Professional Documents

Culture Documents

Design Catalytic Process For Biofuel Production

Uploaded by

romulussikalitOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Catalytic Process For Biofuel Production

Uploaded by

romulussikalitCopyright:

Available Formats

www.catalysis.

ru

1

UIC

DESIGN OF CATALYTIC PROCESSES FOR

BIOFUELS PRODUCTION

III

RUSNANOTECH 2010

Vadim A. Yakovlev

Valentin N. Parmon

Boreskov Institute of Catalysis

Novosibirsk, Russia

yakovlev@catalysis.ru

www.catalysis.ru

2

UIC

Contents of the Presentation

I. Situation in World concerning renewable and local fuel

sources

II. The innovative catalytic ways of biomass processing for the

energetics within international projects and perspective

directions

II.I. Biofuels from wood

II.II. Improved technology of biodiesel production

II.III. Green diesel production

II.IV. Other perspective directions of biofuels production

III. Answer to a question: Can biomass replace fossil oil and

natural gas as feed stock for motor fuels production or not?

www.catalysis.ru

3

UIC

Source: IEA, WEO, Reference scenario, 2002 and 2007.

The present energy model is based on ever-increasing demand and

the perpetuation of fossil fuels

Mtoe = Million tons of oil equivalent

www.catalysis.ru

4

UIC

Shell international BV, Shell energy scenarios to 2050. 2008

www.catalysis.ru

5

UIC

Present problems of biomass processing into fuels and

energy:

At present biofuels have higher first cost than fossil oil-

fuels and natural gas

The main reasons:

1. High costs of farming, harvest, transport of biomass

2. Lower technological level of biomass processing in

comparison with oil refining

On the whole now the situation in bioenergetics is

similar to the one with oil-refining 90-100 years ago.

www.catalysis.ru

6

UIC

Source: New Energy Finance

Bioenergy Technology Pathways

www.catalysis.ru

7

UIC

Biofuel pathway costs

Roberto Rodriguez Labastida, BTL investment trends and levelled costs of production, Bloomberg New

Energy Finance (2010).

Note: The final biofuel product from each pathway, and its associated conversion cost, has been

compared with the energy content of a litre of gasoline.

- Feedstock Cost - Conversation Cost - Capital Cost

Gasoline

www.catalysis.ru

8

UIC

Contents of the Presentation

I. Situation in World concerning renewable and local fuel

sources

II. The innovative catalytic ways of biomass processing for the

energetics within international projects and perspective

directions

II.I. Biofuels from wood

II.II. Improved technology of biodiesel production

II.III. Green diesel production

II.IV. Other perspective directions of biofuels production

III. Answer to a question: Can biomass replace fossil oil and

natural gas as feed stock for motor fuels production or not?

www.catalysis.ru

9

UIC

Biomass

Pyrolysis

plant

Biomass

Pyrolysis

plant

Biomass

Pyrolysis

plant

Standard

Refinery

Upgrader

Biomass

Pyrolysis

plant

Transportation fuels

Chemicals

Heat and power

Schematic representation of the biomass-pyrolysis-upgrading-refinery concept

www.catalysis.ru

10

UIC

Fractionation

during and

after

condensation

Biomass

residues

Co-processing in

conventional

petroleum refinery

De-oxygenation

Hydrocarbon-rich fraction

Lignin-rich

fraction

Conversion

Derivatives of hemicelluloses

and celluloses

Conventional fuels

and chemicals

Liquefaction

Note: hydrocarbon-rich fractions are formed when the biomass feedstock contains a

significant amount of extractive substances; e.g the case for forestry residues.

Energy

production

Process

residues

Oxygenated products

(blending)

role of BIC

Netherlands BTG, University of Twente, Shell Global Solutions

International, University of Groningen, Albemarle Catalysts Co.

Finland VTT, Helsinki University of Technology

France CNRS-IRC, ALMA Consulting Group, Metabolic Explorer

Germany - Ineos-Phenolics, UHDE, Institute of Wood Chemistry Hamburg

United Kingdom - Johnson Matthey

Sweden - STFI-PACKFORSK

Slovenia - Slovenian Institute of Chemistry

Russia - Boreskov Institute of Catalysis

List of BIOCOUP project participants

Tasks of BIC within the project

Development of bio-oil deoxygenation catalysts

www.catalysis.ru

11

UIC

What is bio-oil?

