Professional Documents

Culture Documents

Chemical Processing

Uploaded by

arachman297988Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chemical Processing

Uploaded by

arachman297988Copyright:

Available Formats

4/23/2011

Mixing | How do I calculate the dynami

Print page

How do I calculate the dynamic force on the agitator?

Q: How do I calculate the dynamic force on the agitator? The details are as given: Capacity of mixer: 15 Kl Motor: HP 75 HP shaft speed: 48 rpm diameter of vessel: 2450 mm st. height: 3000 mm dish height: 491 mm stirrer: anchor type sweep dia: 2300 mm material viscosity: 40 poise (emulsion-based paint)

A: Explaining "how" to calculate the dynamic force on the agitator is more difficult than providing a value for the conditions described. Further, "how" the "dynamic force" will be used makes a difference in the suggested safety factors to be applied to the calculated values. For the purposes of equipment design, the dynamic forces should be calculated based on the motor horsepower and agitator speed, since at some viscosity the motor could be fully loaded. On that basis, torque will be about 11,000 N-m. An estimate of the bending load on the shaft and drive is about the same, 10,000 N-m. Those loads require a 125 mm diameter shaft. For the purposes designing a support for the agitator, a rigid mounting is necessary. The support should be designed to handle 2.5 times the calculated torque and 3.0 times the calculated bending load. If all that is needed is an anticipated operating load for the dimensions and viscosity described, the agitator will require about 33 hp. That requirement is based on a viscous power number of 360 (for laminar operation), which is multiplied by a factor of 2.2 for the impeller Reynolds number of about

chemicalprocessing.com//026.html 1/4

4/23/2011

Mixing | How do I calculate the dynami

1,000. The resulting viscous (not turbulent) power number is 780.

The answers by this expert are based on the best available interpretation of the information provided. The consequences of the application of this information are the responsibility of the user. If clarification is needed, please submit a further question.

Here are more of the latest questions on: Mixing What type of impeller and engine power should I use for the following service? What type of impeller and engine power should I use for the following service?

Tank: Diameter = 2m, L = 5m (17m 3 Capacity) Fluid = Vegetable oil (I think viscosity = 60 cP, density = 900 kg/m 3 ) Temperature: Reaches 130 degrees C

What is the best mixer for solids and liquids? I want to mix a solid with a liquid with the ratio of 50/50. But the solid is water wet 30% and I have to drive off the water while mixing the two components. What is the best mixer to use to first get the water to the top of the vessel, evaporate off and also mix the solids and liquid? Solids density is 1.6 g/cc, liquid is 1.5 g/cc. What is causing the mechanical problems with agitators? I am currently mixing 4 tons of product with a density of 8.4lb/gal that is very sensitive to over mixing. My current mixer design has reliability issues. There are two counter rotating agitators in the tank which are about 8' long by 5' wide. While running, the agitators sway due to either fabrication quality or design flaws. I currently have 2" and 4" shafts extending down from the gear box into the tank. I am being sold on two different design options: 1.) Add a steady bearing to bottom of tank to reduce movement and my issues with this are the following: a. Ability to CIP; b. Have not corrected the problem just hid they symptom; c. Failure of the tank due to shaft hitting steady bearing in the repeatedly in the same place.

chemicalprocessing.com//026.html

2/4

4/23/2011

Mixing | How do I calculate the dynami

2.) Increase the size of the shaft to 6" and 3" my issues are the following: a. Work required to perform repair (cut off top of tank and replace with new cover); b. Cost associated with new gear box installs. My question is for this application in a pharmaceutical environment, what would be the best course of action? Is there any published literature on the subject? Lastly are these design solution accurate or should I be looking at other alternatives? What are the motor powers and shaft diameters for these agitators? To be used in various tanks we need to get your answer for agitator motor power and shaft diameter for the following agitator data: Agitator A: Liquid in tank: Density = 1.09 t/m 3 Dynamic viscosity = 150 mPa.s Temperature = 85 degrees C (average) Speed: 95 rpm Length in tank = 3650 mm Impeller: 1 row, 2 blades , 900 mm in dia. Tank volume= 40 m 3 Agitator B: Liquid in tank: Density = 1.4 t/m 3 Dynamic viscosity = 100 mPa.s Temperature = 80 degrees C (average) Speed: 85 rpm Length in tank = 4750 mm Impellers: 2 rows, 2m between rows, 2 blades at each row , 1300 mm in dia. Tank volume= 28 m 3 Agitator C: Liquid in tank: Density = 1.48 t/m 3 Dynamic viscosity = 10000 mPa.s (average) Temperature = 70 degrees C (average) Speed: 66 rpm Length in tank = 5630 mm Impellers: 3 rows, 1m between rows, 2 blades at each row , 800 mm in dia. Tank volume= 15 m 3

