Professional Documents

Culture Documents

Automatic Transmission System

Uploaded by

Mamesh MathankarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automatic Transmission System

Uploaded by

Mamesh MathankarCopyright:

Available Formats

Automatic transmission system

1. INTRODUCTION

Automatic transmission system shifts the gears without assistance from the driver. They start the car moving in first and then shift into higher gears as the car speed increases and engine load decreases. The shifts are produced by hydraulic pressure acting through the transmission fluid. The control system takes into account the engine load and in general produce changes up when the engine load is light and changes down when the engine load is heavy. The main components that make up an automatic transmission include:

The Torque Converter: This acts like a clutch to allow the vehicle to

come to a stop in gear while the engine is still running.

Planetary Gear Sets: They are the mechanical systems that provide

the various forward gear ratios as well as reverse.

The Hydraulic System: It uses a special transmission fluid sent under

pressure to control the transmission

Automatic transmission system

2. TORQUE CONVERTER

2.1 INTRODUCTION: On transmissions, automatic the torque

converter takes the place of the clutch found on standard shift vehicles. It is there to allow the engine to continue running when the vehicle comes to a stop.

2.2 CONSTRUCTION: A torque converter is a large doughnut shaped device that is mounted between the engine and the transmission. As shown in the fig.1, there are four components inside the very strong housing of the torque converter: Impeller or pump (driving element) Turbine (driven element) Stator (reaction member) The one way clutch

Automatic transmission system

The housing of the torque converter is bolted to the flywheel of the engine, so it turns at whatever speed the engine is running at. The pump of the torque converter is attached to the housing, so it also turns at the same speed as the engine. The pump inside the torque converter is a type of centrifugal pump. The pump has many curved vanes, along with an inner ring, which form passages for the fluid to flow through. The turbine is inside the housing and is connected directly to the input shaft of the transmission providing power to move the vehicle. To get maximum force on the turbine vanes when the moving fluid strikes them, the vanes are curved to reverse the direction of flow. The stator is mounted on a one-way clutch so that it can spin freely in one direction but not in the other.

2.3 WORKING: As the pump spins, fluid is flung to the outside due to centrifugal force. As fluid is flung to the outside, a vacuum is created that draws more fluid in at the center. The fluid then enters the blades of the turbine. Since the blades of the turbine are curved, the fluid, which enters the turbine from the outside, has to change direction before it exits the center of the turbine. It is this directional change that causes the turbine to spin. The fluid exits the turbine moving opposite the direction that the pump (and engine) is turning. This is shown in fig. 2. If the fluid were allowed to hit the pump, it would slow the engine down, wasting power. The stator resides in the very center of the torque converter. Its job is to redirect the fluid returning from the turbine before it hits the pump

Automatic transmission system

again. The stator has a very aggressive blade design that almost completely reverses the direction of the fluid. Because of the one-way clutch, the stator cannot spin with the fluid (it can spin only in the opposite direction), forcing the fluid to change direction as it hits the stator blades. 2.4 FLUID COUPLING PHASE: As the speed of the turbine catches up with the pump, the fluid exit the turbine in the same direction as the pump is turning, so the stator is not needed. At these speeds, the fluid actually strikes the back sides of the stator blades, causing the stator to freewheel on its one-way clutch so it doesn't hinder the fluid moving through it. All three now elements begin to turn at approximately the same speed. 2.5 TORQUE CONVERTER EFFICIENCY: It is seen that the efficiency of the torque converter is reasonably good at only narrow range of turbine speeds. The fall-off of efficiency at low speed end of the range can be tolerated because those speeds are used for short periods. But the fall-off of efficiency at high speeds cannot be tolerated and must be circumvented. The efficiency can be increased, by substituting a direct drive for the torque converter at higher speeds.

