Professional Documents

Culture Documents

Advanced Aircraft Design Summary

Uploaded by

Luiz Felipe PerrellaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Advanced Aircraft Design Summary

Uploaded by

Luiz Felipe PerrellaCopyright:

Available Formats

ADVANCED AIRCRAFT DESIGN II SUMMARY

Advanced Aircraft Design II: Summary

I. I NTRODUCTION Progress in ghters: Turbojet and swept wing (1940s) Autostabilisation (1950s) Guided weapons (1950s) Leaky turbojets 1960s) Microprocessors (1970s) Fly-by-wire and articial stability (1970s) Composites (1970s) Stealth (1980s) Supermanoeuvrability (1990s) Requirements: Lethality Manoeuvrability Handling qualities Radius of action Persistence Resilience Visibility Stealth Classcation of jet ghters 1st generation (mid-1940s to mid 1950s) 2nd generation (mid-1950s to early 1960s) 3rd generation (early 1960s to circa 1970) 4th generation (1970 to mid 1990s) 4.5th generation (1990s to present) 5th generation (2005 to present) Combat aircraft types: Reconnaissance Strategic reconnaissance (U2, SR-71) Tactical reconnaissance (derivative of ghter) Ground attack Interceptors Air superiority

Fig. 1.

Drag breakdown

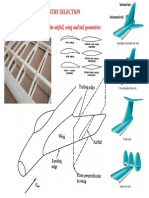

External stores have a large effect on the ight envelope (ight envelope shrinks with stores), mainly due to increased drag and possibly aeroelasic/interference effects. Airfoil design General fact: thinner wings means heavier wings. 2nd generation ghters had thin wings for high speed ight, but this caused leading edge separation at subsonic maneuvers and buffet at low angels of attack. This resulted in a bat ring platform. There was a need for thicker airfoils with good transonic characteristics. The answer was the supercritical airfoil. The good characteristics were a result of a rapid ow expansion about the leading edge and isentropic recompression through benecial wave interaction.

II. A IRFOIL AND WING PLANFORM Trailing edge vortex drag: 75% of total drag during maneuvering 50% of total drag during cruise 5-10% of total drag in low altitude, high speed ight Prole drag: friction drag (30% during cruise) form drag

Fig. 2. Supercritical airfoil

Supercritical airfoil: Increase the drag-rise Mach number for a given thickness ratio and sweep. Allow use of thicker wing for a given MD and sweep in order to improve available wing volume and either reduce wing structure weight or increase the aspect ratio. Reduce wing sweep for a given MD and thickness ratio, so improving lift and lift/drag ratio for take-off and

ADVANCED AIRCRAFT DESIGN II SUMMARY

Gust response small wing, high wing loading So what do we do? Find the smallest wing that meets requirements Opt for variable sweep

Fig. 3.

Wave interaction

landing. Conical drag: Improve off-design performance of supersonic ghters. Suppress leading-edge separation by increasing buffet CL and postponing drag break. Aspect ratio: Effect on Trailing-edge vortex drag (aka induced drag) Lift-curve slope High aspect ratio required for: Long endurance ( L/D) Long range ( M L/D) Subsonic maneuvering (up to certain AoA) Low AoA requirement at take-off and landing Drawbacks of high aspect ratio Weight penalty Supersonic drag increased Sensitive to atmospheric upsets Wing twist: To prevent tip stall To adjust spanwise loading and achieve minimum drag at a certain condition (sometimes also to adjust the pitching moment) (at high g-maneuvers aeroelastic bending causes aerodynamic twist, up to 10 deg) Wing size: Gross wing size: Large effect on drag Crucial role for sizing the aircraft (weight and thus cost) Snowball effect of wing size on airplane size What drives wing size? Field performance low wing loading desired for short elds Subsonic cruise and loiter medium wing loading desired Sustained turn rate low wing loading (high A for low CD,i ) Instantaneous turn rate low wing loading (high CL ) High supersonic dash high wing loading Subsonic SEP not directly affected by wing size Low altitude & high speed small wing, high wing loading

Wing tips: Kuchemann tip (Harrier) Good transonic characteristics Raked tip (F-15) Wing tip can be loaded higher than expected Reduced bending moments Reduced buffet Increased dutch roll dampinning Straight tip (F-16) Allows launcher rail Could improve L/D Taper ratio: Taper ratio in combination with moderate sweep: Low supersonic drag Increased spiral stability (Cl, ) through leading edge sweep Effective trailing-edge aps Cross-wind handling problems at high AoA Increased rolling moment due to sideslip, Cl, ) Less aileron control power due to swept trailing edge Reduces root bending moment and thus wing weight Higher loaded outboard sections Higher possibility of tip stall if combined with sweep: pitch-up and wing drop

Swept and delta wings Benets of wing sweep: Inventors: Adolf Busemann, Albert Betz, Hans Multhopp Velocity compnent perpendicular to the wing: V cot cos Sweep delays drag rise and reduces peak drag At subsonic speeds sweep penalises L/D Reduction of tuck-under effect Supersonic patch results in shift aft shift of aerodynamic center Result = nose down pitching moment (tuck) More gradual shift on a swept wing More gradual variation of lift coefcient across the transonic region Extension of buffet boundaries Lower overspeeds at given Mach number and CL Less strong shockwave terminating supersonic patch Postponement of separation at the foot of the shock Reduction of gust reponse (good for high speed penetration) Sweep reduces CL, For thin, low aspect ratio wings: higher CL,max

ADVANCED AIRCRAFT DESIGN II SUMMARY

Stable vortex separation induces vortex lift up to high AoA Stall might be more gradual With sweep back, wave drag becomes: Independent of span loading Linearly dependent on (t/c)2 Minimized by spreading lift over large chord Wing can stay out of Mach cone (if sweep angle is large than Mach angle)