chemicalprocessing.com//026.html 3/4

4/23/2011

Mixing | How do I calculate the dynami

For the above agitators, I need motor powers and shaft diameters. How do I calculate the dynamic force on the agitator? How do I calculate the dynamic force on the agitator? The details are as given: Capacity of mixer: 15 Kl Motor: HP 75 HP shaft speed: 48 rpm diameter of vessel: 2450 mm st. height: 3000 mm dish height: 491 mm stirrer: anchor type sweep dia: 2300 mm material viscosity: 40 poise (emulsion-based paint)

Back to Ask the Experts

Copyright 2004 - 2011 Chemical Processing All rights reserved Contact Us | Privacy Policy | Legal Disclaimers, Terms and Conditions

chemicalprocessing.com//026.html

4/4

You might also like

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- Agitator DesignDocument6 pagesAgitator DesignGLENDA CASINONo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Agitator DesignDocument6 pagesAgitator Designप्रमोद रणपिसेNo ratings yet

- Design Calculations For Slurry AgitatorsDocument19 pagesDesign Calculations For Slurry Agitatorsmshah222100% (4)

- Diesel Common Rail Injection Electronic Components ExplainedFrom EverandDiesel Common Rail Injection Electronic Components ExplainedRating: 3.5 out of 5 stars3.5/5 (7)

- 1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringDocument3 pages1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringChadaram JagadishNo ratings yet

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowRating: 2 out of 5 stars2/5 (1)

- AT8611 Lab QuestionsDocument9 pagesAT8611 Lab QuestionsChirpiNo ratings yet

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Sheet 4Document5 pagesSheet 4Abdalla Mohamed AbdallaNo ratings yet

- BELT Lecture 01Document56 pagesBELT Lecture 01mahaveer dasNo ratings yet

- Chapter 2 - ExercisesDocument4 pagesChapter 2 - ExercisesMc AxNo ratings yet

- DOM Some Problems 3Document10 pagesDOM Some Problems 3NagarajuRbNo ratings yet

- Machine Design - LDocument2 pagesMachine Design - LNilesh Mistry (Nilesh Sharma)No ratings yet

- Unit 1 - Force Analysis-1 - University Questions PDFDocument2 pagesUnit 1 - Force Analysis-1 - University Questions PDFArafath JazeebNo ratings yet

- MEET 422L2 - Prelims - Experiment 2 - HP Eff - Gear Speed RatiosDocument5 pagesMEET 422L2 - Prelims - Experiment 2 - HP Eff - Gear Speed RatiosCj TilamNo ratings yet

- Gearhead Selection-Application GuidelinesDocument2 pagesGearhead Selection-Application GuidelinesKarim FawziNo ratings yet

- 121Document5 pages121derping lemonNo ratings yet

- DMM-2 3 1 Q&aDocument6 pagesDMM-2 3 1 Q&aAnand vinayNo ratings yet

- ProblemsDocument25 pagesProblemsJohn Paul JuegoNo ratings yet

- Problems Agricultural EngineeringDocument25 pagesProblems Agricultural EngineeringRegan Roldan RolaNo ratings yet

- Hydraulic & Pneumatic MotorsDocument14 pagesHydraulic & Pneumatic MotorsJogi Oscar SinagaNo ratings yet

- Lathe DesignDocument11 pagesLathe DesignShiyas Basheer0% (1)

- Cw1 Part1 M21mae David Chaves Sid8378556Document22 pagesCw1 Part1 M21mae David Chaves Sid8378556David ChavesNo ratings yet

- SQ - 4.7 - Pumps (Table Format)Document5 pagesSQ - 4.7 - Pumps (Table Format)Amitav MishraNo ratings yet

- 2018sme 7 Sem Design of Mechanical Drives Summer 2018Document2 pages2018sme 7 Sem Design of Mechanical Drives Summer 2018Komal HingeNo ratings yet