Liquid (bio-oil)

Upgraded biocrudeoil

HDO

H

2

catalysts

up to 70 mass %

to dry biomass

Dry Biomass

Flash pyrolysis

T > 450

0

C, t < 1 s,

heating rates > 1000

0

C

The main disadvantages of bio-oil:

Very viscous

Unstable (readily polymerized)

Poorly evaporated

Immiscible with ordinary fuels

Strongly acidic (=3)

Because of high content of oxygen

C 30-60 %

30-60 %

H 6 - 7 %

N <1 %

Up to 30 % of H

2

O

Elemental composition:

so, bio-oil has to be upgraded in order to

improve its quality as a fuel

www.catalysis.ru

12

UIC

LMM Lignin:

Catechols, lignine

derived phenols and

guaiacols (~ 13%)

OH

R

OH

R

Acids (~4%)

C R

O

OH

C R

O

OH

C

O

HO

Aldehydes,

Ketones, Alcohols

( ~ 15%)

Sugars (~34%)

HMM Lignin (~ 2%)

dehydration ( H

2

O)

hydrogenolysis ( H

2

O)

decarbonylation ( CO)

decarboxylation ( CO

2

)

decarboxylation ( CO

2

)

cat

T

cat

T, H

2

cat

T, CO

cat

T

cat

T

Upgrading of Bio--Crude--Oil via Catalytic Deoxygenation

www.catalysis.ru

13

UIC

Hydrodeoxygenation catalysts development

as key step of HDO process development

Traditional catalysts for

hydrodeoxygenation (HDO):

1. Sulfided Ni-Mo/Al

2

O

3

, Co-Mo/Al

2

O

3

2. Pd, Pd-Pt, Rh-based catalysts

These catalysts dont fit

for bio-oil upgrading:

- Noble catalysts are very

expensive for large-scale

processes

- Sulfided catalysts are

deactivated in target process

Prices of HDO catalysts active metal

from the year 1996 to 2010.

Conclusion: catalysts have to be cheaper and non-sulfided

Rh $2250

Pt $1703

Pd $625

Ru $178

Ni $ 0,62

1996 1998 2000 2002 2004 2006 2008 2010

0

2000

4000

6000

8000

10000

Rh, Pt, Pd, Ni - http://www.kitco.com

Ru - http://www.platinum.matthey.com

U

S

$

/

T

r

o

y

o

n

c

e

Year

Rh

Pt

Pd

Ru

Ni

www.catalysis.ru

14

UIC

Catalysts screening

Active metal Support

Ni-Mo, Co-Mo sulf.,

Ni-Mo, Co-Mo ox.,

Ni-Mo-Mn, Ni-Mo-Mg,

Rh, Pd, Pt, Rh-Co, Ni,

Co, Cu, Ni-Cu, Co-Cu,

Fe-Cu

Al

2

O

3

, SiO

2

, C-SiO

2

, Al

2

O

3

- SiO

2

, Cr

2

O

3

,

CeO

2

, ZrO

2

, CoSiO

3

Step 1: Screening of HDO catalysts

Catalysts

Rh/CoSiO

3

Rh/ZrO

2

Rh/ CeO

2

LHSV, h

-1

0,5 1,0 0,4

Anisole conversion (%) 82,0 99,6 99,9

HDO degree (%) 79,2 90,8 94,3

HDO tests results:

Catalysts

RhCo/Al

2

O

3

Rh/SiO

2

RhCo/SiO

2

LHSV, h

-1

0,3 0,3 0,3

Anisole conversion (%) 98,2 53,4 99,0

HDO degree (%) 74,7 30,3 81,1

Reaction conditions:

Substrate: anisole

Temperature: 300

o

C

Pressure

H2

: 0,5 MPa

LHSV: 6 h

-1

Reactor type: flow fixed-bed

www.catalysis.ru

15

UIC

Catalysts screening and comparison with the commercial catalysts

Catalyst

S/Ni-Mo/Al

2

O

3

(Albemarle)

