Professional Documents

Culture Documents

Model C-320

Uploaded by

carmenlove123Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model C-320

Uploaded by

carmenlove123Copyright:

Available Formats

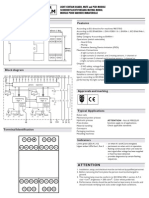

1.- Specifications and Features 1.

1 electrical and Mechanical Specifications Input AC: 100-130 VAC, 50/60 HZ Back-up Battery: 12V/4AH Maximum Total Output:160 W Stand-by Output: 5W Motor Consumption: 100W Warning Light Consumption: 25 W Electric Latch Consumption: 20W Photo sensor Consumption: 5W Working Temperature: -20~55C Dimensions and Weight: 300x245x90mm,4.5Kg 1.2 General Features Single or dual gate application With emergency drive capacity when there is a outage Two kinds of time difference set-up for master and slave gates close 31 kinds of time set-up modules of auto-close (0~155 seconds) Single or Dual gates operation individually Two operation methods: by hand and by the transmitter. Compatible with several remote operation modes Remote antenna for receiving is applicable Users do no need to reprogram the system even if there is on power supply With system recovery function Compatible with other infrared safety devices Programmable with other infrared safety devices The control box judges the limit position of the system by the overcurrent protection reaction

Auto-reverse safety protection function when hitting something The warning light is flashing when it is powered Intellectualized Latch Control We provide 2m and 7m motor cables, and users do not need to connect other cables

2.- System Allocation 2.1 System Minimum Allocation 2.1.1 Control Box Minimum Allocation C-320 PBC: 1pcs Transformer: 1pcs Wire connection terminal of the transformer: 1pcs Control box case kit: 1pcs Recovery switch module: 1pcs

Allocation Function: without remote function /without emergency drive function when there is a outage.

2.1.2 Operating System Minimum Allocation Motor for single gate: 1pcs Keystroke Control Box: 1pcs

Allocation Function: minimum control system for single gate, without electric latch/without flashing warning light/without infrared sensor safety protection function.

2.2 Alternative system Allocation 2.2.1 Control Boxs Alternative allocation 12V/4AH Lead-Acid Storage Battery: 1 pcs

Function: for emergency usage when the system is in a outage. Dip Switch type Transmitterx1~15pcs and non-decoded receiver modulex1pcs

Function: Providing system stability with safer remote operation. Rolling Code type Transmitterx1~15pcs and non-decoded receiver modulex1pcs

Function: Providing system stability with safest and most economical remote operation. Rolling code type transmitter with receiving and emitting components, transmitterx1~15pcs and decoded receiver modulex1pcs

Function: The safest and the most expensive remote operation, providing the best system stability.

2.2.2 Operating Systems Alternative Allocation Motors for dual gates, with 7m cable 1pcs and 2m cables 1pcs

Function: install dual motors, and you can operate either single gate or dual gate. Electric Latch: 1pcs

Function: Intellectual Electric Latch Warning Light kit: 1pcs

Function: Indicating working status of the motors and providing early warning function Photo Bean Sensor (receive and emit): 1set

Function: Infrared detecting function provides the system with safety and protection. Key selector: 1pcs

Function: you can use the key to open and close the gate. Antenna set: 1pcs

Function: For receiving remote signal from far distance.

3. Wire Connection 3.1 Two Installation Methods of the Gate (1) Pull to open A: as Diagram 3.1

Diagram 3.1 Pull to Open

(2) Push to Open B: as Diagram 3.2

Diagram 3.2 Push to Open

3.2 Wire Connection 3.2.1 Wire Connection Diagram Please follow Diagram 3.3 for wire connection.

Table 3.1 the function of DIP-SW

SW No.

