1 Minimum Maximum Level 2 Minimum Maximum Level 3 Minimum Maximum Level 4 Minimum Maximum

SSPC-PA 9 February 1, 2008

6. COnFORManCE TO SPECiFiED THiCKnESS

6.1 Thickness Restriction Levels: Table 1 provides four thickness restriction levels. Level 1 is the most restrictive and does not allow for any deviation of spot or area measurements from the specified minimum and maximum thickness, while Level 4 is the least restrictive. The owner shall specify the dry film thickness restriction level for a given project. There is no restriction on individual gauge readings provided that the spot readings and the average for the area conform to the requirements given in Table 1. 6.2 Minimum Thickness: The average of the spot measurements for each 10 m2 (108 ft2) area shall not be less than the specified minimum thickness in Table 1. No single spot measurement in any area shall be less than the specified minimum thickness in Table 1. If the average of the spot measurements for a given area meets or exceeds the specified minimum thickness, but one or more spot measurements is less than the specified minimum thickness, additional measurements shall be made to define the non-conforming area (see Appendix 1 and Note 8.7). 6.3 Maximum Thickness: The average of the spot measurements for each 10 m2 (108 ft2) area shall not be more than the specified maximum thickness stated in Table 1. Although no single spot measurement in any 10 m2 (108 ft2) area shall be more than 125% of the specified maximum thickness stated in Table 1, it is permissible for any single gage reading to over-run by a greater amount. If the average of the spot measurements for a given 10 m2 (108 ft2) area meets or falls below the specified maximum thickness, but one or more spot measurements is more than the specified maximum thickness, additional measurements shall be made as specified to define the nonconforming area (see Appendix 1).

8. notes

Notes are not requirements of this standard. 8.1 PROBLEM COaTinGS: Ultrasonic gages are not recommended for certain coatings, such as mortars, that are heavily filled with aggregate. Similarly, an acrylic floor coating may contain flakes that were broadcast across the wet coating, creating a non-homogeneous medium whose thickness is difficult to determine accurately with ultrasonic gages. If thickness readings are suspect, they can be verified using destructive means per ASTM D 4138 (see Note 8.8). 8.2 DETERMininG COaTinG SUiTaBiLiTY FOR DFT MEaSUREMEnT USinG ULTRaSOniC TECHnOLOGY: To determine if it is possible to accurately measure coatings described in Note 8.1 using an ultrasonic gage, apply the coating to a smooth steel panel. Verify the measurement accuracy of an SSPC-PA 2, Type 2 electronic gage for use on ferrous substrates per manufacturers instructions. Measure the coating DFT on the steel test panel using the Type 2 electronic gage, and record the results. The procedures for measurement using magnetic gages are described in ASTM D 7091. Next, verify the measurement accuracy of the ultrasonic gage using the manufacturers instructions, and measure the DFT on the same test panel. Compare the results of the Type 2 electronic gage with readings taken by the ultrasonic gage. The readings should be within the combined tolerances of both instruments. If repeatable readings fall outside this tolerance, follow the manufacturers instructions to perform an adjustment to the ultrasonic gage. If repeatable measurements still cannot be obtained, alternative methods of determining DFT should be used (see Note 8.8). 8.3 MEaSUREMEnT RanGE: Ultrasonic thickness gages can measure polymer coating thicknesses from approximately 8 m to 15 mm (0.3 to 600 mils). The upper limit depends on the acoustical properties of the material being measured and the transducer in the probe. 8.4 REPEaTaBiLiTY: Ultrasonic gages are sensitive to small irregularities of the coating surface or of the concrete surface directly below the probe center. Repeated gage readings on a rough surface, even at points very close together, frequently differ considerably, particularly for thin films over a rough surface with a high profile. 8.5 VaRiaTiOn in THiCKnESS (75% of MiniMUM): In any measurement there is a level of uncertainty. Two individuals using the same ultrasonic gage will not necessarily record the exact same number for a given spot measurement using the same 15 cm (6 inch) diameter circle. To allow for this variation, an individual spot measurement is permitted to be below the specified minimum thickness as long as other spots in the 10 m2 (108 ft2) area are high enough to make the average thickness meet or exceed the specified minimum thickness.

