Professional Documents

Culture Documents

Apron Light

Uploaded by

Sanjay LohodasanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Apron Light

Uploaded by

Sanjay LohodasanCopyright:

Available Formats

Light & Engineering Vol. 10, No. 2, pp.

47 - 52, 2002

Svetotekhnika No. 3, pp. 15 - 18, 2002

APRON LIGHTING DESIGN INCLUDING AIRCRAFT SHADOWS

A. A. Bartsev Head of lighting design department, All-Russian Lighting Research Institute, 129626, Russia, Moscow, Prospect Mira 106. e-mail: bartsev_aleksei@mtu-net.ru

Apron lighting is the necessary part of modern airports lighting. The good apron lighting considerably facilitates the apron maneuverings for aircraft pilots. It also increased safety and speed of maneuverings, the quality of maintenance by comfortable vision conditions for attending personnel. All of these are the important factors for fail-safety and reliable flight service. The basic requirement for apron lighting stated in International Civil Aviation Organization (ICAO) rules [1]. In accordance with ICAO Riles the apron defined as "area on a land aerodrome intended to accommodate aircraft for the purpose of loading and unloading passengers, mail and cargo; refueling; parking or maintenance". The primary functions of apron lighting are: to assist the pilot to taxi his aircraft into and out of the final parking position; to provide lighting suitable for embarkation and debarkation of passengers, loading and unloading cargo, refueling and performing other apron service function; maintain airport security. The pilot mainly relies on apron lighting when taxing on the apron. Uniform illuminance of the pavement within the aircraft stand area (parking place) and glare restriction are the major requirements. It is necessary to obtain the following ICAO recommendations: an average horizontal illumination should be not less than 20 lx for aircraft stands. The uniformity ratio (average illuminance to minimum) should be not more then 4:1. Average vertical illuminance at a height of 2 meters should be not less than 20 lx in relevant directions; in order to maintain acceptable visibility conditions the average horizontal illumination on

the apron, except where service functions are taking place, should not be less than 50 % of the average horizontal illuminance of the aircraft stands, within a uniformity ratio of 4:1 (average to minimum). The area between the aircraft stands and the apron limit (service equipment, parking area, service roads) should be illuminated to an average horizontal illumination of 10 lx. The basic means for apron lighting is high masts floodlighting. In these case very often appear unavoidable sharp shadows from other obstacles, and especially from aircraft's. In order to minimize shadows there is ICAO recommendation: the arrangement and aiming of floodlights should be so that aircraft stands receive from different directions. Better results are obtained by uniform illuminance of the total area than by directing individual floodlights at the aircraft [1]. Unfortunately it is impossible to predict exactly the final result of shadowing following these rules. In order to solve this task more correctly it is necessary to take into account the shadows from aircraft's by design of apron floodlighting. Such method which used in lighting design department of VNISI is proposed in this article. The lighting design of apron floodlighting including aircraft shadows can be divided on several steps. The first step is the calculation of illuminance distribution within apron and glare estimation in accordance with ICAO rules. In this calculations we do not take into account the shadows from aircrafts, we can only follow ICAO recommendation to illuminate aircraft stands from two and more directions in order to minimize shadows. Figure 1 presents an example of such lighting calculations for one part of big cargo apron in airport near Moscow.

Light & Engineering

Vol. 10, No. 2

There were used two lighting masts with high limit restriction 30 meters and 14 floodlights (7 per mast) with 1000 W high-pressure sodium lamp. The basic ICAO recommendations were achieved in this solution. The second step is preparing three-dimensional (3D) computer graphics model using special software for 3D modeling (AutoCAD, 3D Studio MAX/VIZ and so on). As a minimum this model should include aircrafts, stands area and lighting

masts for floodlights (Figure 2-a). Then the 3Dapron model and floodlights defined on step 1 should be exported into some computer graphics software witch allow to realize physically accurate lighting simulation [2, 3]. On this step materials and lighting distribution curves (LDC) should be added to 3D model (Figure 2-b). It is necessary to have possibility to define correctly LDC and properties of the materials (color, reflectance and transmittance index) for correct lighting simulation.

a) Apron drawing and calculation scheme.

b) The results of the calculation of horizontal illuminance distribution on the apron pavement E min = 7,1 lx; E aver = 22,6 lx; E max = 63,4 lx; E min /E aver =31,4 % (E aver /E min = 3,2:1) Fig. 1. Apron lighting calculation for fragment of cargo apron in accordance with ICAO recommendations.