IC3-47

(BIC)

Ni/ Cr

2

O

3

(Chirchik)

Rh/CoSiO

(BIC)

H

2

pressure, MPa 0,5 0,5 0,5 0,5

Temperature,

0

C 300 300 300 300

LHSV, h

-1

0,6 6 6 0,5

Conversion, % 92,8 78,6 90,2

82,0

HDO degree, % 15,4 95,9 15,7

79,2

% 100

'

=

i

i

i

i

C

C

HDO

i

C'

i

C

HDO degree corresponds to the selectivity of hydrogenated products formation:

- the concentration of oxygen-free i product

- the concentration of i product

Ni/ Cr

2

O

3

Benzene hydrogenation into

cyclohexane

S/Ni-Mo/Al

2

O

3

Oil hydrotreating

Step 2: Ni-based catalysts

www.catalysis.ru

16

UIC

Catalysts screening and comparison with the commercial catalysts

Catalyst

S/Ni-Mo/Al

2

O

3

(Albemarle)

IC-3-47

(BIC)

Ni/ Cr

2

O

3

(Chirchik)

Products

selectivity, %

cyclohexane 8,5 24,3 9,5

benzene 6,2 59,9 6,2

toluene 1,9 2,9 0

phenoles 70,3 0 0

cyclohexanole 0 2,3 81,7

cyclohexanone 0 1,8 2,6

other products 13,1 2,9 0

OH

OH

desired

product

Step 2: Ni-based catalysts

www.catalysis.ru

17

UIC

System NiCu/ Al

2

O

3

Catalyst

metal, % wt.

support

Cu Ni

24.5Cu 24,50 - Al

2

O

3

5.92Ni18.2Cu 18,20 5,92 Al

2

O

3

13.3Ni11.8Cu 11,80 13,30 Al

2

O

3

13.8Ni6.83Cu 6,83 13,80 Al

2

O

3

16Ni2Cu 2,00 16,00 Al

2

O

3

20.8Ni -- 20,80 Al

2

O

3

Catalyst conversion,% HDO, %

Quartz 2,8 0

Al

2

O

3

11,8 0

24.5Cu 95,3 1,0

5.92Ni18.2Cu 76,9 72,8

13.3Ni11.8Cu 70,3 82,8

13.8Ni6.83Cu 73,8 90,6

16Ni2Cu 78,6 95,9

20.8Ni 66,1 97,8

HDO tests results:

Cu loading into nickel on alumina catalysts increases

the selectivity of hydrogenated aliphatic products

(cyclohexane, methylcyclohexane) formation against

the aromatic products (benzene, toluene)

Spec.cat.activity

molh

-1

g

-1

0,66

0,30

0,34

0,33

0,22

Step 3: Optimization of Ni-Cu catalysts composition

www.catalysis.ru

18

UIC

In-situ XRD analysis of NiCu/ Al

2

O

3

system

(under the hydrogen atmosphere, heating up to 300

)

Support (o-Al

2

O

3

) lattice parameter vs. Ni content

(%, wt.) in the catalyst

Ni ions diffuse into the alumina structure with

formation of the solid solution

Lattice parameter of metallic nickel differs

from the PDF card value

Formation of the solid solution Ni

1-x

Cu

x

Step 3: Optimization of Ni-Cu catalysts composition

www.catalysis.ru

19

UIC

System NiCu/ Al

2

O

3

TPR analysis

(thermo-programmed reduction)

1. The presence of copper

promotes the nickel oxide

reduction at a lower

temperatures.

2. The addition of copper

into Ni/Al

2

O

3

promotes

the decrease of the

surface Ni Al solid

solution content in the

samples.

Step 3: Optimization of Ni-Cu catalysts composition

www.catalysis.ru

20

UIC

Conception of bifunctional nature of HDO catalysts

First type (I) of active component hydrogen activation

(noble metals, nickel, cupper et al.)

