Professional Documents

Culture Documents

Dynamini Series Adhesive Supply Unit

Uploaded by

ITWDynatecCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dynamini Series Adhesive Supply Unit

Uploaded by

ITWDynatecCopyright:

Available Formats

The Next Level of Technology

Dynamini Series - Adhesive Supply Unit

DYNAMINI hot melt adhesive supply units provide exceptional value in a small hot melt unit which has been designed for optimal performance, reliability and simplified daily operation. The patented melt-on-demand hopper with 7 year warranty standard, virtually eliminates adhesive degradation by melting only the adhesive required for the application.

DYNAMINI Series:

Melt-on-Demand Hopper Grid extends adhesive life and performance 7 year Melt-on-Demand hopper warranty Self-diagnostic P.I. digital Temperature controller with platinum sensor accuracy 110/120V and 200/240V configurations fitted with either a piston or gear pump Removable access covers completely expose all components for easy maintenance

Reliability

Melt-On-Demand hopper extends adhesive life and performance.

Performance

Accurate, proportional temperature control for the hopper, hoses and applicators.

Simplicity

Icon-driven control panel simplifies operations.

ITW Dynatec - DynaminiTM Series Models: N05, N10, & N22

The Dynatec Difference...

Melt-on-Demand Hopper

Most suppliers will agree that adhesive degradation is the number one cause of downtime on hot melt equipment. To address this problem, ITW Dynatec has patented a Melt-OnDemand system. ITW Dynatecs vertical, unheated hoppers only melt the amount of adhesive required by the application. Most of the hot melt adhesive in the hopper remains at a much lower temperature, perhaps even solid state. The added benefits of melting only the adhesive required are quicker start-ups, reduced energy costs, better viscosity control, and reduced fumes.

Dynamini - Adhesive Supply Unit

System

Hopper Capacity Operating Temperature Melt Rate (per hour)* Pump Rate (piston) Piston Pump Compression Ratios Gear Pump Hose Output Zones Maximum Working Hydraulic Pressure Temperature Control Stability Electrical Service Standard Electrical Service Standard Working Viscosity

N05

5k (10lbs) 40 to 218C (104 to 425F) 8kg/hr (17.3lb/hr) .91kg/min (2lb/min 12:1 1.5, 3.2, 4.5, .55, & 10cc 2 6.8 MPa (1000psi) 1C (1F) 100 to 120 VAC 1 Phase 50/60 Hz 200 to 240 VAC 1 Phase 50/60 Hz 500 - 50,000 cps

N10

9k (20lbs) 40 to 218C (104 to 425F) 8kg/hr (17.3lb/hr) .91kg/min (2lb/min 12:1 1.5, 3.2, 4.5, .55, & 10cc 2 6.8 MPa (1000psi) 1C (1F) 100 to 120 VAC 1 Phase 50/60 Hz 200 to 240 VAC 1 Phase 50/60 Hz 500 - 50,000 cps

N22

22k (48lbs) 40 to 218C (104 to 425F) 22.6kg/hr (50lb/hr) .91kg/min (2lb/min 12:1 1.5, 3.2, 4.5, .55, & 10cc 2, 6 6.8 MPa (1000psi) 1C (1F) 240 VAC 1 Phase 50/60 Hz 200 to 240 VAC 3 Phase 50/60 Hz 500 - 50,000 cps

*Melt rates vary with adhesive type. All units capable of 2 hoses and applicators. Units can be fitted with a piston or gear pump.

Dimensions

Height (H) Depth (D) Width (W) Weight (empty)

N05

45 cm (17.75 in) 54 cm (21.25 in) 29 cm (11.38 in) 27 kg (60 lbs)

N10

65.4 cm (25.75 in) 54 cm (21.25 in) 29 cm (11.38 in) 34 kg (76 lbs)

N22

61 cm (24 in) 84 cm (33 in) 35.6 cm (14 in) 50 kg (110 lbs)

Optional Accessories

Analog pressure gauge Hose boom Roll cart Swirl kit

Melt-On-Demand Hopper

ASIA

ITW Dynatec Hong Kong Unit A-B, 11/Fl., Leahander Centre 28 Wang Wo Tsai Street Tsuen Wan NT Hong Kong

8/2008 ITW Dynatec ITW Dynatec reserves the right to discontinue or change specifications, designs, materials and equipment without notice or obligation.