Status

ON/OFF

Function

The gate stops then rebounds/stops without rebound, when the Photo sensor is blocked and its function is enable during the gates running; the 1 switch of DS11 must be used associating with 2 & 3 switch of DS11 below

3 4 5 6 7 8 9

2 OFF ON OFF ON

10

The function of Photo sensor is disabled The function of Photo sensor is disabled when the gate is closing The function of Photo sensor is disabled when the gate is opening The function of Photo sensor is enabled when the gate is closing and opening 80 seconds effective/ineffective ON/OFF 40 seconds effective/ineffective ON/OFF 20 seconds effective/ineffective ON/OFF 10 seconds effective/ineffective ON/OFF 5 seconds effective/ineffective ON/OFF The time of gate auto-closing is the Sum of the time of the Dip Switch which is effective, the auto-closing function is ineffective when all of 5 Dip Switch is OFF The delayed start-up time between the master and slave gate is 4 ON seconds The delayed start-up time between the master and slave gate is 2 OFF seconds If the trip of the slave gate is father than the master gate, during the dual gates closing phase, it is possible that the master gate arrives to the end first to block the slave gate even if the slave gate starts to close ahead for 4 seconds. This moment the system will adjust the delayed seconds automatically, and the delayed seconds are not the same as the above-mentioned set-up seconds. Turn the Bit to ON position for over 5 seconds (T1 and T2) the turn it to OFF position to clear the memory of the transmitter. Turn the Bit to ON position less than 5 seconds then turn it to OFF position to set up the memory of the transmitter, Turn it to OFF position in normal use.

3 OFF OFF ON ON

3.2.2 Wire Connection Description (1) Connect the cable of the master gate to MM, connect the white wire with +, connect the black wire with -, the latch should be installed on this gate; (2) Connect the cable of the slave gate to SM, connect the white wire with +, connect the black wire with -, you dont need to connect SM in single gate installation. (3) Connect the wire of the electric latch and the warning light to the PCB of the control box (despite the positive or negative electrode). (4) Make sure to connect the infrared photo sensor +12V output in the right position; (5) The control box will not be worked if the output connection of the infrared photo sensor is wrong, please exchange the NO with the NC terminal of the infrared photo sensor; (6) The antenna with remote function is attached to the control box, if you need farther remote operation, please exchange the concealed antenna with outside-plugged antenna set; (7) This connection diagram A is for pull-to-open installation; Push-to-open installation is the same as this diagram B, exchange the white wire with the black wire of the motor.

Attention: please connect the black-up battery and the transformer to the PCB in the final step

4.- SYSTEM SET-UP

4.1 Description of the Transmitter Buttons Press the button of the transmitter for about 0.2~0.5 seconds each time to make the transmitter work; If the transmitter is out of order, please change a new battery and try again.

4.1.1 Dip switch type Transmitter1 If you get the dip switch type transmitter (Transmitter1) The same as Diagram 4.1, then

(1) Press the red button to operate dual gates (2) Press the yellow button to operate single gate

4.1.2 Rolling Code Type Transmitter2 If you get the rolling code type transmitter without decoded module (Transmitter2) the same as Diagram 4.2, then (1) Button A=Button B, for dual gates operation (2) Button C=Button D, for single gate operation;

4.1.3 Rolling Code Type Transmitter3 If you get the rolling code type transmitter with decoded module (Transmitter3) the same as Diagram 4.3, then (1) Press the black button to operate dual gates (2) Press the green button to operate single gate.

4.2 Operation of the Transmitter

4.2.1 Set-Up of the transmitter The transmitter has to be followed the learning process first then operates the compatible control box.

(1) The learning of Transmitter1 and Transmitter2 Press S12 (L11 is on) no longer than 5 seconds or turn the tenth switch of DS11 (marked 10) from OFF to On position no longer than 5 seconds and turn to OFF position again, and this time L11 will flash for 10 times, during L11 flashing period, press any key of the transmitter 1 or transmitter 2, L11 is off for one second, then flash for 3 times, that means this transmitter is successfully learned and can be compatible with the control box; otherwise the transmitter is not successfully learned, you can try it again. One control box can be compatible with 15 transmitters, if this transmitter is set up successfully, you want to set up other transmitters, L11 will not flash for three times after it is off.

(2) The Learning of Transmitter3 Press S12 (L11 is on) no more than 10 seconds, then L11 is on (for 30 seconds), when L11 is on, press any button of the transmitter3 for over 0.5, then L11 will be off right away, that means a successful learning, L11 is not off results in a learning failure. Please try again if there is a learning failure. One control box can be compatible with 15 transmitters.