2.6 THE LOCKUP IN TORQUE CONVERTER (DIRECT DRIVE):

Automatic transmission system

Because the only connection between two sides of a torque converter is a fluid connection, there is always a little slippage, running from about 2-8%. To increase efficiency and mileage, most modern automatic transmissions also have something called a lockup clutch. It works like this. As the two speed of the car reaches 50 to 60 kph, the highly pressurized transmission fluid is channeled through the transmission shaft and activates a clutch piston. This metal pin locks the turbine to the pump, in effect bypassing the torque converter and giving a direct drive. It remains this way until the vehicle slows below 50 kph, at which point the clutch piston disengages and the torque converter kicks in again.

Automatic transmission system

3. SIMPLE PLANETARY GEAR SET

fig. 3

The basic planetary gear set as shown in fig. 3 consists of a sun gear, a ring gear and two or more planet gears, all remaining in constant mesh. The planet gears are connected to each other through a common carrier. Each of these three components can be the input, the output or can be held stationary. Choosing which piece plays which role determines the gear ratio for the gear set. Following table shows the different gear ratios possible:

Input Sun (S) Planet Carrier (C) Sun (S)

Output Planet Carrier (C) Ring (R) Ring (R)

Stationary Ring (R) Sun (S) Planet Carrier (C)

Gear Ratio 1 + R/S 1 / (1 + S/R) -R/S

Automatic transmission system

4. COMPOUND PLANETARY GEAR SET

4.1 INTRODUCTION: The compound planetary gear set looks like a simple planetary gear set but actually behaves like two planetary gear sets combined. It has one ring gear that is always the output of the transmission, but it has two sun gears and two sets of planets.

4.2 CONSTRUCTION: Fig. 4 shows the exploded view of the compound planetary gear set. The fig. 5 shows the planets in the planet carrier. The planet on the right sits lower than the planet on the left. The planet on the right does not engage the ring gear, it engages the other planet. Only the planet on the left engages the ring gear. The shorter gears are engaged only by the smaller sun gear. The longer planets are engaged by the bigger sun gear and by the smaller planets.

In such gear sets, the sum of number of teeth on sun gear and ring gear divided by the number of planets must be a whole number. Otherwise certain combination of tooth numbers cannot be assembled because of need of equal spacing on the planets.

4.3 GEAR RATIOS:

Automatic transmission system

Consider a planetary gear set with ring gear having 72 teeth the smaller sun gear having 30 teeth and the larger sun gear having 36 teeth. First Gear: In first gear, the smaller sun gear is driven clockwise by the turbine in the torque converter. The planet carrier tries to spin counterclockwise, but is held still by the one-way clutch (which only allows rotation in the clockwise direction) and the ring gear turns the output. Referring to table 1, the gear ratio is: -R/S = - 72/30 = -2.4:1 So the rotation is negative 2.4:1. But the output direction is really the same as the input direction. This is due to the two sets of planets. The first set of planets engages the second set, and the second set turns the ring gear; this combination reverses the direction. This would also cause the bigger sun gear to spin; but because that clutch is released, the bigger sun gear is free to spin in the opposite direction of the turbine (counterclockwise).

Second Gear: This acts like two planetary gear sets connected to each other with a common planet carrier. The first stage of the planet carrier actually uses the larger sun gear as the ring gear. So the first stage consists of the sun (the smaller sun gear), the planet carrier, and the ring (the larger sun gear). The input is the small sun gear; the ring gear (large sun gear) is held stationary by the band, and the output is the planet carrier. For this stage, with the sun as

Automatic transmission system

input, planet carrier as output, and the ring gear fixed, referring to table 1 the gear ratio is: 1 + R/S = 1 + 36/30 = 2.2:1 The planet carrier turns 2.2 times for each rotation of the sun gear. At the second stage, the planet carrier acts as the input for the second planetary gear set, the larger sun gear (which is held stationary) acts as the sun, and the ring gear acts as the output, so referring to table 1, the gear ratio is: 1 / (1 + S/R) = 1 / (1 + 36/72) = 0.67:1 To get the overall reduction for second gear, we multiply the first stage by the second, 2.2 x 0.67, to get a 1.47:1 reduction.