ITW Dynatec 31 Volunteer Drive Hendersonville, TN 37075 Telephone 6158243634 +1.800.860.6150 Fax +1.615.264.5248 dynatec@itwdynatec.com

AMERICAS

JAPAN

ITW Dynatec K.K. Tsukimura Building 5th Floor 26-11, Nishikamata 7-chome Ota-ku, Tokyo 144-0051, Japan Telephone +81.3.5703.5501 Fax +81.3.5703.5505 info@itwdynatec.co.jp

EUROPE, AFRICA and MIDDLE EAST

ITW Dynatec GmbH Industriestrasse 28 D-40822 Mettmann, Germany Telephone +49.210.4915.0 Fax +49.210.491.5111 e.mail@itwdynatec.de

Visit us at www.itwdynatec.com

You might also like

- Dynamelt S Series APS Adhesive Supply UnitDocument2 pagesDynamelt S Series APS Adhesive Supply UnitITWDynatecNo ratings yet

- Dynamelt LC Series - MasterDocument2 pagesDynamelt LC Series - MasterITWDynatecNo ratings yet

- FWT DIAPHRAGM Motor Dosing Pumps ENG Rev1 - 0215Document6 pagesFWT DIAPHRAGM Motor Dosing Pumps ENG Rev1 - 0215Imar KusumaNo ratings yet

- Dynamelt GC Series - MasterDocument2 pagesDynamelt GC Series - MasterITWDynatecNo ratings yet

- Dynamelt M Series Adhesive Supply UnitDocument2 pagesDynamelt M Series Adhesive Supply UnitITWDynatecNo ratings yet

- Dynamelt PUR Series Adhesive Bag MelterDocument2 pagesDynamelt PUR Series Adhesive Bag MelterITWDynatecNo ratings yet

- Manostat CatalogDocument8 pagesManostat CatalogadamdwaldropNo ratings yet

- HR E576qDocument12 pagesHR E576qIsanka SathsaraneeNo ratings yet

- File 133 1637Document21 pagesFile 133 1637Joel AlcantaraNo ratings yet

- NOVA Servo CatalogueDocument7 pagesNOVA Servo CatalogueDip Narayan BiswasNo ratings yet

- RP963 Climatemaster Residential Tranquility Water To Water TCW Series Geothermal Heating and Cooling Systems Product CatalogDocument20 pagesRP963 Climatemaster Residential Tranquility Water To Water TCW Series Geothermal Heating and Cooling Systems Product CatalogZulfah NurkholisNo ratings yet

- Moog ServovalvesDocument8 pagesMoog Servovalvesdylan_dearing@hotmail.com100% (1)

- Rotare Vane PumpsDocument10 pagesRotare Vane PumpsZoran DjurdjevicNo ratings yet

- GulfSea Hydraulic HVI Plus Series PDFDocument2 pagesGulfSea Hydraulic HVI Plus Series PDFObydur RahmanNo ratings yet

- KNF Gas PumpsDocument6 pagesKNF Gas PumpsJhon Jairo Mazuera GuzmanNo ratings yet

- Principle: Foaming Tendency & Stability of Lubricating OilsDocument2 pagesPrinciple: Foaming Tendency & Stability of Lubricating OilsKamruzaman MiahNo ratings yet

- HYD. PumpDocument40 pagesHYD. Pumprohitbhat2345No ratings yet

- TS Sterling Sterlco TC110 Series - Rev09.13.2018Document2 pagesTS Sterling Sterlco TC110 Series - Rev09.13.2018Omar A. HernandezNo ratings yet

- VersaBlue XN Series 50-100-150 Data SheetDocument2 pagesVersaBlue XN Series 50-100-150 Data SheetNordson Adhesive Dispensing SystemsNo ratings yet

