Professional Documents

Culture Documents

Completion Equipment Reliability Database Well Master SPE63112-Paper

Uploaded by

vjourOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Completion Equipment Reliability Database Well Master SPE63112-Paper

Uploaded by

vjourCopyright:

Available Formats

SPE 63112 Application of a Completion Equipment Reliability Database in Decision Making

Einar Molnes, ExproSoft and Geir-Ove Strand, SINTEF Petroleum Research

Copyright 2000, Society of Petroleum Engineers Inc. This paper was prepared for presentation at the 2000 SPE Annual Technical Conference and Exhibition held in Dallas, Texas, 14 October 2000. This paper was selected for presentation by an SPE Program Committee following review of information contained in an abstract submitted by the author(s). Contents of the paper, as presented, have not been reviewed by the Society of Petroleum Engineers and are subject to correction by the author(s). The material, as presented, does not necessarily reflect any position of the Society of Petroleum Engineers, its officers, or members. Papers presented at SPE meetings are subject to publication review by Editorial Committees of the Society of Petroleum Engineers. Electronic reproduction, distribution, or storage of any part of this paper for commercial purposes without the written consent of the Society of Petroleum Engineers is prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of where and by whom the paper was presented. Write Librarian, SPE, P.O. Box 833836, Richardson, TX 75083-3836, U.S.A., fax 01-972-952-9435.

potential benefits which can be drawn from such databases. Some industry cases are now established which have demonstrated the cost saving potential of such databases. Examples of applications of reliability data are: Risk and reliability studies LCC/LCP analysis Tender evaluations and purchasing decisions Rig contracting strategies Incentive based contract definitions Downhole barrier acceptance criteria definitions

Abstract A study (JIP) on reliability of well completion equipment (Wellmaster Phase III) was completed by SINTEF in November 1999. This has resulted in a comprehensive database on well completion equipment, with a total of 8000 well-years of completion experience represented and more than 1000 downhole failures included, given as input from the 16 funding oil companies of this JIP. The database represents all categories of downhole equipment, from tubing hanger level down. The paper points towards the major contributors to well interventions and downtime, indicating industry average and benchmark failure rates of the most vital completion components. A historical evolution in reliability of Subsurface safety valves (SCSSV) is demonstrated, and the industry wide effect of reliability improvements is shown through specific examples. In the North Sea, reliability data has gained widespread acceptance for use in decision making. The paper lists several cases where reliability data of downhole equipment has been used with a major impact on field development and subsequent operational expenditures.

Cautiously defined and consistent reliability data collection requirements is a prerequisite for successful 1 reliability databases. The new ISO 14224 standard constitutes a valuable reference in this context. The Wellmaster Phase III project objective has been to contribute to improvement in completion equipment reliability through systematic collection, analysis and feedback of reliability data to participating oil companies and equipment manufacturers. The main deliverable from the project has been the new Wellmaster data collection software for completions with an integrated analysis tool, an updated database on completion equipment and reliability statistics and a 2 summary report on main findings. Data analysis has focused on in-service equipment failures, defined as failures occurring from 6 days after landing the tubing hanger on the wellhead. Failures occurring prior to that are defined as installation failures, and a fair amount of these failures have also been reported. All failure reported are also listed in a webapplication where the Wellmaster JIP member companies have access.

1. Introduction Reliability data has gained widespread use in the offshore business due to industry studies like OREDA, Wellmaster and others. The introduction of statutory codes and regulations in a number of oil producing countries has also strongly accelerated this development. During the last decade, offshore industry managers have become increasingly aware of the