Third Gear: Most automatic transmissions have a 1:1 ratio in third gear. All we have to do is engage the clutches that lock each of the sun gears to the turbine. If both sun gears turn in the same direction, the planet gears lockup because they can only spin in opposite directions. This locks the ring gear to the planets and causes everything to spin as a unit, producing a 1:1 ratio.

Overdrive: By definition, an overdrive has a faster output speed than input speed. It's a speed increase. When overdrive is engaged, a shaft that is attached to the housing of the torque converter (which is bolted to the flywheel of the engine) is connected by clutch to the planet carrier. The small sun gear

Automatic transmission system

freewheels, and the larger sun gear is held by the overdrive band. Nothing is connected to the turbine; the only input comes from the converter housing. With the planet carrier for input, the sun gear fixed and the ring gear for output, referring to table 1 the gear ratio is: 1 / (1 + S/R) = 1 / (1 + 36/72) = 0.67:1

Reverse: Reverse is very similar to first gear, except that instead of the small sun gear being driven by the torque converter turbine, the bigger sun gear is driven, and the small one freewheels in the opposite direction. The planet carrier is held by the reverse band to the housing. So, referring to table 1, the gear ratio is: -R/S = -72/36 = -2.0:1 So the ratio in reverse is a little less than first gear.

5. HYDRAULIC SYSTEM

5.1 INTRODUCTION: The hydraulic system provides the pressurized fluid to operate an automatic transmission. Major components of the hydraulic system include the bands, clutches and oil pump. Other major components are the governor, throttle valve, modulator and the valve body.

10

Automatic transmission system

5.2 FUNCTIONS OF THE HYDRAULIC SYSTEM: The effective operation of an automatic transmission relies upon a hydraulic control system to actuate the gear changes relative to vehicles road speed and acceleration pedal demands with engine delivering power. The system performs the following functions, Supplies fluid to the torque converter. Directs pressurized fluid to the bands and clutches. Lubricates the internal parts.

5.3 TRANSMISSION FLUID: Trasmission fluid serves a number of purposes including: Shift control. General lubrication Transmission cooling.

Unlike the engine, which uses oil primarily for lubrication, every aspect of a transmission's functions is dependant on a constant supply of fluid under pressure. This is not unlike the human circulatory system where even a few minutes of operation when there is a lack of pressure can be harmful or even fatal to the life of the transmission. A typical transmission has an average of ten litres of fluid between the transmission, torque converter, and cooler tank. In fact, most of the components of a transmission are constantly submerged in

11

Automatic transmission system

fluid including the clutch packs and bands. The friction surfaces on these parts are designed to operate properly only when they are submerged in oil.

5.4 COOLING THE TRANSMISSION FLUID: In order to keep the transmission at normal operating temperature, a portion of the fluid is sent through one of two steel tubes to a special chamber that is submerged in the radiator. Fluid passing through this chamber is cooled and then returned to the transmission through the other steel tube.

6. PARTS OF THE HYDRAULIC SYSTEM

6.1 INTRODUCTION: For the change of gears, lots of things have to be connected and disconnected. The clutches connect different members to be driven and the bands hold the required member stationary. The hydraulic system controls which clutches and bands are energized at any given moment. The hydraulic

12

Automatic transmission system

system receives information from the governor and throttle cable or vacuum modulator.

6.2 CLUTCHES: A clutch consists of

alternating disks that fit inside a clutch drum. As shown in fig. 6, half of the disks are steel and have splines that lock on the inside of the drum. The other half have a friction material bonded to their surface and have splines on the inside edge that lock onto one of the gears. There is a piston inside the drum that is activated by oil pressure at the appropriate time to squeeze the clutch pack together so that the two components become locked and turn as one.

6.3 BANDS: A band is a steel strap with friction material bonded to the inside surface. Fig. 7 shows the band and its servo. One end of the band is anchored against the transmission case while the other end is connected to a servo. At

13

Automatic transmission system

the appropriate time hydraulic oil is sent to the servo under pressure to tighten the band around the drum to stop it from turning, thus locking that part of the gear train to the casing.

