Professional Documents

Culture Documents

Laser Report by Manoj

Uploaded by

manoj_mithunOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Laser Report by Manoj

Uploaded by

manoj_mithunCopyright:

Available Formats

Laser surface treatment

CHAPTER 1

INTRODUCTION

The surface treat to its putting in work or its use ments by laser on the piece confer to the material particular properties adapted to its putting in work or its use. The laser particularly is indicated in the field of the surface treatments in how much allows to obtain high energetic concentrations, and the attainment of elevated skin temperatures in fractions of second, with small thermal alteration of the below material (Bulk) and with negligible Residual deformations. According to the energy density of the incident laser beam, the interaction time, the spatial distribution of the beam and its wavelength and the thermopysical properties of the material. It is possible to obtain various effects on the surface of the piece to treat. So it is possible to obtain as a thermal process type (the quick heating and consequent the fast cooling of the material interested from the passage of the laser beam can provoke, second of the caught up values of temperature on the surface of a material, an heat treatment or a fusion or a vaporization, as a photochemical process type, that removes thin superficial layers of material or coating or other material because of the molecular bond breaking provoked by the absorption of the incident laser radiation.

College of Engineering, Ambajogai

Laser surface treatment CHAPTER 2

LASER CLADDING

Drivers for the laser cladding process include laser beam characteristics, filler material, base material, and thermal properties of the part. The unique capability of laser cladding enables part processing with reduced heat smaller grain structure compared to conventional welding. Applications for laser cladding include depositing a robust surface treatment to salvage and repair used parts. Laser cladding basics include an understanding of the laser light and the interaction of the laser beam with the material. In this article you will be introduced to several of the major components affecting the cladding process. The key components are integrated to form the laser cladding system. 2.1 Process Description

Figure 1 COAX10 in a robot guided 3D cladding system Laser cladding uses the high energy density generated by a laser beam to form a molten pool in a base material for metallurgical bonding with a filler material using a diffusion type of weld. The interaction between the laser beam and the base material is primarily a function of the following properties: 1. Laser beam absorption Absorption of the beam generates the molten zone. A shorter wavelength laser generally absorbs better in metals. 2 College of Engineering, Ambajogai

Laser surface treatment 2. Laser beam reflection Back reflection from the surface of the metal is high. 3. Laser beam transmission For metals, penetration of the laser beam (photons) is low. Absorption of the laser beam results in the heating of the base material. Very high energy densities are possible with a laser. Different material processing results can be achieved with increasing the energy density. The following examples are processes that follow a trend of increasing energy density: a) Surface heating (low energy density) b) Soldering c) Brazing d) Heat treating (surface hardening for appropriate alloys) e) Diffusion welding (low penetration) f) Cladding (diffusion welding plus extra energy for additive mass) g) Keyhole welding (greater penetration) h) Cutting (similar or greater keyhole welding energy density plus coaxial assist cutting nozzle) i) Drilling (generally pulsed beam) j) Ablative material removal (very high energy density) Generally the power, pulse length, and beam quality of the laser determines what material processing techniques are possible. Typical energy densities for cladding or metal deposition range from 104 to 105 watts per square centimeter (W/cm2). Energy densities above 105 W/cm2 result in a keyhole welding process producing larger penetrations than the diffusion process. Diffusion welding of the clad deposit produces a narrow dilution zone between the clad and the base material. A portion of the filler material may be preheated by the laser beam just before wetting into the molten pool. The high energy density enables rapid heating and rapid self-quench times. One of the key advantages of the laser cladding process over conventional welding metal deposition (gas metal arc welding (GMAW) or gas tungsten arc welding (GTAW)) is the smaller dilution zone resulting in a smaller heat-affected zone (HAZ). Figure 2 shows a magnified view through a metallurgical microscope of a laser deposit of 420 stainless powder deposited on 4140 steel. The micro hardness diamond squares show a greater hardness in the deposit (HRC 60+ in the stainless deposit possible). For an example of the reduced heat possible with pulsed laser

College of Engineering, Ambajogai

Laser surface treatment welding see Fig. 3. Laser cladding is similar to laser welding with filler material added to the weld pool. The rapid heating and cooling of a laser welded deposition can result in high hardness being achieved in the deposition

Figure 2 Laser clad deposit of 420 stainless steel on 4140

. Figure 3 Laser beam welding and GTAW visual heat effects.

