Professional Documents

Culture Documents

Companion Feed Stock - A Secoin Invention in Agarwood Oil Distillation

Uploaded by

Dinh xuan BaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Companion Feed Stock - A Secoin Invention in Agarwood Oil Distillation

Uploaded by

Dinh xuan BaCopyright:

Available Formats

COMPANION FEEDSTOCK - A SECOIN INVENTION IN AGARWOOD OIL DISTILLATION

Professor Dinh xuan Ba Director of SECOIN Applied Biology Center

Definitions

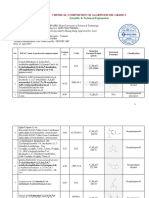

Distillation system is an equipment that usually consists of three main parts: vessel, condenser and Clevenger oil trap (see Appendix 1) Feedstock is raw material can be fed in the vessel of a distillation system making essential oil Companion feedstock is a feedstock which accompanies with other feedstocks for a longer or shorter period aiming at predetermined purposes (in scientific terminology the name companion is usually utilized, for example: companion plant in agronomy) Agarwood is an aromatic resinous wood naturally or artificially formed in heartwood (or inner parts) of several species of the family Thymelaeaceae Jussieu., the trees of those species are hereinafter called agarwood-producing trees. In the appendix 2 and appendix 3 agarwood is described by black part located in the centre of log section. The contiguous area is hereinafter called transitional zone. Tiny transitional bits are also located in Agarwood (see appendix 3). Agarwood has been considered to be a pathological product by infection, so the white part of this log is referred to as healthy wood. In the black part there are both endogenous secretory cells (glandulars) and resin ducts. Secretory cells may also found in transitional zone, even in healthy wood. Please be noted that in several cases agarwood is not concentrated to heartwood of log but dispersed in inner part of log. Agarwood oil is essential oil obtained in Clevenger oil trap after the condensational process of evaporated volatile aromatic compounds (VACs) S312 and S088 is SECOIN companion feedstock that is utilized in Agarwood oil distillation Intact distillation of agarwood oil: is such a hydrodistillation in which a whole log of agarwood-producing tree is cut, chopped and ground into tiny bits (splinters) which are used as feedstock of this hydrodistillation (see appendix 4). Selective distillation of agarwood oil: is such a hydrodistillation in which only Agarwood pieces selected from the central black part and the remains of transitional zone (including shavings) are chopped and ground into tiny bits (splinters) which are used as feedstock of this hydrodistillation (see appendix 2). 1

The evolvement of chemicals during the process of agarwood formation

During the process of agarwood formation several chemicals to be on the decrease in content even disappeared and a number of chemicals to be on the increase in content even newly appeared. For example, Tamuli P. and his colleagues has discovered this finding in their scientific research (see J. Essent Oil.2006, Res 17, 601-604) when studying essential oils obtained from Aquilaria malaccensis tree. In appendix 3, the decreasing chemicals are written in blue letters and located mainly in healthy wood and transitional zone, the increasing chemicals are written in red letters and located mainly in black part of log (agarwood). In intact distillation of agarwood oil, apart from agarwood oil in liquid form we usually obtain congealed matter that is similar to solid fat (see appendix 4), the reason is a significant quantity of healthy wood and transitional zone located in feedstock, it results so many decreasing chemicals to be composed in finished products of intact distillation. The congealed matter must be removed from finished products of intact distillation and has a very low value in market. Please be noted that a small quantity of congealed is also found in finished products of selective distillation of agarwood oil because in agarwood chip there is also tiny transitional bits, moreover a number of shavings of transitional zone are also located in feedstock of selective distillation.

Features and effects of SECOIN companion feedstocks S312 & S088

Companion feedstock S312 (the same for S088) is a biological additive in distillation, but it is not a common additive in usual meaning because it has consanguineous relationship with all agarwood feedstocks. S312 has special properties and effects on distillation, namely: S312 is material made of the tree whose species belongs to the subfamily Thymelaeoideae. All other agarwood-producing species also belong to this subfamily (see appendix 5). This means that S312 has phylogenetic relation with all other agarwood feedstock, in other words it is a congener with all agarwood-producing species. The chemical composition of essential oil derived from S312 contains compatible and uncompetitive compounds with other agarwood oils. Please pay attention to the existence of big content of 10-epi-gamma-eudesmol (30%) (it is also an increasing chemical stated in appendix 3) and alpha-eudesmol (26%) (see appendix 6). Moreover it also contains compound having dissolving effect. Thanks to this feature, all or a part of congealed matter to be dissolved. Distillation yield of S312 essential oil is about 0.3% (while for other agarwood oil it is 0.05% to 0.1% only), thanks to that yield of finished product is significantly augmented. Density and viscosity of essential oil derived from S312 is higher than the one of other agarwood oils, relying on that density and viscosity of finished agarwood oil to be augmented. The smell of essential oil derived from S312 is faintly aromatic that is not in contrary with other agarwood scent, although it has not particular fragrance of other agarwood oils. The production cost of S312 is very low, it is equal to tenth (1/10) hundredth (1/100) the price of other agarwood feedstock, thanks to that the production cost of finished agarwood oil is significantly reduced, especially for expensive agarwood feedstock. territories. 2