Second type (II) of active component oxy-organic activation

(transfer metals in reduced or oxidized forms with variable valence at

HDO reaction conditions)

www.catalysis.ru

21

UIC

48MGeneral Assembly

38

RUG-Results Highlight

Exploratory Catalyst Screening

Pyrolysis oil, 350

o

C, 200 bar H

2

, 4 h. Catalysts provided by BIC/TKK/ALBE

NiCu catalysts are potential for further development

0.00

10.00

20.00

30.00

40.00

50.00

60.00

P

i

n

e

o

i

l

R

u

/

C

5

w

t

%

R

u

/

C

3

.

3

3

w

t

%

R

u

/

C

2

w

t

%

+

a

c

t

P

d

/

C

P

d

P

t

/

S

i

O

2

-

A

l

2

O

3

(

A

lb

e

)

R

h

/

C

e

O

2

R

h

/

Z

r

O

2

R

h

/

C

o

S

iO

3

R

h

/

Z

r

O

2

R

h

P

d

/

Z

r

O

2

R

h

P

t

/

Z

r

O

2

P

d

/

Z

r

O

2

P

d

P

t

/

Z

r

O

2

P

t

/

Z

r

O

2

N

i

C

u

/

A

l

2

O

3

F

e

C

u

/

A

l

2

O

3

N

i

C

u

/

Z

r

O

2

N

i

C

u

/

C

e

O

2

(

c

o

)

N

i

C

u

/

C

e

O

2

(

w

e

t

)

N

i

C

u

/

C

N

i

C

u

/

C

e

O

2

-

Z

r

O

2

c

r

a

c

k

i

n

g

(

N

i

C

u

/

d

-

A

l

2

O

3

)

c

r

a

c

k

+

N

i

C

u

/

C

e

O

2

-

Z

r

O

2

N

i

C

u

/

s

i

b

u

n

i

t

e

N

i

C

u

/

C

e

O

2

Catalyst

O

x

y

g

e

n

c

o

n

t

e

n

t

(

w

t

-

%

)

noble metals

cheaper transition metals

:

flowable products at RT

www.catalysis.ru

22

UIC

Contents of the Presentation

I. Situation in World concerning renewable and local fuel

sources

II. The innovative catalytic ways of biomass processing for the

energetics within international projects and perspective

directions

II.I. Biofuels from wood

II.II. Improved technology of biodiesel production

II.III. Green diesel production

II.IV. Other perspective directions of biofuels production

III. Answer to a question: Can biomass replace fossil oil and

natural gas as feed stock for motor fuels production or not?

www.catalysis.ru

23

UIC

Problems:

- Low quality of biodiesel

- a lot of waste at the production

1. Improved Technology of Biodiesel Production

Application:

as additives (5-20%) to traditional diesel

Plant oils + Methanol Glycerine + Biodiesel

Homogeneous

catalyst

H

2

SO

4

or

NaOH

Traditional technology:

Manufacture of biodiesel:

more than 12 million tons in 2009

Prediction:

biodiesel production growth ~10-15% per year

O

O H

2

C

O

O

HC

O

O H

2

C

R

1

R

2

R

3

CH

3

OH

OH H

2

C

OH HC

OH H

2

C

O

O H

3

C

R

www.catalysis.ru

24

UIC

Why heterogeneous catalysts?

1. Cleaner process

2. Zero soap production

3. Recovery of the catalysts is reusable

4. Cleaner Biodiesel

5. Cleaner Glycerol (99% against 75-80%)

Affordability:

reduction of process cost

2 - 2,1 times

heterogeneous systems

dont form soap during the reaction,

reduce the generation of effluents, no corrosion,

simplify the purification of by products,

facilitate the separation of biodiesel from the reaction media

and also allow the recovery of the catalyst by filtration,

allow regenerate the catalysts by washing with solvents,

oxidation or thermo treatment,

purity of the glycerinic phase obtained after the

alcoholysis reaction.

disadvantages

deactivation and/or lixiviation of the catalysts

usage, the increase in of the time reaction, higher molar ratio

of alcohol/fatty material.

www.catalysis.ru

25

UIC

Technological scheme of biofuels production

(within RG project).