7. Disclaimer

7.1 While every precaution is taken to ensure that all information furnished in SSPC standards is as accurate, complete and useful as possible, SSPC cannot assume responsibility nor incur any obligation resulting from the use of any materials, coatings or methods specified therein, or of the standard itself. 7.2 This standard does not attempt to address problems concerning safety associated with its use. The user of this standard, as well as the user of all products or practices described herein, is responsible for instituting appropriate health and safety practices and for ensuring compliance with all governmental regulations.

SSPC-PA 9 February 1, 2008 8.6 COUPLanT: It is recommended that the couplant be removed from the coating after making a spot measurement, especially if an additional coat is to be applied. 8.7 CORRECTinG LOW THiCKnESS: Non-conforming areas should be corrected as specified. 8.8 DESTRUCTiVE TESTinG: A paint inspection gage (sometimes called a Tooke or PIG gage) can give DFT measurements, but it cuts through the coating, so each measurement site must be repaired. The procedures for measurement using destructive gages are described in ASTM D 4138. The job specification should stipulate the number and location of areas to be tested by destructive means.

or equal to 19 mils. Because the owner required Level 4, no maximum DFT was specified. Considering Metric Measurements: The average, 660 m, exceeds the specified minimum of 640 m and thus satisfies the specification. Next, determine if the lowest spot measurement, 540 m, is within 75% of the specified minimum thickness. Seventy-five percent of 640 m is 480 m (0.75 x 640 = 480). Although 540 m is below the specified minimum, it is still within 75% of it, so the specification is satisfied. There are individual gage readings of 380 m at spot 5 and 460 m at spot 3, both of which are clearly less than 480 m. This is allowed because only the average of the three readings (i.e., the spot measurement) must be greater than or equal to 480 m. Because the owner required Level 4, no maximum DFT was specified. Since the structure used in this example is about 30 m2 (322 ft2), the procedure used to measure the film thickness of part A must be applied to both part B and part C. The measured thickness of part B must exceed the 640 m (25 mils) specified minimum, as must the thickness of part C. To monitor the thickness of this entire 30 m2 (322 ft2) structure, at least 45 individual gage readings must be taken, from which 15 spot measurements are calculated. The five spot measurements from each 10 m2 (108 ft2) part of the structure are used to calculate the thickness of that part.

aPPEnDiX 1 - numerical Example of average Thickness Measurement

Appendix 1 does not form a mandatory part of this standard. The following numerical example is presented as an illustration of Section 5. Suppose this structure is 30 m2 (323 ft2) in area. The owner requires Restriction Level 4, 75% minimum, no maximum. Mentally divide the surface into three equal parts, each being about 10 m2 (108 ft2). Part A - 10 m2 (108 ft2) Part B - 10 m2 (108 ft2) Part C - 10 m2 (108 ft2) First, measure the coating thickness on Part A. This involves at least 15 readings of the thickness gage (see Figure A1). Assume the specification requires 640 m (25 mils) minimum thickness. The average thickness for area A is then the average of the five spot measurements made on area A, namely 660 m (26 mils). Spot 1 640 m 25 mils Spot 2 770 30 Spot 3 540 21 Spot 4 770 30 Spot 5 580 23 Avg. 660 m 26 mils Considering the U.S. Customary Measurements: The average, 26 mils, exceeds the specified minimum of 25 mils and thus satisfies the specification. Next, determine if the lowest spot measurement, 21 mils, is within 75% of the specified minimum thickness. Seventy-five percent of 25 mils is 19 mils (0.75 x 25 = 19). Although 21 mils is below the specified minimum, it is still within 75 percent of it, so the specification is satisfied. There are individual gage readings of 15 mils at spot 5 and 18 mils at spot 3, both of which are clearly less than 19 mils. This is allowed because only the average of the three readings (i.e. the spot measurement) must be greater than

SSPC-PA 9 February 1, 2008

Figure a1 Part a of Structure (area approximately 10 m2 [~100 ft2])

GAGE READINGS

Spot 1

26 mils 30 20 Avg. 25 mils

Spot 2

36 mils 26 27 Avg. 30 mils

~3 m (10 ft)

15 cm (6 inches) inches

Spot 3

18 mils 22 23 Avg. 21 mils

Part B

Spot 4

26 mils 32 31 Avg. 30 mils

Spot 5

15 mils 28 62 Avg. 23 mils

~3 m (10 ft)