- York Furnace ManualDocument8 pagesYork Furnace ManualToky100No ratings yet

- G Series GensetesDocument4 pagesG Series Gensetesskjha61No ratings yet

- Multi-Swt Sde Sse Am04-207Document6 pagesMulti-Swt Sde Sse Am04-207Wayne NefdtNo ratings yet

- DM55 Bulk Adhesive Drum UnloaderDocument2 pagesDM55 Bulk Adhesive Drum UnloaderITWDynatecNo ratings yet

- Turbine Meter NufloDocument8 pagesTurbine Meter NufloJaime SeguraNo ratings yet

- DY2002 Pattern ControllerDocument2 pagesDY2002 Pattern ControllerITWDynatecNo ratings yet

- Specification Jumbo Drill Sandvik DD311-40Document4 pagesSpecification Jumbo Drill Sandvik DD311-40Nathania Boas E S100% (4)

- SPEC Pulsatron E PLUS SeriesDocument2 pagesSPEC Pulsatron E PLUS SeriesAlfonso Javier Medina PernethNo ratings yet

- LMI Series G Metering Pump Datasheet PDFDocument6 pagesLMI Series G Metering Pump Datasheet PDFVkita MolinaNo ratings yet

- Cci Valve 100DSVDocument8 pagesCci Valve 100DSVyg89No ratings yet

- Am Castrol Hyspin AWH M US Eng Pds 05 07Document2 pagesAm Castrol Hyspin AWH M US Eng Pds 05 07victorjcrNo ratings yet

- Graco Lubrication EquipmentDocument12 pagesGraco Lubrication EquipmentpozolabNo ratings yet

- G61MPV - 09 01 2007Document104 pagesG61MPV - 09 01 2007Baryonyx Troodon100% (1)

- wrcc20 2015 GBDocument44 pageswrcc20 2015 GBMohamdNo ratings yet

- pt3 4diaphragm DrumPumpsDocument29 pagespt3 4diaphragm DrumPumpsMatthew NievesNo ratings yet

- VersaBlue XC Series Data SheetDocument2 pagesVersaBlue XC Series Data SheetNordson Adhesive Dispensing SystemsNo ratings yet

- Catalogo ASCODocument4 pagesCatalogo ASCOIkaro MatosNo ratings yet

- Atuador pneumatico-TYCO-RENMC-0111-USDocument4 pagesAtuador pneumatico-TYCO-RENMC-0111-USNueude PachecoNo ratings yet

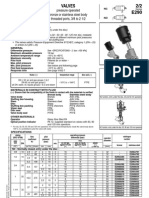

- Valves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Document4 pagesValves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Velpuri RameshBabuNo ratings yet

- Especificaciones Lowara C CE CK CEKDocument11 pagesEspecificaciones Lowara C CE CK CEKAlejandro MozoNo ratings yet

- Jain PE Gas Piping SystemDocument4 pagesJain PE Gas Piping Systemkishore@scribdNo ratings yet

- LTC Filtration SystemDocument4 pagesLTC Filtration SystemAnonymous 9VcxlFErfNo ratings yet

- Dwyer Series DM-1000Document1 pageDwyer Series DM-1000Marco Antonio Rivera DoteroNo ratings yet

- 520 - MPC Plate Chiller BulletinDocument4 pages520 - MPC Plate Chiller BulletinThanh Van LeNo ratings yet

- APEX Adhesive Slot Die ApplicatorDocument2 pagesAPEX Adhesive Slot Die ApplicatorITWDynatecNo ratings yet

- Water Softeners Commercial TMI Softeners Canadian ENGLISH BrochureDocument8 pagesWater Softeners Commercial TMI Softeners Canadian ENGLISH BrochurePromagEnviro.comNo ratings yet

- AD01166M NUFLO Liquid Turbine Flow Meters Data SheetDocument8 pagesAD01166M NUFLO Liquid Turbine Flow Meters Data SheetdediekosNo ratings yet

- Hydrolink General Product CatalogueDocument17 pagesHydrolink General Product CatalogueMarcoAlbaNo ratings yet

- Rock Valve: Stationary Concrete PumpsDocument8 pagesRock Valve: Stationary Concrete PumpsRafael R ANo ratings yet