Light & Engineering

Vol. JO, No. 2

Table 1 The calculating values of shadowing coefficient kS for several variants of apron floodlighting Number of masts Number of floodlights per mast 7 5 3 2 Comparative total cost (in%) 38 53 68 100 Average illuminance (Ix) K S =E 2 /E 1 E2 (with aircrafts) 17.8 20.5 21.6 19.9 E1 (without aircrafts) 22.6 25.0 26.9 21.5 0.79 0.82 0.80 0.93

2 3 4 6

The next step is lighting simulation, which allow calculating illuminance distribution within 3D model taking into account shadows from aircrafts. We use for this lighting simulation the Lightscape Visualization System software from Autodesk Company. This software allows simulating light propagation within 3D model using radiosity method for estimation of plural interreflection and the backward ray-tracing technique for correct shadows and mirror reflections calculations [4]. The results are presented in several forms: color visualization picture, numerical grid of illuminance distribution, pseudo-color picture in scaled colors, pseudo-color picture in scaled gray colors. Figure 3a, b presents the results of lighting simulation for our example of cargo apron as full-color visualization picture and illumination distribution picture in scaled color. These results analysis shows that quality of lighting is not acceptable because of big and sharp shadows. Obviously it is necessary to try minimize the shadow's size and intensity, otherwise to optimize shadows. Shadows minimizing is the final step of lighting design including shadows. The shadows minimizing can be achieved by redirections of some floodlights, changing types of floodlights, their LDC and the placement of lighting masts. As common criteria for shadows minimizing could be used the visual estimation of the shadow's size and intensity. The full-color visualization pictures and especially illuminance distribution in scaled pseudo-colors are very convenient for this. Figure 4 demonstrates the shadows variation on the apron obtained by variation of quantity and placement of lighting masts, quantity and redirections of floodlights. As an numerical estimation could be used the a ratio of

an average horizontal illuminance on the stands area with aircrafts -Ehor.aver. 2 ,to average horizontal illuminance on the same stands area without aircrafts Ehor.aver. 1: Ks =Ehor.aver.

2

/Ehor.aver

The table 1 presents the calculating values of this numerical criteria for four variants of shadows optimization. Maximum value of this criteria signifies the minimum shadowing. The analysis of lighting visualization pictures and Ks values confirms that well known fact that increasing of quantity of lighting masts decrease the shadow's size and intensity, and illuminance level on the stands area approaches to illuminance level without aircraft's. From other hand the modern lighting mast especially with mobile crown is quite expensive device. Also the quantity of lighting masts on the apron very often is restricted because of some technical conditions. Because of this the customer usually try to choose the variant with minimum quantity of lighting masts. In this situation using of criteria of shadow minimizing allows to make more valid choose of lighting masts quantity. Thus in our example of cargo apron lighting the best result is achieved in case of lighting mast arrangement beside every aircraft stand (Figure 4d). But in practice it is very expensive solution, because lighting masts cost can exceed mounting floodlights cost in ten times and more, and the total cost of installation (the foundations building, masts mounting, spending of electrical cable and devices and so on) is high enough. The next variant in minimum of shadowing and almost in two times

Light & Engineering

Vol. 10, No. 2

a) 3D-wireframe model of the apron with aircraft's and lighting masts.

b) 3D model with floodlights and embedded materials. Fig. 2. 3D computer modeling of the cargo apron.

Light & Engineering

Vol. 10. No. 2

a) 3D lighting simulation full-color picture with ray-trased shadows.

b) 3D lighting simulation picture in scaled pseudo-colors. Fig. 3. Apron lighting calculation with aircrafts on stand areas.

Light & Engineering

Vol. 10, No. 2

a) 2 lighting masts, 14 floodlights.

b) 3 lighting masts, 15 floodlights.

c) 4 lighting masts, 12 floodlights.

d) 6 lighting masts, 12 floodlights.