- MEE2003 Laboratory FAT Question PaperDocument4 pagesMEE2003 Laboratory FAT Question PaperKartik ChaturvediNo ratings yet

- PipeDocument168 pagesPipeSunde PascuaNo ratings yet

- Basic Mechanical Engineering SessionalDocument18 pagesBasic Mechanical Engineering SessionalRahik WasifNo ratings yet

- Diploma Board Examination - December 2020Document2 pagesDiploma Board Examination - December 2020Pradeep AppuNo ratings yet

- 2 Stroke TuningDocument6 pages2 Stroke TuningRahul NakheNo ratings yet

- DMDDocument4 pagesDMDSantosh AloneNo ratings yet

- 10M134 AIC Assignment 1 & 2 PDFDocument14 pages10M134 AIC Assignment 1 & 2 PDFChandannnn92No ratings yet

- Basic Two-Stroke TuningDocument9 pagesBasic Two-Stroke TuningAdyNo ratings yet

- Transfer Pump BrochureDocument12 pagesTransfer Pump BrochureRafert RamNo ratings yet

- Sathyabama University: Register NumberDocument3 pagesSathyabama University: Register NumberSecret SecretNo ratings yet

- Torque Agitator CalculationDocument3 pagesTorque Agitator CalculationGeorge Markas100% (1)

- Iii Me Ii Sem Q.bank 2016-17Document32 pagesIii Me Ii Sem Q.bank 2016-17Abhishek SakatNo ratings yet

- Expt. 2A - 4-Stroke Diesel Engine-Without DataDocument6 pagesExpt. 2A - 4-Stroke Diesel Engine-Without DataZen RuNo ratings yet

- A Machine Tool GearboxDocument2 pagesA Machine Tool GearboxSanket ShahNo ratings yet

- Engine Design and Operating ParametersDocument26 pagesEngine Design and Operating Parametersishanv_1430% (1)

- 24Document10 pages24Văn Tuấn NguyễnNo ratings yet

- 2stroke TuningDocument5 pages2stroke TuningRaka Dozer MahardhikaNo ratings yet

- Basic Two Stroke Tuning by Eric Gorr (I Think)Document7 pagesBasic Two Stroke Tuning by Eric Gorr (I Think)Dr DNo ratings yet

- TM 1Document4 pagesTM 1Ketan JoshiNo ratings yet

- Motor Driver Selection For CompressorsDocument13 pagesMotor Driver Selection For CompressorsMuhammad ImranNo ratings yet

- Assignment 2Document2 pagesAssignment 2Siddharth JajoriaNo ratings yet

- DAY1Document24 pagesDAY1Phillip Roger TumenlacoNo ratings yet

- Lecture 7 - I.C Engine - Part 2Document18 pagesLecture 7 - I.C Engine - Part 2Khushank MNo ratings yet

- Hybrid Servo-Driven IMMsDocument32 pagesHybrid Servo-Driven IMMsFalecyaRedinaNo ratings yet

- Machine Design I TutorialDocument3 pagesMachine Design I TutorialbngelotrNo ratings yet

- Plate Format For PPEDocument11 pagesPlate Format For PPEdominiqueNo ratings yet

- Basic Motor Formulas and Calculations PDFDocument11 pagesBasic Motor Formulas and Calculations PDFAditya Shrivastava100% (2)

- Steam EnginesDocument6 pagesSteam Engineschat2adiNo ratings yet

- Dmm-II Assignment TestDocument2 pagesDmm-II Assignment TestSai Srinivas BodapatiNo ratings yet

- DTSDocument7 pagesDTSmithundme659No ratings yet

- r05220304 Thermal Engineering IDocument8 pagesr05220304 Thermal Engineering IandhracollegesNo ratings yet

- DMM 2Document8 pagesDMM 2Robin MessiNo ratings yet

- Arrest AllDocument4 pagesArrest Allarachman297988No ratings yet

- A12 StandardDocument12 pagesA12 Standardarachman297988No ratings yet

- Vortex Breakers: RBRR and RBRQDocument6 pagesVortex Breakers: RBRR and RBRQarachman297988No ratings yet

- Ecobulk MX: Perfect For Transport and StorageDocument1 pageEcobulk MX: Perfect For Transport and Storagearachman297988No ratings yet