R1

MeOH

Rectifying

column

R2

H2O

CH4

Combustion,Q

Rapeseed

oil

Hydrogen

Glycerin

Green

Diesel

240

0

2,0 P

340

0

4,0 P

20% RO

30% BD

20% RO

80% BD

Peculiarities of processes:

- Conjugation of interesterification and hydrocracking processes

- Incomplete conversion of rapeseed oil (up to 80%)

- 50% biodiesel + 50% green diesel

Biodiesel

50% to consumer

Methanol

www.catalysis.ru

26

UIC

Technological scheme of biofuels production

(within RG project) Interesterification.

R1

MeOH

Rectifying

column

R2

H2O

CH4

Combustion,Q

Rapeseed

oil

Hydrogen

Glycerin

Green

Diesel

240

0

2,0 P

340

0

4,0 P

20% RO

30% BD

20% RO

80% BD

HC

H

2

C

H

2

C O

O

O

R

1

O

R

2

O

R

3

O

+ CH

3

OH

H

+

OH

-

HC

H

2

C

H

2

C

OH

OH

OH

+ H

3

C

O

R

O

T=60

0

C

Peculiarities of process:

- Heterogeneous catalyst

- One step of interesterification

- Conditions: 240

0

, 2.0 P,

- trickle-bed reactor employment

Biodiesel

50% to consumer

Methanol

www.catalysis.ru

27

UIC

Development of heterogeneous catalysts for plant

oils interesterification

Heterogeneous basic catalysts : MAl

12

O

19

(M = Ca, Sr, Ba),

so-called hexaaluminates

Cristal structure - magnetoplumbit and |-Al

2

O

3

Advantages of hexaaluminates

Chemical stability

Thermal stability

Possibility of catalysts regeneration

www.catalysis.ru

28

UIC

Development of heterogeneous catalysts for plant oils

interesterification

rapeseed oil

, % Sr-La-O > Ba-La-O > Y-Mg-O La-Mg-O > Ba-Al-O

700

> Sr-Al-O

700

2240-2251cm-1

, mol/m

2

2.23 1.77 1.55 1.35 1.21 1.16

0 2 4 6 8 10

0

20

40

60

80

100

R

a

p

e

s

e

e

d

o

i

l

c

o

n

v

e

r

s

i

o

n

,

%

Reaction time, hours

Sr-Al-O (700)

Sr-Al-O (1200)

Ba-Al-O (700)

Ba-Al-O (1200)

Y-Mg-O (750)

La-Mg-O (750)

Sr-La-O (750)

Ba-La-O (750)

Concentration of middle base centers (determined via vibrational C-D

frequencies (v(CD)) of CDCl

3

adsorbed on samples) is correlated with activity of

catalysts

www.catalysis.ru

29

UIC

Contents of the Presentation

I. Situation in World concerning renewable and local fuel

sources

II. The innovative catalytic ways of biomass processing for the

energetics within international projects and perspective

directions

II.I. Biofuels from wood

II.II. Improved technology of biodiesel production

II.III. Green diesel production

II.IV. Other perspective directions of biofuels production

III. Answer to a question: Can biomass replace fossil oil and

natural gas as feed stock for motor fuels production or not?

www.catalysis.ru

30

UIC

Technological scheme of biofuels production

(within RG project). Hydrodeoxygenation

R1

MeOH

Rectifying

column

R2

H2O

CH4

Combustion,Q

Rapeseed

oil

Hydrogen

Glycerin

Green

Diesel

240

0

2,0 P

340

0

4,0 P

20% RO

30% BD

20% RO

80% BD

Biodiesel

50% to consumer

Methanol

H

3

C

O

R

O

H

2

Cat

Alkanes

Peculiarities of process:

- Heterogeneous catalyst

- One step of hydrocracking

- Conditions: 340

0

, 5.0 P,

- trickle-bed reactor employment

www.catalysis.ru

31

UIC

Hydrodeoxygenation of biodiesel :

Structure of biodiesel:

Methyl ether of linolenic acid

(

19

33

2

) 8 %

Methyl ether of linoleic acid

(

19

35

2

) 20%

Methyl ether of oleic acid

(

19

37

2

) 59%

Methyl ether of erucic acid

(

23

45

2

) 3%

Methyl ether of stearic acid

(

19

39

2

) 10%

1 2

3

2

3

1

2

3

- Plant oil

- Biodiesel

- Green diesel

www.catalysis.ru

32

UIC

Hydrodeoxygenation of biodiesel in the

presence of nickel catalysts

250 275 300 325 350 375 400

20

30

40

50

60

70

80

90

100

,

%

,

0

C

Ni-Cu/CeO

2

-ZrO

2

Ni-Cu/ ZrO

2

Ni-Cu/ CeO

2

Ni / ZrO

2

Ni/ CeO

2

CeO

2

-ZrO

2

250 300 350 400

0

4

8

12

16

20

Y

(

C

H

4

/

b

i

o

d

i

e

s

e

l

)

Temperature,

0

C

P =1,0

LHSV=2 h

-1

1. Ni-Cu/ZrO

2

-CeO

2

is the most active catalyst of hydrodeoxygenation of biodiesel

2. Process of the methanization begins at temperature 280

0

with nickel catalysts,

addition copper moves the beginning of the methanization in high temperature zone

Temperature

C

o

n

v

e

r

s

i

o

n

o

f

b

i

o

d

i

e

s

e

l

,

%

www.catalysis.ru

33

UIC

Hydrocarbons

1. High-cetane diesel components production from biodiesel

Biodiesel

Mild

Hydrocracking

Bio-hydrogen

C

12

-C

17

diesel

Peculiarities:

Using of non-sulfided

and Ni-based catalysts

Process conditions:

290-340

o

C, 3,0-8,0 MPa H

2

Cetane value - 100

Application

Employment as

improved additive to

traditional diesel

O

O H

2

C

O

O

HC

O

O H

2

C

R

1

R

2

R

3

O

O H

3

C

R

Plant oils

www.catalysis.ru

34

UIC

Products of fatty acids triglycerides hydrocracking at

the mild conditions (0,5 MPa H

2

)

Alkanes

C

7

-C

19

Carbonic acids

Aldehydes

Methyl esters of fatty acids

Alcohols

Ketones

Wax

products +

4

+

2

+

2

O C

O

R

O C

O

R

O C

O

R

R OH

R C

O

H

R C

O

CH

3

R C

O

R

R C

O

OR

R C

O

OCH

3

R C

O

OH

www.catalysis.ru

35

UIC

Activity of Ni-Cu/CeO

2

-ZrO

2

at the severer conditions

(

2

=7,0 P =360

0

, LHSV= 1,1 h

-1

)

Y = mole

4

/ mole TGs C

15

- C

18

alkanes yields

0 2 4 6 8 10 12 14

0

5

10

15

20

Y

,

[

m

o

l

e

/

m

o

l

e

]

Time (h)

0 2 4 6 8 10 12 14

0

10

20

30

40

50

60

70

80

90

100

Y

i

e

l

d

s

o

f

C

1

5

-

C

1

8

,

m

o

l

.

%

Time (h)

0 4 8 12 16 20 24 28

0 4 8 12 16 20 24 28

www.catalysis.ru

36

UIC

Possible scheme of non-food renewable feedstock

processing for biofuels production

Jatropha oil

Algae

Biodiesel

Green diesel

Transetherification

Mild hydrocracking

+ CH

3

OH

+ CH

3

OH

+ H

2

+ H

2

www.catalysis.ru

37

UIC

The most perspective directions for transportation biofuels production

(for diesel engine )

Biomass

Wood

Solid

bio-waste

Bio-oil

Plant oil

Fats

Algae

Liquid

Bio-waste

Gasification

+

2

Shift

Bio-H

2

Mild

hydrocracking

Green Diesel

Oil

(problem: high content of sulfur)

Merits:

Renewable

Low content of sulfur

Possibility of fuels

production with different

composition

Transetherification

Biodiesel

www.catalysis.ru

38

UIC

Yearly Energy TW yr Ej

Solar Energy to Earth 178000 5500000

Adsorbed by Atmosphere 120000

Adsorbed by Earth 53000 3700000

Adsorbed by Terrestrial 16000

Terrestrial Photosynthesis (<1%) 128 ~4000

Available for Biomass

Conversion

46 ~1426

Energy Demand Today 14 ~430

Energy Demand in 2050 >30 600-1800

Estimates Biomass in 2050 100-350

TW= Tatra Watts year/year Ej= Exa joules (=10

18

joules)

Supply of Biomass Today Versus the Total Global

Energy Requirement

www.catalysis.ru

39

UIC

The conception of renewable energetics in the field

of development of fuel production processes

Concerning social aspect

Initial feedstock should be from non-food economics sector

Concerning provision aspect

Economic of biomass accretion is sufficient .