Fig. 4. The shadows variation for several variants of apron floodlighting. cheaper is the variant with three lighting masts for every five aircraft stands (Figure 4b). The variants with two and four lighting masts (Figure 4 a, c) are very closely by Ks values, and in this situation the variant with two masts is preferable because of lower cost of installation. By this way the priorities in the variants of lighting from the point of view of shadows minimizing (by other equal conditions) are the following: six, three and two masts. In this way the customer can make valid chouse proceeding of quality of lighting, technical means and financial resources. CONCLUSION The method of apron lighting design proposed in this article allows to choose more validly the variant of lighting masts arrangement and control more exactly the quality of apron floodlighting that increase safety of flight service. REFERENCES 1. "AERODROME DESIGN MANUAL", 1983, PART 4, VISUAL AIDS. ICAO, SECOND EDITION. 2. A.B.Khodulev, E.A.Kopylov "Physically accurate lighting simulation in computer graphics software" // URL: http://rmp.kiaml.rssi.ru/articles/pals/index.htm 3. A.A.Bartsev 1999, "3D-computer graphics in the outdoor architectural lighting design". 24th session of the CIE proceedings. Vol.1, part 2, pp.262-264. 4. Lightscape, release 3.2, User's guide. Autodesk Inc., April 1999, pp. 353.

Dr. Alexei Bartsev, graduated from Moscow Energetic Institute (MEI) 1986. The Chief of project department at VNISI.

2008 LightDesignProject Ltd. All rights reserved. Unauthorized copying, public performance or other distribution prohibited. www.ld-project.ru

You might also like

- 96A0438 ITX A Transformer ManualDocument14 pages96A0438 ITX A Transformer ManualAbdul KurniadiNo ratings yet

- Precision Approach Path Indicator - Wikipedia, The Free EncyclopediaDocument4 pagesPrecision Approach Path Indicator - Wikipedia, The Free EncyclopediaDurgaPrasadKrishnaNo ratings yet

- Caap 72 Aircraft Landing Areas - Private UseDocument51 pagesCaap 72 Aircraft Landing Areas - Private UseSrikanth ReddyNo ratings yet

- Underground Power Cable For AirportsDocument12 pagesUnderground Power Cable For AirportsDevrim GürselNo ratings yet

- 2500+ Series Flyer - Lres PDFDocument4 pages2500+ Series Flyer - Lres PDFVijay BarreyNo ratings yet

- GE Airport Lighting Products 6.6 Amp SystemsDocument2 pagesGE Airport Lighting Products 6.6 Amp SystemsMudassar Nore100% (1)

- Naviads (Ils Dme) SpecificationDocument3 pagesNaviads (Ils Dme) SpecificationNugraNo ratings yet

- Sabiha Gokcen International AirportDocument2 pagesSabiha Gokcen International AirportSumejaZukićNo ratings yet

- Topic 5 - Airport Layout and Design FinalDocument50 pagesTopic 5 - Airport Layout and Design FinalSneha KokaneNo ratings yet

- Backup ATC Centre Maintains Continuous ServicesDocument5 pagesBackup ATC Centre Maintains Continuous ServicesprodigynaveenNo ratings yet

- Manual On Collaborative Decision-Making (CDM) : Doc 9971 AN/485Document48 pagesManual On Collaborative Decision-Making (CDM) : Doc 9971 AN/485Guido Fernandez NinaNo ratings yet

- Airport Engineering 3 TaxiwayDocument17 pagesAirport Engineering 3 Taxiwayraghav VarmaNo ratings yet

- Airport Capacity and Demand Calculations by Simulation - Extended AbstractDocument6 pagesAirport Capacity and Demand Calculations by Simulation - Extended AbstractbbubaloNo ratings yet

- Airport Aviation Solutions Brochure enDocument5 pagesAirport Aviation Solutions Brochure enFELIXDEJNo ratings yet

- Runway OrientationDocument24 pagesRunway OrientationAbdulkareem Adeyinka100% (2)

- Airport ReportDocument53 pagesAirport Reportektagoyal273No ratings yet

- Airfield CableDocument68 pagesAirfield CableJoão Alves C. Junior100% (1)

- CCR - Augier - 6021052Document4 pagesCCR - Augier - 6021052lincoln9003198100% (1)

- Thermal Imaging in Aviation: Marek Štumper Jakub KrausDocument4 pagesThermal Imaging in Aviation: Marek Štumper Jakub KrausDeepan PrasathNo ratings yet

- Runway LightingDocument39 pagesRunway LightingMohammed Haseeb ONo ratings yet

- Runway Design 6Document6 pagesRunway Design 6Pratyush PrasadNo ratings yet

- Akash PDFDocument23 pagesAkash PDFAditya KumarNo ratings yet

- CANRM HeliportsDocument85 pagesCANRM HeliportsJayant LakhlaniNo ratings yet

- Bec 2015 PDFDocument84 pagesBec 2015 PDFJack SoNo ratings yet

- Policy on Airport Infrastructure DevelopmentDocument11 pagesPolicy on Airport Infrastructure DevelopmentRaja174100% (1)