4.2.2 Clearance of the Transmitter Memory All the transmitters cant operate the control box after the following operation. (1) The clearance of Transmitter1 and Transmitter2 Press S12 for over 5 seconds or turn the tenth switch (marked 10) of DS11 from OFF to ON(L11 is on) for over 5 seconds and turn it to OFF position again, L11 will be off for 1 second and flash for 3 times means a successful clearance of the transmitter memory. ATTENTION: if you press S12 less than 5 seconds and release the button, or turn the tenth switch (marked 10) of DS11 from OFF to ON(L11 is on) less than 5 seconds and turn it to OFF position again, this moment L11 will flash for 10 times and go out automatically, this moment the transmitter memory is not cleared, please execute the above-mentioned procedures again to clear the transmitter memory after L11 is off. (2) The Clearance of Transmitter3 Press S12 (L11 is on) for over 10 seconds that will make the clearance of transmitter.

SPECIAL ATTENTION. Be sure to turn the tenth switch of DS11 to OFF position after the system is learned or cleared.

4.3 SYSTEM LEARNING 4.3.1 Clearance of the System Memory The following procedure is necessary especially in your installation and in the system learning progress. Press S11 (SYS Clear) for over 5 seconds, the stored learning memory will be cleared.

4.3.2 Learning Set-up of Dual Gate Memory

If you install dual gates, please execute dual gates set-up progress; the warning light will flash quickly during the system learning progress. Step 1: Clearance of the system memory (Turn all the switches of DS11 to OFF position); Step 2: Press the dual gate operation button of the control box or press the dual gate operation button of the transmitter; Step 3: The slave gate will be closed first this moment, if the slave gate is in close position the system will execute the following step, otherwise press the dual gate button to stop the system operation right away; If the system executes to open the slave gate, please exchange the wire connection of SM and execute Step2. If the slave gate is in an open position and the system executes to close the master gate, please exchange the cables of MM with SM with the same wire connection and execute Step2 again; If the slave gate is in an open position and the system executes to open the master gate, please exchange the cables of MM with SM and exchange the black wire with the white wire connection then execute Step2 again.

Step 4: The system executes to close the master gate, if the master gate is in the closed position then the system will execute the following step, otherwise please press the dual gate button to stop the system operation right away; If the master gate is in an open position and the system executes to open the master gate, please exchange the cables of MM with SM with the same wire connection and execute Step2 again;

Step5: The gate will be closed first and the latch pin will be pulled up; Step6: The master gate will be opened to the end at full speed; Step7: The slave gate will be opened to the end at full speed; Step8: The slave gate will be closed to the end at full speed; Step9: The master gate will be closed to the end at full speed; the warning light stops quick-flashing, dual gates set-up is finished successfully; the system will not memorize this learning trip until the trip memory is cleared coercively.

ATTENTION: During the learning progress, the gate will be stopped if you press any button (not included S12) and result in a learning failure, please execute Step2 for repeating the learning progress; if the gate hits against

something in the middle of the moving process, that will result in an erroneous learning process, please do the dual gates set-up progress again and omit Step1 process; Be sure to cut off all the power supply (included the back-up battery) if you want to exchange the wire connection, please execute the wire connection after one minute of the power supply cut-off; After dual gates set-up is finished, press the dual gates button to operate dual gates, press the single gate button to operate single gate, see the following SYSTEM CONTROL description.