You might also like

- DFT StandardsDocument42 pagesDFT StandardsDandy Adrianto100% (2)

- Astm D1186-01Document5 pagesAstm D1186-01Milenita Paez AcuñaNo ratings yet

- Astm D 5064Document2 pagesAstm D 5064Alejandro 20No ratings yet

- SSPC AB1 Standard For Mineral and Slag AbrasivesDocument5 pagesSSPC AB1 Standard For Mineral and Slag Abrasiveslonglong3003100% (2)

- SSPC Pa 2 2004 PDFDocument11 pagesSSPC Pa 2 2004 PDFrams789100% (1)

- Sspc-Ab 1Document7 pagesSspc-Ab 1Cesar HuertaNo ratings yet

- SSPC Pa 7 PDFDocument10 pagesSSPC Pa 7 PDFkishorekumar.animuNo ratings yet

- Sigmacover 410Document4 pagesSigmacover 410gstketutNo ratings yet

- Paint Application Standard No. 2Document13 pagesPaint Application Standard No. 2ceroride100% (2)

- ASTM D3276 - 07 Standard Guide For Painting Inspectors PDFDocument14 pagesASTM D3276 - 07 Standard Guide For Painting Inspectors PDFFCT80% (5)

- SSPC Paint 20Document6 pagesSSPC Paint 20Juan Carlos Contreras CherresNo ratings yet

- Sspc-Ab 2Document3 pagesSspc-Ab 2HafidzManafNo ratings yet

- SSPC Ab 4Document3 pagesSSPC Ab 4mithileshNo ratings yet

- ASTM 4228 - Calificacion Aplicadores de Recubrimientos PDFDocument3 pagesASTM 4228 - Calificacion Aplicadores de Recubrimientos PDFEl_memito100% (1)

- SSPC SP11Document6 pagesSSPC SP11บวรลักษณ์ จ้อยโหมด50% (2)

- SSPC Guide 12Document6 pagesSSPC Guide 12kishorekumar.animuNo ratings yet

- Astm D714Document5 pagesAstm D714Boris AguilarNo ratings yet

- D 4417 21 Field Measurement of Surface Profile of Blast Cleaned Steel Apiasme Practice TestDocument7 pagesD 4417 21 Field Measurement of Surface Profile of Blast Cleaned Steel Apiasme Practice TestEdgar GuerraNo ratings yet

- SSPC Guide11 PDFDocument5 pagesSSPC Guide11 PDFNgô Trung NghĩaNo ratings yet

- SSPC SP3Document2 pagesSSPC SP3Jose AngelNo ratings yet

- D16 Terminology For Paint, Related Coatings, Materials, and ApplicationsDocument9 pagesD16 Terminology For Paint, Related Coatings, Materials, and ApplicationsEdwin R RuizNo ratings yet

- SSPC AB3 Standard For Ferrous Metallic AbrasiveDocument6 pagesSSPC AB3 Standard For Ferrous Metallic Abrasivelonglong3003100% (1)

- Sspc-Pa 17-2012Document7 pagesSspc-Pa 17-2012ALEXIS MARTINEZ100% (1)

- Non Convertible and Convertible PolymersDocument1 pageNon Convertible and Convertible PolymersdemitsifNo ratings yet

- How To Use SSPC StandardsDocument7 pagesHow To Use SSPC StandardsTimbo6808100% (1)

- Guide No. 12: SSPC: The Society For Protective CoatingsDocument6 pagesGuide No. 12: SSPC: The Society For Protective Coatingsanoopkumar100% (1)

- Pull Off Adhesion Testing of CoatingsDocument12 pagesPull Off Adhesion Testing of CoatingsDANIEL MOYYA100% (2)

- SSPC AB1 Standard For Mineral and Slag AbrasivesDocument5 pagesSSPC AB1 Standard For Mineral and Slag Abrasiveslonglong3003100% (1)

- ASTM D7393-07 (2012) Standard Practice For Indicating Oil in AbrasivesDocument2 pagesASTM D7393-07 (2012) Standard Practice For Indicating Oil in Abrasivesalexander zuritaNo ratings yet

- CoatingPro July2012 - Adhesion Test Methods - Making Sure The Result StickDocument4 pagesCoatingPro July2012 - Adhesion Test Methods - Making Sure The Result StickUgoRibeiro100% (1)