6.4 OIL PUMP: The automatic transmission systems use a gear pump. The gear pump is responsible for producing all the oil pressure that is required in the transmission. The oil pump is mounted to the front of the transmission case and is directly connected to a flange on the torque converter housing. Since the torque converter housing is directly connected to the engine crankshaft, the pump will produce pressure whenever the engine is running as long as there is a sufficient amount of transmission fluid available. The oil enters the pump through a filter that is located at the bottom of the transmission oil pan and travels up a pickup tube directly to the oil pump. The oil is then sent, under pressure to the pressure regulator, the valve body and the rest of the components, as required.

6.5 PRESSURE REGULATOR: The pumps output pressure will increase roughly in proportion to the engines speed. However, the pressure necessary to actuate the various valves and to energise the clutch and band servo pistons will vary under different work conditions. Therefore the fluid pressure generated by the pump, is unlikely to suit the many operating requirements. To overcome these

14

Automatic transmission system

difficulties, a pressure regulating valve is used which automatically adjusts the pumps output pressure to match the working requirements at any one time. The pressure regulating valve is normally a spring-loaded spool type valve.

As pump pressure builds up with rising engine speed, line pressure is conveyed to the rear face of the plunger and will progressively move the plunger forward against a control spring, causing the exhaust port to be uncovered, which feeds back to the pump intake. Hence as the pump output pressure tends to rise, more fluid is passed back to the suction intake of the pump, thus regulating the fluid pressure. To enable the line pressure to be varied to suit the operating conditions, a throttle pressure is introduced to the spring end of the plunger, which opposes the line pressure. 6.6 GOVERNOR: The governor tells the transmission how fast the car is moving. The governor is connected to the output shaft and regulates hydraulic pressure based on vehicle speed. It accomplishes this using centrifugal force to spin a pair of weights against pull-back springs. As the weights pull further out against the springs, more oil pressure is allowed past the governor to act on the shift valves that are in the valve body which then signal the appropriate shifts. 6.7 THROTTLE CABLE AND VACUUM MODULATOR: Vehicle speed is not the only thing that controls when a transmission should shift, the load that the engine is under is also important. The more

15

Automatic transmission system

loads you place on the engine, the longer the transmission will hold a gear before shifting to the next one. The throttle valve and modulator serve the purpose of monitoring engine load. A transmission will use one or the other but generally not both of these devices. Each works in a different way to monitor engine load. The Throttle Cable simply monitors the position of the accelerator pedal through a cable that runs from the gas pedal to the throttle valve in the valve body. The further the gas pedal is pressed, the more pressure is put on the throttle valve. Engine vacuum reacts very accurately to engine load with high vacuum produced when the engine is under light load and diminishing down to zero vacuum when the engine is under a heavy load. The vacuum modulator is attached to the outside of the transmission case and has a shaft which passes through the case and attaches to the throttle valve in the valve body.

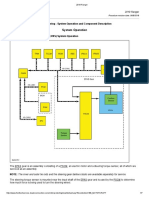

7. VALVE BODY

7.1 INTRODUCTION: The valve body is the brain of the automatic transmission. It contains a maze of channels and passages that direct hydraulic fluid to the numerous valves which then activate the appropriate clutch pack or band servo to smoothly shift to the appropriate gear for each driving situation. Each of the

16

Automatic transmission system

many valves in the valve body has a specific purpose and is named for that function. For example the 1-2 shift valve activates the 1st gear to 2nd gear upshift.

7.2 THE MANUAL VALVE: The manual valve is directly connected to the gear shift handle and covers and uncovers various passages depending on what position the gear shift is placed in. If the gear shift lever is moved in the 1st gear or 2nd gear position, the up-shift and down-shift are inhibited by the manual valve.