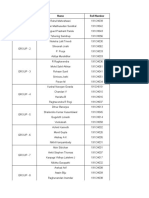

Table 1: Types of lasers used for cladding Laser CO2 Nd:YAG Wavelength 10.6 microns 1.06 microns Beam Quality High Low Beam Delivery Free space Large fiber (typ.0.4-0.6 mm) Fiber 1.07 microns High Small fiber (typ.0.05-0.1mm) Direct diode 0.8-1 microns low Free space (typ.rectangular beam)

College of Engineering, Ambajogai

Laser surface treatment

Figure 4 Diagram of laser cladding beam delivery head.

2.2 Applications With respect to the rising demand within the last years, until now approximately 30 clad-ding units have been developed for users in different branches. Noteworthy examples are the repair of turbine blades and seal fins of gas turbines and aero engines, surface pro-tection of car engine components and wear parts, repair of metal forming tools and mould inserts as well as the direct manufacturing of complex shaped sections of tools. The Figures 5 7 show some of these applications.

College of Engineering, Ambajogai

Laser surface treatment

Figure 5 Cladding of oil drilling tools

Figure 6 Repair of car engine crankshafts

Figure 7 Repair of car engine crankshafts

College of Engineering, Ambajogai

Laser surface treatment CHAPTER 3

LASER COATING 3.1 Introduction

Laser coating is an advanced coating technology for improving surface properties of various components and equipment. Laser coatings are surface coatings with an extremely dense, crack-free and non-porous structure. Laser coatings show excellent metallurgical bonding to the base material, have uniform composition and coating thickness. Laser coating produces also very low dilution and low heat input to the component. Laser coating of new components gives them surfaces with high resistance against wear, corrosion and high temperatures. Besides new manufacturing, the process has shown its importance also in maintenance and repair of worn components, often resulting in component performances superior to those of uncoated ones. Research and development of laser coating processes, properties of coated structures, and industrial applications has been very active during the last years in Finland, primarily due to the rapid development of high power laser technology and recent launching of industrial laser coating activity. Industrial use of laser coatings is expected to increase markedly during the following next years. Table 2: Characteristics of high power lasers for laser materials processing Laser type Property CO2 Nd:YAG lamp-pumped Wavelength (m) Efficiency (%) Power(KW),max Average power density ( W/cm2 ) Service period (h) Fiber coupling No 7 Yes Yes Yes 1000-2000 200 5000-10000 5000-10000 5-10 40 106-8 1-3 5 105-7 106-9 10-12 5 30-50 6 103-5 10.6 1.06 Nd:YAG diode-pumped 1.06 0.8-0.94 HPDL

College of Engineering, Ambajogai

Laser surface treatment High power laser equipment for coating and surface treatment. Several basic properties of lasers make them very useful for a number of industrial applications including laser materials processing. These properties include directionality, monochromaticity, coherence, and high brightness of the laser light. Laser equipment operating with high power levels, i.e. the high power lasers, can produce highly energetic and well focusable laser beams that are usable in marking, drilling, cutting, welding, hardening and laser coating. Table 2 presents the characteristics of different type of high power lasers available for materials processing. Carbon dioxide (CO2) lasers are the most traditional high power lasers and are available in power levels up to several tens of kWs. CO2 lasers have characteristics of very high power and power density, moderate efficiency, reliable operation and excellent beam quality (low beam-parameter product number). The high wavelength of 10.6 m results in a relative low absorption of the laser beam by metals e.g. steels. It is common that an absorption enhancing pretreatment, such as graphitizing of the metal surface, is frequently needed in surface hardening by a CO 2 laser. Solid-state lasers, e.g. Nd:YAG lasers, operate at a still lower wavelength (1.06 m), which markedly improves the absorption characteristics, i.e. the metal surface absorbs now significantly better energy from the Nd:YAG laser beam. However, these lasers operate at significantly lower electrical/optical efficiency, which makes the equipment bulky and costly to run. Fiber coupling of the laser allows the beam to be carried easily through optical fibers from the laser beam supply. 3.2 Laser coating process Among all laser materials processing methods, laser surface engineering is still significantly less used than for example laser marking, cutting or welding. Surface engineering by lasers involves primarily transformation hardening of steels, and laser coating, which is also called laser cladding. Several modifications of laser surface coating and treatment exist. These can be classified as follows: 1. Laser transformation hardening of steels and cast irons 2. Surface modification: remelting (e.g. cast iron), surface alloying, impregnation (e.g. with carbides)