- Poly Drums: Protecting People, Property and The Planet. Since 1894Document16 pagesPoly Drums: Protecting People, Property and The Planet. Since 1894arachman297988No ratings yet

- Load Cell and Transmitter PR PDFDocument1 pageLoad Cell and Transmitter PR PDFarachman297988No ratings yet

- 2 in Wilden Px810 - AluminumDocument1 page2 in Wilden Px810 - Aluminumarachman297988No ratings yet

- VTEC400Document4 pagesVTEC400arachman297988No ratings yet

- X320 700 300Document2 pagesX320 700 300arachman297988No ratings yet

- Fall Arrester Front ViewDocument1 pageFall Arrester Front Viewarachman297988No ratings yet

- R400-702-430-M07 - DatasheetDocument6 pagesR400-702-430-M07 - Datasheetarachman297988No ratings yet

- Fall Arrester - 2-Layout1Document1 pageFall Arrester - 2-Layout1arachman297988No ratings yet

- R400-613-151-M02 - Indicator Manual r420Document149 pagesR400-613-151-M02 - Indicator Manual r420arachman297988No ratings yet

- Fall Arrester - Side ViewDocument1 pageFall Arrester - Side Viewarachman297988No ratings yet

- Ladder Iso TankDocument2 pagesLadder Iso Tankarachman297988No ratings yet

- Fall Arrester Top ViewDocument1 pageFall Arrester Top Viewarachman297988No ratings yet

- Electric Gear Pump - Rev 2Document1 pageElectric Gear Pump - Rev 2arachman297988No ratings yet

- Electric Gear Pump - Rev 1Document1 pageElectric Gear Pump - Rev 1arachman297988No ratings yet

- Cooling Tower Motor TypeDocument1 pageCooling Tower Motor Typearachman297988No ratings yet

- Fall Arrester 3d ViewDocument1 pageFall Arrester 3d Viewarachman297988No ratings yet

- Grounding ClampDocument1 pageGrounding Clamparachman297988No ratings yet

- Rail and Truck Brochure FinalDocument17 pagesRail and Truck Brochure Finalarachman297988No ratings yet

- Color Card JotafloorDocument2 pagesColor Card Jotafloorarachman297988No ratings yet

- Stainless Welding FittingsDocument16 pagesStainless Welding FittingsShane HancockNo ratings yet

- Canadian Bleve TextDocument31 pagesCanadian Bleve Textarachman297988No ratings yet

- Ladder Iso TankDocument2 pagesLadder Iso Tankarachman297988No ratings yet

- Basket FilterDocument8 pagesBasket Filterarachman297988No ratings yet

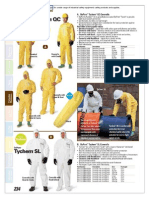

- Tychem. QC: Chemical Resistant ApparelDocument1 pageTychem. QC: Chemical Resistant Apparelarachman297988No ratings yet

- Welcome To Liquid Cargo, IncDocument3 pagesWelcome To Liquid Cargo, Incarachman297988No ratings yet

- Air Impact WrenchDocument1 pageAir Impact Wrencharachman297988No ratings yet

- Load TablesDocument3 pagesLoad Tablesidinjan.ashtariNo ratings yet

- Engine - Activity - Lab - Sheet Rev.ADocument5 pagesEngine - Activity - Lab - Sheet Rev.AAvery KarevNo ratings yet

- Modelling of Short Duration Isopluvial Map For Raichur District KarnatakaDocument4 pagesModelling of Short Duration Isopluvial Map For Raichur District KarnatakaMohammed Badiuddin ParvezNo ratings yet

- Hardness of Die's Components (PSMC) (Recovered)Document4 pagesHardness of Die's Components (PSMC) (Recovered)Subuk T. RathodNo ratings yet

- Design of Ms Pipe:: - (40 MM NB, Class'b'Document4 pagesDesign of Ms Pipe:: - (40 MM NB, Class'b'Kancharla Naga Ratna KumarNo ratings yet

- Charpy Impact TestDocument3 pagesCharpy Impact TestRamana IkkurthiNo ratings yet

- Mind Mapping of WeldingDocument8 pagesMind Mapping of WeldingFadlanbunglonNo ratings yet