4.3.3 Learning Set-up of Single Gate Memory If you only install one gate, you have to connect this gate to the master motor s wire terminal, please operate by the following descriptions of single gate setup; the warning light will flash quickly during the set-up progress. Step1: Clear the trip memory (Turn all DS11 switches to OFF position); Step2: Press the single gate operation button of the control box or press single gate operation button of the transmitter Step3: The gate will be closed first this moment, if the gate is in close position the system will execute the following steps, if the system executes to open the gate, press the single gate button to stop the system operation right away; cut off all the power supply (included the back-up battery), exchange the black wire with the wire of the motor after one minute; execute Step2; Step 4: The gate will be closed first and the latch pin will be pulled up; Step5: The gate will be opened to the end at full speed; Step6: The gate will be closed to the end at full speed; the warning light stops quick-flashing, the single gate set-up is finished successfully; the system will not memorize this learning trip until the trip memory is cleared coercively. Users can execute the single gate learning progress even they install dual gates, the slave gate will not be operated during the single gate learning progress. ATTENTION: If users only install single gate and press dual gate button for setting up the learning progress that will result in a learning failure, this moment the warning light will keep flashing. At this moment press any button of the transmitter to stop and restart to proceed the system learning progress by the abovementioned instruction, user dont need to follow the procedure of Step1 again when they restart to procedure the system learning progress.

If the single date learning progress is finished, users can operate the gates by all the buttons of the transmitter, see the following description of the system control.

5.- SYSTEM CONTROL

1) If the gates stops, press the button and the gate will start to go again; If the gate is moving, press the button and the gate will stop; In dual gates operation, the single gate button works when the slave gate is in the final position, then you can operate the master gate by the single gate button; In single gate operation, the function of single gate button and dual gates button is the same; 2) If the gate is in fast-moving progress and hitting against something; the gate will stop and reverse for one second; the gate is defined in the middle position; If the gate is in slow-moving progress and hitting against something; the gate will stop and will not reverse; the gate is defined in the final position. 3) If the photo sensor is activated during the gates moving progress, the gate is possible to stop or reverse, see the description of DS11 set-up; the gate is defined in the middle position when the photo sensor stops the gates moving progress; 4) The gate is defined in the middle position when its moving is stopped by the press of the transmitter. 5) If the gate is activated again in the middle position, the gate will move slowly toward the opposite direction to the end of the final position then the gate could be operated normally. 6) In dual gates operation, if the gate is activated to close from the middle position, the slave gate will move to the full-closed position, and the master gate will move to the full-closed position; 7) In dual gates operation, if the gate is activated to close from the final position, the master and slave gate will delay for a certain time for opening and closing, see DS11 set-up description. 8) If the gate is activated from the final position, the gate will move fast and move slowly when it reaches of the total trip, then to the final position; 9) The warning light will flash for one second before each start-up, the warning light flashes quickly when the gate is moving fast, the warning

light flashes slowly when the gate is not moving fast, the warning light will not flash when the gates stops; 10) When the gate stops in full-opened position, the auto-close set-up will be activated, see auto-close set-up of DS11 description diagram in Table 3.1; then you can execute the single gate and dual gates operation, your operation will cancel the auto-close set-up; 11) In dual gates installation , the single gate button works only when the slave gate is in the final position, in this situation only the master gate works. 12) If a power failure (means no AC power and no back-up battery) occurs and the system gets power supply again or turn off the switch on the case of the control box then turn it on, users dont need to start the learning progress again, in this situation users press the button and the gate will close in the first movement, users could operate the gates normally when the gates reach to the full-closed position.

ATTENTION: 1) The final position means the gate is in full-opened or full-closed position; others are referred as the middle position; 2) The manual dual gate button of the control box has the function of clearing the system trip memory, dont press this button for 2 seconds otherwise the gate will stop see 4.3.1 Clearance of the System Memory; 3) Press the button of the transmitter for about 0.2~0.5 second and you can operate it with no problem (dont press the button slightly and release quickly).

6.- MAINTENANCE

1) Dont connect the wire in the control box to other application 2) Please apply AC input to the system when operating system-learning process. 3) Dont leave the system without AC input for over 10 hours. Dont use the back-up battery for operation over one hour. 4) Dont leave the back-up battery unused for over three months, please connect the back-up battery to the control box for charging if it is left unused for over three months.

5) Dont open the control box or alter the wire connection randomly if you are not professionals; 6) Please take the transmitter with you and keep it properly. Dont press the button of the transmitter for a long time. 7) Keep the control box and all the accessories clean and clear; keep them away from the sunshine and the fire.

If you have any questions or problems during usage or you have any suggestions to this product, please contact with the dealer or agent for further assistance.