- Astm e 337 - 02Document24 pagesAstm e 337 - 02vlong3003100% (2)

- Sspc-Pa Guide 3 PDFDocument16 pagesSspc-Pa Guide 3 PDFvricardol100% (1)

- SSPC Ab 1Document5 pagesSSPC Ab 1anoopkumarNo ratings yet

- Iso 11126-10Document1 pageIso 11126-10Alfian Imaduddin50% (2)

- 07.3.1.2 SSPC - Ab 2 - 2015 PDFDocument3 pages07.3.1.2 SSPC - Ab 2 - 2015 PDFandaech100% (1)

- SSPC Guide 16Document13 pagesSSPC Guide 16mithileshNo ratings yet

- Astm D 6677Document2 pagesAstm D 6677Ronny Moreno100% (1)

- Astm D 4258Document2 pagesAstm D 4258anthonybarnard100% (1)

- SSPC - Guia 12Document6 pagesSSPC - Guia 12José Alvaro Herrera Ramos50% (2)

- Quality Control of Industrial Painting Operations: William D. Corbett KTA-Tator, IncDocument61 pagesQuality Control of Industrial Painting Operations: William D. Corbett KTA-Tator, IncKis GáborNo ratings yet

- Sspc-Spcom PDFDocument32 pagesSspc-Spcom PDFRoger SchvepperNo ratings yet

- SSPC Guide 27Document7 pagesSSPC Guide 27mithileshNo ratings yet

- 7127 13Document6 pages7127 13Rajib Barua100% (1)

- Sspc-Pa 7-2000 (E 2004) PDFDocument10 pagesSspc-Pa 7-2000 (E 2004) PDFAlfian ImaduddinNo ratings yet

- Astm d6677Document2 pagesAstm d6677Alvaro Iparraguirre Navarro100% (1)

- ASTM D 4285 Blotter Test PDFDocument1 pageASTM D 4285 Blotter Test PDFMurali Dharan100% (1)

- ISO 11126 (Painting)Document6 pagesISO 11126 (Painting)Azhar AhmadNo ratings yet

- 1 PDFDocument12 pages1 PDFFakrul HasanNo ratings yet

- Required Number of Measurements For Conformance To A Thickness SpecificationDocument1 pageRequired Number of Measurements For Conformance To A Thickness SpecificationjenieragavNo ratings yet

- Attachment 1 SSPC-PA2Document6 pagesAttachment 1 SSPC-PA2Tudor MoraruNo ratings yet

- SSPC-PA 2 (2004) - Measurement of DFT With Magnetic Gages PDFDocument11 pagesSSPC-PA 2 (2004) - Measurement of DFT With Magnetic Gages PDFkhuramilyas100% (1)

- SSPC Pa2Document11 pagesSSPC Pa2Nageswara Rao BavisettyNo ratings yet

- Paint Application Standard No. 2: SSPC: The Society For Protective CoatingsDocument6 pagesPaint Application Standard No. 2: SSPC: The Society For Protective CoatingsreghouacheNo ratings yet

- SSPC Pa2 02Document7 pagesSSPC Pa2 02Cristian Espinoza100% (1)

- Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied To Ferrous Metals and Nonmagnetic, Nonconductive Coatings Applied To Non-Ferrous MetalsDocument11 pagesNondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied To Ferrous Metals and Nonmagnetic, Nonconductive Coatings Applied To Non-Ferrous MetalsIvan AlanizNo ratings yet

- SSPC-PA 2 Procedure For Determining Conformance To Dry Coating Thickness RequirementsDocument11 pagesSSPC-PA 2 Procedure For Determining Conformance To Dry Coating Thickness RequirementsDavid Aliaga Sayas100% (1)

- SD 1186 PDFDocument4 pagesSD 1186 PDFgana_1783No ratings yet

- Recubrimientos - SSPC-PA 2-2012Document11 pagesRecubrimientos - SSPC-PA 2-2012ALEXIS MARTINEZNo ratings yet

- SSPC Pa2 02Document7 pagesSSPC Pa2 02Hiep TranNo ratings yet

- Guia para La Medición de Espesores SSPC - PA2Document11 pagesGuia para La Medición de Espesores SSPC - PA2robertabarreiroNo ratings yet