EINAR MOLNES AND GEIR-OVE STRAND

SPE 63112

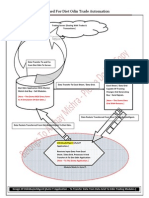

Work process description By means of the Wellmaster software, a completion schematic is built to represent the completion configuration and give details on the equipment in the well. Failure data are captured directly via this schematic by pointing at the failed item and entering detailed data. Failure modes unique to each item are predefined and can be selected when entering information on new failures. In this way, a comprehensive and consistent database can be generated. An integrated processing package is then used to prepare a range of different reliability reports from the database (MTTF, failure mode distribution, MTTW, run time distributions etc.). Upon reporting of failure data, an e-mail connection can be established with the manufacturer with the possibility for the manufacturer to feed back information on the likely cause of equipment failure. Well and equipment performance data is normally collected by the operating company itself, or through assistance from a contractor. The data is then checked for consistency and quality in accordance with the agreed data collection requirement. Upon data quality compliance, the data are merged into a master database, which in turn is fed back to the contributing member companies on CD-ROMs. A subset of the data (equipment failure data) can be viewed by the JIP member companies in a dedicated Internet browser, WellWatch. The different steps of the data collection, QA and data feedback cycle is shown in Figure 1.

but a significant amount of data from water injectors and gas/condensate producers are also included. A breakdown of well type vs. well service time is shown in Figure 3. With respect to completion type, the data are dominated by data from fixed offshore platforms (79.6 %), but a considerable proportion also exists for subsea completed wells (11.4 %). The remaining data are from TLP wells (6.1 %) and onshore wells (2.9 %).

2. Case histories (benefits) Heidrun TLP The first TLP (Tension Leg Platform) on the Norwegian continental shelf was installed in Saga Petroleum's Snorre field. The production risers for the Snorre TLP are fitted with passive fire protection. The decision to use passive fire protection on the risers was based on detailed regulations issued by the Norwegian Petroleum Directorate (NPD) and a series of risk analyses performed by Saga Petroleum. In 1992, the NPD issued the new risk analysis 3 regulations . These regulations state that a risk analysis should be performed for all major potential risks associated with offshore field development and operation. The results from the analysis shall be measured against risk acceptance criteria which have to be pre-defined by the operating oil company. If the risk level as demonstrated by the risk analysis is below the pre-defined acceptance criteria, the results from the risk analysis may in some cases override the requirements given in more detailed regulations concerning certain safety systems. The Heidrun platform is the 2nd TLP installation on the Norwegian Continental shelf. For this development, several risk analyses were performed which addressed the need for passive fire protection of the risers. SINTEF was requested to do a 3rd party verification of these studies, in order to produce input to the final decision concerning the issue of fire protection of the Heidrun risers. The decision point in these risk analyses was the blowout escalation risk, i.e the risk that a blowout on one of the oil production wells would escalate to additional wells - thus jeopardizing the entire Heidrun TLP. The blowout escalation risk is directly related to the rate of critical failures of the downhole safety valve (DHSV/SCSSV). In the 3rd party verification study, a review and update of the studies with the latest reliability data for SCSSVs

Database contents The Wellmaster database is currently the most comprehensive completion equipment database worldwide, with participation from 16 major oil companies in Phase III. Key figures on the database scope are as follows: More than 71000 completion string items represented in equipment database A total of 1002 equipment failures included for a total of 5 different completion equipment categories A total of 1613 wells with 1921 completions are included, representing a total of some 8000 completion-years of experience

The majority of data in the Wellmaster database is from the North Sea. Figure 2 illustrates the data distribution by region. In Phase III, a fair amount of data from the Gulf of Mexico has also been added, whereas earlier project phases have included almost exclusively North Sea data. The database is dominated by data from oil producers,

SPE 63112

APPLICATION OF A COMPLETION EQUIPMENT RELIABILITY DATABASE IN DECISION MAKING

was performed. This clearly indicated that the blowout escalation risk for the Heidrun TLP was within the predefined acceptable level. This led to an approval from the NPD to develop the Heidrun field without passive fire protection of the TLP production risers. This led to a cost saving of minimum NOK 750 million (ca USD 120 million) for the Heidrun TLP when compared to the Snorre TLP. Without the availability of updated and recognized, independent SCSSV reliability data this cost saving would not have been achieved.

U.K., with a study underway in Australia as this paper is written. In the authors opininon, there is no general answer to this question. This issue has to be addressed on the basis of local/regional regulations concerning requirements on external protection of subsea wellheads and x-mas trees and the risk picture (dropped object risk, trawlboard impact risk and other potential external damage factors). Studies have also been performed where nonconventional completion configurations have been studied, typically on removal of annulus safety systems from gas lifted wells.