- Perkins P200Document4 pagesPerkins P200PaulusIwanNo ratings yet

- KMT Waterjet NEOLine 40i &10d PumpsDocument2 pagesKMT Waterjet NEOLine 40i &10d PumpsDaniel AustinNo ratings yet

- Donaldson Visokotlačni FilteriDocument86 pagesDonaldson Visokotlačni FilteriViktor -stNo ratings yet

- Axeon Mktf-112 m1 PB LRDocument4 pagesAxeon Mktf-112 m1 PB LRSohail HanifNo ratings yet

- Helix Rotary SprayDocument2 pagesHelix Rotary SprayITWDynatecNo ratings yet

- Cross CoatDocument2 pagesCross CoatITWDynatecNo ratings yet

- DY2002 Pattern ControllerDocument2 pagesDY2002 Pattern ControllerITWDynatecNo ratings yet

- BF MicroBeadDocument2 pagesBF MicroBeadITWDynatecNo ratings yet

- DynaPack Adhesive Supply UnitDocument2 pagesDynaPack Adhesive Supply UnitITWDynatecNo ratings yet

- Dynamelt PUR Series Adhesive Bag MelterDocument2 pagesDynamelt PUR Series Adhesive Bag MelterITWDynatecNo ratings yet

- TPC-2 Pattern ControllerDocument2 pagesTPC-2 Pattern ControllerITWDynatecNo ratings yet

- DPC-2 Pattern ControllerDocument2 pagesDPC-2 Pattern ControllerITWDynatecNo ratings yet

- Packaging TriFoldDocument2 pagesPackaging TriFoldITWDynatecNo ratings yet

- ITW Dynatec Overview BrochureDocument2 pagesITW Dynatec Overview BrochureITWDynatecNo ratings yet

- DY2002 Pattern ControllerDocument2 pagesDY2002 Pattern ControllerITWDynatecNo ratings yet

- Next Generation Dynamelt S SeriesDocument2 pagesNext Generation Dynamelt S SeriesITWDynatecNo ratings yet

- DY2008 Pattern ControllerDocument2 pagesDY2008 Pattern ControllerITWDynatecNo ratings yet

- Technical Service & Support BrochureDocument2 pagesTechnical Service & Support BrochureITWDynatecNo ratings yet

- ITW Dynatec Overview BrochureDocument2 pagesITW Dynatec Overview BrochureITWDynatecNo ratings yet

- EDI Precision Coating and Laminating SystemDocument2 pagesEDI Precision Coating and Laminating SystemITWDynatecNo ratings yet

- APEX Adhesive Slot Die ApplicatorDocument2 pagesAPEX Adhesive Slot Die ApplicatorITWDynatecNo ratings yet

- Vector Technology White PaperDocument3 pagesVector Technology White PaperITWDynatecNo ratings yet

- Gemini Automatic Adhesive HosesDocument2 pagesGemini Automatic Adhesive HosesITWDynatecNo ratings yet

- BF Micro Adhesive ApplicatorDocument2 pagesBF Micro Adhesive ApplicatorITWDynatecNo ratings yet

- Dynamelt S Series - MasterDocument2 pagesDynamelt S Series - MasterITWDynatecNo ratings yet

- Hot Melt Efficiencies - Cut Costs & Minimize WasteDocument3 pagesHot Melt Efficiencies - Cut Costs & Minimize WasteITWDynatecNo ratings yet

- EVC-1 Electronic Volume ControllerDocument2 pagesEVC-1 Electronic Volume ControllerITWDynatecNo ratings yet

- Consistent Quality in Hot Melt Slot Die CoatingDocument2 pagesConsistent Quality in Hot Melt Slot Die CoatingITWDynatecNo ratings yet

- Benefits of Automatic Bulk Adhesive Feed SystemsDocument2 pagesBenefits of Automatic Bulk Adhesive Feed SystemsITWDynatecNo ratings yet

- Vector Adhesive Spray ApplicatorDocument2 pagesVector Adhesive Spray ApplicatorITWDynatecNo ratings yet

- Using Different Perforated Lids On The MAS-100 Family Air SamplersDocument6 pagesUsing Different Perforated Lids On The MAS-100 Family Air SamplersJuan Salvador MaestreNo ratings yet