- Designing Airport Terminals to Optimize Passenger FlowDocument16 pagesDesigning Airport Terminals to Optimize Passenger FlowSherelyn RoblesNo ratings yet

- Importance of Grid Maps for FirefightersDocument20 pagesImportance of Grid Maps for FirefightersMd Arifur RahmanNo ratings yet

- Tps 4767Document3 pagesTps 4767kirkleeleomoNo ratings yet

- Airfield LightingDocument33 pagesAirfield LightingNational institute of management and researchNo ratings yet

- Ground Power UnitDocument3 pagesGround Power UnitHarish Mathiazhahan50% (2)

- Illumination Class Wizard Questionaire According To CIE 140 en 13201Document6 pagesIllumination Class Wizard Questionaire According To CIE 140 en 13201musleh19No ratings yet

- EFLA Catalogue - ENGDocument19 pagesEFLA Catalogue - ENGAleksander KililovNo ratings yet

- AGL Jessore AirportDocument6 pagesAGL Jessore AirportIshmum Monjur Nilock100% (1)

- Universiti Kuala Lumpur Malaysia Institute Ofaviation TechnologyDocument11 pagesUniversiti Kuala Lumpur Malaysia Institute Ofaviation TechnologyAtiqah Nabilah RazaliNo ratings yet

- Aviation Obstruction LightsDocument2 pagesAviation Obstruction LightsfotopredicNo ratings yet

- Airport ApronsDocument22 pagesAirport ApronsBook Jk100% (1)

- TGL 26 Mel PolicyDocument121 pagesTGL 26 Mel PolicyChabou RafikNo ratings yet

- The First Draft of A Presentation On The Design & Construction of An Automatic Solar-Powered StreetlightDocument23 pagesThe First Draft of A Presentation On The Design & Construction of An Automatic Solar-Powered StreetlightAyo MorakinyoNo ratings yet

- Restriction of Height, IAL AspectDocument28 pagesRestriction of Height, IAL AspectCoochbehar AaiNo ratings yet

- Airport technology chapter explores solutions to congestionDocument50 pagesAirport technology chapter explores solutions to congestionPriyaNo ratings yet

- Icao Annex 14 - AerodromesDocument8 pagesIcao Annex 14 - AerodromesmrdnnmnNo ratings yet

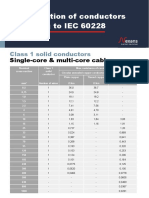

- Classification of Conductors According To IEC 60228Document3 pagesClassification of Conductors According To IEC 60228Jacob de Wilde100% (1)

- Flight PlanningDocument4 pagesFlight PlanningIvan BarriaNo ratings yet

- A Synopsis On: Kinetic Energy Recovery SystemDocument3 pagesA Synopsis On: Kinetic Energy Recovery SystemDhruv Agarwal100% (1)

- CFD Lab1-Exercise Note PDFDocument10 pagesCFD Lab1-Exercise Note PDFSaad Al HelyNo ratings yet

- Run Way LightingDocument16 pagesRun Way LightingMoudud Ul Islam AwanNo ratings yet

- Project Binder 2Document23 pagesProject Binder 2Singh DhirendraNo ratings yet

- Understanding Helicopter Airfoil SectionsDocument2 pagesUnderstanding Helicopter Airfoil Sectionsjetaw109spNo ratings yet

- RBDG MAN 021 0101 - RailwayEnergyPart4 ElectromagneticCompatibilityDocument16 pagesRBDG MAN 021 0101 - RailwayEnergyPart4 ElectromagneticCompatibilityLever LõhmusNo ratings yet

- Neral Capítulo.1 PDFDocument8 pagesNeral Capítulo.1 PDFemhidalgoNo ratings yet

- #9 AdvanceddockingsystemDocument37 pages#9 AdvanceddockingsystemDestiawan MiftahussalamNo ratings yet

- Critical Assessment of Wind Tunnel Data for NACA 0012 AirfoilDocument23 pagesCritical Assessment of Wind Tunnel Data for NACA 0012 AirfoilSlavi72No ratings yet