Penalties of sweepback: Limits of theory: valid for innitely long skewed wings Flow perpendicular to isobars Root and tip effects dominant on low aspect ratio wings Result: Delay in Mcrit overpredicted In practice half of the expected amount in Mcrit is possible Lift curve slope increases, until vortex breaks down at the trailing edge Loss of leading edge suction leads to increased liftdependent drag With increasing leading edge radius the vortex will appear at higher angles of attack Structural problems Reduced effectiveness of high-lift devices Tip stalling (especially with combination of sweep and large aspect ratio) Increased rolling due to sideslip Increased drag due to lift (reduction of lift-curve slope Cl nose-high attitudes at landing raised cockpits required for visibility) Rolling moment due to side-slip is increased due to sweep. Reduction of wing controls and aps Flap leading-edge sweep dominant for its effectiveness High ap sweep angles reduce CLmax As way to counter some of the downsides of sweep is the reduce the trailing-edge sweep and make the root chord larger (additional benet here is that this strengthens the rear spar and central torsion box). So a good way to enhance supersonic maneuvering is to have a low aspect ratio, large wing. Delta wing Alexander Lippisch (1931), Avro Vulcan (1947), Dassault Mirage I (1952) Benets of delta wings: Transsonic drag rise is more gradual and peak supersonic drag is reduced Lift spread over broader chord (lower section cl)

Drag less sensitive to Mach number Easier to obtain satisfactory cross-sectional area distribution (no HT) Gradual change of CL and CL with M Leading-edge vortex gives better stall behavior Allows light wings with high bending and torsional stiffness Thicker wings allow for more volume for fuel and gear Flutter and aileron reversal can be eliminated Low wing loading allows for acceptable maneuvering and handling Smaller wings do not require folding Large wing area available for external stores

Disadvantages of delta wings Tailless deltas have high landing speeds and bad eld performance Low-lift curve slope requires high AoA Tail clearance limits AoA Unable to trim out the nose-down pitching moment from aps High lift-induced drag in subsonic conditions High thrust required Trimmed lift loss at high AoA due to downloading trailing-edge controls Low wing loading Although CL is low, L is high due to low W/S gust response High wing loading would compromize manoeuvrability Supersonic manoeuvrability restricted Trailing-edge ight controls (elevons) are less effective Large absolute shift in a.c. (needs to be trimmed and may demand c.g. shift) Excessive Cl at low speed Large (leading-edge) sweep and high AoA disturbs desired relation between lateral and directional stability, Dutch roll becomes exaggerated, low wing and yaw dampers required. Pitch damping reduced (if there is no horizontal tail) Risk of pitch induced oscillation Pitch dampers might have to be installed In case of horizontal tail use a low-mounted ht to avoid deep stall at high AoA Unstable delta does have some other possible advantages, see Fig. 4. Compound sweep delta (F-16 XL) Longer fuselage Twice the wing area allows for more hard points increases friction drag

ADVANCED AIRCRAFT DESIGN II SUMMARY

Fig. 4.

Advantages of unstable delta

Increased neness ratio and wing fuselage blending Wing optimized for low-level supersonic speeds Trailing edge reex included 70 deg leading edge within the shock cone of the nose 50 deg swept outboard wing with thin prole and sharp leading edge F-16XL ying qualities: Lateral/directional stability is improved External loads no not adversely affect ying qualities In modern air combat ghters delta wings are used because the high degree of leading-edge sweep promotes strong vortex formation at high AoA. It has low wave drag at supersonic speeds and the combination with a foreplane creates benecial interference.

Fig. 5.

Effect of glove size

Variable swept wings, used for: Long-range subsonic cruise or long-endurance loiter on station High-supersonic interception and transonic low-altitude strike Operation from limited-length runways or aircraft carriers. Using a variable sweep wing can also be used for lowaltitude high-speed action (F-111), with the wings swept back the wing has a lower aspect ratio and lower CL so it is less sensitive to gust upsets. High sweep will also bring the a.c more aft and thus increase the corrective effect of Cm (pitch stiffness). When the low-altitude high-speed dash has been completed the aircraft can then benet form the (low speed) advantages of an unswept, high aspect ratio wing (good take-off and landing performance, more efcient subsonic cruise and loiter, better subsonic sustained manoeuvring). Disadvantages of variable sweep wings: Excessive static stability at high sweep (small c.g. excursion, large n.p. excursion) although reduced by aeroelastic effects... Large trim drag due to aft a.c. (induced drag of wing and horizontal tail) Large stabilizer deections required at high AoA Hence: large down force of tail should be compensated by larger lift Even more aft a.c. at transonic conditions reduces maneuverability Possible solutions are a translating wing or to move the pivot point outboard.

Arguments for inboard pivot: Fully swept wing area and span are smaller gives the highest effective aspect ratio in the unswept condition more aeroelastic relieving effect on pitch stiffness. trim drag penalty is not particularly acute for combat aircraft using full sweep only for supersonic dash or lowaltitude, high-speed penetration of limited duration Trim change can be hidden from pilot by pitch dampers The complications of fairing and sealing a xed apex are avoided, allowing the use of full-span leading-edge high-lift devices. Observations of sweep wing: Increasing sweep from 25 deg to 67.5 deg decreases the lift curve slope by 50 percent. This considerably lessens the susceptibility to gusts. Even at subsonic Mach numbers the stability increases greatly with increasing wing sweep notwithstanding the use of a xed glove on the inboard wing. At supersonic speeds stability increases even more. Increasing wing sweep from 25 deg to 65 and 67.5 deg increases the drag rise Mach number from M = 0.75 to close to M = 0.90. Forward swept wings: Main problem is the combination of bending (aerodynamic twist) and torsion (geometric twist) that occurs when a forward swept wing is constructed using an isotropic material. By using an anisotropic material one can decouple the bending and torsion to obtain a wing that does not diverge. (it is also possible with isotropic material, but the structure would become quite heavy)

ADVANCED AIRCRAFT DESIGN II SUMMARY

Advantages of forward sweep: Roll control and damping more effective at high AoA Reduced dihedral effect at high AoA Boundary layer drifts inboard (at high AoA) Higher load inboard section Inboard stall could create pitch-up (when behind c.g.). (Fences, inboard twist or limited area of aft sweep can prevent this) Foreplane (canard) can produce downwash to keep the ow attached For same sock sweep less leading edge sweep required Higher aspect ratio higher CL higher CL at takeoff and landing when restricted by tail strike or pilot visibility Higher aspect ratio lower CD,i increased sustained turn rate and better cruise/loiter performance. Disadvantages of forward sweep: If the root stalls, vertical tail could be in the wake Risk of divergence and new forms of utter Higher aspect ratio higher CL Higher gust sensitivity No aeroelastic relief Higher aspect ratio lower CD,i additional wave drag in supersonic conditions due to volume

High-speed boundary layer discharges from slat training edge Reduces adverse pressure gradient on slat Fresh boundary layer effect A new boundary layer is formed on each new component Characteristics: Possible increase in leading-edge camber Possible increase in chord Small change in Cm

Typical modern ghters have low CLmax and low CL , they are driven by speed and weight requirements, usually resulting in thin wings with high sweep back. Blowing of high-lift devices would increase maximum lift but it also comes at the cost of unusable thrust. Note that high-lift devices can also be used to improve maneuverability.