7.3 SHIFT VALVES: Shift valves, as shown in fig. 8 supply hydraulic pressure to the clutches and bands to engage each gear. The valve body of the transmission contains several shift valves. The shift valve determines when to shift from one gear to the next. The shift valve is pressurized with fluid from the governor on one side, and the throttle valve on the other. The shift valve will delay a shift if the car is accelerating quickly. If the car accelerates gently, the shift will occur at a lower speed.

17

Automatic transmission system

When the car accelerates gently, as car speed increases, the pressure from the governor builds. This forces the shift valve over until the first gear circuit is closed, and the second gear circuit opens. Since the car is accelerating at light throttle, the throttle valve does not apply much pressure against the shift valve. When the car accelerates quickly, the throttle valve applies more pressure against the shift valve. This means that the pressure from the governor has to be higher (and therefore the vehicle speed has to be faster) before the shift valve moves over far enough to engage second gear. Each shift valve responds to a particular pressure range; so when the car is going faster, the 2-to-3 shift valve will take over, because the pressure from the governor is high enough to trigger that valve.

8. ADVANTAGES AND DISADVANTAGES

18

Automatic transmission system

8.1 ADVANTAGES: 1. It minimizes driver fatigue, especially in heavy traffic by eliminating the need to operate the clutch pedal and gear lever for starting from rest and changing gear. 2. It contributes to safer driving because the concentration of the driver is not disturbed by the need to change gear; also, both hands can remain on the steering wheel. 3. Progress can be smoother under normal driving conditions, because gear changes will occur at the theoretically correct moment in terms of road speed and throttle opening.

8.2 DISADVANTAGES:

1. Cars with automatic transmission are costlier than those having manual transmission. 2. Fuel economy of cars with automatic transmission is not very good.

9. CONCLUSION

19

Automatic transmission system

The automatic transmission with its torque converter and planetary gear set, can successfully replace the clutch and the manual transmission gear box.

The planetary gear set gives the required gear ratios and the hydraulic system controls the planetary gear set.

Automatic

transmission

system

shifts

the

gears

automatically,

depending upon both, speed of vehicle and load on the engine.

However in cases like, descending hills, when it is desirable to employ a lower gear, though the load on the engine maybe nil or the engine maybe acting as a brake, the human element has to be retained in control.

REFERENCES

20

Automatic transmission system

1. William H. Crouse & Donald L. Anglin, Automotive Automatic Transmissions, Tata McGraw Hill Publishing Co., Sixth Edition, 1996. 2. John Fenton, Handbook of Automotive Powertrains and Chassis Design, Professional Engineering Publishing Ltd., First Published 1998. 3. Heinz Heisler, Advanced Vehicle Technology, Butterworth-Heinemann Publishers, Second Edition 2002. 4. www.familycar.com 5. www.howstuffworks.com 6. www.edmunds.com

21

You might also like

- Steering SystemDocument12 pagesSteering Systemmayur_lanjewarNo ratings yet

- Automatic Transmission System ExplainedDocument25 pagesAutomatic Transmission System ExplainedHemanth VallalaNo ratings yet

- Four-Wheel Steering ReportDocument21 pagesFour-Wheel Steering ReportMuralee Dharan PillaiNo ratings yet

- Abuki Anti Lock Braking SystemDocument20 pagesAbuki Anti Lock Braking SystemAbubaker MuzayinNo ratings yet

- Linear Control Technique Maintains Wheel Slip Ratio for ABSDocument5 pagesLinear Control Technique Maintains Wheel Slip Ratio for ABSBộ Môn DieuKhienhocNo ratings yet

- Slip Ratio Control of Anti-Lock Braking System With Bang-Bang ControllerDocument8 pagesSlip Ratio Control of Anti-Lock Braking System With Bang-Bang Controllerniveditha trNo ratings yet

- Electronic Brake Force DistributionDocument5 pagesElectronic Brake Force Distributiontamilselvan4160% (1)

- មេរៀន ប្រព័ន្ធហ្វ្រាំង ABSDocument26 pagesមេរៀន ប្រព័ន្ធហ្វ្រាំង ABSYon ChhannakNo ratings yet