- Week 8: ACCG3001 Organisational Planning and Control Tutorial In-Class Exercise - Student HandoutDocument3 pagesWeek 8: ACCG3001 Organisational Planning and Control Tutorial In-Class Exercise - Student Handoutdwkwhdq dwdNo ratings yet

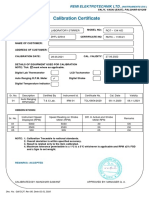

- Calibration CertificateDocument1 pageCalibration CertificateSales GoldClassNo ratings yet

- HSBC in A Nut ShellDocument190 pagesHSBC in A Nut Shelllanpham19842003No ratings yet

- STM - Welding BookDocument5 pagesSTM - Welding BookAlvin MoollenNo ratings yet

- CH 1 India Economy On The Eve of Independence QueDocument4 pagesCH 1 India Economy On The Eve of Independence QueDhruv SinghalNo ratings yet

- Environmental Auditing For Building Construction: Energy and Air Pollution Indices For Building MaterialsDocument8 pagesEnvironmental Auditing For Building Construction: Energy and Air Pollution Indices For Building MaterialsAhmad Zubair Hj YahayaNo ratings yet

- How To Control A DC Motor With An ArduinoDocument7 pagesHow To Control A DC Motor With An Arduinothatchaphan norkhamNo ratings yet

- CV Ovais MushtaqDocument4 pagesCV Ovais MushtaqiftiniaziNo ratings yet

- What Is Retrofit in Solution Manager 7.2Document17 pagesWhat Is Retrofit in Solution Manager 7.2PILLINAGARAJUNo ratings yet

- MSDS - Tuff-Krete HD - Part DDocument6 pagesMSDS - Tuff-Krete HD - Part DAl GuinitaranNo ratings yet

- Unit 2Document97 pagesUnit 2MOHAN RuttalaNo ratings yet

- Schmidt Family Sales Flyer English HighDocument6 pagesSchmidt Family Sales Flyer English HighmdeenkNo ratings yet

- Methodical Pointing For Work of Students On Practical EmploymentDocument32 pagesMethodical Pointing For Work of Students On Practical EmploymentVidhu YadavNo ratings yet

- Reflections On Free MarketDocument394 pagesReflections On Free MarketGRK MurtyNo ratings yet

- Lea 4Document36 pagesLea 4Divina DugaoNo ratings yet

- 09 WA500-3 Shop ManualDocument1,335 pages09 WA500-3 Shop ManualCristhian Gutierrez Tamayo93% (14)

- A320 TakeoffDocument17 pagesA320 Takeoffpp100% (1)

- Proceedings of SpieDocument7 pagesProceedings of SpieNintoku82No ratings yet

- Cabling and Connection System PDFDocument16 pagesCabling and Connection System PDFLyndryl ProvidoNo ratings yet

- Brand Positioning of PepsiCoDocument9 pagesBrand Positioning of PepsiCoAbhishek DhawanNo ratings yet

- Microsoft Word - Claimants Referral (Correct Dates)Document15 pagesMicrosoft Word - Claimants Referral (Correct Dates)Michael FourieNo ratings yet

- General Diesel Engine Diagnostic Guide PDFDocument3 pagesGeneral Diesel Engine Diagnostic Guide PDFan0th3r_0n3No ratings yet

- Efs151 Parts ManualDocument78 pagesEfs151 Parts ManualRafael VanegasNo ratings yet

- BYJU's July PayslipDocument2 pagesBYJU's July PayslipGopi ReddyNo ratings yet

- Final ExamSOMFinal 2016 FinalDocument11 pagesFinal ExamSOMFinal 2016 Finalkhalil alhatabNo ratings yet

- Ajp Project (1) MergedDocument22 pagesAjp Project (1) MergedRohit GhoshtekarNo ratings yet

- Innovations in Land AdministrationDocument66 pagesInnovations in Land AdministrationSanjawe KbNo ratings yet

- Year 9 - Justrice System Civil LawDocument12 pagesYear 9 - Justrice System Civil Lawapi-301001591No ratings yet

- Polytropic Process1Document4 pagesPolytropic Process1Manash SinghaNo ratings yet

- United Nations Economic and Social CouncilDocument3 pagesUnited Nations Economic and Social CouncilLuke SmithNo ratings yet