You might also like

- Sliding Gate Motor Installation Manual: DTS 500 ExpertDocument15 pagesSliding Gate Motor Installation Manual: DTS 500 ExpertAndrás TóthNo ratings yet

- Dts Eco 500: Sliding Gate Motor Installation ManualDocument8 pagesDts Eco 500: Sliding Gate Motor Installation ManualFrancois VaaltynNo ratings yet

- Dts Eco 500: Sliding Gate Motor Installation ManualDocument8 pagesDts Eco 500: Sliding Gate Motor Installation ManualFrancois VaaltynNo ratings yet

- Powertech Pc160 Manual enDocument8 pagesPowertech Pc160 Manual entecnicogato27No ratings yet

- Kapija BenincaDocument5 pagesKapija BenincaMica Ivanovic100% (1)

- Quick Program Sheet For DTS 500 Expert.: ProgrammingDocument5 pagesQuick Program Sheet For DTS 500 Expert.: ProgrammingFrancois VaaltynNo ratings yet

- Acer PDFDocument16 pagesAcer PDFVasile RotaruNo ratings yet

- Motor Za Kliznu Kapiju Detaljno Upustvo Za MontažuDocument10 pagesMotor Za Kliznu Kapiju Detaljno Upustvo Za MontažuSrdjanv5No ratings yet

- F24 60manual (New)Document14 pagesF24 60manual (New)Robert CumpaNo ratings yet

- DWB100het en PhpnWwESrDocument2 pagesDWB100het en PhpnWwESrLuis Alberto MayorNo ratings yet

- D1 Swing Gate Control Board ManualDocument9 pagesD1 Swing Gate Control Board ManualjohnNo ratings yet

- Quick Program Sheet For DTS 512/624: Dipswitch Selections To Activate A FunctionDocument4 pagesQuick Program Sheet For DTS 512/624: Dipswitch Selections To Activate A FunctionIanNo ratings yet

- 1 Channel Power Relay Module With Adjustable Timing Cycle HW 521Document4 pages1 Channel Power Relay Module With Adjustable Timing Cycle HW 521AmitKumarAgrawalNo ratings yet

- Ppa Central Facility ConnectDocument15 pagesPpa Central Facility ConnectgustavoNo ratings yet

- Roller 230 enDocument4 pagesRoller 230 enillemariusNo ratings yet

- Centurion D5 Gate Motor ProgrammingDocument2 pagesCenturion D5 Gate Motor ProgrammingDebraJonesNo ratings yet

- Module Characteristics and UsesDocument4 pagesModule Characteristics and UsesArturs ZedeksNo ratings yet

- Orangerx Taranis Manual 4Document6 pagesOrangerx Taranis Manual 4Demon KingNo ratings yet

- Installation ManualDocument9 pagesInstallation ManualDenis RaudseppNo ratings yet

- Pal Tronic 50Document28 pagesPal Tronic 50Denis Baljak75% (4)

- DMX Strobe: User GuideDocument6 pagesDMX Strobe: User GuidebackvlackoNo ratings yet

- 30A BLDC ESC Product Manual PDFDocument9 pages30A BLDC ESC Product Manual PDFPePe Eduardo Mendoza EstradaNo ratings yet

- Te208 enDocument4 pagesTe208 enMarian Ariciuc100% (3)

- XMTG 7000 Programmer User Manual PDFDocument17 pagesXMTG 7000 Programmer User Manual PDFCường Mchw100% (1)

- TMKCDocument13 pagesTMKC142919ashutoshNo ratings yet

- Ab MSR22LM PsdiDocument12 pagesAb MSR22LM PsdichnanduNo ratings yet

- INTELLIswitch993 Instruction SheetDocument2 pagesINTELLIswitch993 Instruction SheetsegasharkNo ratings yet

- XY-WJ01 Programmable Relay: DescriptionDocument5 pagesXY-WJ01 Programmable Relay: DescriptionandreiNo ratings yet