- Modern Brake SystemDocument24 pagesModern Brake Systemfadhilah91No ratings yet

- Development of Four Wheel Steering System For A Car: K. Lohith, Dr. S. R. Shankapal, M. H. Monish GowdaDocument8 pagesDevelopment of Four Wheel Steering System For A Car: K. Lohith, Dr. S. R. Shankapal, M. H. Monish GowdaGaurav PandeyNo ratings yet

- Vehicle Dynamics ABS ModelingDocument26 pagesVehicle Dynamics ABS ModelingsengottaiyanNo ratings yet

- ABS AlgorithmDocument6 pagesABS AlgorithmadugnaNo ratings yet

- HowStuffWorks - Benefits of Hill-Start ControlDocument3 pagesHowStuffWorks - Benefits of Hill-Start ControlfrapedNo ratings yet

- 360 Degree Load CarrierDocument28 pages360 Degree Load CarrierTanviNo ratings yet

- Project Report: - Suspension SystemDocument33 pagesProject Report: - Suspension SystemAnil KumarNo ratings yet

- Fabrication of Four Wheel Steering SystemDocument14 pagesFabrication of Four Wheel Steering SystemRenju PaulNo ratings yet

- Automatic Transmission: Comparison With Manual TransmissionDocument11 pagesAutomatic Transmission: Comparison With Manual TransmissionAmir SiddiquiNo ratings yet

- Brake System - HMCDocument69 pagesBrake System - HMCDani HidayatulohNo ratings yet

- Regenerative Braking SystemDocument15 pagesRegenerative Braking SystemVinay KumarNo ratings yet

- Anti Lock Braking SystemDocument23 pagesAnti Lock Braking SystemSrinivas Bobby100% (1)

- MM40 Wire&SensorDocument37 pagesMM40 Wire&Sensorapi-19766924No ratings yet

- Hill Station Breaking SystemDocument48 pagesHill Station Breaking Systemkanchan bone80% (5)

- Anti Lock BrakesDocument26 pagesAnti Lock Brakesrishi_p08No ratings yet

- Steering Systems: 4.1 Axle-Beam Steering SystemDocument12 pagesSteering Systems: 4.1 Axle-Beam Steering SystemCallGRNo ratings yet

- Crash Sensors Detect ImpactsDocument5 pagesCrash Sensors Detect ImpactssjramanNo ratings yet

- Nurul Iman's Personal Monthly Budget and Cash Flow StatementDocument5 pagesNurul Iman's Personal Monthly Budget and Cash Flow StatementNur AishahNo ratings yet

- 8.0 Brake by Wire Ja505Document16 pages8.0 Brake by Wire Ja505Nareesh RajNo ratings yet

- Directional IndicatorsDocument8 pagesDirectional IndicatorsAuto VeteranNo ratings yet

- Antilock Braking SystemDocument19 pagesAntilock Braking SystemAlok Ranjan67% (3)

- Electronic Fuel Injection SystemsDocument113 pagesElectronic Fuel Injection SystemsUnni HaridasNo ratings yet

- Automobile Engineering in Brakes Lecture NotesDocument3 pagesAutomobile Engineering in Brakes Lecture NotesraamNo ratings yet

- Part-Iv: Drive ShaftDocument32 pagesPart-Iv: Drive Shaftgebremariam birkieNo ratings yet

- Principle: Power Sources TransmissionDocument18 pagesPrinciple: Power Sources TransmissionGaurav Maithani100% (2)

- Vacuum Braking SystemDocument20 pagesVacuum Braking SystemPrashant RaiNo ratings yet

- Electro Hydraulic Braking 2Document5 pagesElectro Hydraulic Braking 2Indranil SutarNo ratings yet

- Design and Fabrication of Hydraulic Zig Zag Bending MachineDocument46 pagesDesign and Fabrication of Hydraulic Zig Zag Bending MachineAakash DindigulNo ratings yet

- ActuatorsDocument48 pagesActuatorsnahom100% (1)