- Risk Assesment-Rebar Loading & UnloadingDocument1 pageRisk Assesment-Rebar Loading & Unloadingmainraj rajNo ratings yet

- Phy 109 PDFDocument1 pagePhy 109 PDFsohamNo ratings yet

- Design of Queensland Road Infrastructure For High Risk EnvironmentsDocument7 pagesDesign of Queensland Road Infrastructure For High Risk EnvironmentsAnonymous fS6Znc9No ratings yet

- Fighting To Win - Tank in Australian ArmyDocument38 pagesFighting To Win - Tank in Australian ArmyLeo Purdy100% (1)

- Dr. Assad Abu-Jasser, ECE-iugaza: Electrical Machines (EELE 4350)Document37 pagesDr. Assad Abu-Jasser, ECE-iugaza: Electrical Machines (EELE 4350)MohammedSaadaniHassani67% (6)

- KICH MKT PVT LTD Project Report-Prince DudhatraDocument93 pagesKICH MKT PVT LTD Project Report-Prince DudhatrapRiNcE DuDhAtRa67% (3)

- Guidebook 184Document1 pageGuidebook 184Anonymous 7GOnu0xeuCNo ratings yet

- Pal LeDocument10 pagesPal LemoebiuszeroNo ratings yet

- Bailey HangoutsDocument477 pagesBailey Hangoutsmemes MendezNo ratings yet

- Emi 2018Document72 pagesEmi 2018Pushpendra Pratap Singh0% (1)

- Working Drawings: Key PlanDocument1 pageWorking Drawings: Key PlanSharanyaNo ratings yet

- Music Frequency Cheat SheetDocument1 pageMusic Frequency Cheat SheetLeonel Molina AlvaradoNo ratings yet

- Exhibitor 35804 PDFDocument36 pagesExhibitor 35804 PDFulton1237624No ratings yet

- Adamatic Model ADR 2c 2 Poket Divider RounderDocument43 pagesAdamatic Model ADR 2c 2 Poket Divider RounderRogelio Otelio100% (1)

- Am220kxvjnh Id PDFDocument1 pageAm220kxvjnh Id PDFMarwene HlaouiNo ratings yet

- Usage of D6T-44L - 8L - 1A Thermal SensorDocument23 pagesUsage of D6T-44L - 8L - 1A Thermal SensorEduardo ggNo ratings yet

- S8 PDFDocument184 pagesS8 PDFsrdsosonpurNo ratings yet

- FU2185011009 Description PICO With Bayonet Connector ENDocument10 pagesFU2185011009 Description PICO With Bayonet Connector ENDonny Wierya pratamaNo ratings yet

- A Project Report On Financial Performance Evaluation With Key Ratios at Vasavadatta Cement Kesoram Industries LTD Sedam Gulbarga PDFDocument82 pagesA Project Report On Financial Performance Evaluation With Key Ratios at Vasavadatta Cement Kesoram Industries LTD Sedam Gulbarga PDFK Sagar Kondolla100% (1)

- Junction Box PDFDocument2 pagesJunction Box PDFMohan ShanmugamNo ratings yet

- FuzzyDocument75 pagesFuzzyvatsalshah24No ratings yet

- Optical Disc PackagingDocument30 pagesOptical Disc Packagingsameeksha_maury8933No ratings yet

- Introductory Fluid Mechanics Taught Using A Carbur PDFDocument2 pagesIntroductory Fluid Mechanics Taught Using A Carbur PDFUsman Ali Usman AliNo ratings yet

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (51)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CFrom EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CNo ratings yet

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Fuels, Furnaces and Refractories: International Series on Materials Science and TechnologyFrom EverandFuels, Furnaces and Refractories: International Series on Materials Science and TechnologyRating: 5 out of 5 stars5/5 (1)

- Mechanical Vibrations and Condition MonitoringFrom EverandMechanical Vibrations and Condition MonitoringRating: 5 out of 5 stars5/5 (1)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersFrom EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersRating: 4 out of 5 stars4/5 (13)

- Advanced Computer-Aided Fixture DesignFrom EverandAdvanced Computer-Aided Fixture DesignRating: 5 out of 5 stars5/5 (1)

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsFrom EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNo ratings yet

- Chasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItFrom EverandChasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItRating: 4 out of 5 stars4/5 (25)