III. M ANEUVERABILITY Requirements: Superior transonic maneuvering is an important specication Requirements on instantaneous maneuvering (pitch, roll, yaw rates) Requirements on sustained maneuvers (turn rate, climb rate) For sustained maneuvers high specic excess power is required High lift, low drag, high speed, high thrust Flight at high AoA leads to separation Increase in drag, buffet and stability and control problems Result: degradation of combat capability: Reduce pilot control and aiming accuracy Full maneuvering capability is reduced Chance of stalling and spinning the aircraft Increase in drag reduces combat effectiveness Specic excess power Specic excess power is a measure of the ability to (re)gain energy by accelerating or climbing. In level ight: The normal load factor n can be computed by eq. 6. T = D0 + Di CD = CD,0 + k(CL )

2 T D0 = kCL qS = k 2

High-lift devices Three categories of leading-edge devices: Alter leading-edge pressure distribution Alter the boundary layer (blowing and suction) Combination of both Leading-edge devices increase lift through increase of camber. They are most effective on sharp-nosed sections that are prone to separation. It is difcult to apply while maintaining a smooth knuckle. Typical deection is about 25 degrees. Leading-edge devices cause a thicker wake over the trailing edge ap, this reduces the effectiveness of the trailing edge ap. Kruger ap and slat without slot: Increase wing chord or increase nose radius or both Simple rotation about a hinge (Krueger ap) Extension mechanism Slat with slot: Slat effect Reduces suction peak on main component Reduces adverse pressure gradient on main component Circulation effect Slat in upwash of main wing For Kutta condition at training edge of slat: circulation (=lift) Dumping effect

with with

nW qS

qS

(1) 1 (2) k= Ae 1 2 q = qV (3) 2 (4) (5)

T D0 W = kn2 W qS 1 T D0 n2 = q W kW/S

ADVANCED AIRCRAFT DESIGN II SUMMARY

1 dE T D = V = PS W dt W dh V dV PS = 1+ dt g dh dV VC d VC = V =V ; = 0 dh dh 2 1 VC d dh 1 PS = dt g dh dh PS R/C = = 2 1 VC d dt 1

g dh

(19) (20) (21) (22) (23)

Using specic excess power one can also determine the optimum energy climbs or make a plot of the airspeed vs. turn rate (so called doghouse plot . Flap scheduling Program aps to automatically suit ight mode. Buffeting

Fig. 6. Derivation of specic excess power

n=

1 T D0 q W kW/S

(6)

The relation between turn rate(), normal load factor(n) and turn radius (R) is derived in eq. 12 V = R W 1 V = nW 1 2 g n W V = L sin ; = g 1 W = nW cos sin = 1 2 n = g V 1 T D0 q 1 W kW/S R= V V2 1 = g n2 1 (7) (8) bankangle (9) (10) in rad/sec (11) (12)

1) Early formation of weak tip shock 2) Overtaken by aft-moving shock from distorted pressure eld at wing root junction 3) At higher Mach forward shock appears parallel and close to leading edge 4) Forward shock moves inboard and intersects rear shock outboard of intersection is a strong shock with a large pressure rise. This invariably causes ow separation

In eq. 23 the relation between specic excess thrust and rate-of-climb (R/C) will be derived, starting with Newtons law along the ight path. W dV g dt T D V dV dh V dV V = V sin + = + W g dt dt g dt W1 2 E = Wh + V ; E = T otal Energy g 2 E V2 ES = =h+ W 2g dES 1 dE E dW = 2 = PS dt W dt W dt dW = 0; weight constant dt T D W sin =

(13)

Fig. 7. Flow over swept wings

(14) (15) (16) (17) (18) Vortex Lift See gures 8, 9 and 10, that pretty much explains it. Weapons vs. Maneuverability

Weapon capability determines aircraft agility requirements (both for attack and defense)

ADVANCED AIRCRAFT DESIGN II SUMMARY

IV. A IR I NTAKES Intake design criteria Spillage drag Internal performance (total pressure recovery) Inlet/engine airow matching Flow distortion at compressor face steady state time-variant Bypass ow Inlet bleed requirements Interference with external ow Stealth (radar detectability) Boundary-layer diverter and bleed drag Intake buzz and bypass drag Flight and operational safety Foreign object damage The engine face average total recovery is of prime interest due to its direct effect on engine thrust. Steady state distortion: = pressure recovery pattern across the engine face = felt by compressor blades as variation in velocity Results in vibrations of the blades May cause stalling of blades on several stages Can result in engine surge

Fig. 8.

Vortex lift

Fig. 9.

Pressure distribution vortex lift

Gun/cannon armament (ballistic unguided) is classical solution Early warning radar and guided missile development has eliminated high altitude penetration (SAM) Air-to-air missiles have longer range and maneuvering capability, plus higher speed than opposing aircraft (but disengaging is difcult or impossible) Missiles have a minimum engagement distance, to lock on and stabilize ight plus a limited aiming cone Cannon armament to supplement missiles Long range engagement (BVR) identication not certain Engagement may develop into close combat Missile capabilities improvements benet from (short time) aircraft pointing capability This may be traded against energy conservation/management supermanoeuvrability

Fig. 11.

Distortion

Fig. 10.