Alternative SCSSV leakage acceptance criteria 4 A paper presented earlier this year summarized the findings from a study which has looked at alternative leakage acceptance criteria for SCSSVs. The basis for the widely used API RP 14B was reviewed and compared with an alternative method to define acceptance criteria (leak rate levels). This alternative method utilizes principles from risk and reliability analysis to suggest a systems oriented approach for primary and secondary barriers (the x-mas tree master valve and the SCSSV) in combination - rather than looking at these items on an isolated basis. Rather than applying the API RP 14B criteria for all well types, the paper suggests the use of a matrix with recommendations on well type specific risk levels and corresponding acceptance criteria. Compared to todays practice, this implies a certain relaxation of acceptance criteria without compromising the overall safety level. This is achieved through increasing the test frequency whenever a situation arises in which one of the main barriers (PMV/SCSSV) has failed according to the existing API RP 14 B criteria. The direct implication of this is that considerable cost savings can be achieved during the wells lifetime. The cost saving potential is greatest for subsea producers, due to the high cost of interventions. The results from the work described in this paper are now carried forward and implemented into a new NORSOK standard for risk based acceptance criteria for SCSSVs. This standard will be applicable for the Norwegian Continental Shelf, but can also be applied internationally. The standard is expected to be ready by the end of 2000.

2. Results The Wellmaster Phase III project extended previous historical data provided by SINTEF. The Ekofisk Bravo blowout in Norway in April 1977 paved the way for a collective effort on improvement of safety levels for Norwegian offshore installations and was the basis for SINTEFs initial reliability study on SCSSVs which was published in 1983. Since then, an unbroken chain of historical data on performance of both SCSSVs and other completion equipment data has followed. Figure 4 illustrates the historical evolution in SCSSV reliability. A significant improvement in SCSSV performance has resulted, from an initial Mean Time to Failure (MTTF) of 14.2 years (1983) to the most recent result of 36.7 years (1999). This represents a tremendous boost in well production availability and availability of the SCSSV as a safety barrier. Morever, downhole reliability data has become an important instrument in communication with interpretation of auhorities rules and regulations in many offshore regions around the world. The challenge for many operators is the time lag from demonstration of performance improvement to revisions of governmental regulations. A distinct trend in well completions is the increased preference towards the use of single rod piston, flapper type tubing retrievable safety valves without equalizing feature. This trend towards design standardization is paying off when looking at this purely from a SCSSV reliability and well intervention standpoint. However, as a result of the reduction in piston area, the control pressure needs to be increased. This has some negative effects for subsea completions, with high control umbilical pressures, increased probability of hydraulic leaks in control pods, subsea hydraulic connections and other. High completion equipment reliability is particularly important for subsea completed wells, particularly in

SCSSV removal from subsea completions? A hot issue over the last 1-2 years involving extensive use of completion and subsea equipment reliability data in risk analysis is the issue of SCSSV removal from subsea completions. Studies have been performed on this issue in Brazil, Gulf of Mexico (through) and in the

EINAR MOLNES AND GEIR-OVE STRAND

SPE 63112

deep waters. This is illustrated by some examples from the North Sea, which were reported in the Wellmaster Phase III project: Well A experienced a failure (leakage in closed position) of the TR-SCSSV in June 1995. Upon failure diagnosis of the well, a tubing to annulus communication due to a leaking GLV was noted. The well was shut down and a subsea workover followed. Due to problems with rig availability and production allocation restraints, the well was off production until October 1996. During the workover, the failed GLV was replaced and an insert valve was run inside the failed TR-SCSSV. Total well downtime was 476 days. Well B also involved a failure of the SCSSV. A critical failure (leakage in closed position) occurred on the TRSCSSV during initial completion, in August 1997. The failure was caused by a coiled tubing bottom hole assembly hanging up while pulling out of hole at TRSCSSV depth, indicated through flapper and hinge pin damage during the subsequent workover. Workover 1 took place during January/February 1998. The tubing hanger was found to be stuck in the wellhead and failed to release. Dolomite particles from a kill pill was found to be jamming the tubing hanger lock/unlock mechanism. The workover was aborted, and preparations were made to re-enter the well through Workover 2, where the tubing hanger was to be milled out. Workover 2 was performed during April/May 1999, when the tubing hanger was successfully milled, the tubing pulled and a new completion string run. The well was brought back on production in May 1999 after a shut-in period of 482 days. In both cases, the shut-in period was extended due to limitations in rig availability. Both wells are prolific producers, causing significant loss of revenues in this period.

throughout the organizations and more frequent updating of the historical data now high on the agenda of the participating oil companies. Collection, analysis and feedback of reliability data is an effective means of communicating performance of equipment and operations across organizations boundaries. The fact that reliability data is now being utilized for definition of new standards and governmental regulations, is another indication of the need for continuous collection and analysis of reliability data by independent third parties.