- The tree species used for making S312 is not available in Vietnam, but abundant in other

Appendix 1

Condenser

Clevenger Oil Trap

SS vessel

Appendix 2

Appendix 3

Appendix 4

Appendix 5

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- IOO Chemical CompositionDocument7 pagesIOO Chemical CompositionDinh xuan BaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Method SEC1 For Evaluation of Agarwood Essential Oil QualityDocument2 pagesMethod SEC1 For Evaluation of Agarwood Essential Oil QualityDinh xuan BaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Differences Between Kynam and Normal AgarwoodDocument4 pagesDifferences Between Kynam and Normal AgarwoodDinh xuan BaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Three Main Classes of Essential Oils in BlendingDocument6 pagesThree Main Classes of Essential Oils in BlendingDinh xuan BaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Springjournals - Publication of IJARR 17 084 DinhDocument4 pagesSpringjournals - Publication of IJARR 17 084 DinhDinh xuan BaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- API Msds New 3.3.16Document5 pagesAPI Msds New 3.3.16Dinh xuan BaNo ratings yet

- Additional Explanation of IOO Chemical CompositionDocument1 pageAdditional Explanation of IOO Chemical CompositionDinh xuan BaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Suggested Method For Evaluation of Agarwood Oil QualityDocument2 pagesSuggested Method For Evaluation of Agarwood Oil QualityDinh xuan BaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Agarwood Oil-Grade S Sample-Chemical CompositionDocument6 pagesAgarwood Oil-Grade S Sample-Chemical CompositionDinh xuan BaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- About Migi-KDocument1 pageAbout Migi-KDinh xuan BaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Vietnamese Farmer Uses Ants To Create Rare Aloeswood-Journal of Global Issues & Solutions-May - June 2015Document9 pagesVietnamese Farmer Uses Ants To Create Rare Aloeswood-Journal of Global Issues & Solutions-May - June 2015Dinh xuan BaNo ratings yet

- Graphic Description of The Evolution of Agarwood CompoundsDocument1 pageGraphic Description of The Evolution of Agarwood CompoundsDinh xuan BaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 2011 Price List of Kynam-Updated 23.9.2011Document6 pages2011 Price List of Kynam-Updated 23.9.2011Dinh xuan BaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 2011 Price List of Agarwood Bead StringsDocument1 page2011 Price List of Agarwood Bead StringsDinh xuan BaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- 2011 Price List of SECOIN Agarwood ChipsDocument1 page2011 Price List of SECOIN Agarwood ChipsDinh xuan BaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2011 Price List of KynamDocument1 page2011 Price List of KynamDinh xuan BaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Inclusive Business: SECOIN Comments and ProposalsDocument16 pagesInclusive Business: SECOIN Comments and ProposalsDinh xuan BaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- New Sesquiterpene From Vietnamese AgarwoodDocument4 pagesNew Sesquiterpene From Vietnamese AgarwoodDinh xuan BaNo ratings yet

- About Mucuna Pruriens-Dau MeoDocument3 pagesAbout Mucuna Pruriens-Dau MeoDinh xuan BaNo ratings yet

- Medicinal Uses of Moringa Oleifera (After J.A. Duke)Document1 pageMedicinal Uses of Moringa Oleifera (After J.A. Duke)Dinh xuan BaNo ratings yet

- Sprintails (Collembolan) Living in Perionyx Excavatus FarmDocument16 pagesSprintails (Collembolan) Living in Perionyx Excavatus FarmDinh xuan BaNo ratings yet

- About Arachis Pintoi Krap. (L C D I)Document8 pagesAbout Arachis Pintoi Krap. (L C D I)Dinh xuan BaNo ratings yet

- Sedative Effects of Vapor Inhalation of Agarwood OilDocument6 pagesSedative Effects of Vapor Inhalation of Agarwood OilDinh xuan Ba100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Offer - Agarwood Pieces and KynamDocument5 pagesOffer - Agarwood Pieces and KynamDinh xuan BaNo ratings yet

- Relation of Production Cost and Stalk YieldDocument1 pageRelation of Production Cost and Stalk YieldDinh xuan BaNo ratings yet