College of Engineering, Ambajogai

Laser surface treatment 3. Laser coating: a) 2-step process: remelting of pre-placed or pre-deposited layer (2-step process, melting/alloying); pre-placed layer of powder,

with/without organic binder b) 1-step process: laser coating with powder or wire; laser coating with coaxial or off-axis powder nozzles 4. Laser assisted hybrid processes a) laser surface cleaning with thermal spraying b) laser assisted thermal spraying; hybrid spraying Principle of laser coating: Transformation hardening is a relatively straightforward process and involves rapid heating of the steel surface to the austenite region, which is then followed by self-quenching to form a martensitic case of high hardness. Laser hardening allows hardening of local well-defined areas, high-intensity local heating and very high self-cooling rates with good hardenability of various ferrous alloys. Laser coating is an overlay deposition process, where the coating material, a powder or wire, is applied on the surface of the base material through a melting process.

Figure 8 Principle of laser coating.

College of Engineering, Ambajogai

Laser surface treatment Figure 9 a) and b) show two different laser coating equipment with co-axial and offaxial powder feeding principles, respectively. In laser coating, a fine powder, e.g. 50150 m in size, is injected with a carrier gas to the laser beam traversing on the surface of the material or component to be coated. The powder absorbs energy from the laser beam, starts heating and melting in-flight, and deposits on the surface of the base material. Part of the energy is also absorbed by the surface causing controlled melting of a thin layer of the base material. This ensures formation of a real metallurgical bonding between the coating and the base material. In laser coating a melt pool of the coating material is formed, which in turn results in coatings without porosity. The mixing between the two materials (coating and base material), i.e. dilution, must be as small as possible to utilize the properties of the coating material most effectively.

a)

b)

Figure 9 a) 6 kW CO2 laser coating with coaxial powder nozzle and b) 6 kW diode laser coating process with off-axis

10

College of Engineering, Ambajogai

Laser surface treatment Table 3 Comparison of thermal spraying, weld surfacing and laser cladding. Coating process property Heat source Combustion flame, electric or plasma arc Bond strength Coating structure Low to moderate Lamellar from porous to nearly dense Heat load to work piece Dilution Coating thickness Coating materials Very low to moderate Nil 0.05-some mms Wide range of metals, alloys, hard metal, ceramics, polymers Productivity Low to high Low to very high Low to moderate Moderate to high Several mm Metals and alloys, alloys with hard particles Low Typically 0.5-3 mm Metals and alloys, alloys with hard particles Very high Low to moderate High Dense, cracks and pores may exist High Dense, cracks and pore-free layers Combustion flame, electric arc High intensity laser radiation Thermal spraying Weld surfacing Laser cladding

3.3 Coating materials and properties:Laser coatings can be prepared on several types of base materials. Most commonly the base materials used are unalloyed steels, alloy steels, hard enable steels, stainless steels, nickel or cobalt based alloys. Also various cast irons can be coated successfully by laser process. Laser coating on copper and its alloys, aluminum alloys and even on titanium alloys have been reported. Laser coating offers a wide range of possible coating materials. Most commonly used laser coatings= are various cobalt base hard alloys, e.g. Stellite 6 and 21, nickel based super alloys, e.g. Inconel 625, self fluxing alloys, e.g. NiCrBSi, and stainless steels. In order to improve the wear resistance, hard carbide particles can be added. Also some hard metals with high carbide contents can be prepared by the laser coating process. Ceramic coatings can also prepared, e.g. Al2O3-TiO2on aluminum alloys.