Effect of strakes on vortex lift

Dynamic distortion = how the distortion/turbulence pattern varies with time High distortion levels result in low pressure recovery Multi-shaft bypass engine more susceptible to distortion than pure jets Spillage drag At high forward speed a low throttle setting: stream tube smaller than inlet Momentum loss of air that spills around the inlet = spillage drag. Intake may be matched to ow conditions by variable geometry, blow-in doors etc. Energy loss in bypass air, boundary layer bleed is proportional to mass ow velocity reduction Boundary layer bleed Boundary layers impair pressure recovery Goal: to remove fuselage and intake boundary layer Means: use of boundary layer diverter Result for fuselage boundary layer diverter diverter drag (momentum lost by diverted ow Result for intake boundary layer diverter: Boundary layer bleed drag (momentum lost from time they enter the intake until they leave the aircraft + exit door pressure drag)

ADVANCED AIRCRAFT DESIGN II SUMMARY

Goal: Make sure excess thrust due to higher pressure recovery is not lower than additional drag Boundary layer bleed is required for stable and undisturbed engine intake ow Radar detectability Diverterless inlets Intake shaping very important for front radar crosssection Intake design features Intake size Usually sized for high-subsonic speeds Excess airow is diverted back to the freestream Intake sizing should account for increased mass ow due to engine development Cowl lip shape Fixed prole Variable radius inlet Suck-in doors (Alternative to high mass ow requirement, they suppress separation without adding thickness to the lips) Blunt lip avoids separation at low speeds Blunt lip will cause shock wave and boundary layer separation at high subsonic speeds due to spillage Sharp lip causes ow separation at high angle-ofattack and low M can lead to distortion Alternative: variable radius inlet/auxiliary intakes Intake shape Sideplates Intake boundary-layer management Fuselage boundary layer (separated by splitter plate) Internal boundary layer (can be thinned by porous surfaces or diverted by throat slot bypass Engine bypass system Air that is captured but not accepted by the engine can be bled off using the incorporated boundary layer bleeding system Much larger quantity of air than just the boundary layer If bypass/bleed are not used correctly a severe drag penalty can occur Intake duct length and shape Air is decelerated by a (series of) shock wave(s) Further diffusion required to decelerate to M =0.6 Compatibility with area ruling (outside) and diffuser shaping (internal) Result often S-shaped duct Duct length is trade-off between weight, distortion levels, diffuser losses (bl friction), (directional stability, example F-16) Intake location Engine intake to be optimized with airframe: avoid disturbed ow, make use of precompression/ow straightening No single conguration provided the best performance at all conditions

Side by side vs. separated engine/inlets: transonic vs. supersonic performance Asymmetric engines have low spillage drag 2-D inlets have good pressure recovery with acceptable inlet drag Nose intake (mainly used in early jet ghters, suffered form high pressure losses due to wall friction, less ow distortion, no bl diverters necessary, no large radar dishes at the time) Wing-root leading-edge intakes (small depth of intake face, rapid changes in cross section and low wetted area) Side intakes (induced by shape of nose, underbody, canopy, nose droop and fuselage camber, subject to magnied AoA effects, need adequate handling of fuselage boundary layer) Shielded intakes (reduce intake AoA during maneuvres, wing shielding improves pressure recovery, massive ow separation in sideplate at high angle of sideslip possible) Ventral inlet (fuselage is an efcient ow straightener when wider than inlet, low distortion, large pressure recovery, magnied side-slip effect on intake inow, nose wheel should be more aft, larger VT required) Dorsal inlet (low RCS, bad high AoA performance) Under wing inlet (under wing Mach number is lower (precompression), high AoA capability, forces caused by ow spillage might actually improve the lift of the airplane, increasing L/D and easy access) Intake types

First generation of supersonic intakes: sharp-lipped pitot intake long subsonic duct (high internal friction) large total pressure loss due to normal shock wave

Second generation: addition of conical spike (Mig 21) Houses radar dish Improves supersonic pressure recovery (oblique shock)

Horizontal ramp inlet Fuselage boundary layer diverter required Long ramp lengths due to inlet aspect ratio (thicker boundary layer) Variable geometry capability in the ramp angle changes for mass ow regulation Large side areas require sideplates to prevent side spillage. Reduces stable mass ow range. BL growth on sideplate. Flow separation off leading edges of sideplate during sideslip conditions Ramp and throat boundary layer removal to minimize terminal shock/boundary layer interaction to improve subsonic diffuser performance and reduce distortion and turbulence. Aspect ratio chosen for best integration to aircraft conguration Small cowl lip area available for cowl suction (reduction of spillage drag) but cowl drag is reduced. Cowl lip shaping for subsonic high angles-of-attack

ADVANCED AIRCRAFT DESIGN II SUMMARY

Possible inclusion of variable cowl devices to enhance inlet engine matching Very good predictable angle-of-attack performance Subsonic: Ramp reduces inow angles. Cowl lip blunting can prevent internal ow separation. Supersonic: Shock system moves forward relative to cowl lips: maintains low distortion level of intake air. Recovery may increase due to change in effective capture area.

V. S TEALTH The act of moving, proceeding, or acting in a covert way. Advantages of stealth: Can penetrate highly hostile regions Provides initial breakthrough by shock and surprise Precision bombing High Survivability in hostile conditions One mission, multiple targets Cost effective in the long run High morale and condence in the troops Linear changes in aircraft survivability produce exponential changes in force effectiveness and aircraft attrition rates. Susceptibility reduction: Threat warning Noise jammers and deceivers Signature reduction Expendables Threat suppression Tactics Vulnerability reduction: Component Redundancy Component Location Passive Damage Suppression Active Damage Suppression Component Shielding Component Elimination/Replacement Classication of aircraft signatures: Active: Radar Airframe Engine Intake Weapons Navigational Radar Passive: Infrared Fuselage Airframe Exhaust plume Tailpipe Sun glint Acoustic Engine Parts Engine Exhaust Airframe Visual Airframe Engine Exhaust Glow Canopy Glint Aircraft Lighting Misc.