- Runway Orientation Factors and Wind Data AnalysisDocument47 pagesRunway Orientation Factors and Wind Data AnalysisMilind GuptaNo ratings yet

- Aeronautical RiskDocument208 pagesAeronautical RiskfjackalaNo ratings yet

- Apron LightDocument6 pagesApron LightDUTY JAGANo ratings yet

- Intelligent Vision System Quality Class Airport Lamp Prisms CorrectedDocument4 pagesIntelligent Vision System Quality Class Airport Lamp Prisms CorrectedAdam DabrowskiNo ratings yet

- CHAPTER 9. Display Systems: 9.1. Situational AwarenessDocument12 pagesCHAPTER 9. Display Systems: 9.1. Situational AwarenesspradeepNo ratings yet

- Simulation of wind conditions around buildingsDocument17 pagesSimulation of wind conditions around buildingsPaolo Mocellin100% (1)

- R02i16 Wsu XX ZZ DWG ST 33012 PDFDocument1 pageR02i16 Wsu XX ZZ DWG ST 33012 PDFSanjay LohodasanNo ratings yet

- Parking Fares PDFDocument2 pagesParking Fares PDFImranNo ratings yet

- Parking Fares PDFDocument2 pagesParking Fares PDFImranNo ratings yet

- Deepika Calendar2018Document8 pagesDeepika Calendar2018akash nairNo ratings yet

- Site LTG PlanDocument1 pageSite LTG PlanSanjay LohodasanNo ratings yet

- BS en 12464 1 Lighting Levels PDFDocument3 pagesBS en 12464 1 Lighting Levels PDFGUNABALAN100% (1)

- BS en 12464 1 Lighting Levels PDFDocument3 pagesBS en 12464 1 Lighting Levels PDFGUNABALAN100% (1)

- AVLITE Brochure Complete Solar Airfield Lighting Solutions A4 2018 V1 Pages WebsiteDocument8 pagesAVLITE Brochure Complete Solar Airfield Lighting Solutions A4 2018 V1 Pages WebsiteSanjay LohodasanNo ratings yet

- Electric Vehicles Charging Systems - Ewr Addendum No. 1 PDFDocument18 pagesElectric Vehicles Charging Systems - Ewr Addendum No. 1 PDFSanjay LohodasanNo ratings yet

- EI Lecture No.11Document7 pagesEI Lecture No.11satendra yadavNo ratings yet

- Abb IsolatorDocument84 pagesAbb IsolatorSanjay LohodasanNo ratings yet

- ALSF SSALR SSAL Approach Lighting SystemsDocument1 pageALSF SSALR SSAL Approach Lighting SystemsSanjay LohodasanNo ratings yet

- Hand Held MD PDFDocument2 pagesHand Held MD PDFSanjay LohodasanNo ratings yet

- Al Sahraa Advanced ECS BrochureDocument2 pagesAl Sahraa Advanced ECS BrochureSanjay LohodasanNo ratings yet

- Abb IsolatorDocument84 pagesAbb IsolatorSanjay LohodasanNo ratings yet

- AWOS Brochure VaisalaDocument2 pagesAWOS Brochure VaisalaSanjay LohodasanNo ratings yet

- Mareco Luce Wix Led outdoor light data sheetDocument1 pageMareco Luce Wix Led outdoor light data sheetSanjay LohodasanNo ratings yet

- NIRS Al Sahraa LeafletDocument2 pagesNIRS Al Sahraa LeafletSanjay LohodasanNo ratings yet

- CX6040D DatasheetDocument2 pagesCX6040D DatasheetSanjay LohodasanNo ratings yet

- MD2100 Datasheet LowDocument2 pagesMD2100 Datasheet LowSanjay LohodasanNo ratings yet

- Cx6040d - Stac ApprovalDocument2 pagesCx6040d - Stac ApprovalSanjay LohodasanNo ratings yet

- 3) Gen. Arrangement Ceiling FinishesDocument1 page3) Gen. Arrangement Ceiling FinishesSanjay LohodasanNo ratings yet

- MD0120 Datasheet LowDocument2 pagesMD0120 Datasheet LowSanjay LohodasanNo ratings yet

- Install a solid circular lightning protection systemDocument6 pagesInstall a solid circular lightning protection systemSanjay LohodasanNo ratings yet

- 971SmartRadarLTi ServMan 416716 Rev3Document56 pages971SmartRadarLTi ServMan 416716 Rev3HeshamEl-naggarNo ratings yet