11

College of Engineering, Ambajogai

Laser surface treatment 3.4 Metals and alloys: Unalloyed and alloy steels Self-fluxing alloys (NiBSi, NiCrBSi, etc.) Stainless steel (AISI 304, 316, 420, etc.) Nickel and nickel based super alloys (Inconel 625, Alloy 59, NiCr,NiCrAl,NiCu, etc.) Cobalt alloys (Stellite 6, 12, 21, Triballoys, Ultimet, etc.) Copper alloys (Aluminum bronze), light metals Carbide containing alloys and composites; ceramics: WC, Cr3C2, TiC, SiC + metal alloys - carbide-metal- blends (max. 50 vol. % carbides) Hard metals WC-Co, Cr3C2-NiCr, TiC-Ni/Co, etc. composites (max 80...90 vol. % carbides) Ceramic/metal - composites Al2O3/Ni, TiB2/CrB2-Ni etc. Ceramics Al2O3-TiO2, Al2O3-ZrO2

Figure 10 Cross section of high chromium Ni-Cr alloy laser coating layer 20 mm wide & 2 mm thick

Figure 11 Micro-structure of high-quality coating a) Stellite 21 b) WC+NiCrBSi Figures 11.a) and 11.b) show examples of laser coatings. Figure 6 shows an optical micrograph (cross-section) of a high chromium Ni-Cr alloy laser coating prepared by the 6 kW HPDL coating process. The laser beam used was 20 mm wide,

12

College of Engineering, Ambajogai

Laser surface treatment the traverse speed 400 m/min and the powder feed rate 100 g/min. By using overlapping, large surfaces can be coating effectively. Figure 4 presents the microstructures of two different laser coatings; Fig.11 a) is an SEM micrograph of a micro structurally dense Stellite 21 coating on steel; Fig.11. b) is NiCrBSi self fluxing alloy coating containing hard WC particles as reinforce- resistant base materials (steels) from corrosion.

. Figure 12 Laser coated by-pass valve spindle

Figure 13 Laser coating of a large shaft sleeve 1.5 m in diameter

13

College of Engineering, Ambajogai

Laser surface treatment

. Figure 14 a) Thermally sprayed coating with several detachment due to heavy corrosion of the coating and the base material beneath the coating,

Figure 14 b) Laser coating of the shaft after removal water (sea water) pump shaft.

Figure 14 c) Laser coated surface ready for post finishing by turning

14

College of Engineering, Ambajogai

Laser surface treatment CHAPTER 4

LASER GLAZING

4.1 Laser Glazing of Railroad Rails:-

Figure 15 Laser glazing of railroad rails Laser glazing treatment is applied on the gage face of the rails to help minimize flange and rail wear, reduce fuel consumption, and decrease the likelihood of derailments caused by flange climb and low-rail rollover. To maintain the toughness and relative inexpensiveness of rail steel while reducing wheel/rail friction, an ideal approach is to modify the loading surface of existing rail in a way that renders it substantially harder yet leaves the substrate unaffected. Laser treatment can accomplish this by changing the surface microstructure, and doing so in such a way that the surface layer undergoes a smooth transition into the substrate and is well bonded to it. One way to harden the surface of rail steel is by laser surface hardening, i.e. selective austenitization and martensitization of the local surface region of rail steel by rapid heating and cooling. The hard surface layer will resist plastic flow and reduce friction and wear. This simple process has some minor disadvantages. Unlike in the case of hard bulk materials, like diamond, o thin hard surface when loaded substantially will transmit these loads to the soft substrate, which can deform even if the surface does not. If the surface layer has the same elastic modulus as the substrate, it can not mitigate stress concentrations any differently than an untreated surface. However, a surface layer with a smaller modulus than the substrate can distribute surface stress concentrations