Half cone inlet Variable geometry for mass ow regulation via translating cone Throat boundary layer removal necessary to minimize terminal shock/BL interaction to improve subsonic diffuser performance and reduce distortion both steady state and time varying. Lower cowl angles required due to nature of conical ow Long length of cowl lip perimeter available for lip suction. Benets to reduce spillage drag Structurally more efcient Splitter plate not required with proper diverter design (which would minimize leakage off cone edge) AoA performance: Subsonic: Lower cowl lip blunting required Supersonic: Asymmetric compression, increased distortion. Shock pattern intersects plane of inlet. Large degradation in recovery Stable mass ow ratio change at Mach 2.0 is approx 30 to 50% with an inlet design Mach number of 2.2

Vertical ramp inlet Variable geometry capability in ramp angle changes for mass ow regulation Ramp and throat boundary layer bleed to minimize terminal shock boundary layer interaction and improve subsonic duct performance and reduce turbulence and distortion Minimal side spillage areas due to aspect ratio (chosen for best integration of aircraft conguration) Side plates eliminated to improve angle-of-attack performance. Increase stable spillage range Large cowl/lip area available for cowl suction reduction of spillage drag Good angle-of-attack performance: Subsonic: Blunting of lower lip is required but internal ow separation is prevented Supersonic: Shock pattern not greatly inuenced by angle-of-attack. Small degradation in recovery. Stable mass ow ratio at Mach 2.0: approx 10 to 30% with and inlet design Mach number of 2.2

Variable-geometry intakes

Moving cowl Extra chin intakes Rotating intake cowl

ADVANCED AIRCRAFT DESIGN II SUMMARY

10

Communication Countermeasures

Band Designation VHF UHF S C X KU Nominal Frequency 30-300 MHz 300-1000 MHz 2-4 GHz 4-8 GHz 8-12 GHz 12-18 GHz

Shape Sphere of diam. A Flat plate (area A) Cone (semi cone angle ) Ellipsoid (major axis 2a, minor axis 2b) Paraboloid with apex radius of p Circular ogive (nose semi angle ) Circular cylinder (length L and radius a) Trihedral (3 plane intersecting at 90 )

Radiation Direction any normal to surface Parallel to axis Parallel to 2a Parallel to axis Parallel to axis Perpendicular to axis Any angle between two faces

RCS a2

4A2 2 tan () 16 b2 a2 4p2

2

2 tan 4 2aL2 12L4 2

TABLE I F REQUENCY BANDS

TABLE II R ADAR CROSS SECTIONS

NOTE: RCS varies with frequency. Long range with low frequency, long wavelength radars (resolution not so good), short range with high frequency, short wavelength (high resolution)

Rmax

PR G2 2 R (4)4 N (S/N )min

1/4

(24)

Fig. 14. Fig. 12. Relative size contribution to RCS

Reducing the RCS.

Fig. 13.

Radar sources

Types of reection: Diffuse reection (rough surface) Specular reection (smooth surface) Retro reection (retroecting foil of cats eyes reector) Radar reection type: Rayleigh Region ( > ) Resonant Region ( ) Optical Region ( < ) Radar detection range, see eq. 24.

Overall RCS reduction: Reection: Minimise overall size of the aircraft Clean external geometry having no protuberances or gaps Internal weapons carriage Highly swept leading edges Eliminate cockpit transparencies Use of composites Use of passive onboard detection system (FLIR, IRST) Use of radar screen on engine air intakes Appropriate shaping of the intake lips and inlet ducts Stealth aircraft must be low probability of intercept (LPI) Absorption: Attenuating RAM Resonant RAM Active Interference Plancks radiation law: eq. 25 E(, T ) = 2 h c2 n2 5 = 1 e nkT 1 AT 4

hc

(25)

Qemitted

(26)

ADVANCED AIRCRAFT DESIGN II SUMMARY

11

Plank constant Boltzmann constant Speed of light Refractive index

h = 6.626 cot 1034 Js k = 1.3806 1023 J/K c = 229 792 458m/s n = 1 (for vacuum)

TABLE III C ONSTANTS

Sources of IR signature: Emitting surfaces (engine casing, nozzle, exhaust plume, other associated hot parts and airframe) Reecting surface (sun glint off the airframe opaque surfaces and transparencies like cockpit canopy VI. F USELAGE D ESIGN Functions of the fuselage is to accommodate: crew communications and navigation equipment the ight control system search and re-control systems large proportion of its fuel load Engine(s) Components of the landing gear Gun + ammunition Missiles, bombs, ares Nose and forward fuselage Forebody shape is driven by Cockpit visibility requirements which usually govern forebody camber. High-AoA handling which inuences the length, crosssectional shape and application of nose strakes Requirement for radar and laser-ranging installations inuece the nose size and shape Crew accommodation, including cockpit canopy design, governs the cross-sectional area Forward camber: positive camber generates a negative pitching moment, so reducing the forebody camber will reduce the horizontal tail download required. Forebody vortex ow: has dominant effect on stability in post stall (high AoA conditions) vortices are shed from the nose of the airplane n subjected to wing wake and vortices shed by the forebody it is inuenced by nose neness ratio (large yawing moments if large neness ratio), bluntness, crosssectional shape and the use of nose strakes (aka spin strakes/strips) Forebody effect on stability A well-designed forebody can also contribute to positive directional stability at high angle of attack Requirement = stable separation

Vertical ellipse = unstable in yaw Horizontal ellipse = stable in yaw Flattened fuselage is longitudinally less stable (nose-up pitch) Nose strakes allow for symmetric vortex formation Apex of vortices is xed Strakes improve lateral/directional stability Strakes prevent spinning Strakes deteriorate RCS the effect of strakes is also dependent on other components and can also be destabilizing in yaw.

Nose shape affected by radar Primary geometric factors affecting radar performance: Location of a pitot-static boom, nose strakes (and sometimes AOA and angle-of-sideslip vanes) adjacent to the radome. High neness ratio, resulting from aerodynamic shaping of the nose for low drag. Aerodynamic shaping of the nose cross-section for good high-AOA directional stability Trade-off between Low drag Excellent high-AoA characteristics Acceptable radar performance Forebody affected by crew Lage neness ratios desired for supersonic ight, this requires low cross-sectional area no more side-by-side cockpits, but rather tandem. High visibility for the pilot improves survivability.

Center Fuselage Center fuselage accommodates: Main ducts for engines Fuel tanks The main undercarriage (optional) Armament bay (optional) Ejection units for stores (optional) Pipes, cables and wiring Some requirements in the design of the center fuselage are space, accessability (especially for engines) and vulnerability of systems.

Internal engines: when engine grows, more space is required. Podded engines: Engine growth easily realized No need for fuselage boundary layer diverter More wetted area Heavier structure (of pods) Less wing weight (inertia relief) Less intake weight (no S-duct) OEI condition is more critical

ADVANCED AIRCRAFT DESIGN II SUMMARY

12

Better longitudinal stability (pancake area aft) Better directional stability (mode side area) Area rule: Any two bodies which have the same area distribution, will experience the same amount of wave drag independent of their actual shape.

Sears bodies describe the optimum shapes for minimum wave drag. Sears-Haack body = minimal drag for given length and volume. Von Karman ogive = minimal drag for given length and cross sectional area.