- Chapter 1Document65 pagesChapter 1Jad Antonios JelwanNo ratings yet

- Team 6 - Crystal MazeDocument56 pagesTeam 6 - Crystal MazeLohith YadavNo ratings yet

- A TCP TutorialDocument11 pagesA TCP Tutorialpfck4589No ratings yet

- Create Your Own Operating System - Lucus DarnellDocument138 pagesCreate Your Own Operating System - Lucus DarnellRahul Rana100% (6)

- Liebherr Hydraulic Components For Heavy Duty On Highway Engines Application Flyer Es WebDocument4 pagesLiebherr Hydraulic Components For Heavy Duty On Highway Engines Application Flyer Es WebDaniel Castillo PeñaNo ratings yet

- 7749289-TheClandestineChemist 'Snotebook PDFDocument28 pages7749289-TheClandestineChemist 'Snotebook PDFTonNo ratings yet

- Perry 02Document2 pagesPerry 02Thaly MejiaNo ratings yet

- GROUP 7 - Banksia-SD-SE-T1-Hazard-Report-Form-Template-V1.0-ID-200278Document5 pagesGROUP 7 - Banksia-SD-SE-T1-Hazard-Report-Form-Template-V1.0-ID-200278Samir Mosquera-PalominoNo ratings yet

- Full Analyse of JULIADocument19 pagesFull Analyse of JULIArenan55026No ratings yet

- History of UASDocument44 pagesHistory of UASAswin BalasubramaniamNo ratings yet

- Job Procedure For Puncture/Floatation/Rain Water Accumulation TestDocument4 pagesJob Procedure For Puncture/Floatation/Rain Water Accumulation Testfaisal jasim100% (1)

- LIDO Introduction PDFDocument127 pagesLIDO Introduction PDFStiliyana Bakalova100% (2)

- Lecture Notes For Week Ten Mechanics of Chain DrivesDocument11 pagesLecture Notes For Week Ten Mechanics of Chain DrivesJohn KimaniNo ratings yet

- SchedulingDocument41 pagesSchedulingBeing VikramNo ratings yet

- Abrasive Cleaning SystemDocument4 pagesAbrasive Cleaning SystemSulfikar SalimNo ratings yet

- Ultimate ESAS Data Bank CompilationDocument19 pagesUltimate ESAS Data Bank CompilationVea ValcorzaNo ratings yet

- Network AssignmentDocument4 pagesNetwork AssignmentOsamah ElaiwahNo ratings yet

- VentureDeckingInstallationInstructions LRDocument13 pagesVentureDeckingInstallationInstructions LRGhislainTremblayNo ratings yet

- MD Primer ErcolessiDocument52 pagesMD Primer ErcolessiAjinBaby MyladiyilNo ratings yet

- Accounting Information Systems: Basic Concepts and Current Issues 4th Edition Robert L. HurtDocument29 pagesAccounting Information Systems: Basic Concepts and Current Issues 4th Edition Robert L. HurtJamieNo ratings yet

- Assignment Payment 1Document5 pagesAssignment Payment 1Mohamad SafwanNo ratings yet

- S419Document2 pagesS419Syed IhyaNo ratings yet

- Mini Project 1Document16 pagesMini Project 1SadikAhmedNo ratings yet

- MCQs On Queue With AnswersDocument7 pagesMCQs On Queue With AnswersBabuLalSainiNo ratings yet

- Design of Queensland Road Infrastructure For High Risk EnvironmentsDocument7 pagesDesign of Queensland Road Infrastructure For High Risk EnvironmentsAnonymous fS6Znc9No ratings yet

- Sintech Pumps For Sugar Processing PlantDocument18 pagesSintech Pumps For Sugar Processing Plantsahildhingra100% (2)

- TNCS EarthingDocument3 pagesTNCS Earthingjoan benwari100% (1)

- The VI Editor PDFDocument7 pagesThe VI Editor PDFPurandhar TataraoNo ratings yet

- Ams 2404Document9 pagesAms 2404Anonymous T6GllLl0100% (1)