Concerning ecological aspect

Technology has to be power efficient and ecological

Concerning commercial aspect

Technologies have to be competitive (without development of new

technologies it is not possible)

www.catalysis.ru

40

UIC

Thank you very much for

your attention !

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

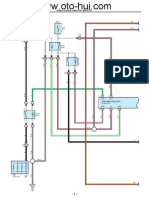

- Wiring Diagram ECU 2KD-FTVDocument13 pagesWiring Diagram ECU 2KD-FTVDam Nguyen87% (95)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Making Sense Your Project Cost EstimateDocument5 pagesMaking Sense Your Project Cost Estimateromulussikalit100% (1)

- Biodiesel Handling and Use GuidelinesDocument68 pagesBiodiesel Handling and Use GuidelinesromulussikalitNo ratings yet

- 2nd Biofuel Market PDFDocument49 pages2nd Biofuel Market PDFromulussikalitNo ratings yet

- Refinery PDFDocument22 pagesRefinery PDFromulussikalitNo ratings yet

- Bio Fuels Blending & Technology PresentationDocument62 pagesBio Fuels Blending & Technology PresentationDaniel KunnigerNo ratings yet

- Unit Conversion SI UnitsDocument6 pagesUnit Conversion SI UnitsJhanvi Rao NarayanaNo ratings yet

- Biofuels Markets Targets PDFDocument49 pagesBiofuels Markets Targets PDFromulussikalitNo ratings yet

- Refinery PDFDocument22 pagesRefinery PDFromulussikalitNo ratings yet

- 2nd Biofuel Policies PDFDocument57 pages2nd Biofuel Policies PDFromulussikalitNo ratings yet

- Refinery PDFDocument22 pagesRefinery PDFromulussikalitNo ratings yet

- Biofuels Markets Targets PDFDocument49 pagesBiofuels Markets Targets PDFromulussikalitNo ratings yet

- Biofuels Markets Targets PDFDocument49 pagesBiofuels Markets Targets PDFromulussikalitNo ratings yet

- Biofuels Markets Targets PDFDocument49 pagesBiofuels Markets Targets PDFromulussikalitNo ratings yet

- ApphDocument2 pagesApphravindranathchitturiNo ratings yet

- Second-Generation Biofuels: Policy Research Working Paper 5406Document57 pagesSecond-Generation Biofuels: Policy Research Working Paper 5406romulussikalitNo ratings yet

- Complications of FractureDocument7 pagesComplications of FractureChedan B. Ceriaco100% (1)

- A Picture of JesusDocument295 pagesA Picture of JesusLee WalserNo ratings yet

- Well-To-Wheels Analysis Advanced Fuel Vehicle SystemDocument238 pagesWell-To-Wheels Analysis Advanced Fuel Vehicle SystemromulussikalitNo ratings yet

- ApphDocument2 pagesApphravindranathchitturiNo ratings yet

- Second and Third Generation BiofuelsDocument13 pagesSecond and Third Generation Biofuelsguru9anandNo ratings yet

- Third Generation Biofuel Vs Direct FermentationDocument19 pagesThird Generation Biofuel Vs Direct FermentationromulussikalitNo ratings yet

- Complications of FractureDocument7 pagesComplications of FractureChedan B. Ceriaco100% (1)

- WTO Disciplines BiofuelsDocument44 pagesWTO Disciplines Biofuelshowserob100% (2)

- Method of Predicting N Optimizing Production PIMSDocument13 pagesMethod of Predicting N Optimizing Production PIMSromulussikalitNo ratings yet

- Learning About The of Nghi Son Refinery: Rude Istillation NitDocument17 pagesLearning About The of Nghi Son Refinery: Rude Istillation NitTrường Tùng LýNo ratings yet