- How Hybrid Car WorksDocument11 pagesHow Hybrid Car WorksVivek SharmaNo ratings yet

- 10 Automatic Transaxle SystemDocument35 pages10 Automatic Transaxle SystemYun ZhenNo ratings yet

- Project Report On Power Transmission in AutomobilesDocument74 pagesProject Report On Power Transmission in AutomobilesRahul Yargattikar100% (1)

- A Seminor Report On Coupling PDFDocument24 pagesA Seminor Report On Coupling PDFAnup Singh71% (7)

- Regenerative Braking Seminar ReportDocument24 pagesRegenerative Braking Seminar ReportĨ Åm MoħănNo ratings yet

- T SB 0274 09Document5 pagesT SB 0274 09goombaNo ratings yet

- Emission TestsDocument30 pagesEmission TestsBoobalakrishnan A R MoorthyNo ratings yet

- Sensotronic Brake ControlDocument27 pagesSensotronic Brake ControlBishal MaskeyNo ratings yet

- Automatic Gearbox WorkingDocument10 pagesAutomatic Gearbox Workingsaurabhsharma1990No ratings yet

- Clutch in AutomobileDocument10 pagesClutch in AutomobileTAHIR QAMARNo ratings yet

- Basic Emission Control SystemsDocument5 pagesBasic Emission Control SystemsNadhirah JohaNo ratings yet

- Automobile Engineering: Steering SystemDocument50 pagesAutomobile Engineering: Steering SystemKarne Dheeraj KumarNo ratings yet

- Dual Clutch Transmission - Seminar Report, PPT, PDF For MechanicalDocument5 pagesDual Clutch Transmission - Seminar Report, PPT, PDF For MechanicalSachin Yadav100% (3)

- Drive LinesDocument30 pagesDrive LinesRITESH ROHILLANo ratings yet

- Advanced Chassis and Body Control Systems-Part2Document60 pagesAdvanced Chassis and Body Control Systems-Part2aliNo ratings yet

- 211-02 Power Steering - Description and Operation - System OperationDocument7 pages211-02 Power Steering - Description and Operation - System OperationCARLOS LIMADANo ratings yet

- Bump Steer by Longacre RacingDocument5 pagesBump Steer by Longacre RacingFotis FotopoulosNo ratings yet

- Automatic Brake Failure IndicatorDocument15 pagesAutomatic Brake Failure IndicatorThirumal Valavan100% (1)

- Chassis Dynamo MeterDocument5 pagesChassis Dynamo MeterHKD89No ratings yet

- Auto Matic Gear BoxDocument3 pagesAuto Matic Gear BoxPubudu DhananjayaNo ratings yet

- Automatic Transmission5 ReportDocument17 pagesAutomatic Transmission5 ReportManhar MidhaNo ratings yet

- Document 8Document3 pagesDocument 8Simulation BrodhahNo ratings yet

- How Automatic Transmissions Work ?Document17 pagesHow Automatic Transmissions Work ?bishal.sonar100% (2)

- A M O E B A-The Study of A Distributed Operating SystemDocument20 pagesA M O E B A-The Study of A Distributed Operating SystemMamesh MathankarNo ratings yet

- Magnetic Bearing Technology ExplainedDocument19 pagesMagnetic Bearing Technology ExplainedMamesh MathankarNo ratings yet

- Environmental Aspects of River ValleyDocument15 pagesEnvironmental Aspects of River ValleyMamesh MathankarNo ratings yet

- Intelligent Tutoring System 101Document19 pagesIntelligent Tutoring System 101Mamesh MathankarNo ratings yet

- Fiat Palio FIRE 1.3 16V DespieceDocument429 pagesFiat Palio FIRE 1.3 16V DespieceRichard Valera82% (33)

- Bicycle Gear Ratio Calculator (Table Calculations Example) : Toggle ButtonsDocument1 pageBicycle Gear Ratio Calculator (Table Calculations Example) : Toggle Buttonsabhinav abburiNo ratings yet