Differential area ruling Favorable lift interference is created by differential area ruling Requires lower AoA to attain certain CL Reduces drag due to lift (remember this is proportional to CL tan ) 5% increase in sustained turn rate at M=1.2 Favorable pitching moments with reduced trim drag Area ruling conclusion: Lowest body drag: Large neness ratio Proper area ruling Issues: Large pitching moment of inertia Large yawing moment of inertia Small rolling moment of inertia Hazard of inertia cross coupling Rear Fuselage Requirements: Have to be compatible with large tail plane angles Minimize leakage between HT and fuselage through gaps House HT actuators (pivot axis of HT should be close to its AC for actuator sizing) House engine (usually in the back to reduce structural heating and acoustic effects) VII. F INS AND RUDDERS Functions: Balance in asymmetric ight Ensure maneuverablilty Provide directional stability (weathercock function) Spin prevention/recovery

Cn

destabilizing fuselage requirement to suppress sideslip rapidly lateral stability requirements Result Difcult to predict required n size for directional stability External store asymmetry: Imbalances occur when stores are released asymmetrically Mass asymmetry causes rolling moment Can be balanced by aileron deection Aileron deection produces variable rolling moment during high-g maneuvers Required lateral moment can be relieved id airplane is allowed to sideslip but this requires sufcient directional stability Missile ring generates asymmetric ow eld, this can generate a yawing moment Compressibility effects: Fin usually becomes less effective at higher Mach numbers At high angles of attack the low energy wake (wake of the wing/forebody) can immerse the n, this can result in yaw-off due to directional instability. At subsonic speeds it is mainly the n height that inuences stability (not so much the area). However, because of fuselage vortex interaction with the vertical n, at high angels of attack and at yaw angle, a higher n can cause reduced stability. Twin ns Can reduce required tail height ( less aeroelastic penalties) Mutual interference at subsonic conditions reduces effectiveness and could render a single n more effective Most benecial in supersonic conditions; beyond a certain Mach number there is no mutual interference, the Mach lines do not interfere with the other tailplane Reasons for applying twin ns on the F-14: End plating effect if the twin verticals results in far more effective horizontal tail control. Twin verticals provide a more constant value of Cn and high Cn for improved Dutch roll characteristics. Rudder control redundancy for combat survivability. Better infrared stealth due to exhaust shielding. No spine boom required to mount n between engines Reduced height makes them less sensitive to utter Larger distance form centerline required less heavy structure lower temperatures, less noise. Lower height means less hanger space required Reasons for not choosing twin ns on YF-16: Flow separations from both forebody and wing at high AoA interacted adversely with twin verticals.

must be positive.

Fin area requirements: Directional moments generated by Destabilizing forebody Stabilizing n Fin size dominated by

ADVANCED AIRCRAFT DESIGN II SUMMARY

13

Under certain combinations of and visible buffeting of the tails occurred. Single n reduced friction drag due to lower required wetted area.

Aeroelastic distortion reduces effectiveness of rudder at high dynamic pressure high aspect ratio rudders not used; wide, swept rudders are used as well as all-moving ns

The n is usually placed as far aft as possible (taking into account area ruling and interference between horizontal and vertical tail at high AoA). Canting the ns: Reduce rolling moment. Reduce radar cross-section. Reduce adverse interference with forebody vortices, wing vortices and nacelle vortices. Toe angle may be required to reduce vortex interference. Fin shape: High aspect ratio is benecial for effectiveness Low aspect ratio is benecial for stall behaviour Alternative: dorsal n Raked ns on Russian ghters: increase in utter speed Ventral ns: Oppose roll due to sideslip Is destabilizing in roll: offsets the dihedral effect good for Dutch roll characteristics Low aspect ratio High structural stiffness At low AoA might interfere with fuselage stores Rudders Design factors Crosswind landing (often most critical) High AoA ight (spin recovery) Asymmetric stores Asymmetric thrust (engine failure, engine unstart) Transonic effectiveness High AoA ight The rudder effectiveness is determined by the wing planform and its stall pattern (position of the stalled wake w.r.t. the rudder). Also (part of) the rudder can be blanked by the wake from the horizontal tail. If the rudder is not used for spin recovery however that is no problem, Right yaw + right aileron: combined with low Cn at high AoA: sideslip to the left is induced combined with low Cl : a roll to the left in incurred (roll reversal) If aileron reversal occurs switch to rudder-only roll control beyond a certain AoA, this is automatically done via Aileron-Rudder Interconnect (ARI) Transonic effectiveness Compressibility effects reduce effectiveness of hinged control surface in transonic and supersonic speeds

VIII. N OZZLES AND AFT BODIES Nozzles are needed to control the expansion of exhaust gasses, by preventing uncontrolled expansion one can achieve increased gross and net thrust.

Fig. 15. Area ratio changes by a factor of 1.7 to 1.8, theoretically something like 3 would be best but that would result in very large areas and lots of drag.

Off-design operation, low supersonic speeds: Nozzle expands ow below back pressure. Corrective shock wave occurs. Shock-induced separation follows. Effective loss not as high as in ideal case (normal shock), but the total loss is still substantial Off-design operation, low subsonic speeds: Divergent part acts as subsonic diffuser Velocity decreases downstream pressure increases downstream Adverse pressure gradient can cause unstable separation Causes the jet stream to attach to one side and then the other Causes violent vibrations Thrust vectoring is the manipulation of jet exhaust such that the resultant reaction forces augment or replace those forces normally generated by the aerodynamic control surfaces of the aircraft. Thrust vectoring can give you increased range (no need for trim-deection of control surfaces), improved agility and better survivablilty. Axis-symmetric nozzles High strength/weight Easier to cool Less leakage between upper/lower ramps and sidewalls 2D thrust vector control Reduced complexity Easy integration with aft fuselage More effective TVC Lower IR signature Thrust vectoring conclusion

ADVANCED AIRCRAFT DESIGN II SUMMARY

14

Only increases maneuverability at low speeds Can replace (some part of) control surfaces and could reduce weight; no RCS benet, small benet in endurance Can allow for lower landing speeds if TVC can roll the airplane (limited by impaired pilot visibility)