- Sony XM Zr602Document20 pagesSony XM Zr602Josue AlbaNo ratings yet

- SW280 User ManualDocument10 pagesSW280 User ManualPetre MarianNo ratings yet

- Sentry Manual 403 Bin 1 3Document1 pageSentry Manual 403 Bin 1 3Yousuf RagieNo ratings yet

- PC160 Merik Home Access Home DepotDocument8 pagesPC160 Merik Home Access Home DepotIsaac SantoyNo ratings yet

- Vek M2HDocument2 pagesVek M2HChu QuynhNo ratings yet

- HW25A30ADocument2 pagesHW25A30AclauderayNo ratings yet

- LRX 2102R ++ GBDocument5 pagesLRX 2102R ++ GBbrunozoNo ratings yet

- E1 - E1A - E1Box - E1FDocument14 pagesE1 - E1A - E1Box - E1FDarek SlonskiNo ratings yet

- Time Delay Relay Module XY-J02: Product FeaturesDocument4 pagesTime Delay Relay Module XY-J02: Product FeaturesDaniel BauerNo ratings yet

- CC !"#$ % & ' +) ,-.' ' +) , - c3'4/!!1564243) B@"Document7 pagesCC !"#$ % & ' +) ,-.' ' +) , - c3'4/!!1564243) B@"Kamrujjaman SakiNo ratings yet

- Instrukcja XT 546 - WWW - Ebmia.plDocument3 pagesInstrukcja XT 546 - WWW - Ebmia.plAwdhesh Singh BhadoriyaNo ratings yet

- User Manual of AE-20A、 25A、 30A Electronic Speed Controller (ESC)Document4 pagesUser Manual of AE-20A、 25A、 30A Electronic Speed Controller (ESC)avolaarNo ratings yet

- Avionic User Manual For Aircraft Esc Ver2Document2 pagesAvionic User Manual For Aircraft Esc Ver2nopeNo ratings yet

- AC6 Dual Motor Controller Instruction ManualDocument10 pagesAC6 Dual Motor Controller Instruction ManualderbalijalelNo ratings yet

- F25-60 Industrial Remote Controller: Lee's Hi-Tech Enterprise. Co., LTDDocument8 pagesF25-60 Industrial Remote Controller: Lee's Hi-Tech Enterprise. Co., LTDrahimsoltaniNo ratings yet

- Viper 4806v Install GuideDocument2 pagesViper 4806v Install Guidejllaredo0% (2)

- Manual Saga 1l10 1l12 PDFDocument25 pagesManual Saga 1l10 1l12 PDFJESUSCALVILLO100% (1)

- ICM 450 InstallationDocument2 pagesICM 450 InstallationRay RavelNo ratings yet

- Sony - XM-ZR604-Ver. 1.1 2007. 08 Car Audio Amplifier SMDocument24 pagesSony - XM-ZR604-Ver. 1.1 2007. 08 Car Audio Amplifier SMRoger Martínez Bermúdez100% (1)

- Control Keyboard: User ManualDocument28 pagesControl Keyboard: User Manualanser123459No ratings yet

- Gemini 7561 PDFDocument9 pagesGemini 7561 PDFwww_lili_pulpaNo ratings yet

- Sony XM 552zrDocument20 pagesSony XM 552zrAndres RaymondNo ratings yet

- Sentry 4 Zone Alarm Panel: User ManualDocument8 pagesSentry 4 Zone Alarm Panel: User ManualpeterNo ratings yet

- Pump Control Model FPC 30010Document4 pagesPump Control Model FPC 30010vstojnicNo ratings yet

- Model 800+ Platinum With Alarm: Manual Automatic TransmissionDocument6 pagesModel 800+ Platinum With Alarm: Manual Automatic TransmissionkokoNo ratings yet

- Cellsecure E12 Nuska Product User ManualDocument30 pagesCellsecure E12 Nuska Product User ManualCellSecure IndonesiaNo ratings yet

- Model736T InstallDocument2 pagesModel736T Installrst1205No ratings yet

- F3 9000 EngDocument7 pagesF3 9000 Engjohn_kyrNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Infineon SPP - I - A15N60C3 DS v03 - 03 EN 53478Document15 pagesInfineon SPP - I - A15N60C3 DS v03 - 03 EN 53478Jeferson TorresNo ratings yet