15

College of Engineering, Ambajogai

Laser surface treatment elastically within the layer and mitigate their effect on the substrate. Also, if the hard surface layer does deform plastically, it will do so in the same manner as untreated rail steel, producing a damage layer along which separation can eventually occur leading to delaminating. What is needed then is a surface layer that is hard with respect to plastic flow is elastically compliant, and, when it does deform plastically, does not produce a damage layer, Laser glazing can be an ideal treatment to achieve this goal.

Figure 16 Micrograph of laser-glazed 1080 steel Figure shows the metal grain structure of the glazed (G), hardened (H) and substrate (S) regions. In laser glazing, a thin surface layer is melted and rapidly solidified to produce an amorphous or quasi-amorphous surface film. The lack of crystalline order in such materials makes them substantially resistant to plastic flow, and hence very hard. They exhibit about a 30% or greater reduction in elastic modulus. If they do deform plastically, localized defects are not involved, and the more open structure tends to be self healing. Consequently, repeated plastic flow is less likely to result in debris being deposited in a subsurface damage layer. For these reasons, the laser glazing process alone is sufficient to provide satisfactory reductions in friction and wear.

16

College of Engineering, Ambajogai

Laser surface treatment CHAPTER 5

LASER SURFACE MELTING (LSM).

In this technique (also known as laser surface remelting or laser glazing) melting is induced in the near surface by relatively high intensity, short duration laser interaction. No additional alloying elements are incorporated. Since the bulk of the material is unaffected by the laser, a large heat sink is provided for the subsequent rapid cooling of the melted surface and cooling rates in the region of lo4-lo8 K.S-' can be obtained. This can result in non equilibrium microstructures which may confer substantial increases in hardness and wear resistance, the application areas which have received the most attention, particularly for steels, cast irons and aluminum alloys. A schematic diagram of the experimental arrangement for LSM treatment is shown in Figure 17.

Figure 17 Experimental arrangement for laser surface melting Enhanced corrosion properties can be produced by LSM as a result of altering the surface composition, changing the microstructure of impurities and second phase. In general the non-equilibrium surface microstructures produced result in finer, more

17

College of Engineering, Ambajogai

Laser surface treatment uniform structures with superior homogeneity compared with conventional surfaces. For example, redissolution of MnS inclusions following LSM resulted in increase in the critical pitting potential of type 304 stainless steel in 0.1 M NaCl solution. Deterioration in resistance to pitting in Mo-bearing ferritic stainless steels at low Mo contents as a result of LSM has been observed. LSM has been applied to sensitized type 304 and type 316 stainless steels.

18

College of Engineering, Ambajogai

Laser surface treatment CHAPTER 6

AUTOMOTIVE - HEAT TREATING AND SURFACE MODIFICATION

Figure 18 Heat Treating And Surface Modification Laser heat treatment and surface modification are the key technologies available today to enhance the effective use of materials and achieve the desired properties of the components used in the automotive industry to improve the performance of the car. The high power heat source produced by a laser beam is ideal for surface modification. Laser heating produces local changes at the surface of the material whilst, leaving the properties of the bulk of a given component unaffected. The principle laser surface engineering applications can be divided into three broad areas. The following processes can also be divided into those relying on metallurgical changes in the surface of the bulk material i.e. transformation hardening, annealing, grain refining, glazing and shock hardening, and those involving a chemical modification to the surface by addition of new material i.e. alloying and cladding. Heating without melting, commonly know as heat-treating. This involves solid-state transformation, so that surface of the metal is not melted. The fraction of the beam power absorbed by the material is controlled by the absortivity of the material surface. Both mechanical (hardness, abrasion, resistance etc.) and chemical 19 College of Engineering, Ambajogai