- Differentiation Between Kynam and Normal AgarwoodDocument3 pagesDifferentiation Between Kynam and Normal AgarwoodDinh xuan BaNo ratings yet

- Relation of Production Cost and Stalk QualityDocument1 pageRelation of Production Cost and Stalk QualityDinh xuan BaNo ratings yet

- Summarization On Trial Cultivation of Sweet SorghumDocument1 pageSummarization On Trial Cultivation of Sweet SorghumDinh xuan BaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Kynam - Highest-Quality Agarwood PiecesDocument5 pagesKynam - Highest-Quality Agarwood PiecesDinh xuan Ba100% (1)

- INUKA Communication - 7 January 2021Document1 pageINUKA Communication - 7 January 2021Ânchelin NhanalaNo ratings yet

- SL 15 Issue Final PDFDocument48 pagesSL 15 Issue Final PDFErik NguyenNo ratings yet

- Glossary of Terms - Fragrances - LuckyscentDocument3 pagesGlossary of Terms - Fragrances - LuckyscentMohamed EldawNo ratings yet

- AGEON GMBH Pricelist 20230705 ENDocument44 pagesAGEON GMBH Pricelist 20230705 ENegorNo ratings yet

- The Song of Songs commentary explores Solomon's loveDocument169 pagesThe Song of Songs commentary explores Solomon's lovepsebooks100% (1)

- Guidance On Essential OilsDocument18 pagesGuidance On Essential OilsJuanGuillermoCarmonaOcampoNo ratings yet

- Essential Oil of The Month: SandlewoodDocument2 pagesEssential Oil of The Month: SandlewoodAnumeha Jindal0% (1)

- AbstractDocument26 pagesAbstractSohham ParingeNo ratings yet

- Song of Myself-EssayDocument6 pagesSong of Myself-Essayvlad stefanNo ratings yet

- Victoria's Secret BrochureDocument7 pagesVictoria's Secret BrochuregennmarinduqueNo ratings yet

- zw3 D 240 Kao Floor Cleaner Clear Drying - LevelDocument2 pageszw3 D 240 Kao Floor Cleaner Clear Drying - LevelSomnath singha royNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ReadingDocument6 pagesReadingTUTOR IELTS0% (1)

- Final Final Business Plan PDFDocument51 pagesFinal Final Business Plan PDFSofia AgudonNo ratings yet

- Aromatic Artistry 2 Pre Fixing Alcohol PDFDocument3 pagesAromatic Artistry 2 Pre Fixing Alcohol PDFArie JbNo ratings yet

- Essential Oils and Meditation 1Document15 pagesEssential Oils and Meditation 1adext100% (1)

- BOUNCE CURL GuideDocument8 pagesBOUNCE CURL Guidejulianavasquez097No ratings yet

- Project Calm January 2020 PDFDocument152 pagesProject Calm January 2020 PDFChantal ElieNo ratings yet

- SUGAR INDUSTRY: HISTORY, MANUFACTURING, AND ECONOMICSDocument40 pagesSUGAR INDUSTRY: HISTORY, MANUFACTURING, AND ECONOMICSgingerootNo ratings yet

- DocumentDocument4 pagesDocumentSazidNo ratings yet

- Brand SpinzDocument6 pagesBrand SpinzRahul ParateNo ratings yet

- Sensory Diet Exploration: Activity Checklist: MovementDocument3 pagesSensory Diet Exploration: Activity Checklist: MovementsaraNo ratings yet

- Niral Course Catalogue 2015Document30 pagesNiral Course Catalogue 2015NarendraNo ratings yet

- The Perfumes of Tenute Rio MaggioDocument2 pagesThe Perfumes of Tenute Rio MaggioDebbie GioquindoNo ratings yet

- Car Care Module (ALL IN ONE)Document15 pagesCar Care Module (ALL IN ONE)Diztrict GarageNo ratings yet

- Nocominter PDFDocument124 pagesNocominter PDFsyedamiriqbalNo ratings yet

- Production of With Formulations: Flavours and PerfumesDocument137 pagesProduction of With Formulations: Flavours and PerfumesTatag Adi SasonoNo ratings yet

- IFF - Perfume FormulasDocument20 pagesIFF - Perfume FormulasMattCanadianintokyo83% (23)

- Scents of Rome: Aromatics in Late Republic and Early EmpireDocument35 pagesScents of Rome: Aromatics in Late Republic and Early EmpireAbdul WasayNo ratings yet

- Beauty & Fragrance Product Information FormDocument5 pagesBeauty & Fragrance Product Information FormGennadiy BondarenkoNo ratings yet

- Fake Cosmetics Product Effects On HealthDocument5 pagesFake Cosmetics Product Effects On Healthdiana ramzi50% (2)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)