ACKNOWLEDGEMENT The authors wish to thank the participants of the Wellmaster Phase III project for permission to publish this paper. The participants were A/S Norske Shell, Amerada Hess Norge A/S, BHP Petroleum Pty. Ltd., BP Exploration Operating Company Ltd., British Gas Exploration and Production plc, Enterprise Oil plc Mobil Exploration Norway Inc., Norsk Agip A/S Norsk Hydro ASA, Norske Conoco AS,TOTAL Norge A.S, Saga Petroleum ASA, Statoil, Chevron Petroleum Technology Company, Exxon Production Research Company and Texaco Group Inc.

NOMENCLATURE GLV MTTF MTTW NORSOK OREDA SCSSV TR WR Gas lift valve Mean time to failure Mean time to workover The competitive standing of the Norwegian Continental Shelf Offshore Reliability Data Surface Controlled Subsurface Safety Valve Tubing retrievable Wireline retrievable

3. Conclusions Reliability databases have been present in the offshore industry for some two decades, with the number of applications of reliability data in decision making continually growing. The key to successful reliability databases in the offshore sector lies in populating the databases with data in sufficient quality and quantity. In the current low cost era of the industry, it is difficult to convey the benefits of these databases to management. A wider acceptance of the benefits of the results now seems to be emerging, with current focus on stronger implementation of the data collection software REFERENCES /1/ ISO 14224: Petroleum and natural gas industries Collection of reliability and maintenance data for equipment. Issued by ISO/TC 67/WG 4 N5. Molnes, E. and Strand, G.-O.: Reliability of Well Completion Equipment Phase III Main Report. SINTEF Petroleum Research Report 32.0898.00/04/99 (Confidential). Trondheim, November 1999.

/2/

SPE 63112

APPLICATION OF A COMPLETION EQUIPMENT RELIABILITY DATABASE IN DECISION MAKING

/3/

The Norwegian Petroleum Directorate: Regulations concerning implementation and use of risk analysis in the petroleum activities. Molnes, E. and Strand, G.-O.: Towards risk based acceptance criteria for downhole safety valves. Paper presented to Petrobras VI Technical Meeting Reliability Engineering, Rio de Janeiro, 28-30 March 2000.

/4/

EINAR MOLNES AND GEIR-OVE STRAND

SPE 63112

Buffer Database Manufacturer

Failure report duplicate

Failure cause comment

Moderator/ QA

Wellmaster Client version 2.5

Wellmaster Windows NT Agent Online WellWatch Database

ExproSoft Wellmaster Server

Company Database

Generate automatic reply and confirmation

WellWatch HTML Web Browser

Users - Oil companies

Users - Manufacturers

Figure 1 Wellmaster/WellWatch information flow chart.

Distribution Wells by Region

Adriatic 0.1 % GoM 8.1 % Africa 2.7 %

S.E. Asia/Australia 2.5 %

Other 0.1 %

North Sea 86.5 %

North Sea

Other

GoM

Adriatic

Africa

S.E. Asia/Australia

Figure 2 Distribution of wells by region.

SPE 63112

APPLICATION OF A COMPLETION EQUIPMENT RELIABILITY DATABASE IN DECISION MAKING

Service Time (well years)

5000 4500 4000 3500 3000 2500 2000 1500 1000 500 0 Oil production Water well injection well Gas production well Gas injection well Other

Welltype

Figure 3 Distribution of well service time by welltype.