- Crude TBP Country Africa Distillation: Brass RiverDocument1 pageCrude TBP Country Africa Distillation: Brass RiverAngelo Danny VelascoNo ratings yet

- Victorian Brown Coal Fact SheetDocument4 pagesVictorian Brown Coal Fact SheetMindfk GsNo ratings yet

- Bionic LeafDocument7 pagesBionic LeafAsad Saeed100% (1)

- 465Document18 pages465Mabel SanhuezaNo ratings yet

- MC DE - EEC Form 4B AEUR Industrial DEs_v2.0_0 (1)Document9 pagesMC DE - EEC Form 4B AEUR Industrial DEs_v2.0_0 (1)penapple51No ratings yet

- Coal Analysis ParameterDocument21 pagesCoal Analysis ParameterYuliyanti YuliyantiNo ratings yet

- Hydrogen Fuel Engine-Ppt AbstractDocument7 pagesHydrogen Fuel Engine-Ppt AbstractVijay RaghavanNo ratings yet

- Fuel Pressure Regulator Removal GuideDocument26 pagesFuel Pressure Regulator Removal GuidecjtovarNo ratings yet

- LPG Market OutlookDocument8 pagesLPG Market OutlooksyaefNo ratings yet

- (Rearrange The Letters To Make One Word) : Settler Activity: Solve The AnagramDocument48 pages(Rearrange The Letters To Make One Word) : Settler Activity: Solve The AnagramMuhd Syahmi Afif CamadNo ratings yet

- Topic 4.1 E.SDocument2 pagesTopic 4.1 E.SPrecious GalanNo ratings yet

- Coal and Petroleum Assignment Class 8 CBSE ScienceDocument1 pageCoal and Petroleum Assignment Class 8 CBSE Sciencegurdeepsarora8738100% (1)

- SulfurDocument8 pagesSulfurAndreeduis RodriguezNo ratings yet

- Shell Gas Compressor Oil S4 PN 220 TDS - UnlockedDocument2 pagesShell Gas Compressor Oil S4 PN 220 TDS - UnlockedOmer IkhlasNo ratings yet

- Ankur Biomass Gasifier SystemsDocument2 pagesAnkur Biomass Gasifier Systemsamu_cbe1443No ratings yet

- Prospects of Sustainable BiofuelsDocument5 pagesProspects of Sustainable BiofuelsSuhufa AlfarisaNo ratings yet

- Lingga, Chapter 11 From Indonesia Post Pandemic Outlook Energy FINALDocument27 pagesLingga, Chapter 11 From Indonesia Post Pandemic Outlook Energy FINALaurizaNo ratings yet

- 18 Inch Gas Pipeline Data PDFDocument2 pages18 Inch Gas Pipeline Data PDFAliZenatiNo ratings yet

- 2019 Scott ICOPDocument4 pages2019 Scott ICOPGregorSmithNo ratings yet

- IOCL-Mathura Overall Brief DescriptionDocument6 pagesIOCL-Mathura Overall Brief DescriptionAshwani KumarNo ratings yet

- Petroleum Refining by Bhaskara Rao PDFDocument5 pagesPetroleum Refining by Bhaskara Rao PDFPritesh DarjiNo ratings yet

- Advances in Methanol SynthesisDocument6 pagesAdvances in Methanol SynthesisManuel Angel AlvaNo ratings yet

- SeaoilDocument16 pagesSeaoilMo NassifNo ratings yet

- P&ID Additive Injection SkidDocument4 pagesP&ID Additive Injection SkidOctavianus Harahap100% (3)

- Coal & Petroleum Revision WorksheetDocument2 pagesCoal & Petroleum Revision Worksheettheedshanna uthayakumarNo ratings yet

- Biofuels Assignment 1Document6 pagesBiofuels Assignment 1Arturo Salazar100% (1)

- Assignment 1 PRPC 6th SemDocument1 pageAssignment 1 PRPC 6th SemKaushal BaldhaNo ratings yet

- Biogas in Romania PDFDocument10 pagesBiogas in Romania PDFNicolici FlorianNo ratings yet