- ZF Atf PDFDocument7 pagesZF Atf PDFEd Morales100% (1)

- Maxtrak Cone PartsDocument39 pagesMaxtrak Cone PartsAshik Rahaman100% (1)

- ZEISS - Measurement - Report - Gear - Pro - InvoluteDocument3 pagesZEISS - Measurement - Report - Gear - Pro - Involutesandeep kumarNo ratings yet

- ZF Transmission Adaptations Drive CycleDocument3 pagesZF Transmission Adaptations Drive CycleKrzysztof KjbNo ratings yet

- Gear Manufacturing Process With QuestionsDocument60 pagesGear Manufacturing Process With QuestionsUjwala Sonawane100% (1)

- Fenner Flexible Gear Couplings Transmit PowerDocument4 pagesFenner Flexible Gear Couplings Transmit Powerren kaiNo ratings yet

- SSG Module 0.5, 0.8 Ground Spur Gears SpecsDocument8 pagesSSG Module 0.5, 0.8 Ground Spur Gears SpecsMarlon EvangelistaNo ratings yet

- Acadia 6T75 ShiftingDocument3 pagesAcadia 6T75 Shiftinglamping_apNo ratings yet

- New MRP List for Brake PartsDocument20 pagesNew MRP List for Brake PartsHanzoNo ratings yet

- Gates Bushings CatalogDocument17 pagesGates Bushings CatalogvibhorbhantiNo ratings yet

- Mc135 - Transmission - Main Shaft - Creep SpeedDocument2 pagesMc135 - Transmission - Main Shaft - Creep SpeedJouni MikkolaNo ratings yet

- Automatic Gear-Shifter Bicycle DesignDocument32 pagesAutomatic Gear-Shifter Bicycle DesignJohn Rafael AtienzaNo ratings yet

- RT 750 - TransmisionDocument21 pagesRT 750 - TransmisionLeydi Martin100% (1)

- Gear Backlash - KHK GearsDocument7 pagesGear Backlash - KHK Gearsadhytia farma arsalNo ratings yet

- ESTIMATING HOBBING TIMESDocument6 pagesESTIMATING HOBBING TIMESsosu_sorin3904100% (2)

- Transmision ToyotaDocument16 pagesTransmision ToyotaMartin Santoyo100% (2)

- 60765B, 04Document2 pages60765B, 04Oscar beltranNo ratings yet

- What Are Gears?Document3 pagesWhat Are Gears?José MedinaNo ratings yet

- Motorcycle TransmissionDocument12 pagesMotorcycle TransmissionChhetin SherpaNo ratings yet

- 1.1.3. Presentation Gears and SprocketsDocument24 pages1.1.3. Presentation Gears and SprocketsJoshua DeLoryNo ratings yet

- MASTER - Publications 15 PDFDocument1 pageMASTER - Publications 15 PDFgioNo ratings yet

- Problem Set MD Day 4Document4 pagesProblem Set MD Day 4DE GUZMAN, MELVIN CARLO A.No ratings yet

- ZF 5HP24A Transmission Repair ManualDocument200 pagesZF 5HP24A Transmission Repair ManualAlvaro MoraNo ratings yet

- Toyota Starlet L4-4KC 1982: Timing Chain: Service and RepairDocument4 pagesToyota Starlet L4-4KC 1982: Timing Chain: Service and RepairNicolas Antonio Godoy SolisNo ratings yet

- FormulasDocument11 pagesFormulasAbdelrhman Essam AttiaNo ratings yet

- Manual de Partes MOLINO BUTCHER AF52Document9 pagesManual de Partes MOLINO BUTCHER AF52ivan reyes TorresNo ratings yet

- AT2011 Nissan To ToyotaDocument138 pagesAT2011 Nissan To ToyotaTransmisiones Guero100% (2)

- Gear Drive, Belt and Chain Drive - Lecture NotesDocument26 pagesGear Drive, Belt and Chain Drive - Lecture NotesVarun KavvampalliNo ratings yet