- Administrator's Guide For Oracle Internet DirectoryDocument820 pagesAdministrator's Guide For Oracle Internet Directorygleen lewisNo ratings yet

- CharCoat CC - Cable Coating - Fireproof Coating - Cable RepairDocument5 pagesCharCoat CC - Cable Coating - Fireproof Coating - Cable RepairnaveedfndNo ratings yet

- Multicolumn Blast Valve PV-KKDocument2 pagesMulticolumn Blast Valve PV-KKyousufbashaNo ratings yet

- Fast Company-All Issues: Home Stories Newspapers CouponsDocument6 pagesFast Company-All Issues: Home Stories Newspapers Couponsketoan viki mediaNo ratings yet

- 2023 GIST Undergraduate Admission GuideDocument28 pages2023 GIST Undergraduate Admission GuideZubia NazNo ratings yet

- PV Elite: System RequirementsDocument10 pagesPV Elite: System RequirementsasmarNo ratings yet

- SPE 11579 Improved Well Stimulation With Resin-Coated ProppantsDocument8 pagesSPE 11579 Improved Well Stimulation With Resin-Coated ProppantsbayuNo ratings yet

- Suasana Sekolah Bari Raya-Score and PartsDocument17 pagesSuasana Sekolah Bari Raya-Score and PartsoAeonNo ratings yet

- ContentsDocument8 pagesContentsabdallh452112No ratings yet

- Cricket Database ManagementDocument19 pagesCricket Database ManagementRaj Bangalore60% (5)

- HostsDocument1 pageHostsThet Aung Moe50% (2)

- Chatbots: Bank of AmericaDocument8 pagesChatbots: Bank of AmericarohinNo ratings yet

- Introduction To LinuxDocument17 pagesIntroduction To Linuxسليمان الشمريNo ratings yet

- Plantech Industries Company Deck v1Document19 pagesPlantech Industries Company Deck v1Nemanja RadićNo ratings yet

- Ipses d2xx Usermanual enDocument27 pagesIpses d2xx Usermanual enLojze MiškovičNo ratings yet

- Solved Problem - Critical Path MethodDocument6 pagesSolved Problem - Critical Path MethoddyingasNo ratings yet

- FOI Finder - Rev01Document90 pagesFOI Finder - Rev01Muhammad Fahmmi Bin MahmudNo ratings yet

- Data Flow DiagramDocument8 pagesData Flow DiagramCha AcuezaNo ratings yet

- Lecture 2Document98 pagesLecture 2pushpendra singhNo ratings yet

- Upload A Document For Free Download Access.: Select Files From Your Computer or Choose Other Ways To Upload BelowDocument2 pagesUpload A Document For Free Download Access.: Select Files From Your Computer or Choose Other Ways To Upload BelowMasoud MonjeziNo ratings yet

- KEI - Cable List Price - April 2021Document5 pagesKEI - Cable List Price - April 2021smithNo ratings yet

- Tekapur Pistolska Mega 65 Zimska enDocument2 pagesTekapur Pistolska Mega 65 Zimska enEzeval GráficaNo ratings yet

- Bard - Site Rite - Ultrasound-EnDocument42 pagesBard - Site Rite - Ultrasound-EnVicNo ratings yet

- Iso 17637 VTDocument15 pagesIso 17637 VTИван ИвановNo ratings yet

- Maxtest SoftwareDocument47 pagesMaxtest SoftwareGMAR Comercializadora100% (1)

- Wfa - Metric - Tube FittingsDocument75 pagesWfa - Metric - Tube FittingsandywanderNo ratings yet

- SIngle Crystal Technology and Turbines, Lecture NotesDocument2 pagesSIngle Crystal Technology and Turbines, Lecture NotesPatrick BatemanNo ratings yet

- SAVA LEAFLET A4 EN TyresDocument2 pagesSAVA LEAFLET A4 EN TyresFilipposNo ratings yet

- Gen Math Rational FunctionsDocument20 pagesGen Math Rational FunctionsMGrace P. VergaraNo ratings yet