Laser surface treatment properties, (corrosion resistance etc.) can often be greatly enhanced through the metallurgical reactions produced during these heating and cooling cycles. Heating with melting, i.e. laser glazing, surface homogenization, remelting. This method produces very rapid heating, melting and cooling to modify the surface properties. Melting with addition of material, i.e. cladding, alloying impregnation, which involves melting of the surface plus material added to the surface to form a modified surface layer. The principles of laser heating are similar to those of conventional through heating. The time scales involved in the former are, however, typically an order of magnitude shorter. Whereas heating is conventionally induced by a furnace, flame, arc or induction coil, the laser beam is focused or shaped into a suitable pattern and scanned over the component. The high energy density laser beam heats the surface much more rapidly, reducing the time for conduction into the bulk of the component. Laser heat treatment and surfacing techniques must compete directly with a wide range of comparatively low cost conventional processes and must therefore offer significant advantages. The common advantages of laser surfacing compared to alternative processes are: a) Chemical cleanliness and cosmetic appearance b) No post machining required c) Non-contact process d) Ease of integration The range of alloys that can be transformation hardened by laser techniques covers all those than can be hardened by conventional methods. The response of steel to hardening increases with increasing carbon content, and hardness values have exceeded 700HV for steels containing 0.75% carbon content. In addition because of the high cooling rates plain carbon steel (0.2%C) will harden. The hardenability of cast irons is controlled by the amount of pearlite present, and only martensitic

20

College of Engineering, Ambajogai

Laser surface treatment stainless steels will respond to heat-treating. Transverse section of laser hardened track in low carbon steel. Automotive industry has been responsible for much of the laser heat- treatment process development and some of the applications are listed in below table. Table 4: Applications in automotive industry Industry sector Automotive Automotive Automotive Automotive Automotive Automotive Automotive Component Axel bearing seat Blanking die Engine valve Gear teeth Shaft Piston ring Steering gear housing Material AISI 1035 steel Tool steel Alloy steel Steel Steel Steel Malleable cast iron

21

College of Engineering, Ambajogai

Laser surface treatment CHAPTER 6

CONLUSION

1) Despite outstanding advantages of laser surface treatment techniques for enhancement of corrosion resistance; these techniques are not yet widely employed because of the small area that can be processed in a single pass. Development of large area treatment techniques would dramatically change this situation. 2) A brief review of laser surface melting, laser surface alloying and laser cladding techniques on steel substrates has shown that the potential for the production of corrosion resistant coatings by these means is considerable. 3) A new alloy prototyping technique based on laser cladding via the blown powder technique which has been developed at Liverpool has been outlined. This should provide a valuable tool in work aimed at the development of alloys of enhanced corrosion resistance and other significant materials properties. An advantage of the technique is that deposition parameters via laser surface cladding for any composition within the alloy system in question are simultaneously determined.

22

College of Engineering, Ambajogai

Laser surface treatment

Chapter 7 REFERENCES

1. Anubha Bhatla, Y. Lawrence Yao Department of Mechanical Engineering Columbia University New York, NY 10027

2. Journal De Physique IV Colloque C9, supply Cement au Journal de Physique 111, Volume 3, December 1993

3. Dr. Khansaa Dawood Salman* Received on:5/8/2008 Accepted on:31/12/2008

4. X.b. Zhou and J.Th.M. De Hosson Department of Applied Physics, Materials Science Centre, University of Groningen, Nijenborgh 4, 9742 AG Groningen, The Netherlands.

23

College of Engineering, Ambajogai

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- BHEL Readies Design For 800 MW Plant With Ultra Supercritical ParametersDocument1 pageBHEL Readies Design For 800 MW Plant With Ultra Supercritical Parameterslaloo01No ratings yet

- Practical Exercise 02Document17 pagesPractical Exercise 02FeRro ReniNo ratings yet

- SEMIKRON Material Content Data Sheet SEMITRANS® 2 EN 2019-07-13 Rev-05Document2 pagesSEMIKRON Material Content Data Sheet SEMITRANS® 2 EN 2019-07-13 Rev-05erode els erodeNo ratings yet