50 45 40 35 30 25 20 15 10 5 0

36.69

MTTF (years)

20.2 14.2 16.4 12.7

19.55

SCSSV I (1983)

SCSSV II (1986)

SCSSV III (1989)

SCSSV IV (1992)

Wellmaster II Wellmaster III (1996) (1999)

Figure 4 Historical development of TR-SCSSV (flapper valve type) reliability during the period 1983-1999.

You might also like

- WellMaster - 05 10 2011Document16 pagesWellMaster - 05 10 2011Zayed AlkatheeriNo ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Reliability of Downhole EquipmentDocument390 pagesReliability of Downhole EquipmentAnthonyNo ratings yet

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsFrom EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsNo ratings yet

- SPE Simplified Series Cherie Henshaw and Bill Latham Premier Oils Well Integrity Journey Leveraging Software To Manage Well Integrity 1Document24 pagesSPE Simplified Series Cherie Henshaw and Bill Latham Premier Oils Well Integrity Journey Leveraging Software To Manage Well Integrity 1Ghahremani SoheilNo ratings yet

- SPE-142449-MS - The Seven Pillars of Well Integrity ManagementDocument16 pagesSPE-142449-MS - The Seven Pillars of Well Integrity ManagementIsaias Castro ArmendarizNo ratings yet

- An Approach To Define Well Operating EnvelopeDocument6 pagesAn Approach To Define Well Operating EnvelopeSam100% (1)

- Otc 15179 MSDocument10 pagesOtc 15179 MSHafiz AsyrafNo ratings yet

- Achieving HSE Performance On A Previously Inactive Rig Through Crew Resource Management Approach SPE-185244-MSDocument7 pagesAchieving HSE Performance On A Previously Inactive Rig Through Crew Resource Management Approach SPE-185244-MSДмитрий SolodNo ratings yet

- Paper 83 - Spe 117121-Pp Total Well Integrity - Column FormatDocument9 pagesPaper 83 - Spe 117121-Pp Total Well Integrity - Column FormatalizareiforoushNo ratings yet

- Well Integrity ManagementDocument5 pagesWell Integrity ManagementSteve Ukoha100% (1)

- SPE-182968-MS Well Integrity ManagementDocument14 pagesSPE-182968-MS Well Integrity ManagementJuan Camilo Lugo BecerraNo ratings yet

- SPE-193424-MS Chevron 2018Document17 pagesSPE-193424-MS Chevron 2018LawNo ratings yet

- Spe 114781 MSDocument16 pagesSpe 114781 MSJessica KingNo ratings yet

- Sand Control and Frac PackDocument14 pagesSand Control and Frac PackImran SadiqNo ratings yet

- Well StoryDocument7 pagesWell Storyrslisbon100% (1)

- Well Integrity Analysis Applied To WorkoDocument8 pagesWell Integrity Analysis Applied To WorkoAdolfo AnguloNo ratings yet

- Recommend Frequency of Well Integrity MonitoringDocument1 pageRecommend Frequency of Well Integrity MonitoringalizareiforoushNo ratings yet

- Shell Ox Exploration PlanDocument182 pagesShell Ox Exploration Planjdlouhy3911100% (1)

- Sand Control To Improve Well PerformanceDocument10 pagesSand Control To Improve Well PerformanceDobrescu MariusNo ratings yet

- SPE-196333-MS - Safeguarding Well Integrity Through Vigilant Sand Production Monitoring and Surveillance in Digital Field PDFDocument6 pagesSPE-196333-MS - Safeguarding Well Integrity Through Vigilant Sand Production Monitoring and Surveillance in Digital Field PDFAlejandra Arbelaez LondonoNo ratings yet

- Completation Inteligent RevistaDocument9 pagesCompletation Inteligent RevistaGabriel Castellon HinojosaNo ratings yet

- ED Offshore Inspection Guide: Well Integrity (Operate Phase)Document46 pagesED Offshore Inspection Guide: Well Integrity (Operate Phase)IgorCencičNo ratings yet

- Subsea Well Plug and Abandon Intervention Using A Coiled Tubing Conveyed Inflatable Packer A Case Study KopyaDocument7 pagesSubsea Well Plug and Abandon Intervention Using A Coiled Tubing Conveyed Inflatable Packer A Case Study KopyaErdal AYDINNo ratings yet