- Machine Learning Algorithms in Depth (MEAP V09) (Vadim Smolyakov) (Z-Library)Document550 pagesMachine Learning Algorithms in Depth (MEAP V09) (Vadim Smolyakov) (Z-Library)AgalievNo ratings yet

- Proposal Spotify Recommendation SystemDocument13 pagesProposal Spotify Recommendation SystemAmarjeet VishwakarmaNo ratings yet

- Testing PreliminaryDocument6 pagesTesting PreliminaryPrashantHegdeNo ratings yet

- PC Based Oscilloscope Using ArduinoDocument2 pagesPC Based Oscilloscope Using ArduinoFernando EstupinianNo ratings yet

- Manual OJSDocument142 pagesManual OJSMariela HerreroNo ratings yet

- ADC Guide: Analog-to-Digital Conversion BasicsDocument30 pagesADC Guide: Analog-to-Digital Conversion BasicsBenedict JoNo ratings yet

- Serverside Scripting - Ch3Document28 pagesServerside Scripting - Ch3Abdi BoruuNo ratings yet

- Download Byculla To Bangkok EpubDocument3 pagesDownload Byculla To Bangkok EpubSurajit MondalNo ratings yet

- Smart Call Home Quick Start Configuration Guide For Cisco Integrated Services RoutersDocument5 pagesSmart Call Home Quick Start Configuration Guide For Cisco Integrated Services RoutersYen Lung LeeNo ratings yet

- Past 4 ManualDocument293 pagesPast 4 ManualMiguel HenleyNo ratings yet

- The - Future - of - Healthcare - Internet - of - Things - A - Survey - of - Emerging - TechnologiesDocument47 pagesThe - Future - of - Healthcare - Internet - of - Things - A - Survey - of - Emerging - TechnologiesultrahornytgtNo ratings yet

- CD Lab FileDocument28 pagesCD Lab FileAyush MishraNo ratings yet

- Oracle RAC DBA Resume With 4+expDocument6 pagesOracle RAC DBA Resume With 4+expreddy007No ratings yet

- CIS 112 Computer Technology: - Lectuerer: Karabo Macheng - EmailDocument74 pagesCIS 112 Computer Technology: - Lectuerer: Karabo Macheng - EmailMohsan MinhasNo ratings yet

- ExceptionDocument188 pagesExceptionAzhar MullaNo ratings yet

- SD WanDocument3 pagesSD Wanraditio ghifiardiNo ratings yet

- Huawei SmartAX MA5628 Brief Product Brochure (09-Feb-2012)Document2 pagesHuawei SmartAX MA5628 Brief Product Brochure (09-Feb-2012)Syed Abid AleemNo ratings yet

- Automated Solar Panel Cleaning SystemDocument52 pagesAutomated Solar Panel Cleaning Systemakhil katariNo ratings yet

- Advanced View of Projects Raspberry Pi List - Raspberry PI ProjectsDocument189 pagesAdvanced View of Projects Raspberry Pi List - Raspberry PI ProjectsBilal AfzalNo ratings yet

- Installation - Manual KX-TVM 200Document248 pagesInstallation - Manual KX-TVM 200SERVICE CENTER PABX 085289388205No ratings yet

- Being Himachali - ... - .Document4 pagesBeing Himachali - ... - .nk637No ratings yet

- Alumni ManagementDocument18 pagesAlumni ManagementGagan GuptaNo ratings yet

- Multiple SsidDocument4 pagesMultiple SsidPrismaNo ratings yet

- 3 - Content - Proceedings of Regional Conference On Knowledge Integration in ICTDocument9 pages3 - Content - Proceedings of Regional Conference On Knowledge Integration in ICTKhirulnizam Abd RahmanNo ratings yet

- C5/See5 Procedural ExampleDocument13 pagesC5/See5 Procedural ExampleSem LesanNo ratings yet

- Certified SolidWorks Associate Exam Contents - SolidWorksDocument1 pageCertified SolidWorks Associate Exam Contents - SolidWorksAlberto Caraban CarabanNo ratings yet

- Andrew Joseph L. RamosDocument80 pagesAndrew Joseph L. Ramoslee.macalisangNo ratings yet

- PreDCR Do and DontDocument31 pagesPreDCR Do and Dontvenkata satyaNo ratings yet

- Lab Activity 3Document9 pagesLab Activity 3Amirul AminNo ratings yet