- Physics II Problems PDFDocument1 pagePhysics II Problems PDFBOSS BOSSNo ratings yet

- 4.2-Bonding, Structure and The Properties of MatterDocument6 pages4.2-Bonding, Structure and The Properties of MatterGabriel HoNo ratings yet

- School of Chemistry SOP For Operation of Glove BoxesDocument7 pagesSchool of Chemistry SOP For Operation of Glove BoxesharNo ratings yet

- Let Drills Gen Ed General ScienceDocument132 pagesLet Drills Gen Ed General ScienceJoyanne DiwaNo ratings yet

- Photosynthesis and Cellular Respiration NewDocument15 pagesPhotosynthesis and Cellular Respiration NewMaria Valerie BaculiNo ratings yet

- Pump Powered Cocaine Extraction PDFDocument43 pagesPump Powered Cocaine Extraction PDFDaria SchkaNo ratings yet

- Safety Data Sheet For NEBNext End Prep Reaction BufferDocument9 pagesSafety Data Sheet For NEBNext End Prep Reaction BufferNabilahNo ratings yet

- MT Lab Mini Project Groups - 3!2!2022Document6 pagesMT Lab Mini Project Groups - 3!2!2022Pavan ChinnaNo ratings yet

- Stain Resistant FabricDocument4 pagesStain Resistant FabricARCUSNo ratings yet

- Distillation Column Design MethodsDocument4 pagesDistillation Column Design Methodsramu karriNo ratings yet

- Dental Porcelain: by Dr. Tayseer MohamedDocument63 pagesDental Porcelain: by Dr. Tayseer MohamedAnonymous LRPHmxh02No ratings yet

- LIVRO Physical Analysis For TribologyDocument506 pagesLIVRO Physical Analysis For TribologyLuizNo ratings yet

- Castech Rel WB Technical Data Sheet: Description Shelf LifeDocument2 pagesCastech Rel WB Technical Data Sheet: Description Shelf LifeDileepa DissanayakeNo ratings yet

- CSWIP 3.4U - Underwater Inspection ControllerDocument532 pagesCSWIP 3.4U - Underwater Inspection Controllerkirubha_karan200089% (9)

- Emulsion Polymerization and Latex ApplicationsDocument158 pagesEmulsion Polymerization and Latex ApplicationsGemunu Wilson75% (4)

- Why Tight-Binding Theory?: Walter A. HarrisonDocument5 pagesWhy Tight-Binding Theory?: Walter A. HarrisonzoehdiismailNo ratings yet

- G200Document4 pagesG200Gul Hassan Akhunzada100% (2)

- Toward Merging Untargeted and Targeted Methods in Mass Spectrometry-Based Metabolomics and LipidomicsDocument22 pagesToward Merging Untargeted and Targeted Methods in Mass Spectrometry-Based Metabolomics and LipidomicsNadeem AkramNo ratings yet

- Finnish Li Pegmatites PDFDocument88 pagesFinnish Li Pegmatites PDFcrazybearNo ratings yet

- IP4. Separation and Classification of SolidsDocument23 pagesIP4. Separation and Classification of SolidsYzon Aldwin Gundran Balag100% (1)

- 10000-PVC Fabric BpsDocument4 pages10000-PVC Fabric BpsHussain ElboshyNo ratings yet

- Things Your Screw Designer Never-FinalDocument6 pagesThings Your Screw Designer Never-FinalRajesh Kumar100% (2)

- SSC DWDocument4 pagesSSC DWsanketpavi21No ratings yet

- AADE/Fluids Management Group: Advances in Deepwater FluidsDocument15 pagesAADE/Fluids Management Group: Advances in Deepwater FluidsBarry TrettNo ratings yet

- EMA3050 Oct 17Document5 pagesEMA3050 Oct 17Alicina DaleNo ratings yet

- Structural Steel DesignDocument108 pagesStructural Steel DesignMilomir Gavrilovic77% (13)

- Indian & International STDDocument8 pagesIndian & International STDMirza Sameer Ali BaigNo ratings yet