- Completion Technology For Unconsolidated FormationsDocument256 pagesCompletion Technology For Unconsolidated FormationsHamid Reza BabaeiNo ratings yet

- Well Stimulation ServicesDocument6 pagesWell Stimulation ServicesAfzal AktharNo ratings yet

- JT - IPTC 13405. Well Integrity Management Systems, Achievements Vs ExpectationsDocument10 pagesJT - IPTC 13405. Well Integrity Management Systems, Achievements Vs ExpectationsjuantellezcoNo ratings yet

- Advances in Well and Reservoir SurveillanceDocument22 pagesAdvances in Well and Reservoir SurveillanceRosa K Chang HNo ratings yet

- Analysis of Non-Productive Time in Geothermal Drilling Operations - A Case Study of OlkariaDocument8 pagesAnalysis of Non-Productive Time in Geothermal Drilling Operations - A Case Study of OlkariaibidaboNo ratings yet

- Iptc 12145 MS PDocument22 pagesIptc 12145 MS PAli Aliiev100% (1)

- Plugging and Abandonment of Oil and Gas Wells: Paper #2-25Document21 pagesPlugging and Abandonment of Oil and Gas Wells: Paper #2-25Fabian MontoyaNo ratings yet

- Chemical Sand Consolidation Trials (Shell)Document33 pagesChemical Sand Consolidation Trials (Shell)Nur Syaffiqa Mohamad RuzlanNo ratings yet

- A Case Study On The Effect of Production Segmentation CompletionDocument9 pagesA Case Study On The Effect of Production Segmentation CompletionSara Kamil Abd Al-RedahNo ratings yet

- Screenless methods control sand productionDocument16 pagesScreenless methods control sand productionCamilo Andres Bejarano Caicedo100% (1)

- Well Integrity PDFDocument1 pageWell Integrity PDFAdolfo AnguloNo ratings yet

- 2 Mature FieldDocument10 pages2 Mature FieldMohamed SadekNo ratings yet

- Key Issues in Multilateral Technology: Steve BosworthDocument15 pagesKey Issues in Multilateral Technology: Steve BosworthArcenio Jimenez MorganNo ratings yet

- Identification and Evaluation of Well Integrity and Causes of Failure of Well Integrity Barriers (A Review)Document41 pagesIdentification and Evaluation of Well Integrity and Causes of Failure of Well Integrity Barriers (A Review)Fabian MontoyaNo ratings yet

- Chevron LPSADocument9 pagesChevron LPSAanon_413680978No ratings yet

- Assessment of Sustained Well Integrity On Norwegian Continental ShelfDocument20 pagesAssessment of Sustained Well Integrity On Norwegian Continental ShelfmehranlnjdNo ratings yet

- Well Completion Maintenance Abandonment Guideline Sept Working v.1.18 2015 PDFDocument57 pagesWell Completion Maintenance Abandonment Guideline Sept Working v.1.18 2015 PDFAwani KesterNo ratings yet

- Riserless Drilling AppendixDocument2 pagesRiserless Drilling AppendixDr K GallowglaichNo ratings yet

- King - DOE Well Integrity - Basics, Prevention, Monitoring, Red Flags and Repair Options 21 Nov 2014 v3Document27 pagesKing - DOE Well Integrity - Basics, Prevention, Monitoring, Red Flags and Repair Options 21 Nov 2014 v3Luis Eduardo Segura100% (1)

- SPE-57390-Underbalance or Extreme OverbalanceDocument10 pagesSPE-57390-Underbalance or Extreme Overbalancecv sabiraNo ratings yet

- SPE Perforating For Inflow PerformanceDocument28 pagesSPE Perforating For Inflow PerformanceRamiro Rivera Cardenas0% (1)

- Gravel Pack Process ExplainedDocument3 pagesGravel Pack Process ExplainedMusah HarunaNo ratings yet

- Casing LeaksDocument8 pagesCasing LeaksJames "Chip" NorthrupNo ratings yet

- D-010 Well Integrity in Drilling and Well OperationsDocument162 pagesD-010 Well Integrity in Drilling and Well OperationsbreeeeezzzzzeNo ratings yet

- Oil Well Servicing ManualDocument75 pagesOil Well Servicing Manualresim mangalik100% (1)