Afterbody contours: How to reduce subsonic boattail drag? Expansion of the nozzle until its area coincides with that of the nacelle. This can eliminate base drag but it causes jet over-expansion and internal losses. Careful design of the boat-tail. A minimum boat tail angle at 15 has been suggested, the maximum angle is dominated by boundary layer fatigue. If the angle is smaller than 10 this will result in extra length, with extra skin friction and excess rear fuselage weight. (possible solution is the addition of a nacelle-to-nozzle fairing (F16)) Operation of the nozzle at limited area ratio Boundary layer separation on the boat tail might cause: Excessive boat tail drag Violent buffeting Reduction in boat tail angle: Causes at base area Clean boundary layer detachment at the rim of the fuselage Does not result in too high drag when close to an exhaust Interference drag Change in boat-tail pressure w.r.t. tail without nozzle and jet + nozzle drag + change in gross thrust due to the external ow eld interference drag reduces with increased nozzle spacing (optimum spacing to minimize total drag s/d = 2.5)

You might also like

- The Design and Construction of Flying Model AircraftFrom EverandThe Design and Construction of Flying Model AircraftRating: 5 out of 5 stars5/5 (2)

- Supersonic Flight - Design Features Lesson 7Document61 pagesSupersonic Flight - Design Features Lesson 7MarvinNo ratings yet

- 16-Vortex Lattice Methods PDFDocument42 pages16-Vortex Lattice Methods PDFpriyaNo ratings yet

- Helicopter TheoryDocument40 pagesHelicopter TheoryAbraham Benjamin Britto100% (1)

- High Lift Devices: Aswin.B.D 19AE60R07Document12 pagesHigh Lift Devices: Aswin.B.D 19AE60R07Aswin B DNo ratings yet

- Wing Design Requirements and Surface ConfigurationsDocument46 pagesWing Design Requirements and Surface ConfigurationsprasannabalajiNo ratings yet

- Introduction To Helicopter ThoeryDocument85 pagesIntroduction To Helicopter Thoeryyuyu2809100% (1)

- Efficient Light Aircraft Design - GlidingDocument43 pagesEfficient Light Aircraft Design - GlidingkearnscribdNo ratings yet

- High Lift DevicesDocument33 pagesHigh Lift DevicesNitsugaNo ratings yet

- Helicopter IntroductionDocument28 pagesHelicopter IntroductionLight HouseNo ratings yet

- BAA AGK Lesson 1 - 2-WingDocument86 pagesBAA AGK Lesson 1 - 2-WingReece BhaveNo ratings yet

- Propellers, Rudders and Bow Thrusters: Burak AcarDocument42 pagesPropellers, Rudders and Bow Thrusters: Burak AcarRAMSINGH CHAUHANNo ratings yet

- Conception Aero FighterDocument34 pagesConception Aero Fighterdhruv pramanik100% (2)

- Helicopter Aero IntroDocument28 pagesHelicopter Aero IntroPeter ChanceNo ratings yet

- What Are Disadvantages of Wing SweepDocument57 pagesWhat Are Disadvantages of Wing SweepElton CacefoNo ratings yet

- F14PresS07 PDFDocument19 pagesF14PresS07 PDFNasr PooyaNo ratings yet

- Mae 1202: Aerospace Practicum: Lecture 12: Swept Wings and Course RecapDocument20 pagesMae 1202: Aerospace Practicum: Lecture 12: Swept Wings and Course RecapBhàráth BittuNo ratings yet

- Propeller 2Document194 pagesPropeller 2Umar Ubaidullah100% (2)

- Aircraft LimitationsDocument31 pagesAircraft LimitationsSanajyNo ratings yet

- Tails Design PDFDocument19 pagesTails Design PDFAgostino De GiuseppeNo ratings yet

- RotorcraftDocument21 pagesRotorcraftAdrianNo ratings yet

- PropellerDocument252 pagesPropellerAhmadFaisal100% (3)

- AE1350 Lecture Notes on Airfoil Drag Forces and High Lift Device DesignDocument25 pagesAE1350 Lecture Notes on Airfoil Drag Forces and High Lift Device Designpsycho_zahranNo ratings yet

- AircraftWing DesignDocument25 pagesAircraftWing Designmurad_ashourNo ratings yet

- MH-RF2: A Cargo Aircraft With Giant Structure and Full of Modern TechnologyDocument69 pagesMH-RF2: A Cargo Aircraft With Giant Structure and Full of Modern Technologyjohn tanvirNo ratings yet

- Scrib RamjetDocument34 pagesScrib RamjetNafis Zahran Ed100% (1)

- Aircraft Design Day1Document62 pagesAircraft Design Day1arun_sanga1233515100% (3)

- Aircraft Design Configuration GuideDocument19 pagesAircraft Design Configuration Guidemurad_ashourNo ratings yet

- Aircraft Design: Airfoil and Geometry SelectionDocument94 pagesAircraft Design: Airfoil and Geometry SelectionYak100% (10)

- Chapter 7 - 8 FinalDocument71 pagesChapter 7 - 8 FinalSAROOSH AHMEDNo ratings yet

- Powerpoint Presentation On DragDocument45 pagesPowerpoint Presentation On DragrubberdookieNo ratings yet

- PerformanceDocument17 pagesPerformanceSharon AbrahamNo ratings yet

- Wing Design IIDocument11 pagesWing Design IIArun DamodaranNo ratings yet

- Group 1 - Aircraft CharacteristicsDocument40 pagesGroup 1 - Aircraft CharacteristicsLoren JeanNo ratings yet

- Aircraft Design - Aerofoil and Geometry SelectionDocument55 pagesAircraft Design - Aerofoil and Geometry SelectionKrishanth Sivanathan100% (1)

- Theory of Flight: 6.01 Aircraft Design and ConstructionDocument45 pagesTheory of Flight: 6.01 Aircraft Design and ConstructionmanisekNo ratings yet

- Airport CompleteDocument107 pagesAirport CompleteAbhishek NarineNo ratings yet

- Aircraft Descent Performance: Factors Affecting Rate of Descent & GradientDocument22 pagesAircraft Descent Performance: Factors Affecting Rate of Descent & Gradientethiopian art2020No ratings yet

- Types of PropulsionDocument64 pagesTypes of PropulsionAnitha Raja BNo ratings yet

- Propeller and Helicopter Design BasicsDocument209 pagesPropeller and Helicopter Design BasicsAeriel AldanaNo ratings yet