- SPE Certification Exam 2014 PDFDocument1 pageSPE Certification Exam 2014 PDFMarcelo VeronezNo ratings yet

- Rock Mechanics in Wellbore ConstructionDocument65 pagesRock Mechanics in Wellbore ConstructionAnonymous rey6aU3ZNo ratings yet

- SPE 88525 Hybrid Monobore Completion Design: An Application For Multilayer ReservoirDocument6 pagesSPE 88525 Hybrid Monobore Completion Design: An Application For Multilayer ReservoirAhmadFauziNo ratings yet

- 2 Kellifereday Downhole ProblemsDocument26 pages2 Kellifereday Downhole ProblemsChu LưuNo ratings yet

- Rig SelectionDocument3 pagesRig SelectionMegat RitzhanNo ratings yet

- Effective zone isolation key to cementing operationsDocument2 pagesEffective zone isolation key to cementing operationsMauricio Sanchez BNo ratings yet

- SPE 88736 Expandable Tubular Completions For Carbonate ReservoirsDocument5 pagesSPE 88736 Expandable Tubular Completions For Carbonate ReservoirsmsmsoftNo ratings yet

- SPE 185420 MS Operational ExcellenceDocument14 pagesSPE 185420 MS Operational ExcellenceDeepak RanaNo ratings yet

- Schlum Gravel PackDocument22 pagesSchlum Gravel PackLaurentiu FrusinoiuNo ratings yet

- Evaluation and Assessment of Probit Functions 1.2Document7 pagesEvaluation and Assessment of Probit Functions 1.2vjourNo ratings yet

- RAM Report 2Document119 pagesRAM Report 2maxnokiaNo ratings yet

- Arctic Waters Oil Transfer Guidelines - Tp10783eDocument34 pagesArctic Waters Oil Transfer Guidelines - Tp10783evjourNo ratings yet

- Ship-To Ship Transfer Risk AssessmentDocument40 pagesShip-To Ship Transfer Risk AssessmentvjourNo ratings yet

- Quantitative Risk Analysis Approach To Port Hydrocarbon LogisticsDocument15 pagesQuantitative Risk Analysis Approach To Port Hydrocarbon LogisticsvjourNo ratings yet

- Risk Analysis of LNG Spill Over WaterDocument167 pagesRisk Analysis of LNG Spill Over WatervjourNo ratings yet

- Risk Analysis of LNG Spill Over WaterDocument167 pagesRisk Analysis of LNG Spill Over WatervjourNo ratings yet

- DNV RP-F206 Riser Integrity Management 2008-04Document66 pagesDNV RP-F206 Riser Integrity Management 2008-04vjourNo ratings yet

- Assessment of A Ship's Performance in AccidentsDocument10 pagesAssessment of A Ship's Performance in AccidentsvjourNo ratings yet

- Drilling Fluid Observations For Us Polar ProgramDocument32 pagesDrilling Fluid Observations For Us Polar ProgramvjourNo ratings yet

- Getting Started With Ataccama DQ Analyzer 6 Pg. 1Document26 pagesGetting Started With Ataccama DQ Analyzer 6 Pg. 1Balur BalurovicNo ratings yet

- Infomaker PDFDocument798 pagesInfomaker PDFanoop2010No ratings yet

- PhonologicalDocument363 pagesPhonologicalakbar mekka hamiduNo ratings yet

- Cs2258 Dbms Lab ManualDocument169 pagesCs2258 Dbms Lab ManualRamesh Kumar100% (1)

- Syntax AnalysisDocument115 pagesSyntax AnalysisPavan KumarNo ratings yet

- Tn179 05 PDFDocument517 pagesTn179 05 PDFchimbwaNo ratings yet

- Documentation - Diet Odin Demo ApplicationDocument4 pagesDocumentation - Diet Odin Demo Applicationashucool23No ratings yet

- 10 Essential Steps for New Linux Mint 18.2 Mate UsersDocument7 pages10 Essential Steps for New Linux Mint 18.2 Mate UsersAnonymous vcdqCTtS9No ratings yet

- Appl Note 809810 R6 PDFDocument94 pagesAppl Note 809810 R6 PDFcarlos alfaro maciasNo ratings yet

- Create A Social Network With SocialGODocument7 pagesCreate A Social Network With SocialGOmodemlooperNo ratings yet

- Deliver Tangible Business Value with Two IT Releases per YearDocument72 pagesDeliver Tangible Business Value with Two IT Releases per YearRodionov RodionNo ratings yet

- Purchasing Doc Release With Multiple CurrenciesDocument8 pagesPurchasing Doc Release With Multiple CurrenciesBalanathan VirupasanNo ratings yet

- Data Sheet 6GK5204-2BB10-2CA2: Transmission RateDocument5 pagesData Sheet 6GK5204-2BB10-2CA2: Transmission Ratejanajith reddyNo ratings yet

- CH03Document19 pagesCH03Farhana25111988No ratings yet

- PCA Gen ManualDocument11 pagesPCA Gen ManualElia CFNo ratings yet

- Dxdiag LumionDocument49 pagesDxdiag Lumionrahmat nurfitriantoNo ratings yet

- Mysql For Excel enDocument58 pagesMysql For Excel enphamhuuhoanNo ratings yet

- Econ Boot Camps MMDocument6 pagesEcon Boot Camps MMDiogo LimaNo ratings yet

- Design-Patterns Cheat SheetDocument36 pagesDesign-Patterns Cheat SheetcesarmarinhorjNo ratings yet

- Maths M T.3 Game TheoryDocument2 pagesMaths M T.3 Game TheoryKelvin FookNo ratings yet

- AIF20 Master GuideDocument52 pagesAIF20 Master GuideAntonio Di BellaNo ratings yet

- Sap IntertrDocument28 pagesSap IntertrAnonymous 4PnhkGJ0PNo ratings yet

- Ocularis Installation and Licensing GuideDocument26 pagesOcularis Installation and Licensing GuideEl Librero RecolectorNo ratings yet

- DDDW 2 InglesDocument5 pagesDDDW 2 InglesJose Luis Silguero SamaniegoNo ratings yet

- Linear Algebra Textbook for MSc MathematicsDocument2 pagesLinear Algebra Textbook for MSc MathematicsAinee MalikNo ratings yet

- Zenith ERP Solutions for Staffing, Real Estate and Telecom IndustriesDocument16 pagesZenith ERP Solutions for Staffing, Real Estate and Telecom IndustriesChinmay MohapatraNo ratings yet

- Vamsi Krishna Myalapalli ResumeDocument2 pagesVamsi Krishna Myalapalli ResumeVamsi KrishnaNo ratings yet

- Non Interacting SystemDocument5 pagesNon Interacting SystemJitender YadavNo ratings yet

- 3 Storey Front PageDocument3 pages3 Storey Front PagejansenrosesNo ratings yet

- Cse Viii Advanced Computer Architectures 06CS81 Notes PDFDocument156 pagesCse Viii Advanced Computer Architectures 06CS81 Notes PDFHarshith HarshiNo ratings yet

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (241)

- An Architect's Guide to Construction: Tales from the Trenches Book 1From EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1No ratings yet

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- Building Construction Technology: A Useful Guide - Part 2From EverandBuilding Construction Technology: A Useful Guide - Part 2Rating: 5 out of 5 stars5/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsFrom EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsRating: 4.5 out of 5 stars4.5/5 (6)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- Field Guide for Construction Management: Management by Walking AroundFrom EverandField Guide for Construction Management: Management by Walking AroundRating: 4.5 out of 5 stars4.5/5 (3)

- How to Write Construction Programmes & SchedulesFrom EverandHow to Write Construction Programmes & SchedulesRating: 4 out of 5 stars4/5 (9)

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsFrom EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsRating: 1 out of 5 stars1/5 (4)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Markup & Profit: A Contractor's Guide, RevisitedFrom EverandMarkup & Profit: A Contractor's Guide, RevisitedRating: 5 out of 5 stars5/5 (11)

- The E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItFrom EverandThe E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItRating: 4 out of 5 stars4/5 (16)

- Estimator's General Construction Manhour ManualFrom EverandEstimator's General Construction Manhour ManualRating: 4.5 out of 5 stars4.5/5 (20)