- Technical Topics: Understanding MY Conversion Rules Go-MindedDocument39 pagesTechnical Topics: Understanding MY Conversion Rules Go-MindedGábor KapuyNo ratings yet

- Fighter Aircraft Wing Designs and ConfigurationsDocument34 pagesFighter Aircraft Wing Designs and ConfigurationsHari NaniNo ratings yet

- Lec#12, Aircraft Characterisitcs (Compatibility Mode)Document46 pagesLec#12, Aircraft Characterisitcs (Compatibility Mode)Nawaz AliNo ratings yet

- HELO AerodynamicsDocument23 pagesHELO AerodynamicsRamanujam SankarNo ratings yet

- Lesson 2 - Aircraft Structure, AirfoilDocument61 pagesLesson 2 - Aircraft Structure, Airfoilaahsan345100% (1)

- Chapter 3 PT 1 N 2-Theory of FLightDocument23 pagesChapter 3 PT 1 N 2-Theory of FLightzuliana_ismail8564100% (1)

- Air Propulsion AcvsDocument9 pagesAir Propulsion AcvsMini DangNo ratings yet

- Lesson AerodynamicsDocument113 pagesLesson AerodynamicsShermeen Khan100% (1)

- Transonic and Supersonic Flight of Swept-Wing AircraftDocument21 pagesTransonic and Supersonic Flight of Swept-Wing AircraftHan Thu AungNo ratings yet

- Wind Turbine TechnologyDocument29 pagesWind Turbine Technologyudaysinh0032878No ratings yet

- Airfoil GeometryDocument5 pagesAirfoil GeometryRoyston ShiehNo ratings yet

- Ae2204 NotesDocument37 pagesAe2204 NotesMani KandanNo ratings yet

- Aero 3sem 111305nolDocument37 pagesAero 3sem 111305nolKrishna MyakalaNo ratings yet

- F-14 Tomcat Variable Sweep Wing FighterDocument19 pagesF-14 Tomcat Variable Sweep Wing FighterAerospaceAngel100% (1)

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionFrom EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionRating: 4 out of 5 stars4/5 (1)

- Acum Paper PDFDocument80 pagesAcum Paper PDFJack AzadNo ratings yet

- Feasibility Study of Metal To Polymer Hybrid Joining PDFDocument125 pagesFeasibility Study of Metal To Polymer Hybrid Joining PDFJack AzadNo ratings yet

- Design and Manufacturing of A Tactical Unmanned Air VehicleDocument135 pagesDesign and Manufacturing of A Tactical Unmanned Air VehicleJack AzadNo ratings yet

- Teaching Aircraft Design Course Using Real and Virtual Wind TunnelDocument14 pagesTeaching Aircraft Design Course Using Real and Virtual Wind TunnelJack AzadNo ratings yet

- Introduction To Manufacturing SystemsDocument60 pagesIntroduction To Manufacturing SystemsMahesh Babu TalupulaNo ratings yet

- Aerodynamics of Impulsive Insect Wing DesignDocument133 pagesAerodynamics of Impulsive Insect Wing DesignJack AzadNo ratings yet

- Aircraft Basic ConstructionDocument22 pagesAircraft Basic ConstructioncongngthanhNo ratings yet

- Dissimilar Metal Joining Technologies For Steel Sheet and AL Sheet in Auto Body PDFDocument8 pagesDissimilar Metal Joining Technologies For Steel Sheet and AL Sheet in Auto Body PDFJack AzadNo ratings yet

- Design and Computational Analysis PDFDocument143 pagesDesign and Computational Analysis PDFJack AzadNo ratings yet

- PDFDocument22 pagesPDFJack AzadNo ratings yet

- Unconventional Aircraft ConceptsDocument172 pagesUnconventional Aircraft ConceptsJack Azad100% (2)

- Unconventional Aircraft Design MITDocument119 pagesUnconventional Aircraft Design MITJack AzadNo ratings yet

- Aerodynamics of High Subsonic BWB ConfigarationDocument9 pagesAerodynamics of High Subsonic BWB ConfigarationJack AzadNo ratings yet

- Taxilian Wings Final Design Report PDFDocument33 pagesTaxilian Wings Final Design Report PDFAisha ChaudharyNo ratings yet

- NeratorsDocument6 pagesNeratorsimtiyazNo ratings yet

- Aerodynamic Measurements at Low Reynolds Numbers For Fixed Wing Micro-Air VehiclesDocument33 pagesAerodynamic Measurements at Low Reynolds Numbers For Fixed Wing Micro-Air VehiclesPradeep RoyNo ratings yet

- Review of Morphing Aircraft TechnologiesDocument55 pagesReview of Morphing Aircraft TechnologiesJack AzadNo ratings yet

- Aerodynamic Modeling of A Membrane WingDocument236 pagesAerodynamic Modeling of A Membrane Wingmatthew_6No ratings yet

- Distributed PropulsionDocument252 pagesDistributed PropulsionMesay NasirNo ratings yet

- Modelling and Control of The SiMiCon UAVDocument145 pagesModelling and Control of The SiMiCon UAVJack AzadNo ratings yet

- Open Brain Wave Interface Hardware 1Document18 pagesOpen Brain Wave Interface Hardware 1Jack AzadNo ratings yet

- Implementation of UAV Design Into CADDocument147 pagesImplementation of UAV Design Into CADJack AzadNo ratings yet

- Electric TricycleDocument27 pagesElectric TricycleJack Azad100% (1)

- 0408 PDFDocument258 pages0408 PDFRisgam PutraNo ratings yet

- Light Electric Vehicle One Passenger 14mph 21Document18 pagesLight Electric Vehicle One Passenger 14mph 21Jack AzadNo ratings yet

- Large Commercial Case StudyDocument4 pagesLarge Commercial Case StudyJack AzadNo ratings yet

- Build Your Own RC HovercraftDocument16 pagesBuild Your Own RC HovercraftJack AzadNo ratings yet

- How To Radio Control DC Motors CheaplyDocument8 pagesHow To Radio Control DC Motors CheaplyJack AzadNo ratings yet

- Self Repairing AircraftDocument2 pagesSelf Repairing AircraftJack AzadNo ratings yet

- Ducted Fan ThesisVTOhanian2011Document203 pagesDucted Fan ThesisVTOhanian2011pest619No ratings yet